Fuel composition for stove

A composition and fuel technology, which can be applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of people's health hazards, etc., and achieve the effects of no carbon deposition, low pollution, and moderate viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Example 1 includes the composition, proportion, preparation method and various test indexes of the fuel composition obtained in the present invention.

[0038] Example 1:

[0039] The recipe of the furnace fuel composition of the present invention is: waste oil 42%, waste mineral oil 20%, waste ethanol 15%, fried bone oil 15.7%, ferrocene 0.02%, butyl acetate 1.28%, butanone 3% , isobutanol 3%.

[0040] The preparation method is: first, mix butyl acetate, butanone and isobutanol in a container to make an additive. Then, add other components and additives together into the mixing tank, stir at room temperature for 30 minutes, and mix thoroughly. After mixing evenly, filter with a 200-mesh sieve to obtain the furnace fuel composition of the present invention.

[0041] The test index of the fuel composition gained in the present embodiment is:

[0042] Flash point (closed mouth, °C): 61

[0043] Ignition point (℃): 68

[0044] Freezing point (℃): -32

[0045] Kinemat...

Embodiment 2-14

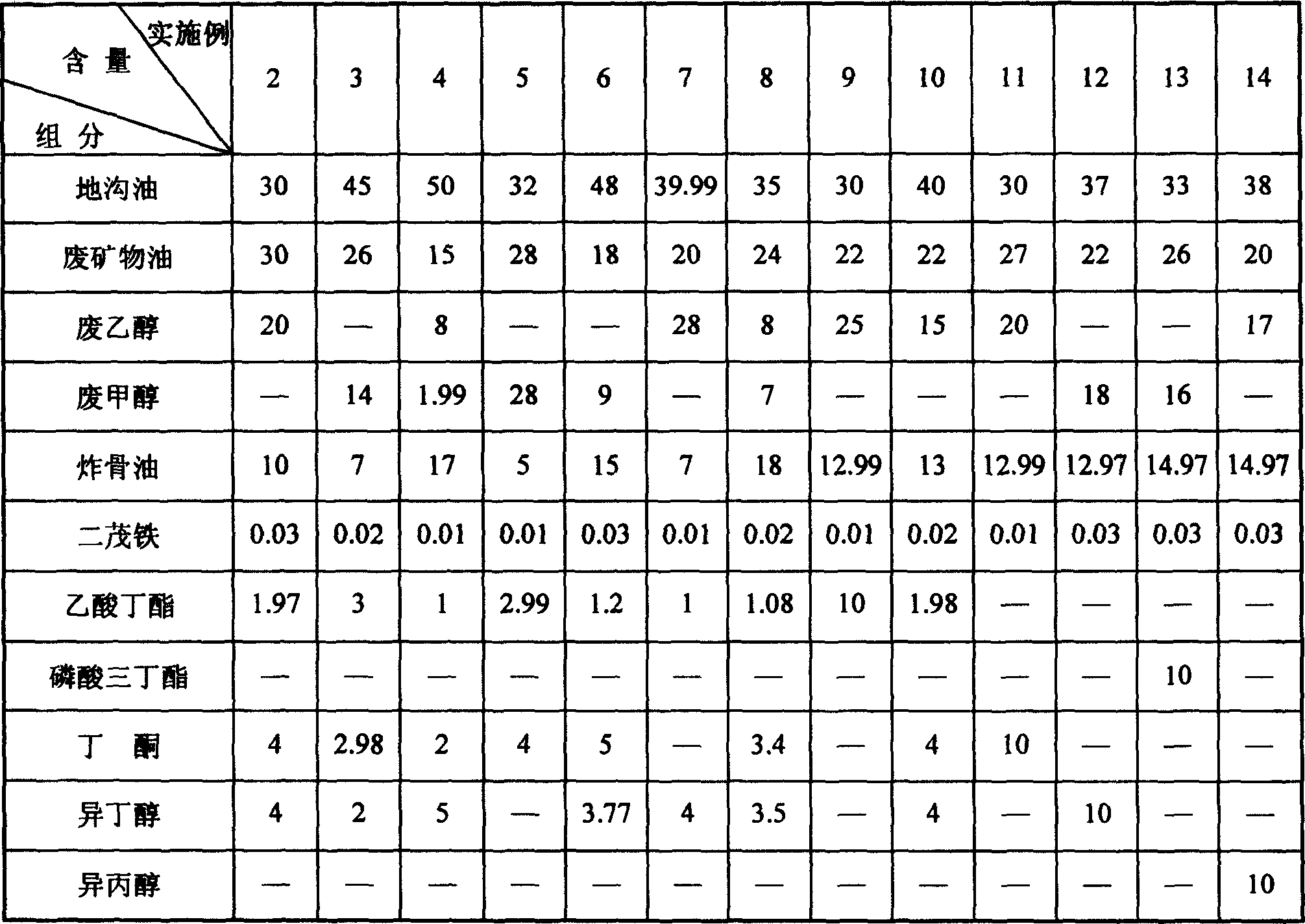

[0053] The recipes and proportions of Examples 2-14 are shown in the table below, and the preparation method is the same as that of Example 1.

[0054] Embodiment 2-14 sees the following table:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com