Vitamin D soft capsule and making method thereof

A production method and technology of vitamins, applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as inability to absorb calcium, difficult to be squeezed out with oil, unstable fusion, etc., to achieve good results Water-locking effect, simple ingredients, and few additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] d. Post-preparation and processing of vitamin D soft capsules; the soft capsules containing the capsule contents prepared in step c are pulled out from the coolant, and dried for the first time in cold wind at room temperature until no obvious coolant water stain remains The soft capsules are washed with petroleum ether twice, then washed in ethanol with a concentration of 95%, and then dried at 30-35°C for 8-12 hours to complete the whole process of making vitamin D soft capsules.

[0030] Among them, among all calcium-containing compounds, calcium carbonate has the highest calcium content, which is suitable for human body to supplement calcium; vitamin D 3 It is the main substance for the human body to supplement vitamin D. It is difficult for people whose skin is not exposed to sunlight to synthesize enough vitamin D by themselves. 3 For their own needs, so vitamin D needs to be taken orally 3 .

[0031] Corn oil is rich in dienaldehyde compounds, palmitic acid, sq...

Embodiment 1

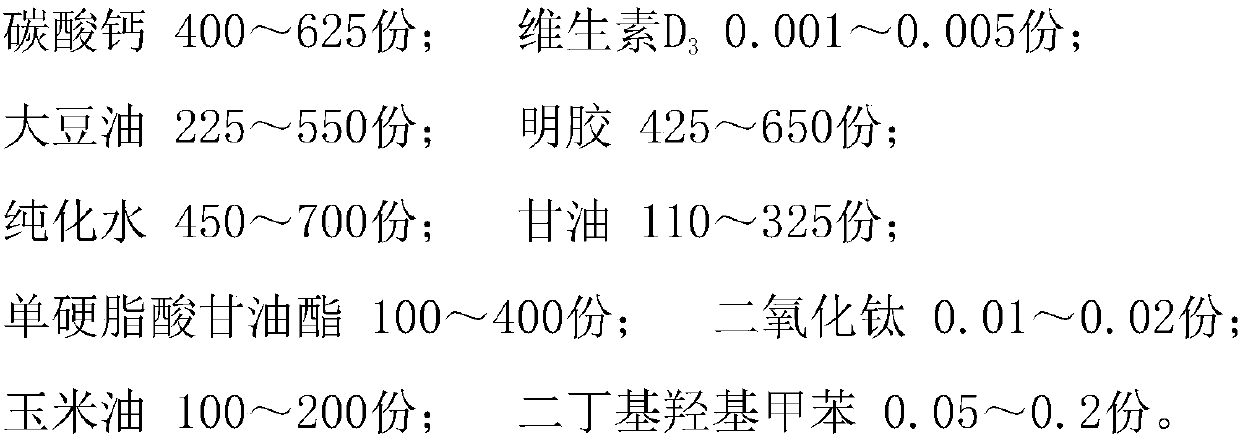

[0036] A vitamin D soft capsule is composed of the following materials in parts by mass:

[0037] Calcium Carbonate 400 parts; Vitamin D 3 0.005 copies;

[0038] 225 parts of soybean oil; 650 parts of gelatin;

[0039] 450 parts of purified water; 325 parts of glycerin;

[0040] 100 parts of glyceryl monostearate; 0.02 parts of titanium dioxide;

[0041] 100 parts of corn oil; 0.2 parts of dibutyl hydroxytoluene.

[0042] In the present embodiment, the manufacturing process of vitamin D soft capsule is:

[0043] a, make the capsule contents; 400 parts of calcium carbonate solids are ground into calcium carbonate powder that can pass through a 200 mesh sieve, and the calcium carbonate powder is uniformly mixed with 225 parts of soybean oil by a colloid mill to obtain a calcium preparation; 0.005 parts Vitamin D 3 Add it to 100 parts of corn oil for mechanical stirring, and continuously add 0.133 parts of dibutyl hydroxytoluene to it while stirring; continue stirring for 1...

Embodiment 2

[0049] A vitamin D soft capsule is composed of the following materials in parts by mass:

[0050] Calcium Carbonate 625 Parts; Vitamin D 3 0.001 copies;

[0051] 550 parts of soybean oil; 425 parts of gelatin;

[0052] 700 parts of purified water; 110 parts of glycerin;

[0053] 400 parts of glyceryl monostearate; 0.01 part of titanium dioxide;

[0054] 200 parts of corn oil; 0.05 parts of dibutyl hydroxytoluene.

[0055] In this example, the difference between the production process of vitamin D soft capsules and Example 1 is that the number of parts added to each component is different, and the number of dibutyl hydroxytoluene added in step a is 0.033 parts, and glyceryl monostearate is 134 parts. part, the dibutyl hydroxytoluene added in step b is 0.017 part, and glyceryl monostearate is 266 parts.

[0056] The content of calcium in each vitamin D soft capsule prepared in this example is 165 mg, and the content of vitamin D is 0.7 micrograms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com