Phenolic resin/silicon dioxide composite aerogel materialand preparation method thereof

A composite airgel and silica technology, which is applied in the production of bulk chemicals, etc., can solve the problems of unavoidable phase separation, materials that cannot continue to maintain heat insulation and fire prevention, and fall off quickly, so as to achieve excellent heat insulation and fire prevention performance, and easy operation Simple, Response Safe and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

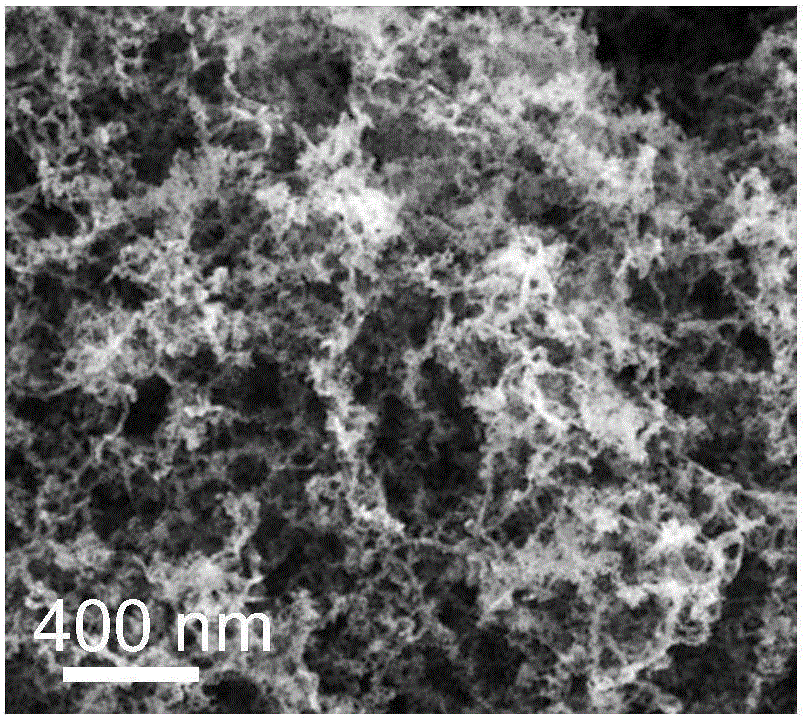

[0054] The present invention also provides a preparation method of phenolic resin / silicon dioxide composite airgel material, comprising the following steps:

[0055] a) In the presence of an acid, dispersing the organosilicon precursor and the phenolic compound in an aqueous solution, so that the organosilicon precursor is hydrolyzed to obtain a mixed solution;

[0056] b) mixing the mixed solution with chitosan, aldehyde compounds and water to form a sol, and then performing a hydrothermal reaction to obtain a phenolic resin / silicon dioxide composite hydrogel;

[0057] c) Drying the phenolic resin / silica composite hydrogel with supercritical carbon dioxide to obtain a phenolic resin / silica composite airgel material.

[0058] The preparation method provided by the present invention can prepare the above-mentioned phenolic resin / silicon dioxide double network airgel material with excellent heat insulation, fire prevention and ablation resistance. application in large-scale ind...

Embodiment 1

[0076] The present embodiment phenolic resin / silica double network aerogel is carried out as follows:

[0077]a. In a beaker with a volume of 50mL, add 15mL of water and 15mL of absolute ethanol, and add 1.882g of phenol, 6mL of tetraethyl orthosilicate and 0.6mL of glacial acetic acid, seal it, stir at room temperature for 24h, and perform hydrolysis to obtain The mixed solution is denoted as solution A;

[0078] B, in another beaker, 0.45g chitosan (Shanghai Sinopharm Group, CAS number: 9012-76-4) is dispersed in 15mL water, and gained chitosan solution is recorded as solution B;

[0079] Pour solution A into solution B quickly, and add 3mL formaldehyde solution (37wt% formaldehyde) to it, and continue to stir vigorously for 10min to form a sol;

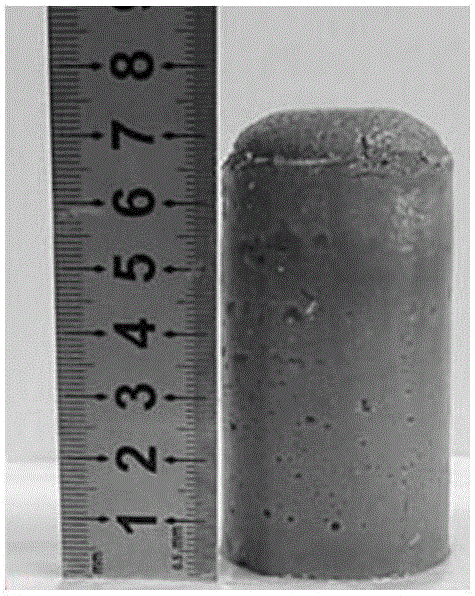

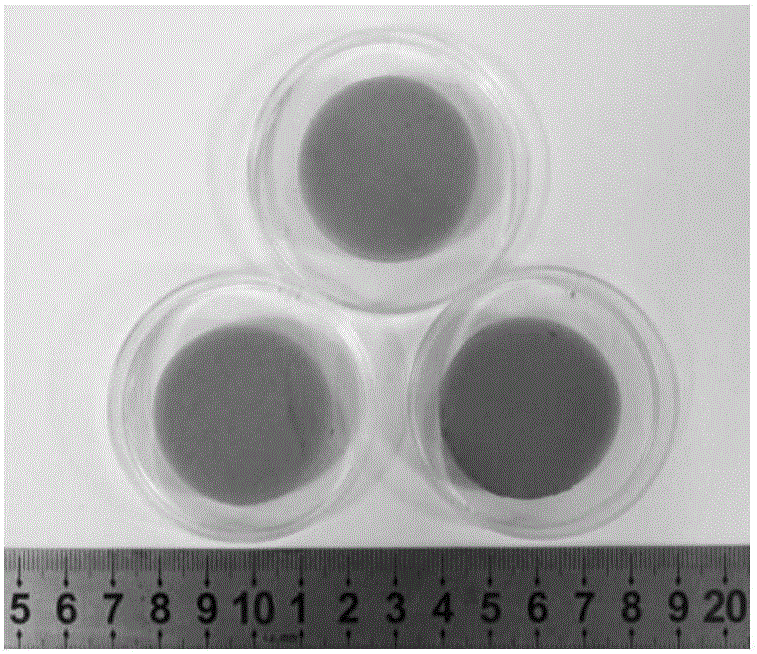

[0080] The sol was packed into a 50mL polytetrafluoroethylene-lined hydrothermal reaction kettle, placed in an oven at 160°C, and hydrothermally reacted for 10h to obtain a yellow phenolic resin / silica double network composite hyd...

Embodiment 2

[0086] Utilize the preparation method identical with embodiment 1:

[0087] a. In a 50mL beaker, add 10mL of water and 20mL of absolute ethanol, and add 2.202g of resorcinol, 6mL of methyl orthosilicate and 0.6mL of glacial acetic acid, seal it, stir at room temperature for 24 hours, and perform hydrolysis , the resulting mixed solution is denoted as solution A;

[0088] B, in another beaker, 0.45g chitosan (Shanghai Sinopharm Group, CAS number: 9012-76-4) is dispersed in 15mL water, and gained chitosan solution is recorded as solution B;

[0089] Pour solution A into solution B quickly, and add 3mL formaldehyde solution (37wt% formaldehyde) to it, and continue to stir vigorously for 10min to form a sol;

[0090] The sol was packed into a 50mL polytetrafluoroethylene-lined hydrothermal reaction kettle, placed in an oven at 100°C, and subjected to a hydrothermal reaction for 10h to obtain a resorcinol-formaldehyde resin / silica double network composite hydrogel ( hybrid gel). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com