Patents

Literature

97results about How to "Suitable for large-scale industrial promotion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenolic resin/silicon dioxide composite aerogel materialand preparation method thereof

ActiveCN106189066ANo sheddingNo separabilityBulk chemical productionThermal insulationNanoscopic scale

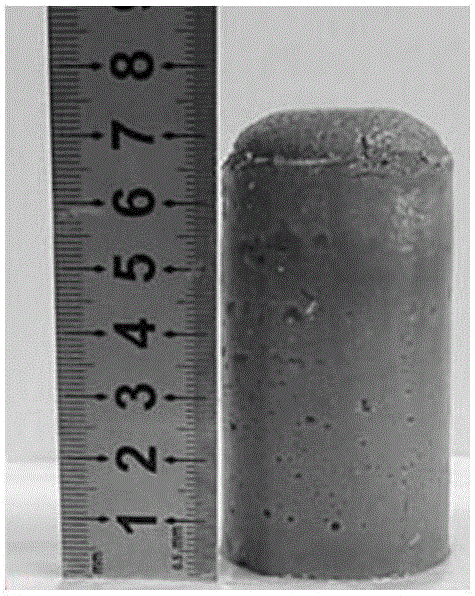

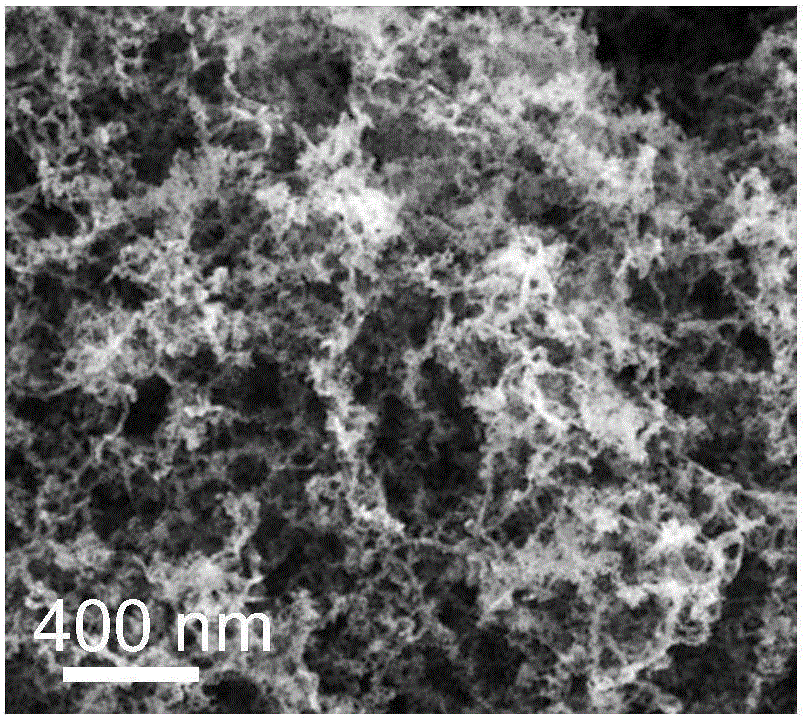

The invention provides a phenolic resin / silicon dioxide compositeaerogel material and a preparation method thereof. The phenolic resin / silicon dioxide composite aerogel material has a nano-grid structure in which a silicon dioxide phase and a resin phase are mutually tangled. The phenolic resin / silicon dioxide composite aerogel material is prepared from a material containing an organic silicon precursor, a phenolic compound, an aldehyde compound and chitosan by virtue of a sol-gel method and supercritical carbon dioxide. According to the composite aerogel material, an organic phase and an inorganic phase are respectively continuous nano-scale tangle structures and are integrated with the mechanical property of organic aerogel and the thermal insulation property and fire resistance of silicon dioxide aerogel; and after the composite gel material with a thickness of 1cm is impacted by the 1300-DEG C flame of a blast burner for over 30 minutes, the falling and the separation of the inorganic phase are not caused, and meanwhile, the temperature of a protected side does not exceed 300 DEG C. The preparation method has the beneficial effects that the operation is simple, the reaction is safe and reliable, and the thermal insulation property and the fire resistance of the material can be regulated and controlled by simply changing the material proportion.

Owner:UNIV OF SCI & TECH OF CHINA

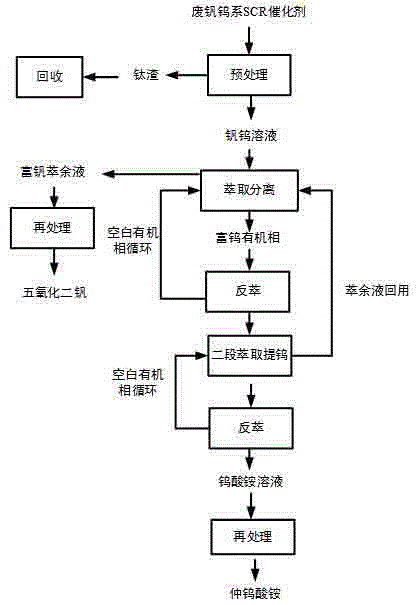

Vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts

ActiveCN104862485ARealize separation and recoveryRealize recycling of resourcesProcess efficiency improvementPtru catalystAmmonium paratungstate

The invention discloses a vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts. The method comprises the following steps: a spent catalyst is pretreated to obtain titanium slag and a vanadium and tungsten solution; the vanadium and tungsten solution is extracted for separation, and an obtained vanadium-rich raffinate is treated again to obtain vanadium pentoxide; a tungsten-rich organic phase obtained through separation is subjected to two-stage extraction for tungsten extraction after back extraction, a product is subjected to back extraction again to obtain an ammonium tungstate solution, and the ammonium tungstate solution is treated to prepare ammonium paratungstate. The blank of lack of a vanadium and tungsten separating, purifying and recovering technology for the spent vanadium and tungsten SCR catalysts in the denitration industry is filled up completely, the recovery rates of vanadium and tungsten both exceed 95%, the obtained vanadium pentoxide and ammonium paratungstate products all meet the high-purity standard, and the purity is higher than 99%.

Owner:BOTREE CYCLING SCI &TECH CO LTD

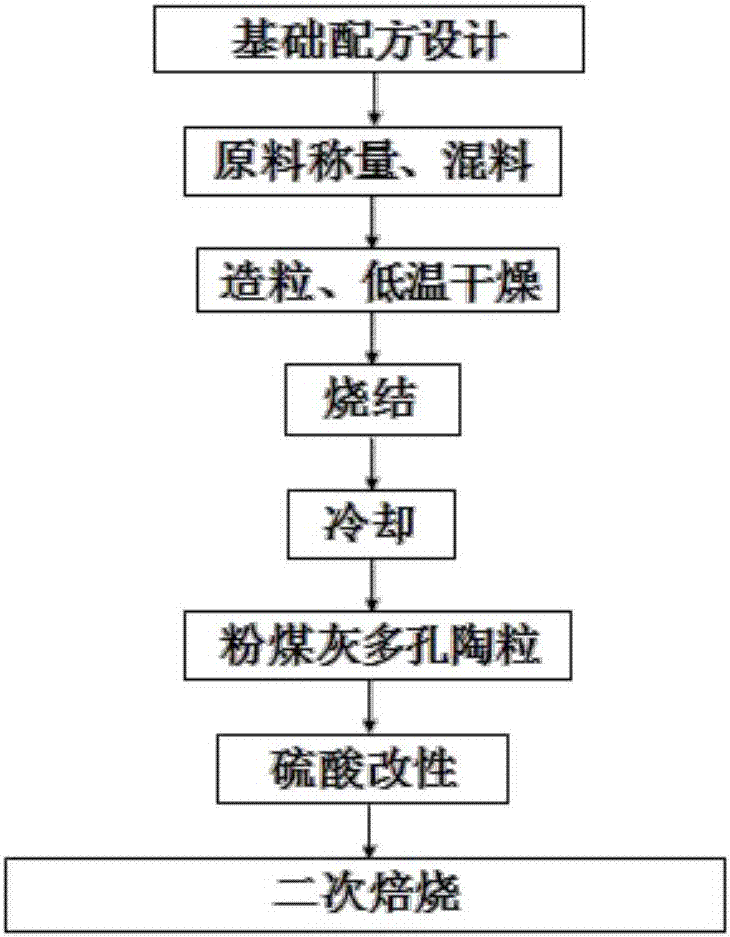

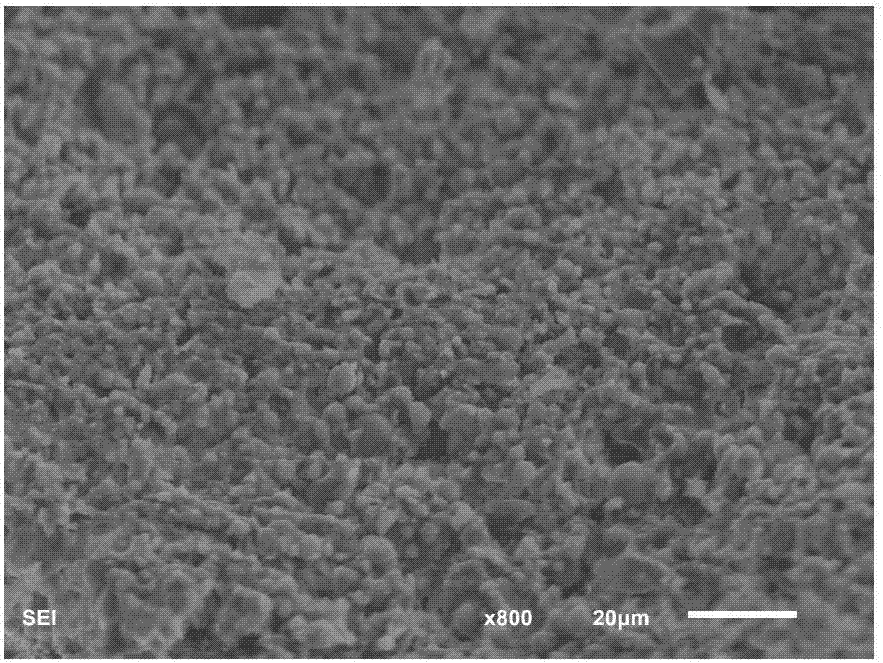

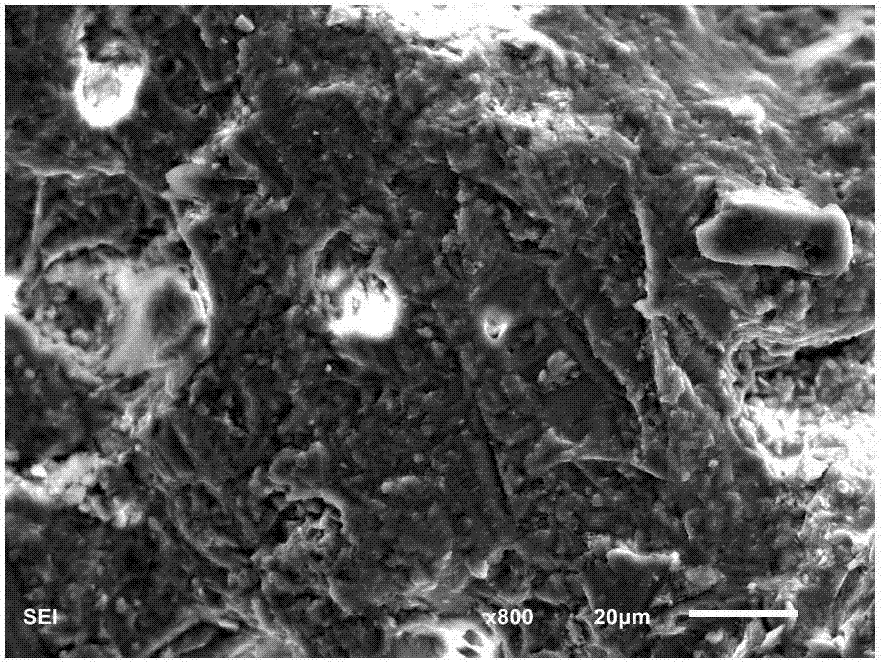

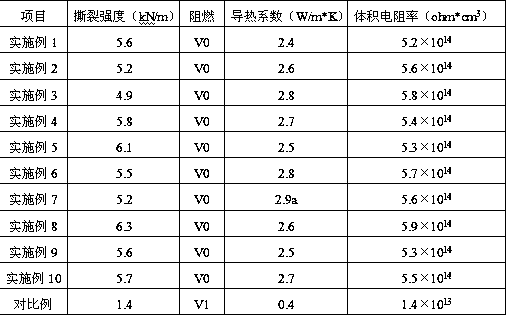

Modified fly ash ceramsite and preparation method and application thereof

InactiveCN106915972AEasy to operateMild conditionsCeramic materials productionWater/sewage treatment by sorptionExpanded clay aggregateMullite

The invention provides modified fly ash ceramsite and a preparation method and an application thereof. Fly ash, a pore forming agent and water are mixed, the mixture is subjected to ball formation and granulation and then is sintered to obtain the fly ash ceramsite having a mullite and glass phase structure, and the mechanical properties of the fly ash ceramsite product are improved; then the fly ash ceramsite is soaked by an inorganic acid solution and is subjected to acid modification, closed pores on the surface of the ceramsite in the sintering process are opened through acidification, and at the same time, active adsorption centers of the fly ash ceramsite are increased; finally, after roasting, modified ions are fixed and attached to the fly ash ceramsite pores and surface, so the product has an effect on removing specific contaminants, especially ammonia-nitrogen wastewater. Experimental results show that after the ammonia-nitrogen wastewater is treated for 3 h by the modified fly ash ceramsite provided by the invention, the ammonia-nitrogen removal rate can reach 81.66%; and compared with ordinary fly ash ceramsite, the modified fly ash ceramsite has the ammonia-nitrogen removal rate increased by 57.7%.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Insulation silica gel material and silicon fabric used for new-energy vehicle battery heater

InactiveCN108178929AExcellent electrical insulation propertiesImprove flame retardant performanceFiberElectrical battery

The invention relates to an insulation silicon material and a silicon fabric used for a new-energy vehicle battery heater. The insulation silicon material comprises the following raw materials in parts by weight: 90-120 parts of silicone rubber, 15-40 parts of a composite fire retardant, 40-60 parts of a filling material, 2-6 parts of a lubricant, 1-5 parts of a promoter, and 2-12 parts of a vulcanizing agent; the silicon fiber comprises a glass fiber cloth, a sulfurated insulation silicon layer arranged at one surface of the glass fiber cloth, an un-sulfurated insulation silicon layer arranged at the other surface of the glass fiber cloth, and a PE membrane. Compared with the prior art, the silicon material has excellent electrical isolation characteristic, good flame retardation effect,and protruded heat conduction effect, the silicon fabric prepared by the insulation silicon material has good flexibility and compression performance, can tightly attach on the surface of a power battery, has the advantages of good shock resistance, good aging-resistant performance, and convenient installation and dismounting, is repeatedly usable, and has good application prospect.

Owner:无锡市辉英电力电子有限公司

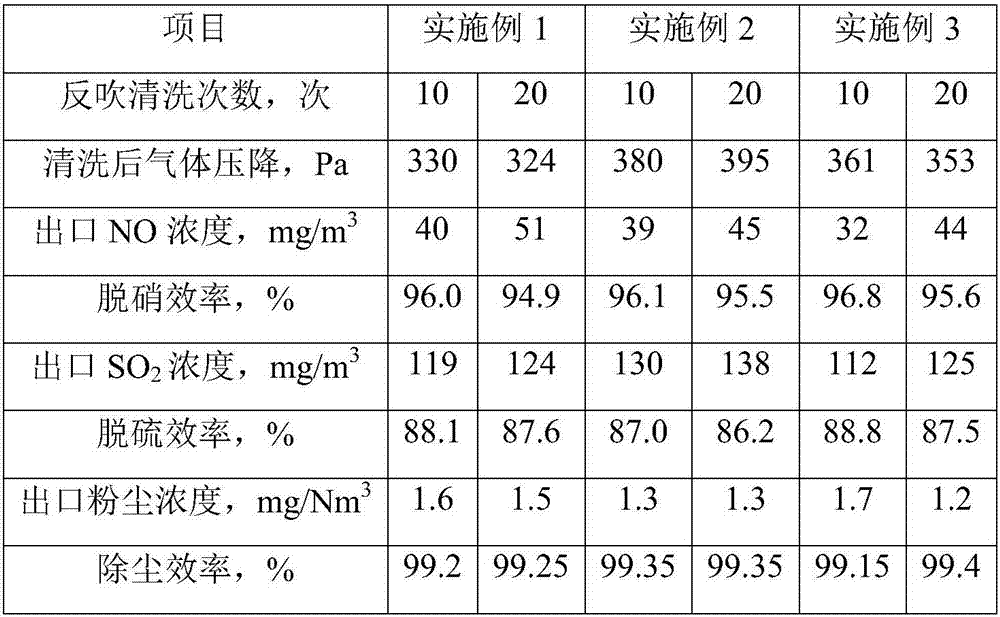

Ceramic catalytic filter element for flue gas purification and flue gas desulfurization and denitrification integrated dust removal method

ActiveCN107876043AExtended service lifeReduce loadDispersed particle filtrationTransportation and packagingActive matrixFlue gas

The invention relates to a ceramic catalytic filter element for flue gas purification and a flue gas desulfurization and denitrification integrated dust removal method. The ceramic catalytic filter element is prepared from the following steps that a microporous alumina ceramic filter tube with a pore diameter of 40-80 microns is taken as a matrix; the matrix is immersed in a mixed sol made of zincacetate, and after the matrix is impregnated under a negative pressure, the matrix is roasted to obtain a modified matrix modified by zinc oxide; an equal volume impregnation method is adopted, and the modified matrix is impregnated with an mixed oxalic acid solution containing ammonium metavanadate and ammonium metatungstate, so that total loading mass of V2O5 and WO3 in pores of the matrix reaches 4.0%-6.0% to obtain an active matrix; the active matrix is immersed in a mixed sol made of Al2O3-SiO2-TiO2, the active matrix is dried and roasted after the active matrix is taken out, and a densefilm with a thickness of 0.2-0.6 millimeter and a pore diameter of 1-10 microns is formed on the outer surface of the active matrix to obtain the ceramic catalytic filter element. A denitrification catalyst of the ceramic catalytic filter element has the advantages of being strong in load, high in denitrification efficiency, long in service life and applicable to popularizing and using.

Owner:济南玉泉生物发电有限公司

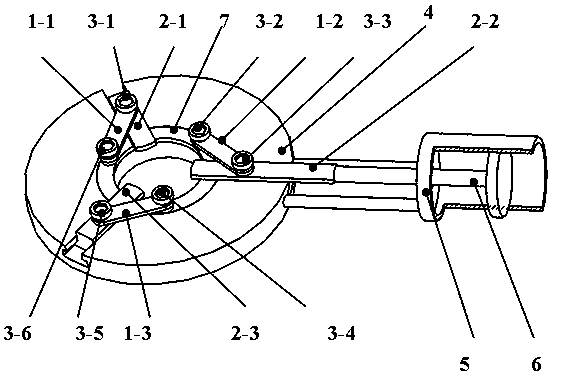

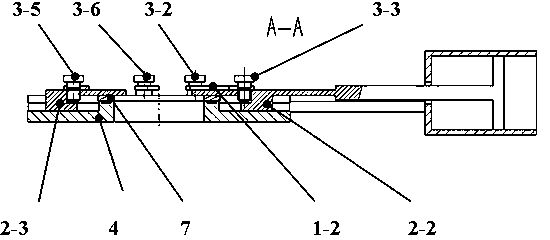

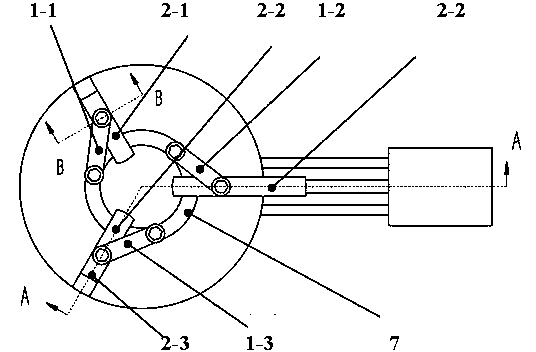

Three-jaw manipulator formed by three crank-slider mechanisms

The invention discloses a three-jaw manipulator formed by three crank-slider mechanisms. The three crank-slider mechanisms are equidistantly and circumferentially distributed on a mother disc and share a crank, each crank-slider mechanism is composed of a finger slider, a connecting rod, a mother disc and a turntable, the finger slider of one of the crank-slider mechanisms is connected with an air cylinder through which opening and closing of fingers are realized, and three fingers can simultaneously slide centripetally or centrifugally and can realize centering of cylindrical workpieces.

Owner:扬州仙发建设有限公司

Fe-based alloy and WC/TiC/TaC/Re composite powder formula, Fe-based alloy and WC/TiC/TaC/Re composite coating and preparation process of Fe-based alloy and WC/TiC/TaC/Re composite coating

The invention discloses a Fe-based alloy and WC / TiC / TaC / Re composite powder formula, a Fe-based alloy and WC / TiC / TaC / Re composite coating and a preparation process of the Fe-based alloy and WC / TiC / TaC / Re composite coating, and belongs to the technical field of coating materials. The Fe-based alloy and WC / TiC / TaC / Re composite powder formula is characterized by mainly involving the following components of, by weight part, 68-84.5 parts of Fe-based alloy powder, 5-20 parts of WC powder, 5-20 parts of TiC powder, 5-20 parts of TaC powder and 0.5-3 parts of Re powder. High-power powder feeding typelaser cladding is adopted for cladding the prepared composite powder on a pretreated base material surface to form the Fe-based alloy and WC / TiC / TaC / Re composite coating; and the Fe-based alloy and WC / TiC / TaC / Re composite coating prepared through the preparation process has excellent mechanical properties and mechanics properties, is fine and smooth in microstructure, is free of crack and pore defects and other defects, is high in surface hardness, has excellent wear resistance and corrosion resistance, can greatly prolong the service life of a part under a harsh working condition, and has awide application prospect.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

Super-hydrophobic nano-ceramic material and coating layer formed by super-hydrophobic nano-ceramic material

The invention relates to a super-hydrophobic nano-ceramic material and a coating layer formed by the super-hydrophobic nano-ceramic material, belonging to the technical field of coating layer materials. The super-hydrophobic nano-ceramic material mainly contains the following components in parts by weight: 60-80 parts of nano-titanium dioxide powder, 8-25 parts of nano-hexagonal boron nitride powder, 2-10 parts of nano-aluminum oxide powder, 2-8 parts of nano-zirconium oxide powder, 5-10 parts of silicon dioxide powder, 2-6 parts of super-hydrophobicity lead tungstate nanocrystallines and 1-10parts of a modifying agent. The coating layer is prepared by coating the surface of a base material with the super-hydrophobic nano-ceramic material. The coating layer prepared from the super-hydrophobic nano-ceramic material has excellent super-hydrophobicity and chemical stability, good durability, mechanical property and mechanical property and high surface hardness, has strong bonding force with the base material and is capable of bearing relatively large load, the super-hydrophobicity can be maintained for a long time, the surface structure is unlikely to be broken by an external force,and the service life is long.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

Preparation method of halogen-free flame retardant rubber

The invention relates to a preparation method of halogen-free flame retardant rubber. The method comprises the following steps: mixing butadiene styrene rubber in an SK-160-type dual-roll plastic mixing mill, wherein the temperature of a front roll of an open mill is 135 DEG C, and the temperature of a rear roll is 125 DEG C; plastifying for 15 minutes, and then adding zinc oxide, stearic acid, magnesium hydrate, 5-(4-hydroxycyclohexyl phenyl)-2H-pyran-2-ketone, carbon black, petroleum resin and tetramethyl thiuram disulfide; rolling the raw materials left and right on rollers in a crossing manner, and mixing evenly; thinning and packing for 5 times, and discharging slices, so as to obtain a sizing material with good dispersity; after preserving the sizing material for 8 hours, vulcanizing under the conditions of 50 DEG C and 10MPa. The halogen-free flame retardant rubber disclosed by the invention has the advantages of good fire resistance, and small harm to environment due to no halogen; therefore, the preparation method is very suitable for large-scale industrial popularization.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

A circuit board producing method for preventing golden fingers from exposing copper

ActiveCN103619131AEfficient removalIncrease surface tensionPrinted element electric connection formationEngineeringCopper

The invention provides a circuit board producing method for preventing golden fingers from exposing copper. The circuit board producing method is characterized in that the OSP process of the method comprises following processing: removing spots residing on a circuit board; micro-etching the copper surfaces of lines on the circuit board; and coating the copper surfaces with an organic solderability preservative, wherein micro-etching the copper surfaces of lines on the circuit board means that the circuit board is immersed in a micro-etching liquid in order that the copper surfaces are etched 80 to 100 [mu] " at a rate of 30 to 60 [mu] " / min. With the micro-etching operation, micro-etching liquid medicine, and the optimization of a gold plating process and a nickel plating process, the method effectively prevents a phenomenon of exposed golden finger copper which is commonly generated in a circuit board producing process and guarantees the quality of produced circuit boards. Compared with a method in the prior art in which the golden fingers are shielded by insulating material to be prevented from exposing copper, the method makes progress in operational simplification and increase in efficiency, and is especially suitable for large-scale industrialized popularization.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

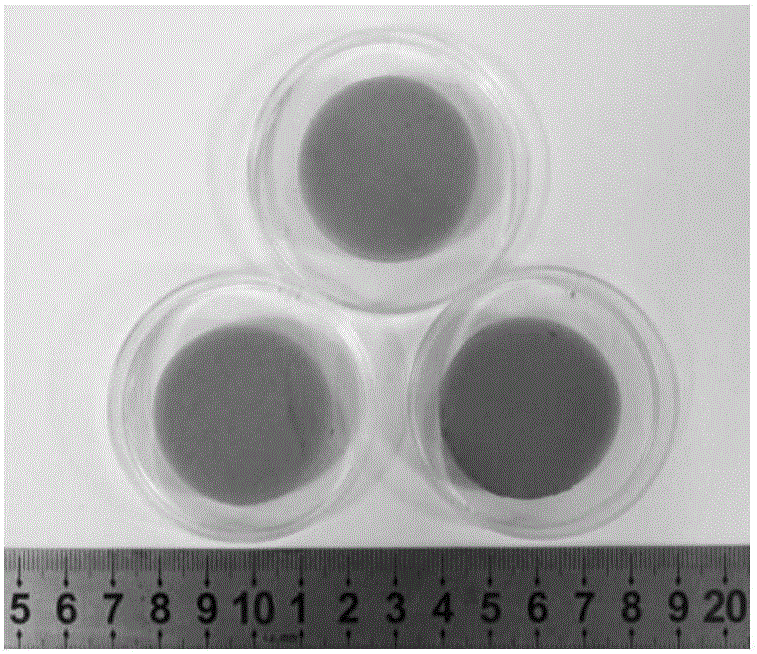

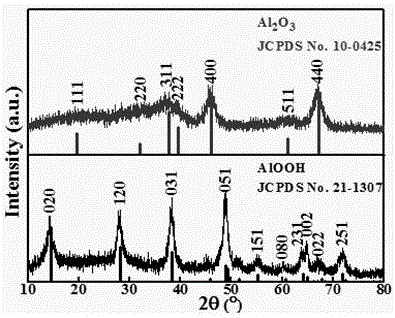

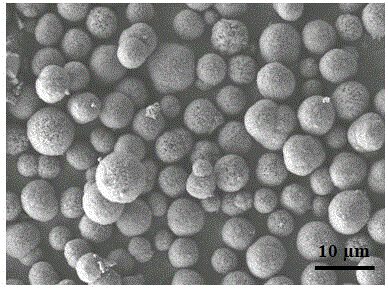

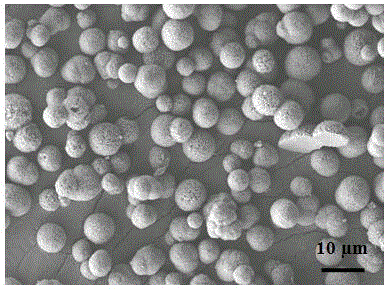

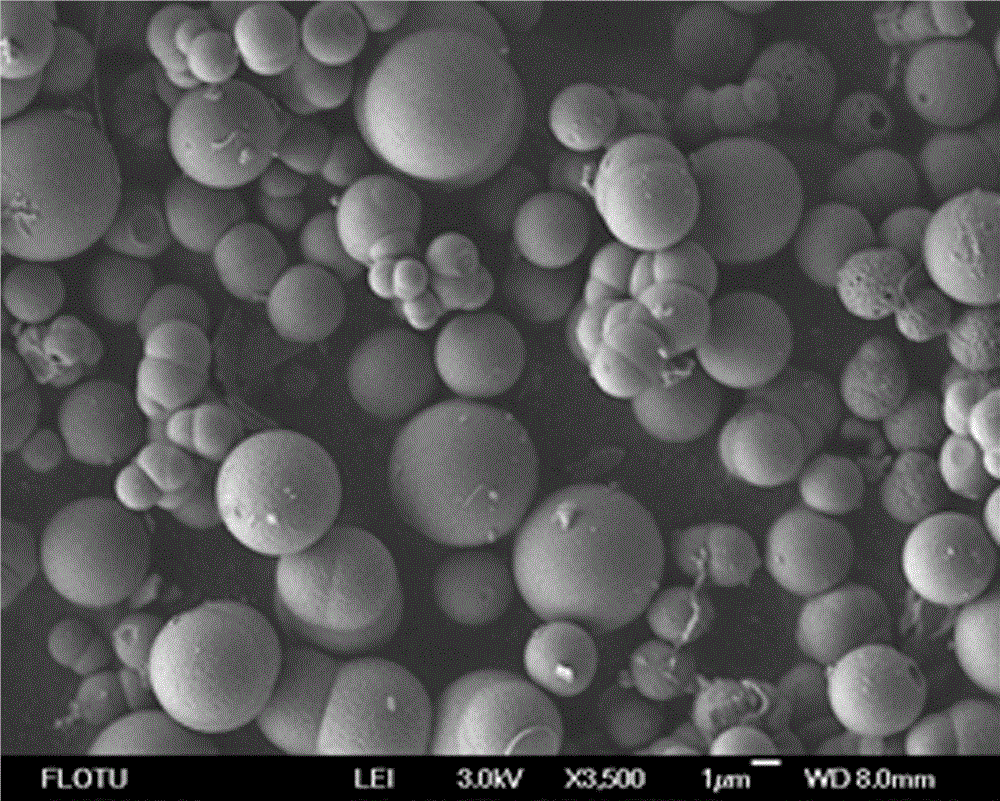

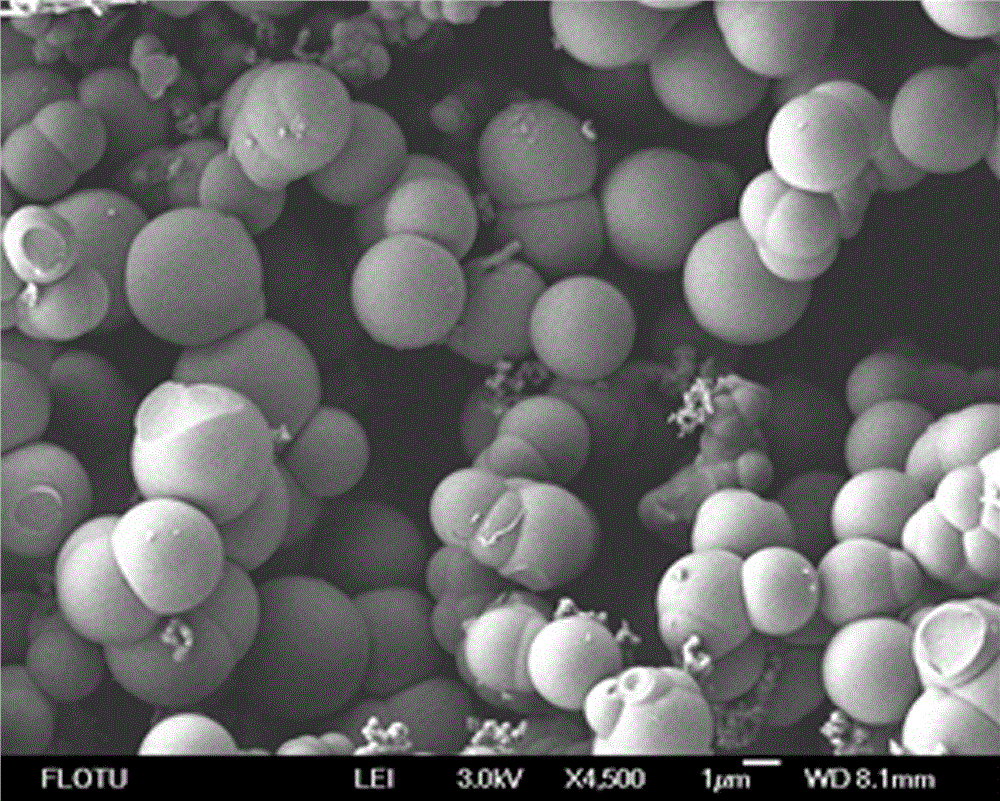

Hydrothermal-thermal conversion method for preparing active boehmite and alumina porous microsphere with red mud as raw material

ActiveCN106830024AHigh crystallinityPure compositionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesRed mudMaterials science

The invention relates to a hydrothermal-thermal conversion method for preparing active boehmite and alumina porous microsphere with red mud as a raw material. The aluminium element extracted from red mud is used as a basic aluminium source and undergoes hydrothermal treatment at 120-210 DEG C in the presence of a proper amount of urea for 1.0-12.0 h so as to prepare AlOOH porous microspheres (diameter is 2.0-10.0 microns and pore diameter is 2-80 nm); and through medium temperature roasting, Al2O3 porous microspheres with morphology maintained greatly are obtained (diameter is 1.5-8.5 microns and pore diameter is 4-120 nm). By using aluminium in waste red mud as the raw material, the AlOOH / Al2O3 porous microsphere structure which has excellent properties and has a wide application prospect in fields of water treatment, industrial catalysis and the like is synthesized by the method. The raw materials are cheap and easily available; equipment is simple; the technological condition is mild; and the method is environment-friendly and is easy for enlarge production.

Owner:QUFU NORMAL UNIV

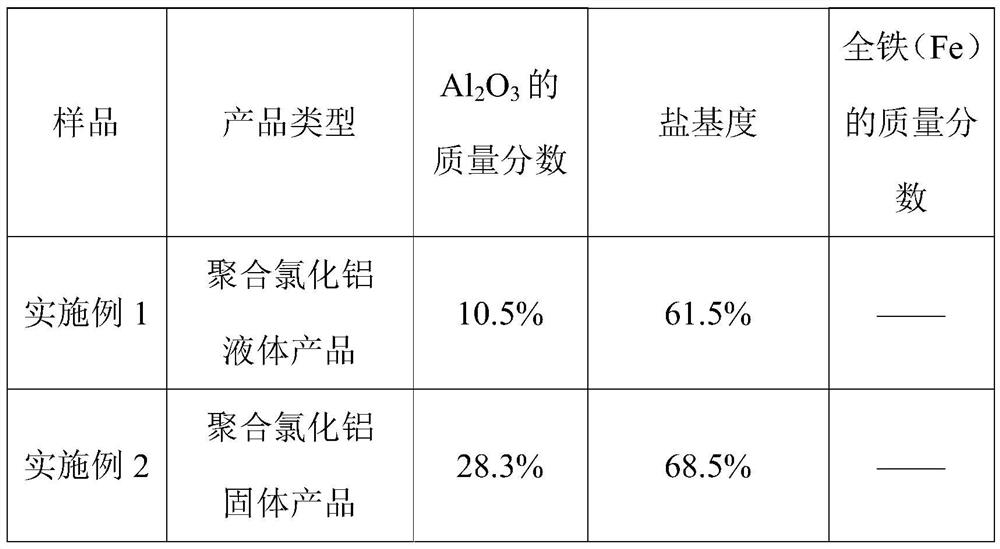

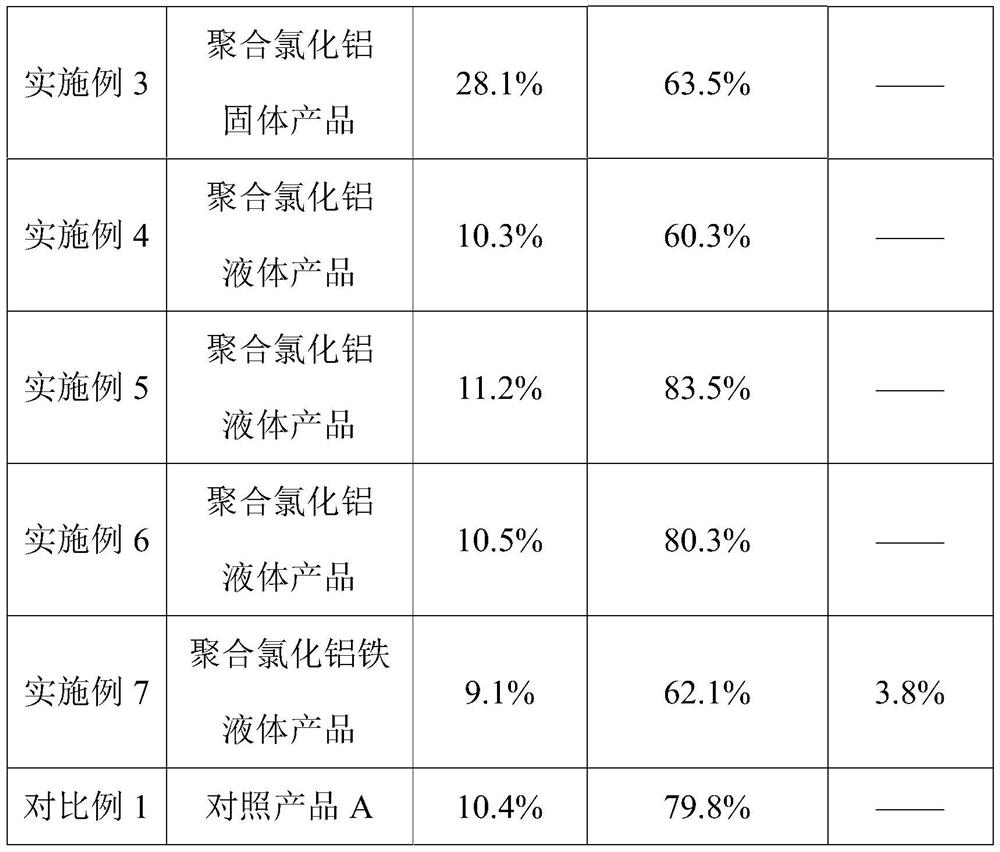

Treatment method for solid sodium tetrachloroaluminate residue

ActiveCN111804704AResolve disposal issuesIncrease added valueSolid waste disposalAluminium chlorideLiquid product

The invention relates to a treatment method for solid sodium tetrachloroaluminate residue. The treatment method comprises the following steps: mixing the solid sodium tetrachloroaluminate residue withwater and dissociating at first; then adding alkali and carrying out polymerization reaction; then carrying out concentration and crystallization, and solid-liquid separation to obtain a sodium chloride solid and a concentrated mother solution; and then curing the obtained concentrated mother solution to obtain a polyaluminum chloride liquid product. According to the treatment method, aluminum chloride and sodium chloride which are obtained by dissociating the solid sodium tetrachloroaluminate residue are adequately recovered, so that the problem of disposal for the solid waste is solved, andthe polyaluminum chloride liquid product with a high additional value is prepared, the mass fraction of Al2O3 is not less than 10%, the basicity of Al2O3 is not less than 60%, and the index requirements of the national standards GB 15892-2009 are met; and according to the treatment method, an organic solvent does not need to be introduced, so that cross contamination is avoided, and the cost canbe lowered, and the treatment method has the advantages of being simple in process flow, simple and convenient to operate, low in equipment investment, and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

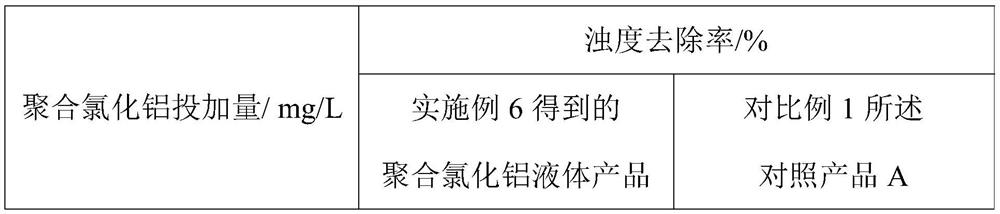

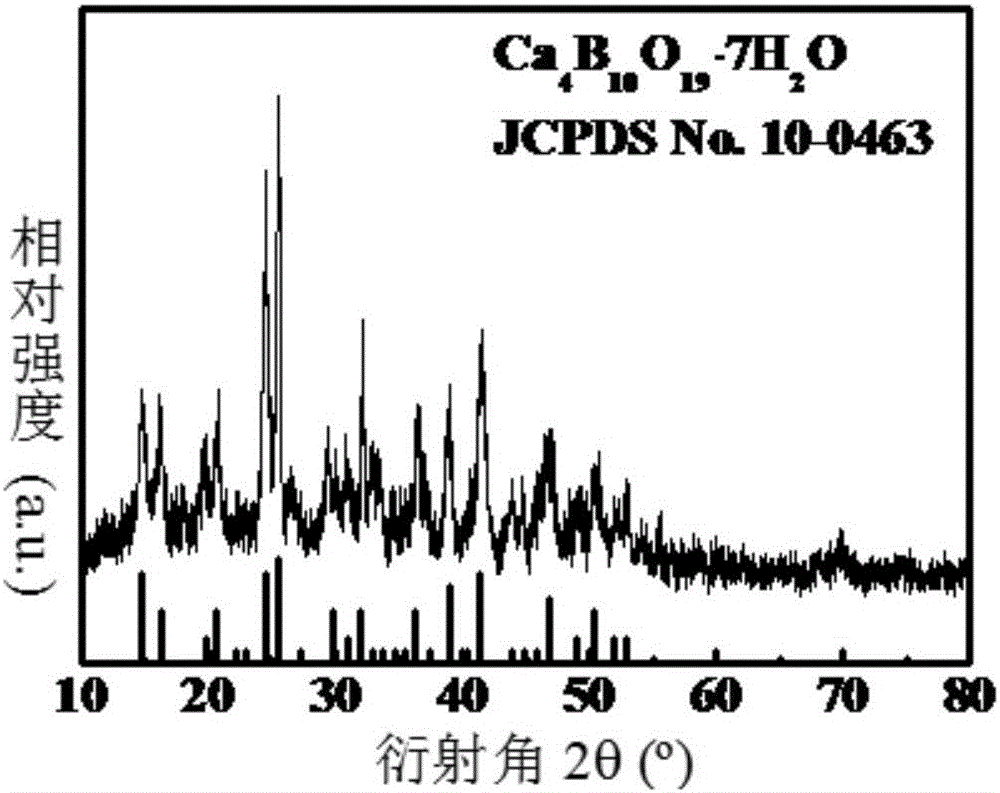

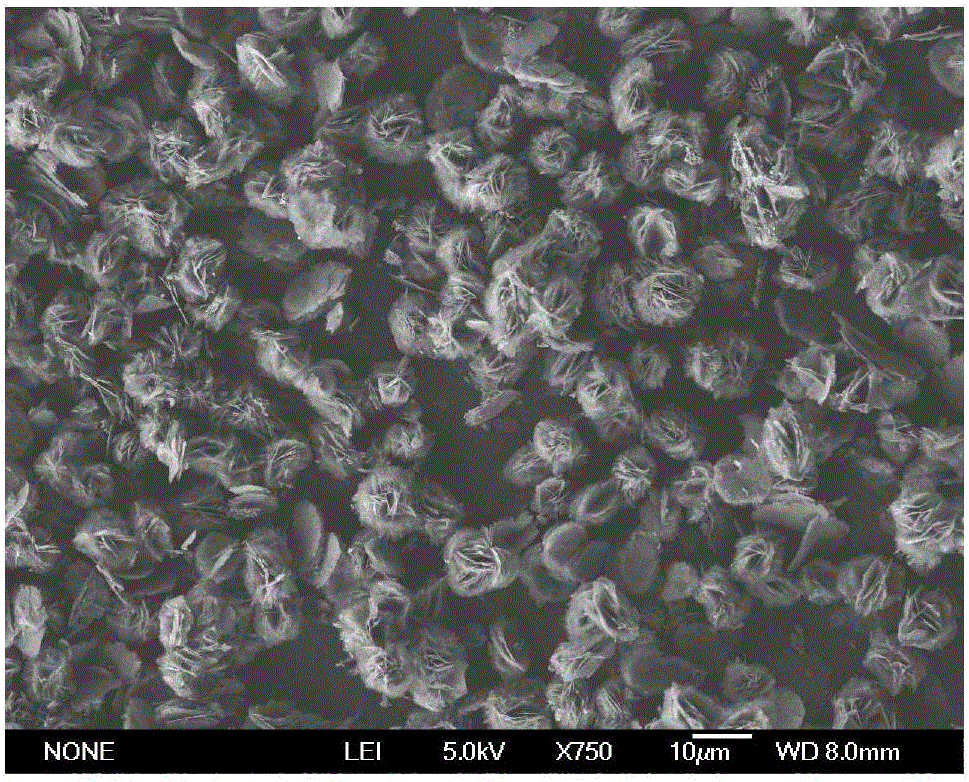

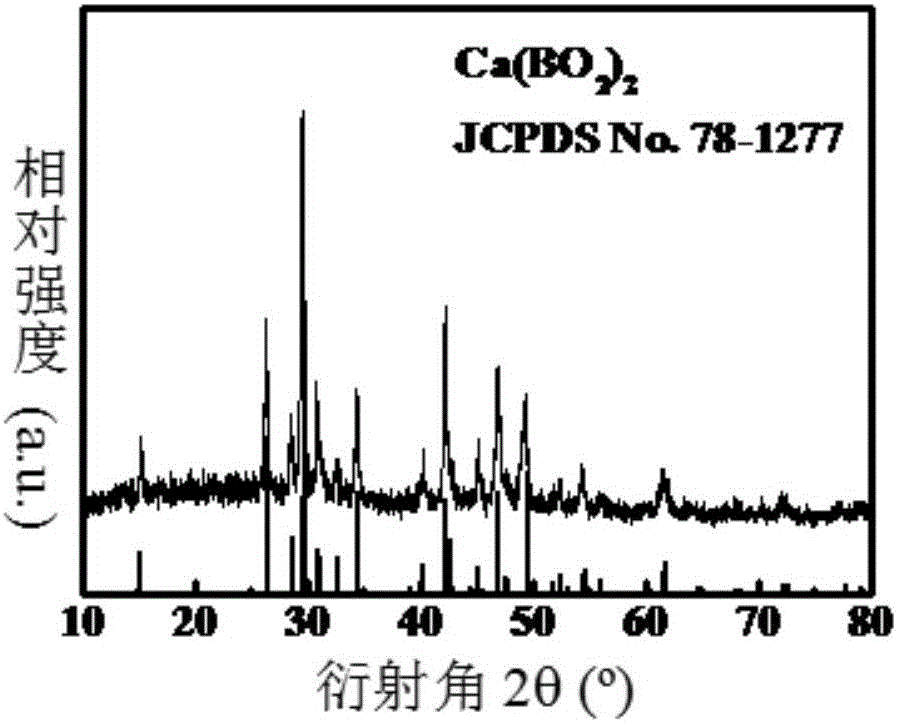

Hydration and anhydrous multistage porous calcium borate microsphere low-temperature hydrothermal-thermal conversion synthetic method

The invention discloses a hydration and anhydrous multistage porous calcium borate microsphere low-temperature hydrothermal-thermal conversion synthetic method. The method comprises the steps of adding aqueous alkali into a calcium salt solution, adding borate solid powder into the mixture, supplementing water and performing stirring; putting the obtained slurry in a hydrothermal reaction kettle, raising the temperature to enable the slurry to be reacted, and washing, filtering and drying hydrothermal products to obtain hydration calcium borate (Ca4B10O19. 7H2O) microspheres; putting the microspheres in a roaster to be roasted, washing, filtering and drying the roasted microspheres to obtain anhydrous multistage porous calcium borate (Ca (BO2)2) microspheres. By the aid of the method, hydrothermal controllable preparation of Ca4B10O19.7H2O is achieved, subsequent medium-temperature roasting of hydrothermal products is used for achieving crystal water removal to obtain three-dimensional anhydrous multistage porous Ca (BO2)2 microspheres. The method has the advantages of being simple to operate, mild in condition, cheap and easy to obtain in material, capable of not adding any additives and the like and easy to produce industrially.

Owner:QUFU NORMAL UNIV

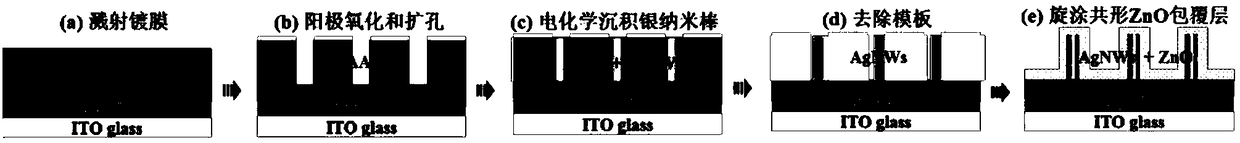

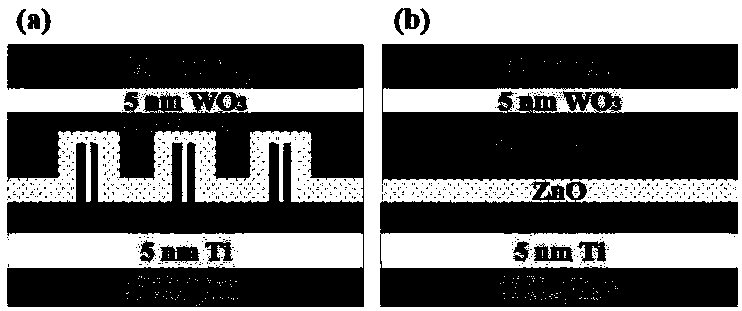

Fabrication method of Ag/ZnO core-shell structure nanorod array electrode material

ActiveCN108878660AEasy to operateProcess is easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingElectron hole recombinationPhotoelectric conversion efficiency

The invention discloses a fabrication method of an Ag / ZnO core-shell structure nanorod array electrode material. The fabrication method comprises the steps of (1) electrically depositing a silver nanorod array on a conductive glass substrate; (2) fabricating pinhole-free conformal ZnO coating layer; (3) spinning a polymer; and (4) evaporating a buffer layer and a metal electrode. With the Ag / ZnO core-shell structure nanorod array electrode material fabricated by the method, the efficiency of transmitting charges in a solar cell to an electrode can be substantially improved, the electron-hole recombination rate is effectively reduced, and the photoelectric conversion efficiency is favorably improved; and the fabrication method is simple to operate, is suitable for production on a large scale and is relatively low in production cost, the process is easy to control, and thus, the fabrication method is suitable for industrial protection on a large scale.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

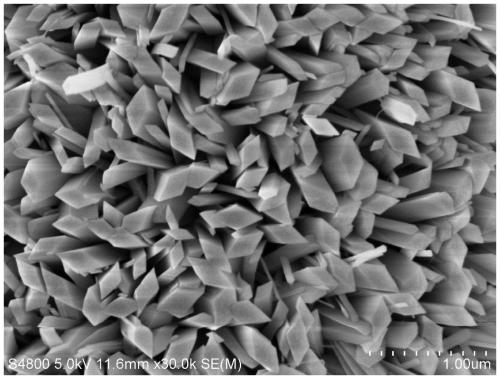

Efficient NO degradation glass fiber cloth in-situ loaded BiOCl photocatalytic material and method for preparing same

ActiveCN108525681AHigh strengthHigh catalytic activityPhysical/chemical process catalystsDispersed particle separationGlass fiberHydrofluoric acid

The invention relates to an efficient NO degradation glass fiber cloth in-situ loaded BiOCl photocatalytic material. The efficient NO degradation glass fiber cloth in-situ loaded BiOCl photocatalyticmaterial comprises glass fiber cloth and BiOCl layers. The BiOCl layers grow on the glass fiber cloth in an in-situ manner, and BiOCl nano-sheets are densely assembled to obtain the BiOCl layers. A method for preparing the efficient NO degradation glass fiber cloth in-situ loaded BiOCl photocatalytic material includes 1), soaking the glass fiber cloth in hydrofluoric acid solution and then washingand drying the glass fiber cloth for standby application; 2), soaking the glass fiber cloth in saturated solution of bismuth nitrate pentahydrate, then taking the glass fiber cloth out of the saturated solution and draining solution attached to the surfaces of the glass fiber cloth; 3), soaking the glass fiber cloth obtained at the step 2) in potassium chloride solution, then taking the glass fiber cloth out of the potassium chloride solution and draining solution attached to the surfaces of the glass fiber cloth; 4), repeatedly carrying out the step 2) and the step 3) and ultimately drying the glass fiber cloth to obtain the BiOCl photocatalytic material on the basis of the glass fiber cloth.

Owner:HUAZHONG NORMAL UNIV +1

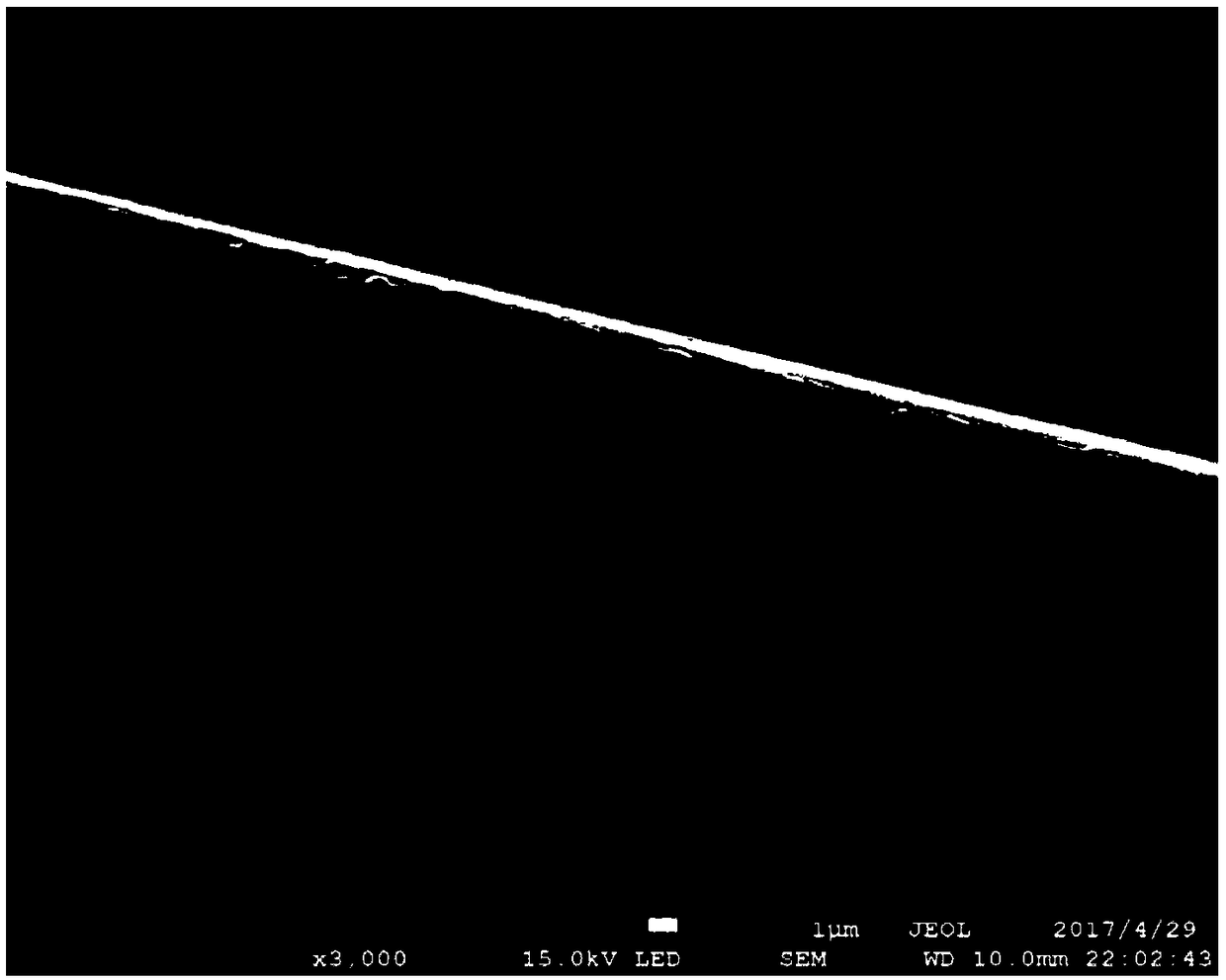

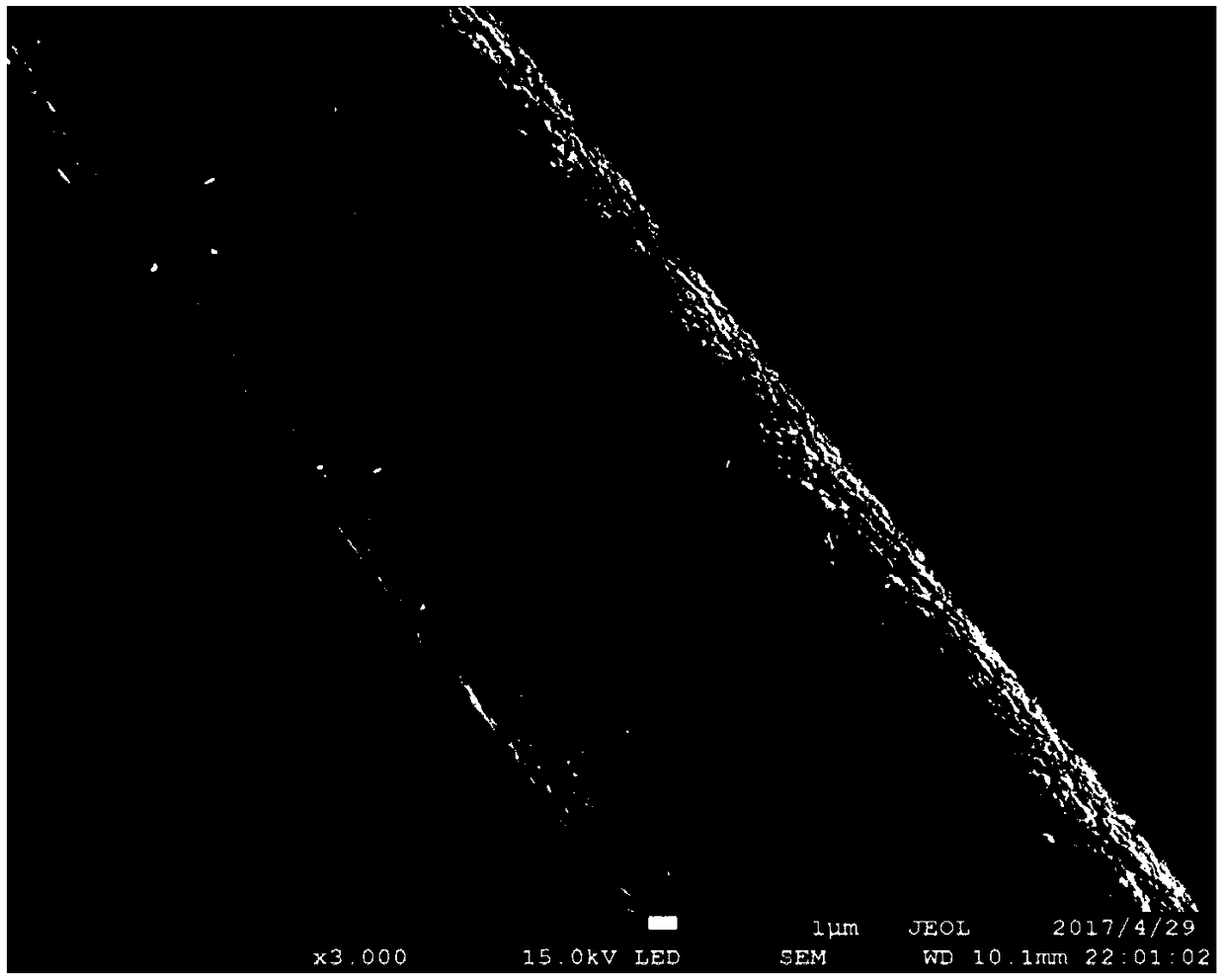

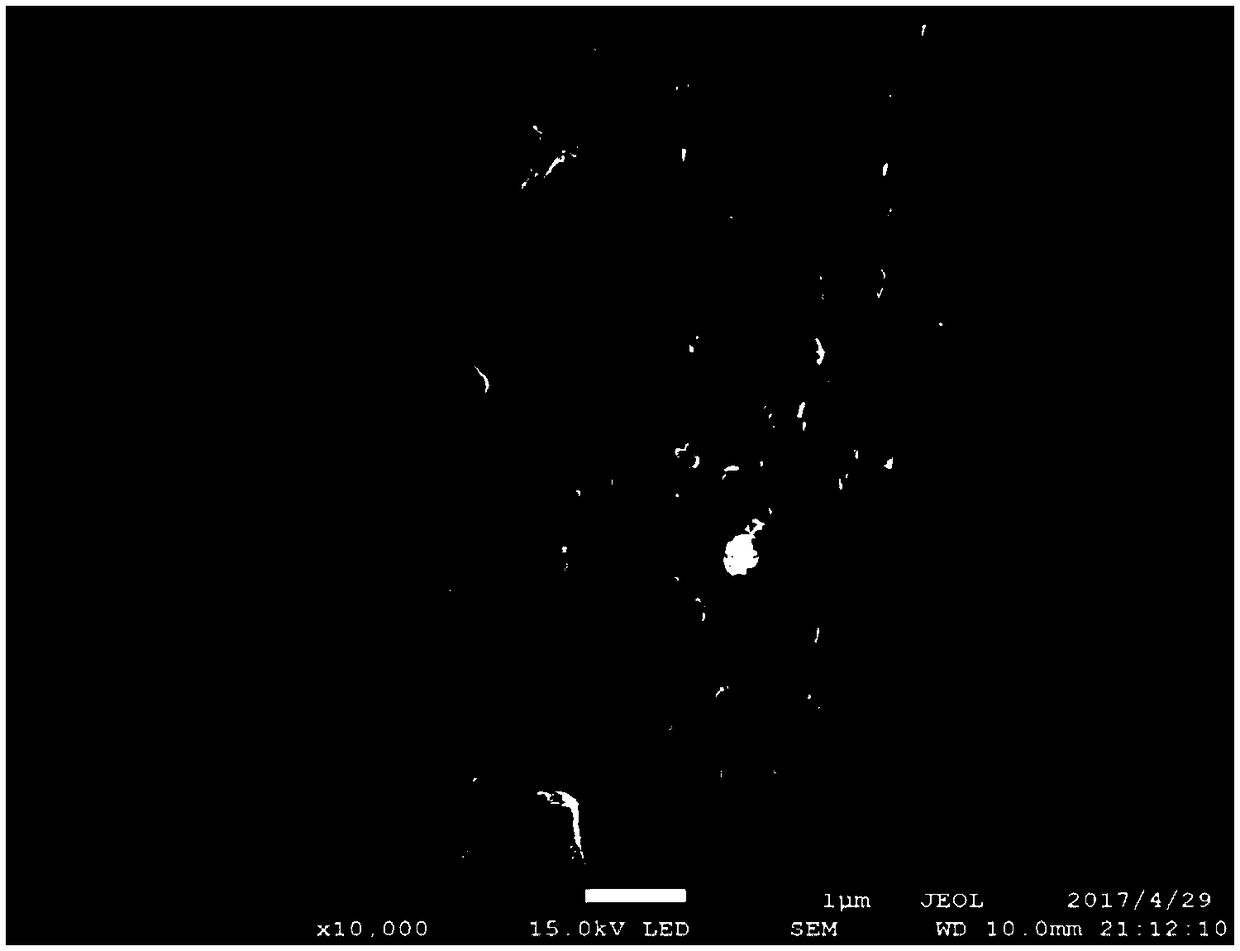

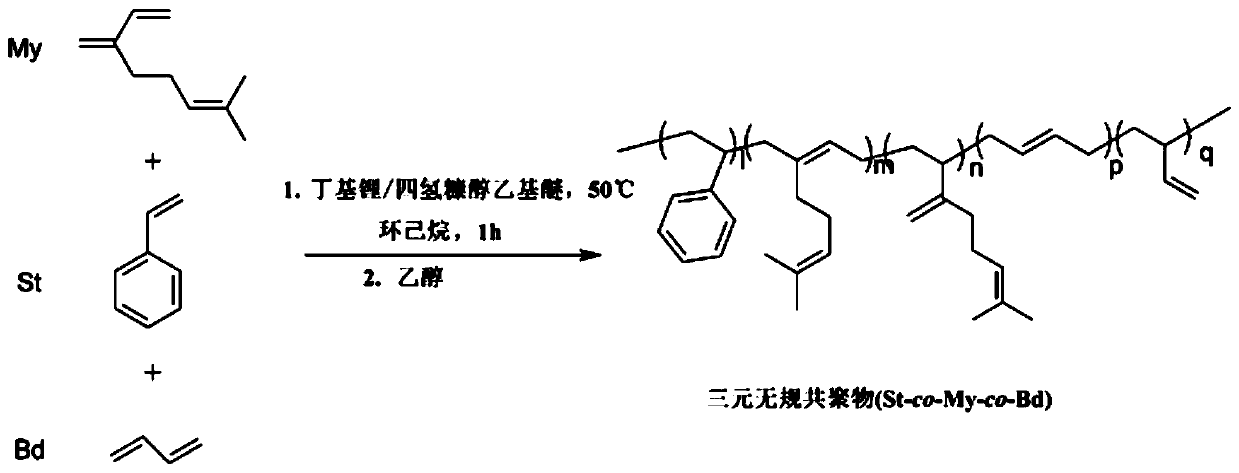

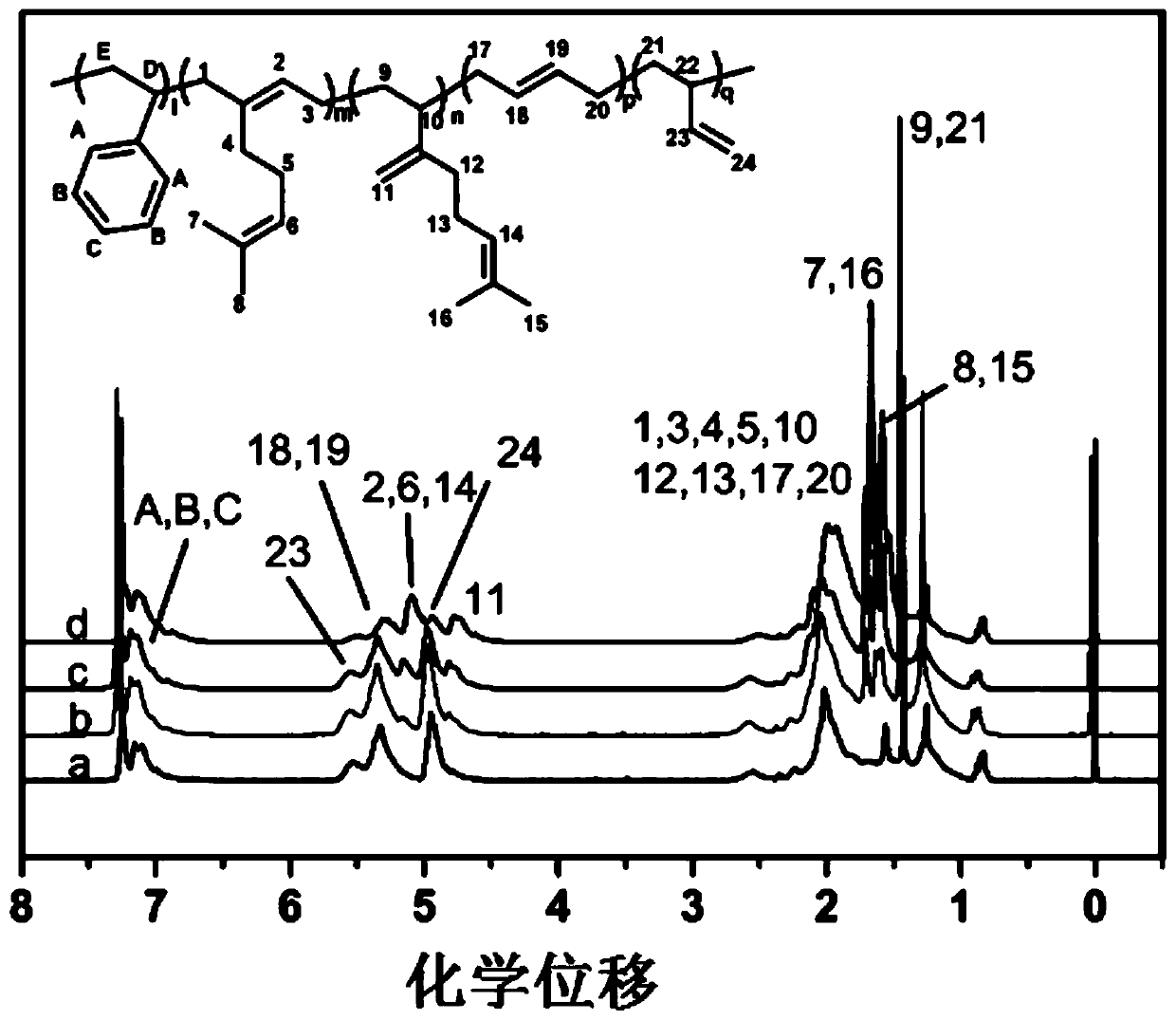

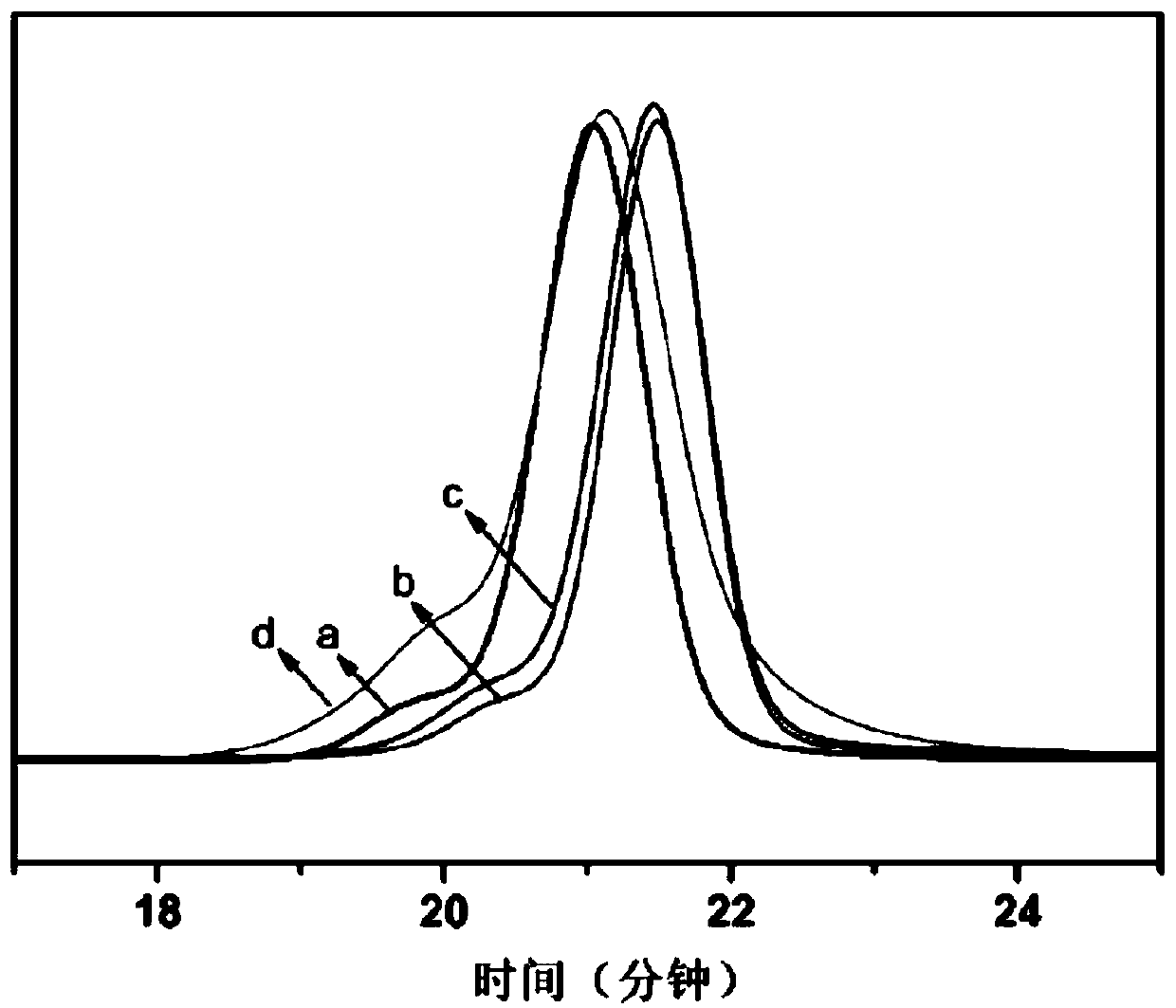

Ternary random copolymer containing beta-myrcene, preparation method and applications thereof

InactiveCN110256631AGuaranteed uniformityEliminate microphase separationRolling resistancePolymer science

The invention provides a ternary random copolymer containing beta-myrcene, a preparation method and applications thereof, and relate to the field of synthetic rubbers, wherein the ternary random copolymer containing beta-myrcene comprises a beta-myrcene structure unit, a styrene structure unit and a butadiene structure unit, and has a structure represented by a formula (I), the beta-myrcene structure unit accounts for 5-70 wt% of the ternary random copolymer, and the copolymer is prepared by copolymerizing a bio-based monomer beta-myrcene, styrene and butadiene anions. According to the present invention, the method has characteristics of simple process, high efficiency, low cost, high functionalization degree and good industrial adaptability, and can achieve the efficient and precise control of the composition and the structure of random copolymers; and the long branch chain, the carbon particles and other fillers contained in the product have good adhesion, and can significantly improve the dispersibility of the carbon black, and the vulcanized rubber prepared by using the copolymer has characteristics of high wet-skid resistance, low rolling resistance and the like, and is a novel environmental protection and energy saving tread rubber.

Owner:BEIJING UNIV OF CHEM TECH

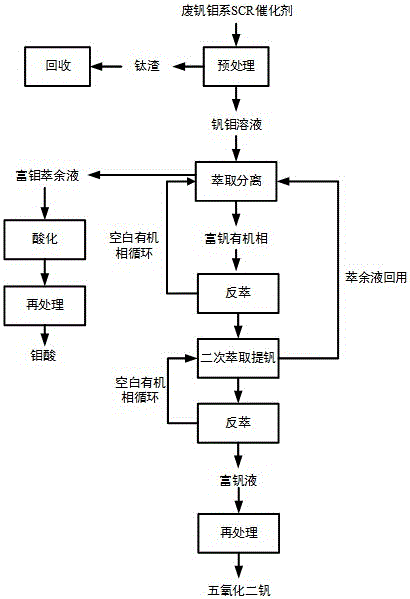

A kind of vanadium, molybdenum separation and purification method of waste vanadium molybdenum series SCR catalyst

ActiveCN104831075BRealize separation and recoveryReduce consumptionProcess efficiency improvementSlagEconomic benefits

The invention discloses a method for separating and purifying vanadium and molybdenum of a waste vanadium-molybdenum SCR (selective catalytic reduction) catalyst. The method comprises the following steps: firstly, carrying out pretreatment on a catalyst to obtain a titanium slag and a vanadium-molybdenum solution; extracting and separating the vanadium-molybdenum solution, acidifying the obtained molybdenum-rich raffinate, and reprocessing to prepare a molybdenic acid product; carrying out reverse extraction on the obtained molybdenum-rich organic phase, then carrying out a two-stage extraction and vanadium purification process, and carrying out reverse extraction again to obtain a vanadium-rich solution; and reprocessing the vanadium-rich solution to prepare vanadium pentoxide. According to the method disclosed by the invention, the problem of difficult vanadium and molybdenum separation, recovery and purification of the waste vanadium-molybdenum SCR catalyst in industry is thoroughly solved; in addition, the recovery rates of vanadium and molybdenum exceed 95%; a high-purity (greater than 99%) molybdenic acid product and a vanadium pentoxide product of which the purity exceeds 99.5% can be respectively obtained; recycling of resources is really realized; and the method has good environmental and economic benefits, and is suitable for industrial popularization and application.

Owner:BOTREE CYCLING SCI & TECH CO LTD

Preparing method for water-proof fused silica ceramics

InactiveCN106336118ATo achieve the purpose of waterproofingSmall coefficient of thermal expansionAluminium hydroxideTemperature resistance

The invention discloses a preparing method for water-proof fused silica ceramics and the method comprises the following steps of 1, combining lithium carbonate, calcium carbonate, aluminium hydroxide, zirconium oxide, zinc oxide together, smelting the mixture and obtaining vitreous humour; 2, obtaining the solid glass after carrying out water quenching on the vitreous humour obtained from step one, and then grinding the solid glass into finely-crushed glass powder less than 10 microns; 3, combining and stirring evenly terpineol, absolute ethyl and Primary Alcobol Ethoxylate,to obtain a mixed liquor, pouring the finely-crushed glass powder obtained in step 2 into the mixed liquor to obtain vitreous glaze pulp, dispersing evenly the pulp; 4, coating evenly the vitreous glaze pulp obtained in step 3 on the surface of fine fused silica ceramics, carrying out sintering and heat setting on the coated fine fused silica ceramics, finally obtaining the water-proof fine fused silica ceramics after the ceramics cools down. Waterproof microcrystalline glass coating obtained form the invention has multiple excellent performances such as small thermal expansivity, good thermal shock resistance, high temperature resistance, high intensity, and the like, and is capable of obviously extending the serving life of the fine fused silica ceramics under tough environment.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Preparation method of ferrosilicon nitride porous ceramic sliding plate

The invention belongs to the field of inorganic nonmetallic materials, and relates to a preparation method of a sliding plate for a steel-making ladle sliding gate mechanism, in particular to a preparation method of a ferrosilicon nitride porous ceramic sliding plate. The ferrosilicon nitride porous ceramic sliding plate disclosed by the invention is characterized in that the inner core of the sliding plate is prepared by directly cutting an original ferrosilicon nitride blank body; and the periphery of the sliding plate is poured and formed by adopting an unshaped fire-resistant material. The ferrosilicon nitride sliding plate is a carbon-free sliding plate; therefore, molten steel carburetion of the sliding plate generated in the use process can be avoided; the production requirements of clean steel in the future can be satisfied; the chrome-free property of the sliding plate is realized; pollution of chrome to the environment is avoided; the processing technology is simple; sintering and heat treatment are unnecessary; raw materials, energy, equipment, manpower and time are saved greatly; the cost is low; the preparation method is applied to large-scale industrial popularization; the porous ceramic material is applied in the sliding plate, so that the basic performances of the sliding plate are ensured, and simultaneously, the thermal shock resistance of the sliding plate is increased; the porous ceramic is applied in the sliding plate disclosed by the invention for the first time, so that a new field is created for developing the sliding plate material, and the development direction shows a promising future.

Owner:UNIV OF SCI & TECH BEIJING

Graphene body wash

InactiveCN111904884ALarge specific surface areaFacilitate contact areaCosmetic preparationsToilet preparationsBenzoic acidShower gel

The invention relates to the technical field of graphene and chemical engineering, in particular to graphene body wash. Every 100 parts by weight of the graphene body wash comprises the following rawmaterials in parts by weight: 0.5-4 parts of p-hydroxybenzoate, 10-24 parts of olefin sulfonate, 10-16 parts of cocamidopropyl betaine, 0.2-3 parts of citric acid, 0.5-5 parts of lauramidopropyl hydroxy sulfobetaine, 1-3 parts of ethylene glycol distearate, 0.2-10 parts of graphene and the balance of deionized water. The natural environment-friendly raw materials are adopted, and the graphene as abiocompatible material which is large in specific surface area, large in area of contact with the skin and high in adsorption capacity is added, so that the dirt removal capacity of the body wash isimproved, and skin dirt is thoroughly cleaned away; and a formula is mild and has a certain moisturizing and skin-care effect on the skin. A preparation method is simple in process, convenient to operate, environmentally friendly and suitable for large-scale industrial popularization, and the produced graphene body wash can clean the skin dirt more thoroughly and also can moisturize and protect the skin.

Owner:GUANGDONG MORION NANOTECHNOLOGY CO LTD

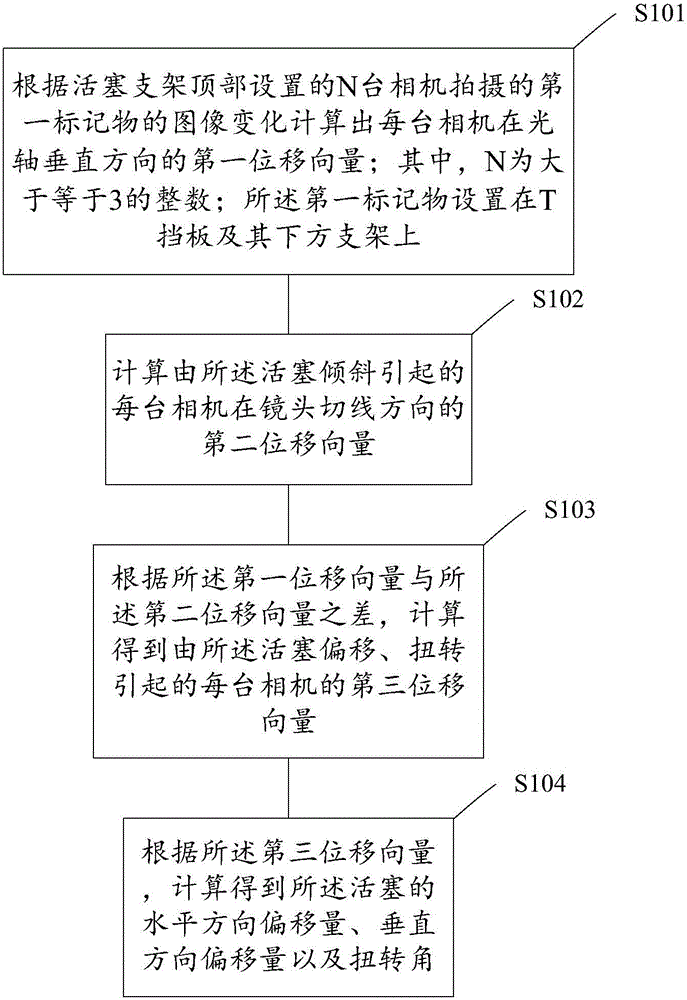

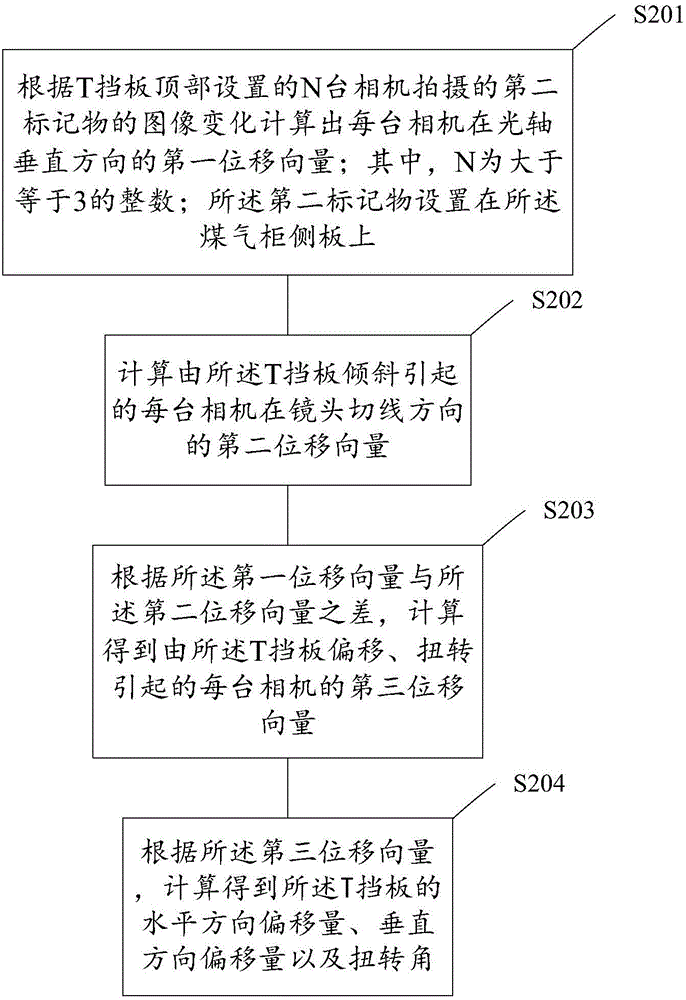

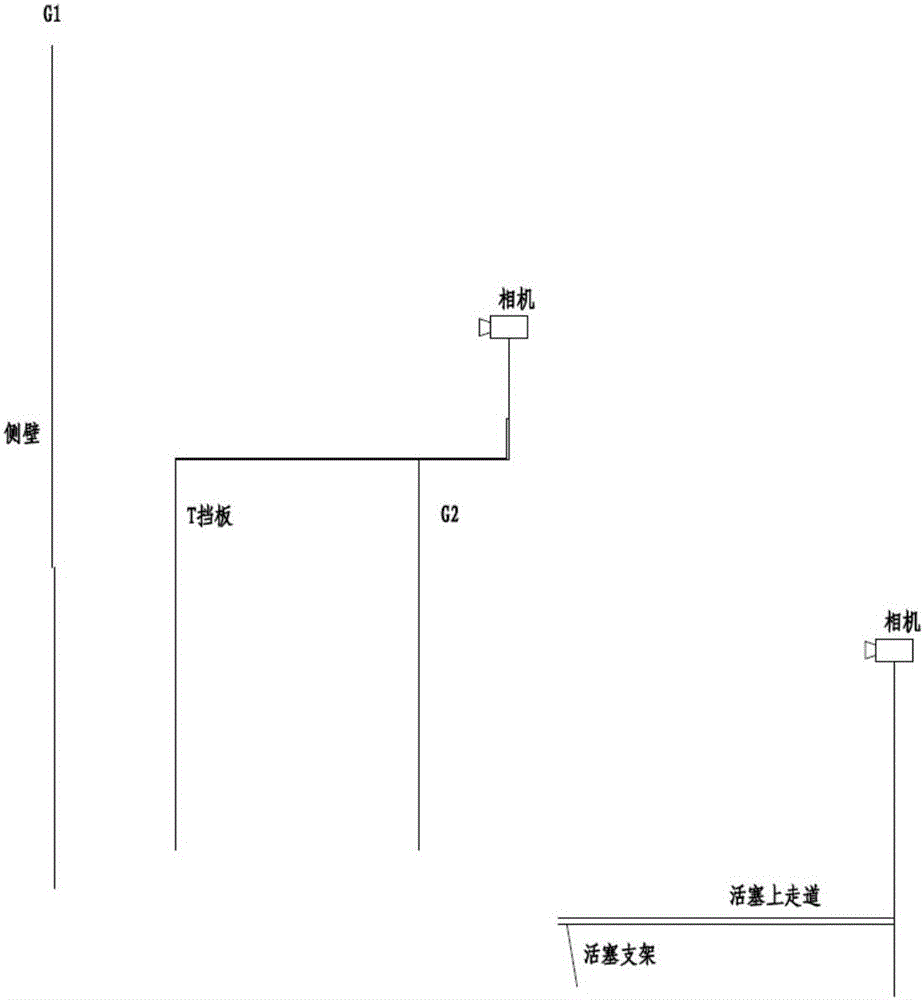

Gas tank piston and T baffle offset and torsion measuring methods and devices

ActiveCN105953732AImprove maintenance efficiencyReal-time control of operating statusUsing optical meansOptical axisEngineering

The invention provides a gas tank piston offset and torsion measuring method comprising the following steps: calculating a first displacement vector of each camera in a direction perpendicular to an optical axis according to the change in images of a first marker shot by N cameras arranged on the top of a piston bracket; calculating a second displacement vector of each camera in a direction tangential to the lens caused by piston inclination; calculating a third displacement vector of each camera caused by piston offset and torsion according to the difference between the first displacement vector and the second displacement vector; and calculating the horizontal offset, the vertical offset and the torsion angle of the piston according to the third displacement vector. The invention provides methods and devices for precisely measuring the offset and torsion of the piston and the T baffle of a gas tank online. Maintenance personnel can control the operation condition of a gas tank piston remotely and in real time. The number of times that a worker goes into a gas tank for measurement is reduced, the efficiency of gas tank maintenance is improved, and the safety of maintenance work is improved.

Owner:WISDRI ENG & RES INC LTD

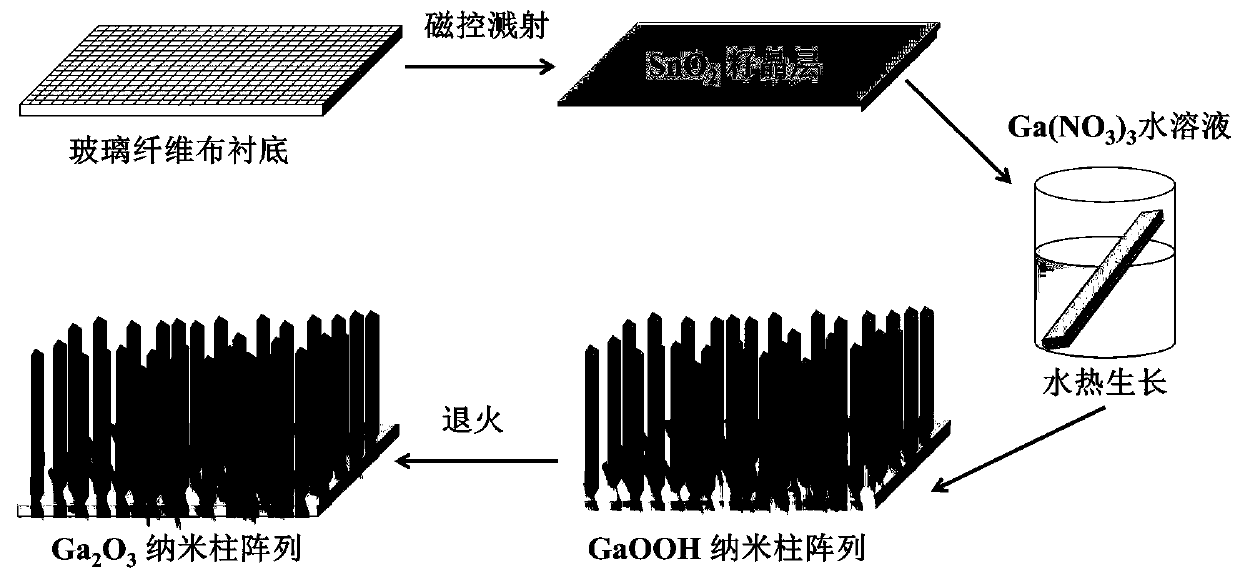

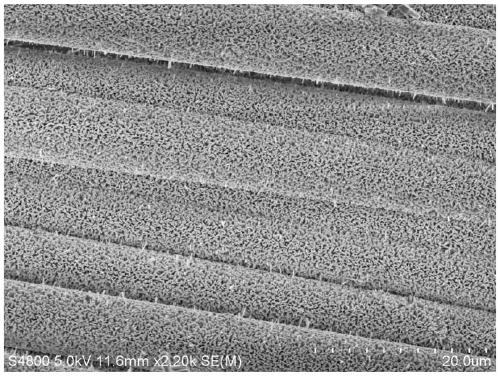

Ga2O3 nano-pillar photocatalytic material based on flexible substrate, and preparation method thereof

PendingCN111215044ALarge specific surface areaFully absorb lightMetal/metal-oxides/metal-hydroxide catalystsNanopillarPhoto catalysis

The invention relates to a Ga2O3 nano-pillar photocatalytic material based on a flexible substrate, and a preparation method thereof. The Ga2O3 nano-pillar array comprises a flexible substrate layer,a SnO2 seed crystal layer located on the flexible substrate layer and a Ga2O3 nano-pillar array located on the SnO2 seed crystal layer, the Ga2O3 nano-pillar array is formed by arranging a plurality of Ga2O3 nano-pillars at intervals in an array mode, and the cross section of each Ga2O3 nano-pillar is quadrilateral. The Ga2O3 nanopillars are synthesized on the flexible substrate in situ, so that the photocatalytic material is firm in combination, good in stability, good in photocatalytic performance, large in specific surface area, easy to recycle and separate and suitable for industrial production.

Owner:ZHEJIANG SCI-TECH UNIV

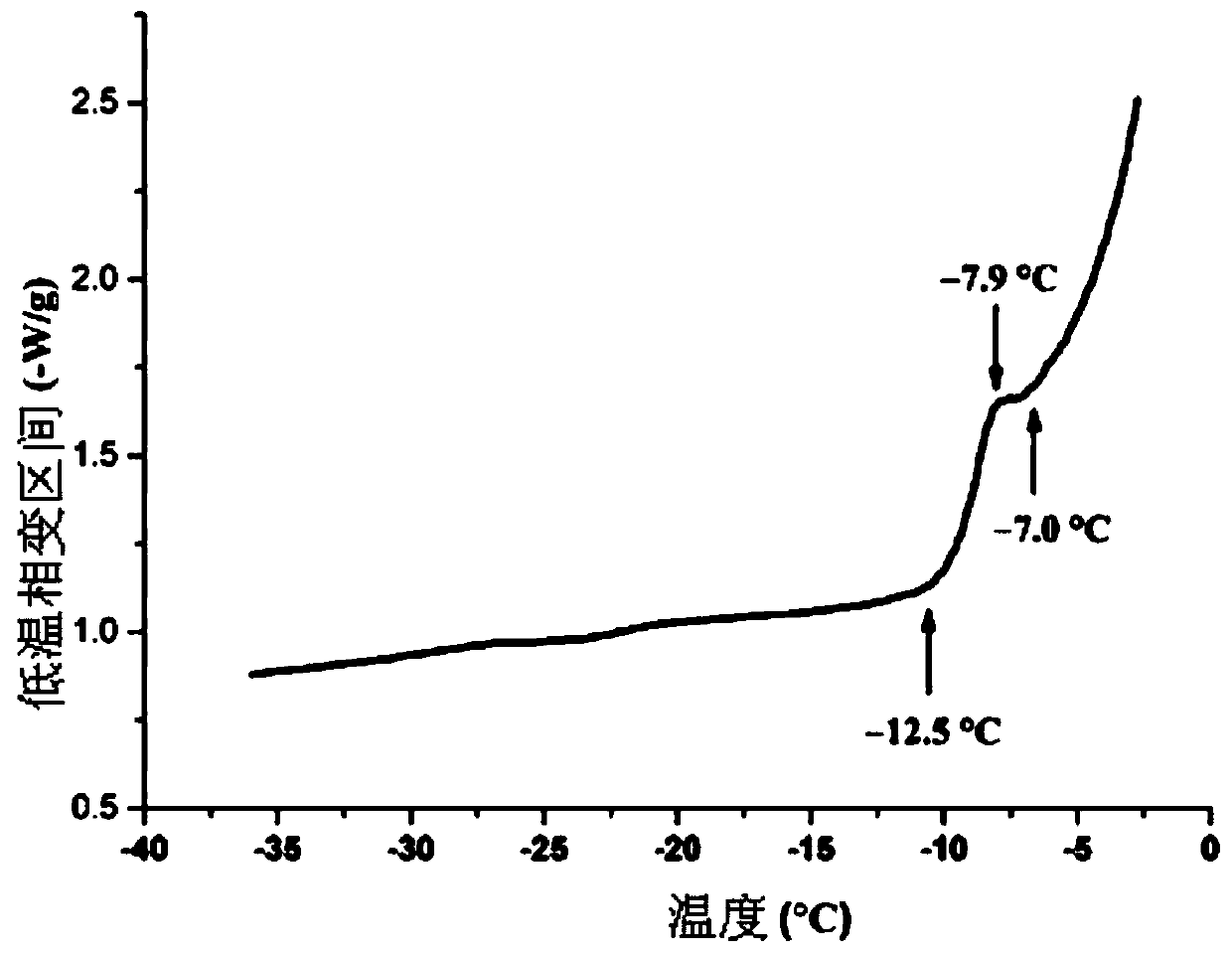

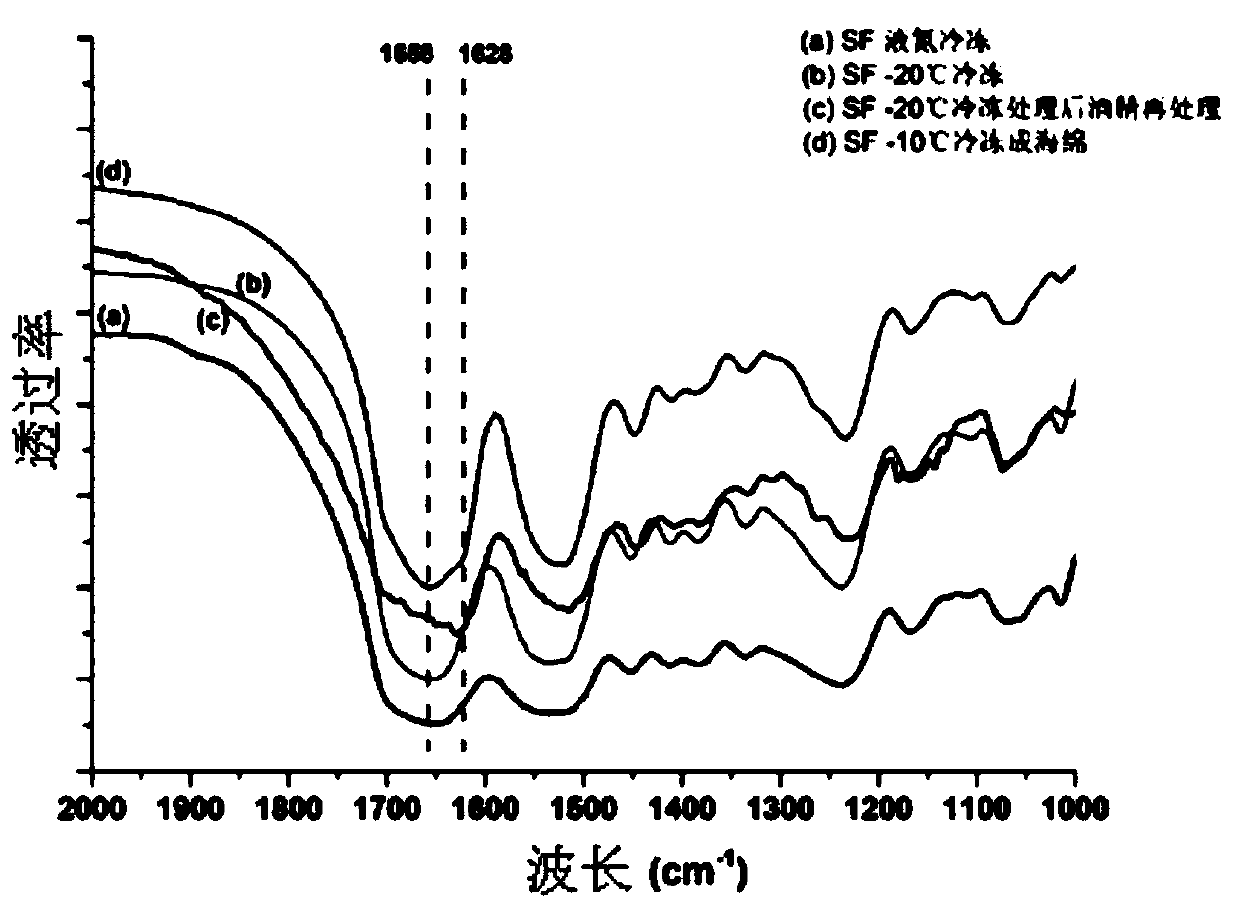

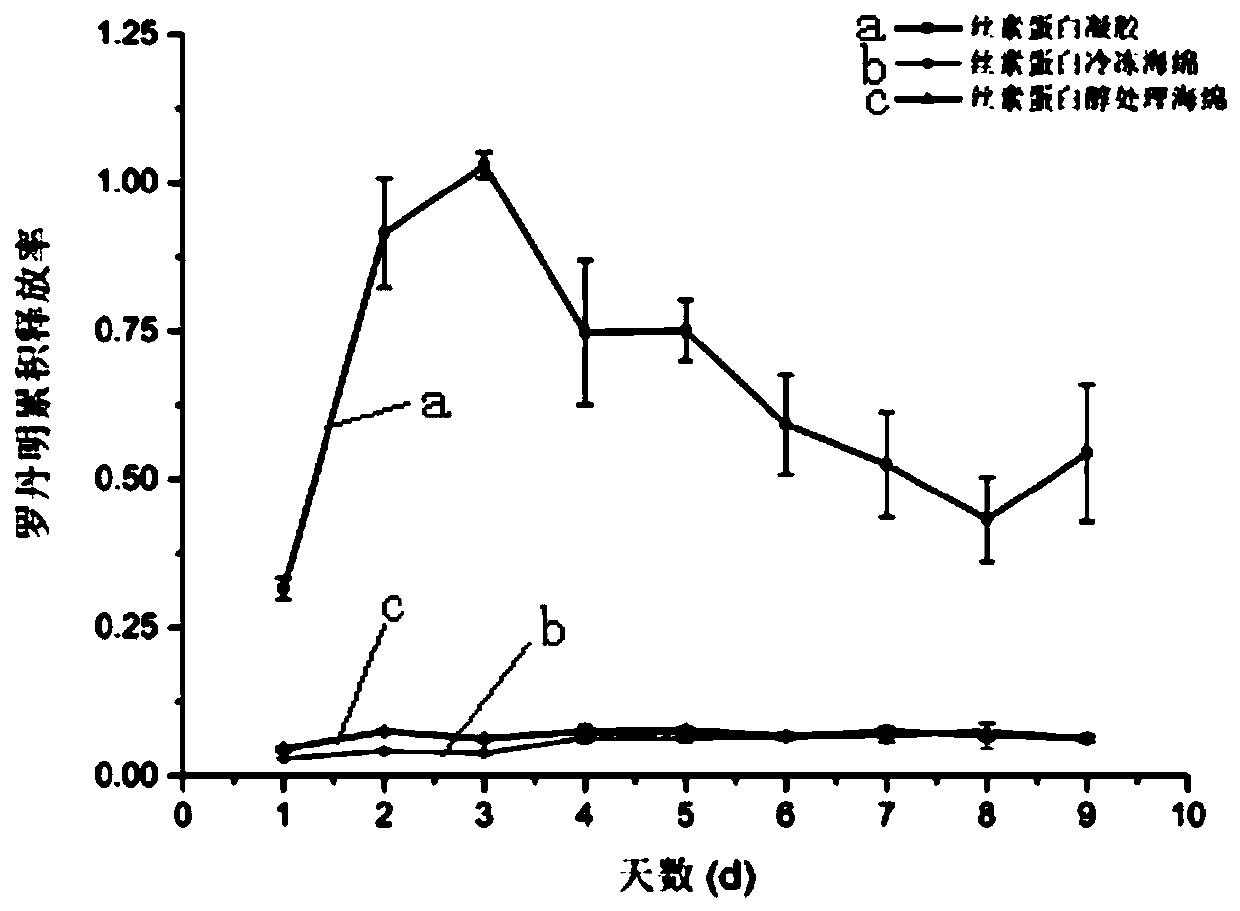

Preparation method of silk fibroin scaffold material capable of realizing long-acting medicine sustained release

ActiveCN110624135AAchieve long-term controlled releaseHigh drug loading rateProsthesisOrganic solventSelf assemble

The invention relates to a preparation method of a silk fibroin scaffold material capable of realizing long-acting medicine sustained release. Silk fibroin frozen sponge prepared through liquid nitrogen quick freezing serves as a carrier of a sustained-release medicine, medicine wrapping and sustained release are realized by utilizing the low-temperature self-assembling characteristic of the silkfibroin, and long-time controllable sustained release of the medicine is realized according to a technical route from preparation of a silk fibroin solution to final medicine loading, namely differential thermal experiment to find glass transition temperature-medicine addition-low-temperature cryostorage-unfreezing and use. Compared with other medicine loading forms, the medicine loading rate is extremely high; furthermore, the preparation process of the technical scheme is simple, controllable and suitable for large-scale industrial promotion.

Owner:PEKING UNIV THIRD HOSPITAL

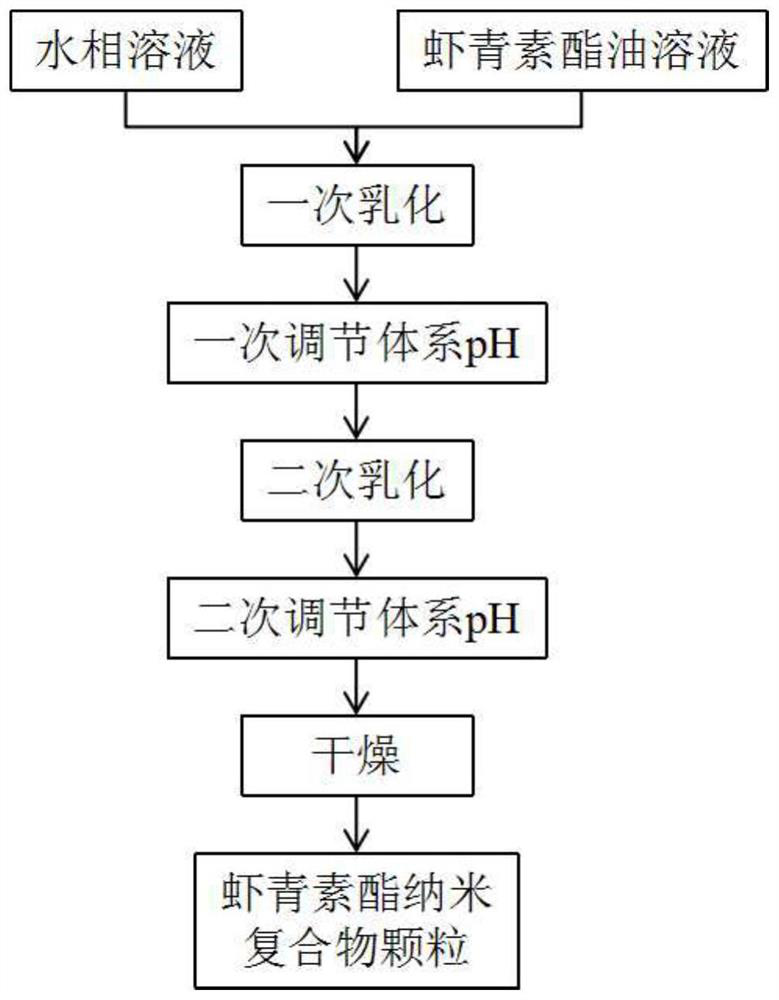

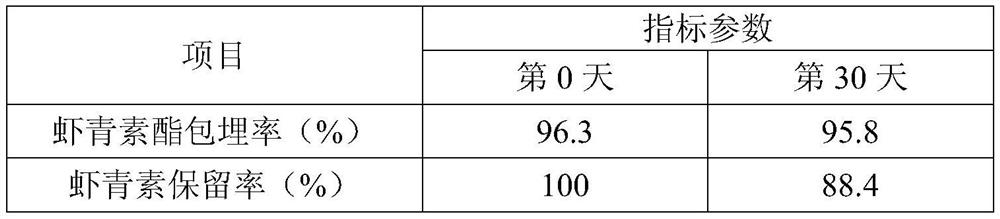

Preparation method of astaxanthin ester nano-composite particles

PendingCN112402404AImprove thermal stability and processing, storage and transportation stabilityImproved water dispersibility and bioavailabilityCosmetic preparationsOrganic active ingredientsAstaxanthinSolvent

The invention relates to the technical field of astaxanthin, in particular to a preparation method of astaxanthin ester nano-composite particles. The preparation method comprises the following steps:dissolving protein in deionized water or a buffer solution, and hydrating to obtain an aqueous phase solution; dissolving astaxanthin ester in the oil phase to prepare an astaxanthin ester oil solution; adding the astaxanthin ester oil solution into the aqueous phase solution, adding tea polyphenol into the system at the same time, and then fully homogenizing and emulsifying the system by adoptinghigh-pressure microjet; adjusting the pH value of the emulsified system to 11-13 by using an alkaline substance, and carrying out secondary homogeneous emulsification; adjusting the pH value of the system subjected to secondary emulsification to 6.5-7.2 by using an acidic substance while stirring; and drying. The astaxanthin ester prepared by the method has obviously improved thermal stability and processing, storage and transportation stability, has good dispersibility in water, and has good processing and application performance; and in the preparation process, an alcohol solvent and a surfactant are not used, so that the problem of residues caused by the alcohol solvent and the surfactant is avoided, and the safety is improved.

Owner:RIZHAO POLYTECHNIC

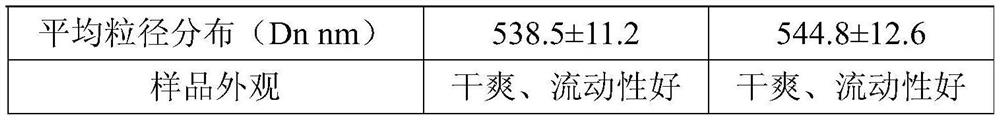

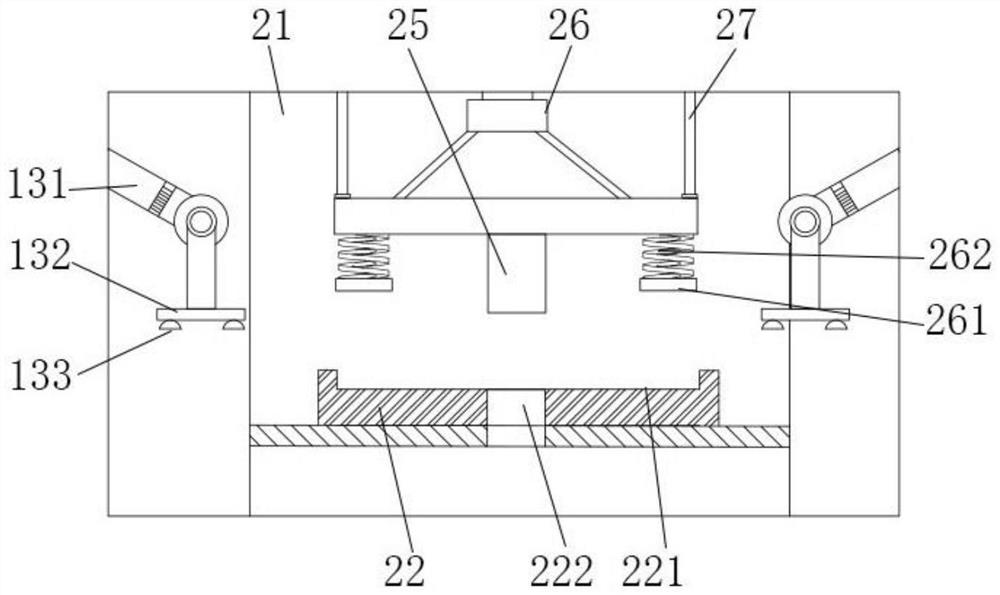

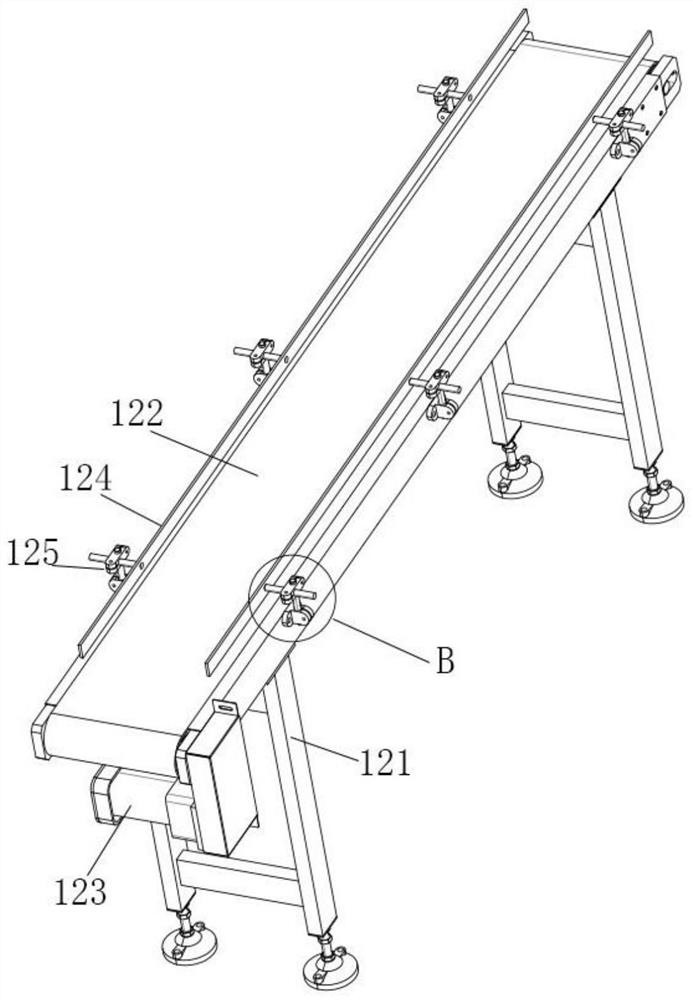

Automobile part punching automatic production line and working method thereof

PendingCN113953375AImprove punching efficiencySimple working methodPerforating toolsMetal-working feeding devicesProduction lineMotor vehicle part

The invention provides an automobile part punching automatic production line and a working method thereof, and belongs to the technical field of machining equipment. The automobile part punching automatic production line comprises a feeding part, a punching part and a discharging part, the punching part is arranged between the feeding part and the discharging part, and the feeding part sequentially comprises a vibration disc, a feeding conveying part and a feeding taking part; the punching part comprises a rack, an air cylinder and a punch, a workbench is arranged on the rack, a top plate is arranged at the top of the rack, the air cylinder is arranged on the top plate, the punch is arranged above the workbench and is in driving connection with the air cylinder through a piston rod, and a blanking hole opposite to the position of a punching portion of the punch is formed in the workbench; and the discharging part sequentially comprises a discharging and taking part, a discharging and conveying part and a collecting box. According to the automobile part punching automatic production line, automobile parts are automatically punched in the whole process; and the automobile part punching automatic production line is simple in working method, high in automobile part punching efficiency and suitable for industrial large-scale popularization.

Owner:江苏华兑金属科技有限公司

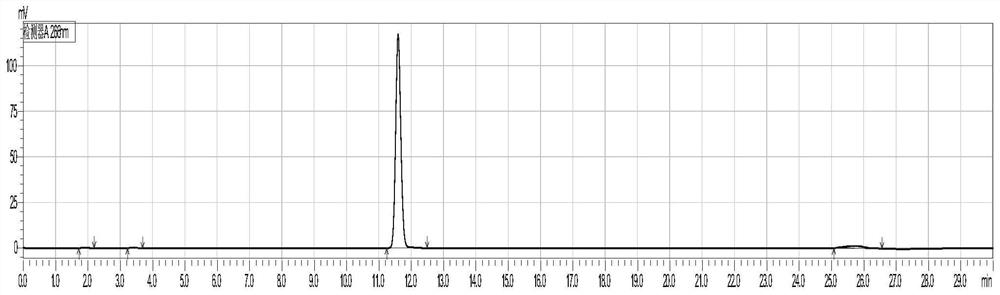

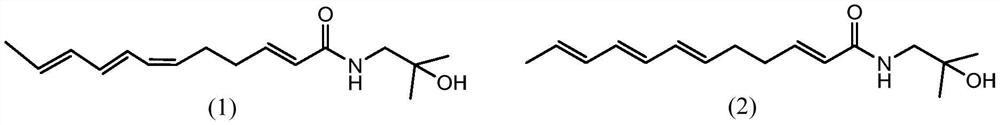

Preparation method of hydroxyl-alpha-sanshool single substance

ActiveCN112321450AGuaranteed stabilityLow technical requirementsCarboxylic acid amide separation/purificationAlcoholPharmaceutical drug

The invention provides a preparation method of a hydroxyl-alpha-sanshool single substance, and belongs to the technical field of natural medicine extraction and separation. The preparation method comprises the following steps: (1) conducting leaching with low alcohol to obtain a pepper extract total extract; (2) conducting extracting by adopting ethyl acetate, and enriching a hydroxysanshool mixture by column chromatography; (3) removing impurities by adopting a freezing crystallization method, and enriching hydroxyl-alpha-sanshool; and (4) separating and purifying the hydroxyl-alpha-sanshool.The preparation method of the hydroxyl-alpha-sanshool single substance is simple and convenient to operate and has low technical requirements on operators; the conditions in the preparation process are mild, so that the stability of the hydroxyl-alpha-sanshool is guaranteed, and the hydroxyl-alpha-sanshool is very safe; and meanwhile, the hydroxyl-alpha-sanshool single substance prepared by the preparation method is high in purity, the purity of the prepared hydroxyl-alpha-sanshool single substance can reach 99% or above, and the hydroxyl alpha-sanshool single substance can be used as a standard substance of the hydroxyl alpha-sanshool single substance. The preparation method is low in cost, suitable for large-scale industrial popularization and good in application prospect.

Owner:SOUTHWEST JIAOTONG UNIV

Hydrated calcium borate microsphere and anhydrous calcium borate microsphere, and preparation methods thereof

The invention provides a hydrated calcium borate microsphere and an anhydrous calcium borate microsphere, and preparation methods thereof. The preparation method of the hydrated calcium borate microsphere is characterized in that a hydrothermal-thermal conversion technology is adopted, a calcium salt, a boron source and an alkali source are adopted as raw materials, a surfactant is added to an aqueous solution in order to effectively regulate the composition and the morphology of products, and a hydrothermal reaction is carried out to obtain the hydrated calcium borate microsphere with uniform dimension. The preparation method of the anhydrous calcium borate microsphere is characterized in that the hydrated calcium borate microsphere is roasted to improve the crystallization degree in order to obtain the anhydrous calcium borate microsphere with uniform dimension. The hydrated calcium borate microsphere and the anhydrous calcium borate microsphere are hopeful to be widely applied to the fields of treatment of wastewater containing heavy metal ions or dyes, supported catalysis and flame retardation. The preparation methods have the advantages of simplicity in operation, mild conditions, low energy consumption, low cost, easy control of the process, and suitableness for large-scale industrial production.

Owner:QUFU NORMAL UNIV

Pharmaceutical preparation for treating pharyngitis and use thereof

InactiveCN105748899AGood treatment effectBalance of yin and yangCapsule deliveryRespiratory disorderSmoked PlumSide effect

The invention relates to a pharmaceutical preparation for treating pharyngitis and use thereof. The pharmaceutical preparation is prepared from the following components: folium isatidis, burdocks, poria cocos, boat-fruited scaphium seeds, chrysanthemum indicum, smoked plums, radix ophiopogonis, root barks of the peony trees, herba menthae, radix paeoniae alba, radix scrophulariae, platycodon grandiflorum, honeysuckle flower, fructus forsythia, liquorice root and Chinese date. According to the invention, based on the theory of traditional Chinese medicine, the components are scientifically processed to prepare the pharmaceutical preparation which is reasonable in compatibility of medicines, and is balanced in yin and yang; the medicines are matched with one another to achieve the effects of diminishing inflammation, eliminating phlegm and relieving a cough, treatment effect for a patient suffering from pharyngitis is remarkable, and pharyngitis is not liable to relapse. Moreover, the pharmaceutical preparation is various in dosage form, is easy to take and is low in toxic and side effect on a human body; and the preparation method is simple, is easy to operate, and is suitable for large-scale popularization.

Owner:段希福

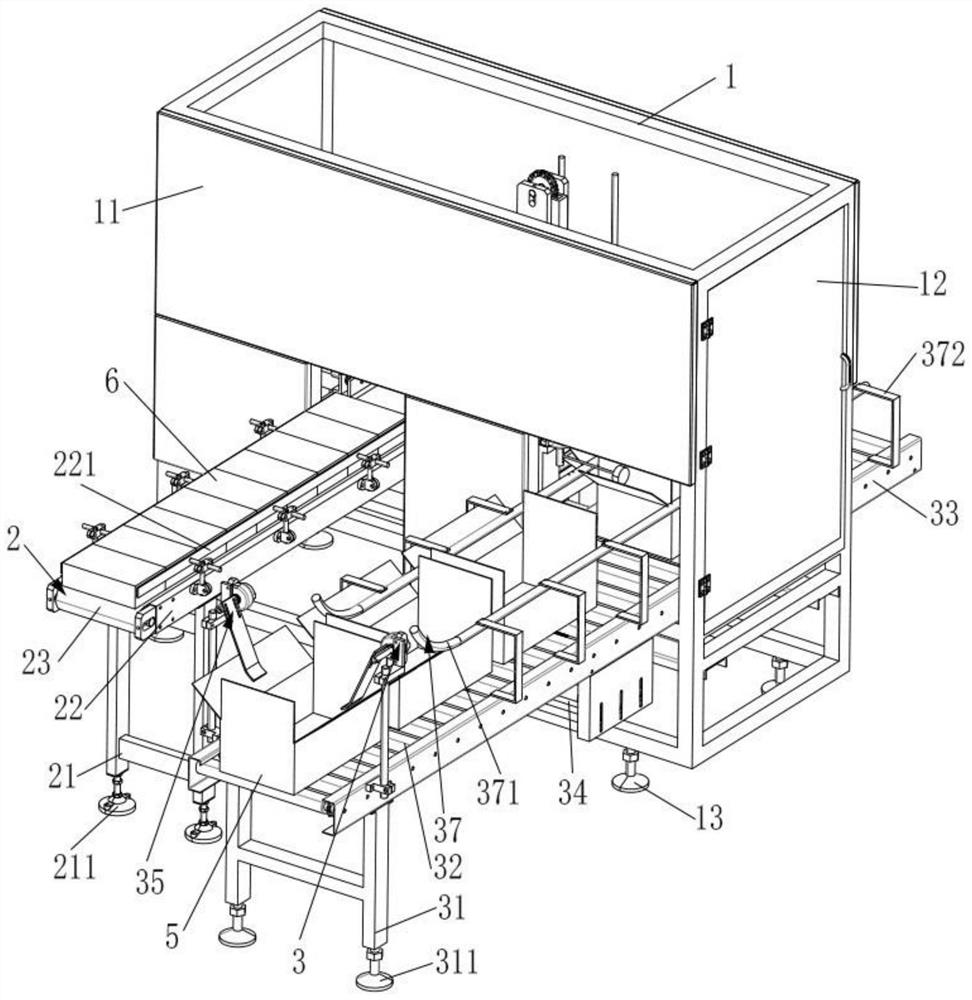

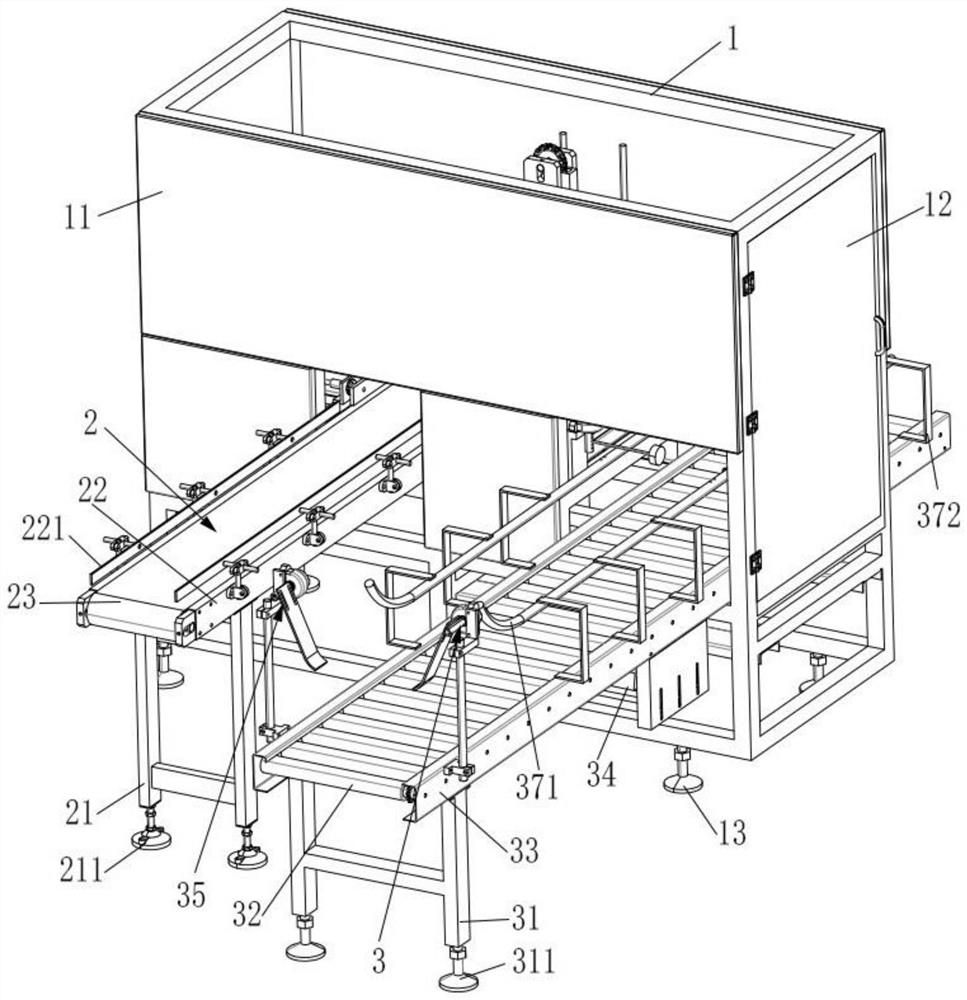

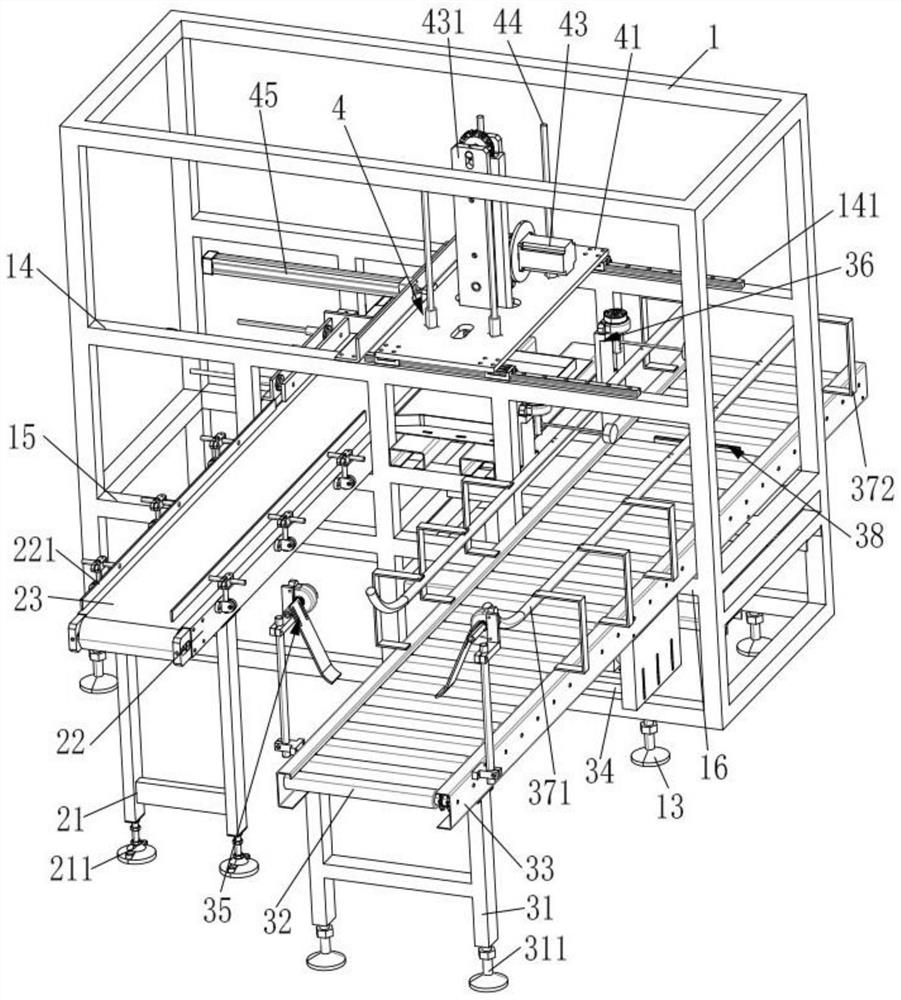

Box opening and boxing integrated automatic production line and working method thereof

PendingCN113232934ASimple working methodSimple structurePackagingManufacturing lineIndustrial engineering

The invention provides a box opening and boxing integrated automatic production line and a working method thereof, and belongs to the technical field of packaging equipment. The integrated automatic production line comprises a rack, a feeding component for conveying products, a box opening component for opening a packaging box cover, and a material taking component, and the feeding component is partially arranged in the rack through a second fixing beam; the box opening component is partially arranged in the rack through a third fixing beam, and the material taking component is arranged in the rack through a first fixing beam; a guide rail is arranged on the first fixing beam, and the material taking component is connected with the guide rail slidably; and the feeding component and the box opening component are arranged in parallel, and the material taking component is arranged above the feeding component and the box opening component. According to the box opening and boxing integrated automatic production line, automatic equipment is adopted, and packaging boxes can be automatically opened; the products can be automatically boxed, and the labor cost can be effectively saved; and the packaging efficiency of the products is improved.

Owner:江苏群昌智能科技有限公司

Composite glass fiber reinforced plastic waste lightweight high-strength ceramsite and preparation method thereof

ActiveCN108440015AEasy to operateCalcination temperature is lowCeramic materials productionCeramicwareGlass fiberPlastic waste

The invention provides a composite glass fiber reinforced plastic waste lightweight high-strength ceramsite and a preparation method thereof. The composite glass fiber reinforced plastic waste lightweight high-strength ceramsite is mainly prepared from the following raw materials in percentages by mass: 36-42% of glass fiber reinforced plastic wastes, 32-40% of flyash, 0-8% of alkali residues and18-24% of sandy soil, wherein water is added according to the water-solid ratio (taking the masses of all solids as a reference) being 0.2-0.3. The preparation method comprises the following steps: accurately weighing the glass fiber reinforced plastic wastes, the flyash, the alkali residues, the sandy soil and the water according to the proportion of the raw materials and uniformly mixing the rawmaterials to form a uniform basic admixture; and carrying out pelleting and forming by an artificial method to obtain ceramsite raw meal nodules, and firing the ceramisite raw meal nodules to obtainthe composite glass fiber reinforced plastic waste lightweight high-strength ceramsite. The lightweight high-strength ceramsite is prepared by taking the glass fiber reinforced plastic wastes as a main gas forming agent, and is applied to the fields of lightweight concrete wall materials, lightweight concrete tube materials and the like, glass fiber reinforced plastic waste resources can be reutilized, furthermore, environmental pollution can be relieved, and the economic benefit and the environment benefit are remarkable.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com