Modified fly ash ceramsite and preparation method and application thereof

A technology of fly ash ceramsite and fly ash, which is applied in the field of modified fly ash ceramsite and its preparation, can solve the problems of poor pollutant removal effect and poor selectivity, and achieve suitable conditions for large-scale industrial promotion. Gentle, process-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of modified fly ash ceramsite, comprises the following steps:

[0028] (1) Fly ash, pore forming agent and water are mixed, and granulated into balls to obtain mixed pellets;

[0029] (2) sintering the mixed pellets obtained in the step (1) to obtain fly ash ceramsite;

[0030] (3) Soak the fly ash ceramsite obtained in the step (2) with an inorganic acid solution to obtain a modified fly ash ceramsite precursor;

[0031] (4) Roasting the modified fly ash ceramsite precursor obtained in the step (3) to obtain the modified fly ash ceramsite.

[0032] The invention mixes the fly ash, the pore-forming agent and water, forms balls and granulates to obtain the mixed pellets. In the present invention, the mass ratio of the fly ash, pore forming agent and water is preferably 0.6-0.9:0.05-0.3:1, more preferably 0.7-0.8:0.1-0.2:1. In the present invention, the particle size of the fly ash is preferably above 100 mesh, more p...

Embodiment 1

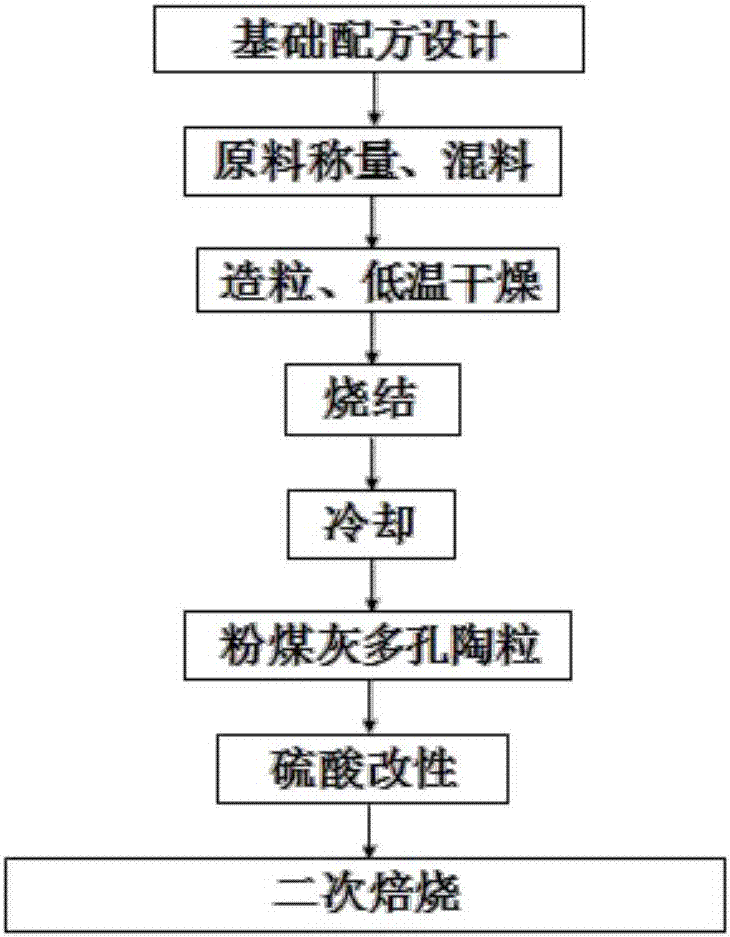

[0046] figure 1 It is a flow chart for the preparation of modified fly ash ceramsite in this embodiment. As can be seen from the figure, the preparation steps of modified fly ash ceramsite in this embodiment include: basic formula design, raw material weighing, mixing Material, granulation, low-temperature drying, sintering, cooling, sulfuric acid modification and secondary roasting, the specific preparation method is as follows:

[0047] 100 mesh fly ash, pore forming agent and water are mixed according to the mass ratio of 6:3:10, and pelletized to obtain a mixed ball material with a particle size of 5mm;

[0048] Dry the mixed pellets in a drying oven at 40°C for 48 hours, and sinter at 960°C for 60 minutes to obtain fly ash ceramsite;

[0049] The fly ash ceramsite is soaked with 2mol / L sulfuric acid solution for 24h to obtain the modified fly ash ceramsite precursor;

[0050] The modified fly ash ceramsite precursor was calcined at 500° C. for 3 hours to obtain the modi...

Embodiment 2

[0053] 200 mesh fly ash, pore forming agent and water are mixed according to the mass ratio of 20:3:10, and pelletized to obtain a mixed ball material with a particle size of 5mm;

[0054] Dry the mixed pellets in a drying oven at 50°C for 24 hours, and sinter at 1140°C for 10 minutes to obtain fly ash ceramsite;

[0055] The fly ash ceramsite is soaked with 3mol / L sulfuric acid solution for 20h to obtain the modified fly ash ceramsite precursor;

[0056] The modified fly ash ceramsite precursor was calcined at 600° C. for 2 hours to obtain the modified fly ash ceramsite.

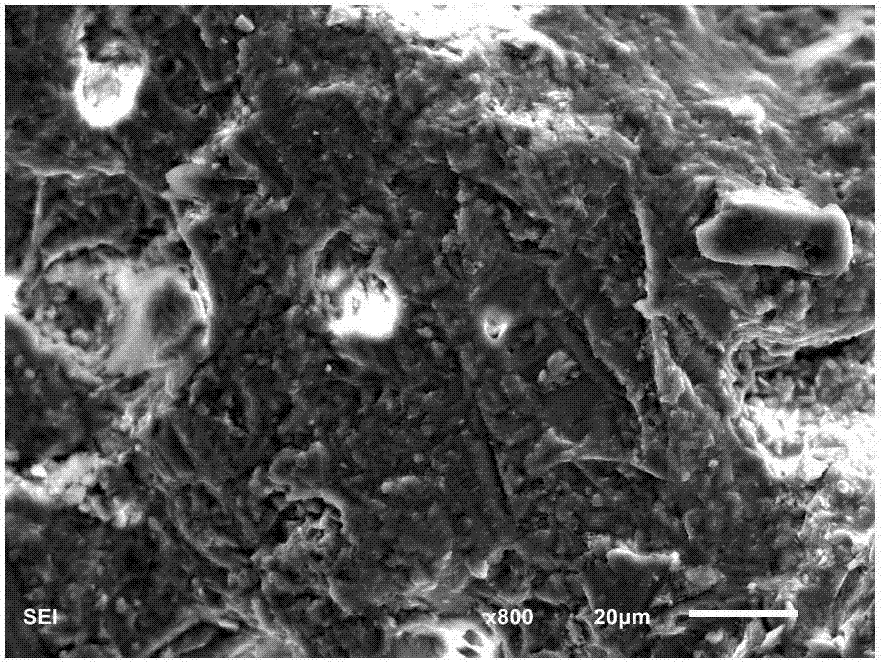

[0057] The volume of pores in the modified fly ash prepared in this example is 43.49% of the volume of the modified fly ash ceramsite. The SEM photo of the modified fly ash ceramsite prepared in the present embodiment is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com