Automobile part punching automatic production line and working method thereof

An automated production line and auto parts technology, applied in the direction of perforating tools, vehicle parts, manufacturing tools, etc., can solve the problems of manual placement, difficulty in improving processing efficiency, and processing methods that cannot meet production needs, etc., to achieve simple working methods, punching The effect of high hole efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

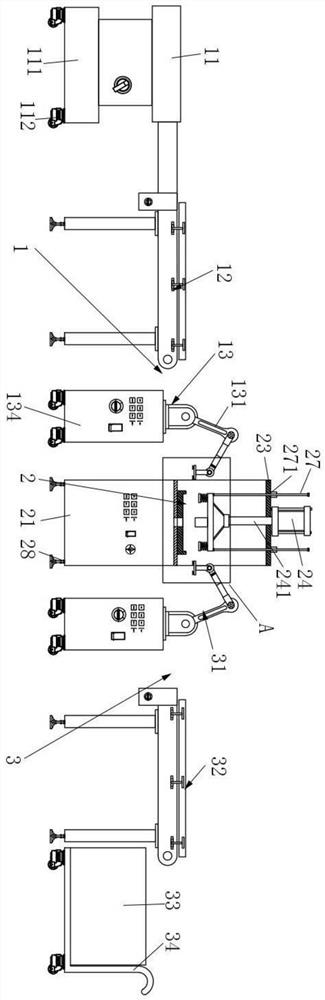

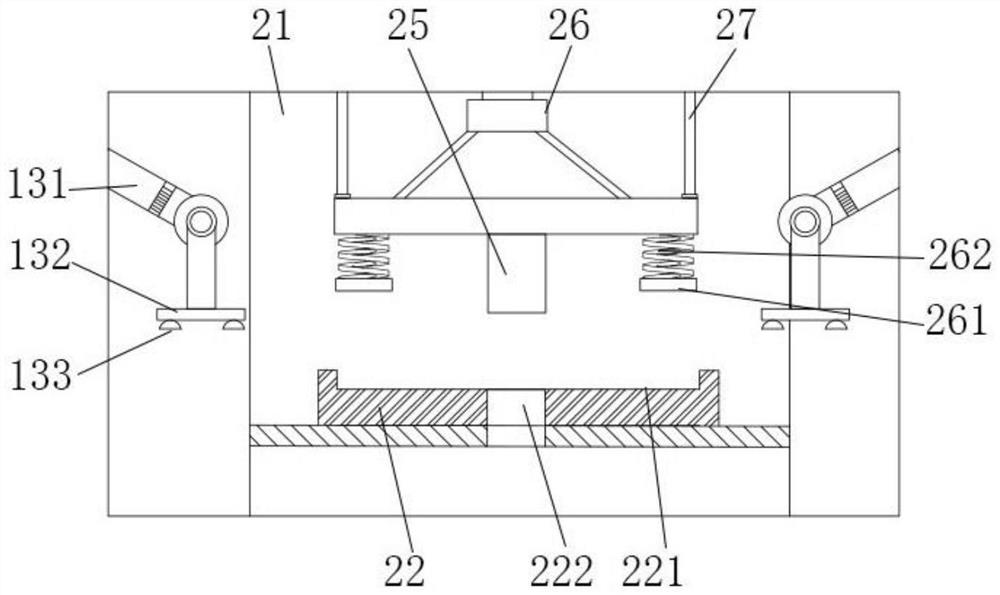

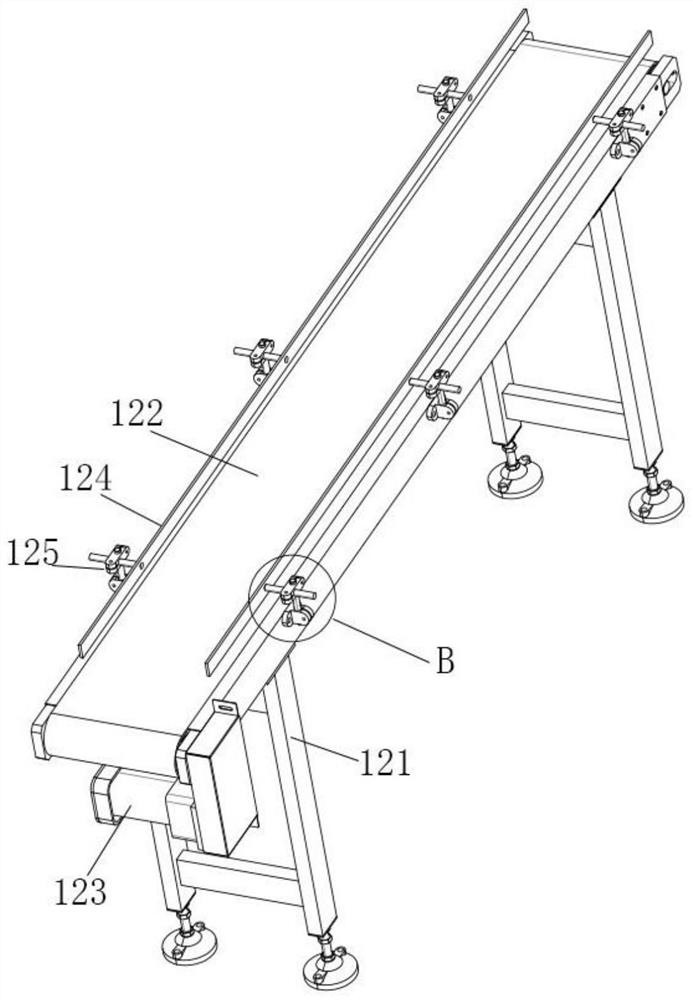

[0030] An automatic punching production line for auto parts, comprising a loading part 1, a stamping part 2 and a blanking part 3, the stamping part 2 is arranged between the loading part 1 and the blanking part 3, and the loading part 1 is sequentially It includes a vibrating plate 11, a feeding conveying part 12 and a feeding and retrieving part 13. The vibrating plate 11 is set on a support base 111, and the bottom of the support base 111 is provided with a universal wheel 112. The stamping part 2 includes a machine Frame 21, cylinder 24 and punch 25, described frame 21 is provided with workbench 22, and described workbench 22 is provided with storage slot 221, and described frame 21 bottom is provided with a group of evenly distributed supporting feet 28, The top of the frame 21 is provided with a top plate 23, the cylinder 24 is arranged on the top plate 23, the punch 25 is arranged on the top of the workbench 22 and is driven to be connected with the cylinder 24 by the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com