Ternary random copolymer containing beta-myrcene, preparation method and applications thereof

A technology of random copolymer and myrcene, which is applied in the field of ternary random copolymer and its preparation, can solve the problems of rare types of polar monomers in anionic living polymerization, low functional group content, complicated process, etc., and achieve guaranteed Ideal cross-linked network, abundant sources, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

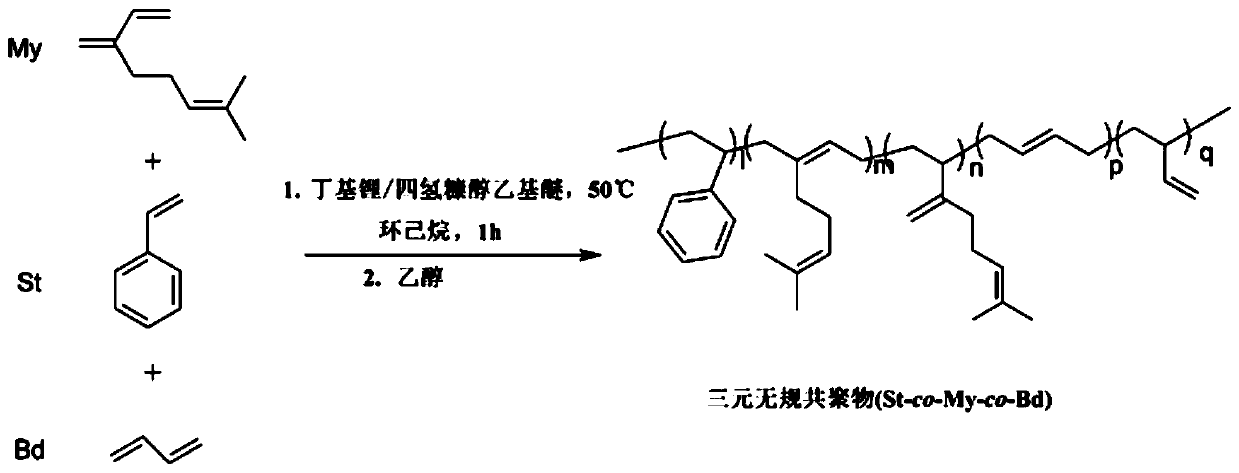

Method used

Image

Examples

Embodiment 1 3

[0065] The preparation of embodiment 1 ternary random copolymer

[0066] 1 # β-Myrcene-Styrene-Butadiene Terpolymer Random Copolymer

[0067] Add 1L of cyclohexane, 30g of styrene, 10g of β-myrcene, 60g of butadiene and 0.47mmol of tetrahydrofurfuryl alcohol ethyl ether solution into a reaction kettle filled with nitrogen, and add 0.58mmol of secondary For butyllithium, set the temperature at 50°C. After 1 hour of reaction, add the polymerization liquid in the reactor to absolute ethanol through a rubber tube to terminate, and stir to make it flocculate to form a precipitate. Leave it for 1 hour. After the precipitation is complete, Dry in a vacuum oven at 50°C to obtain β-myrcene-styrene-butadiene terpolymer random copolymer, denoted as 1 # sample.

[0068] 2 # β-Myrcene-Styrene-Butadiene Terpolymer Random Copolymer

[0069] Preparation process and 1 # The β-myrcene-styrene-butadiene terpolymer random copolymers are roughly the same, except that the mass of β-myrcen...

Embodiment 2

[0094] Embodiment 2 The preparation of rubber composition and vulcanized rubber thereof

[0095] With the 1 prepared in embodiment 1 # ~14 # The ternary random copolymer sample is a polymer component, and auxiliary components such as a reinforcing agent, a vulcanizing agent, a vulcanization activator, a vulcanization accelerator, and an anti-aging agent are added respectively to prepare a rubber composition. The rubber composition was mixed on an open mill and vulcanized on a flat vulcanizer to obtain a vulcanized rubber sample.

[0096] with 1 # ~5 # The ternary random copolymer sample is typical, and it is mixed and vulcanized. The process is as follows:

[0097] for 1 # ~3 # Ternary random copolymer sample, get 100g respectively and pass 10 times with small roller distance (0.5mm) on the two-roller open mill, then relax the roller distance (1mm) for mixing, first add 25g of carbon black and mix evenly, then Add 2g of stearic acid, 4g of zinc oxide, and then add the r...

experiment example 1

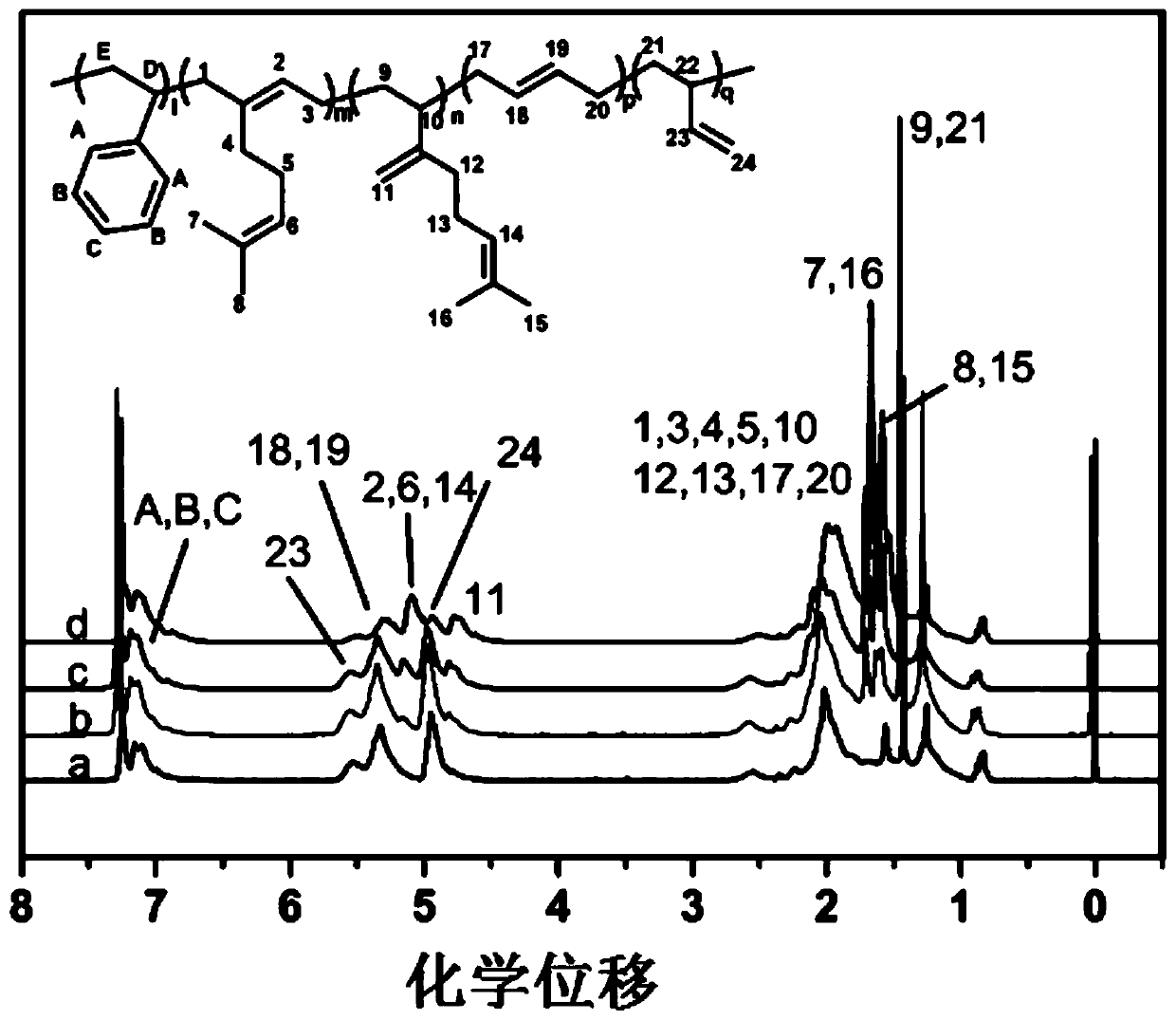

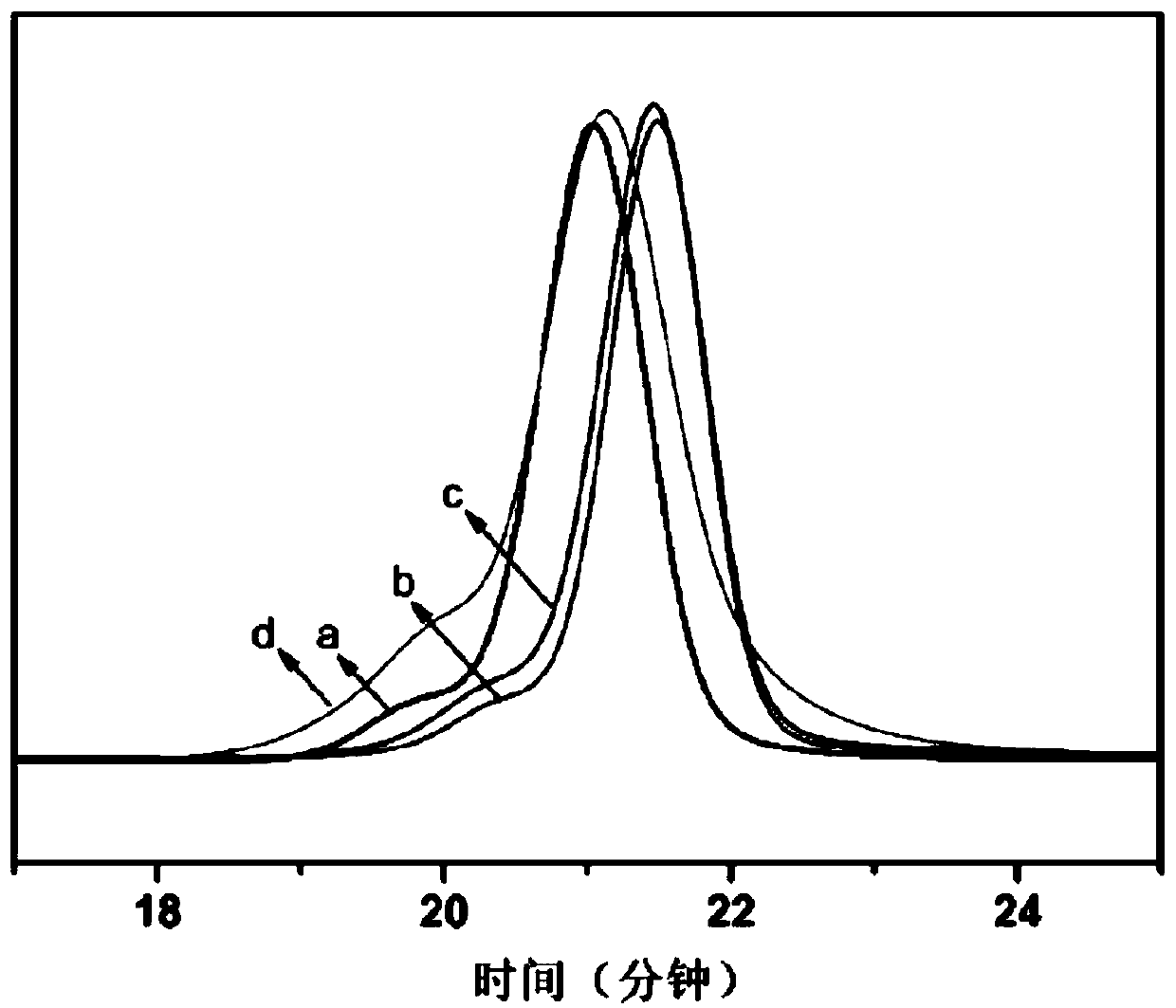

[0104] Structural characterization of experimental example 1 random copolymer

[0105] Adopt the AV-600 (BRUKER) type tester that Germany Bruker Company produces to test and obtain polymer 1 H NMR. With the 1 prepared in embodiment 1 # ~3 # Terpolymer samples are typical, figure 2 gives 1 in # ~3 # D1 in sample and comparative example 1 # The hydrogen-nuclear magnetic spectrum of the sample, and the copolymer structure composition is calculated according to the characteristic hydrogen area ratio. Depend on figure 2 The characterization results show that the comparative example D1 # In the sample, the styrene content is 30wt.%, butadiene content is 70wt.%, and there is no absorption peak at 6.2-6.8ppm simultaneously, indicating that the resulting product is a binary random copolymer; Example 1 # The styrene content in the medium is 30wt.%, the myrcene content is 10wt.%, and the butadiene content is 60wt.%; 2 # The styrene content in the medium is 30wt.%, the myrcene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com