Patents

Literature

30 results about "Tetrachloroaluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrachloroaluminate [AlCl₄]⁻ is an anion formed from aluminium and chlorine. The anion has a tetrahedral shape, similar to carbon tetrachloride where carbon is replaced with aluminium. Some tetrachloroaluminates are soluble in organic solvents, creating an ionic non-aqueous solution, making them suitable as component of electrolytes for batteries. E.g. lithium tetrachloroaluminate is used in some lithium batteries.

High voltage rechargeable magnesium batteries having a non-aqueous electrolyte

InactiveUS20130252112A1Improve conductivityImprove solubilityOrganic electrolyte cellsSecondary cellsGrignard reagentMetallic materials

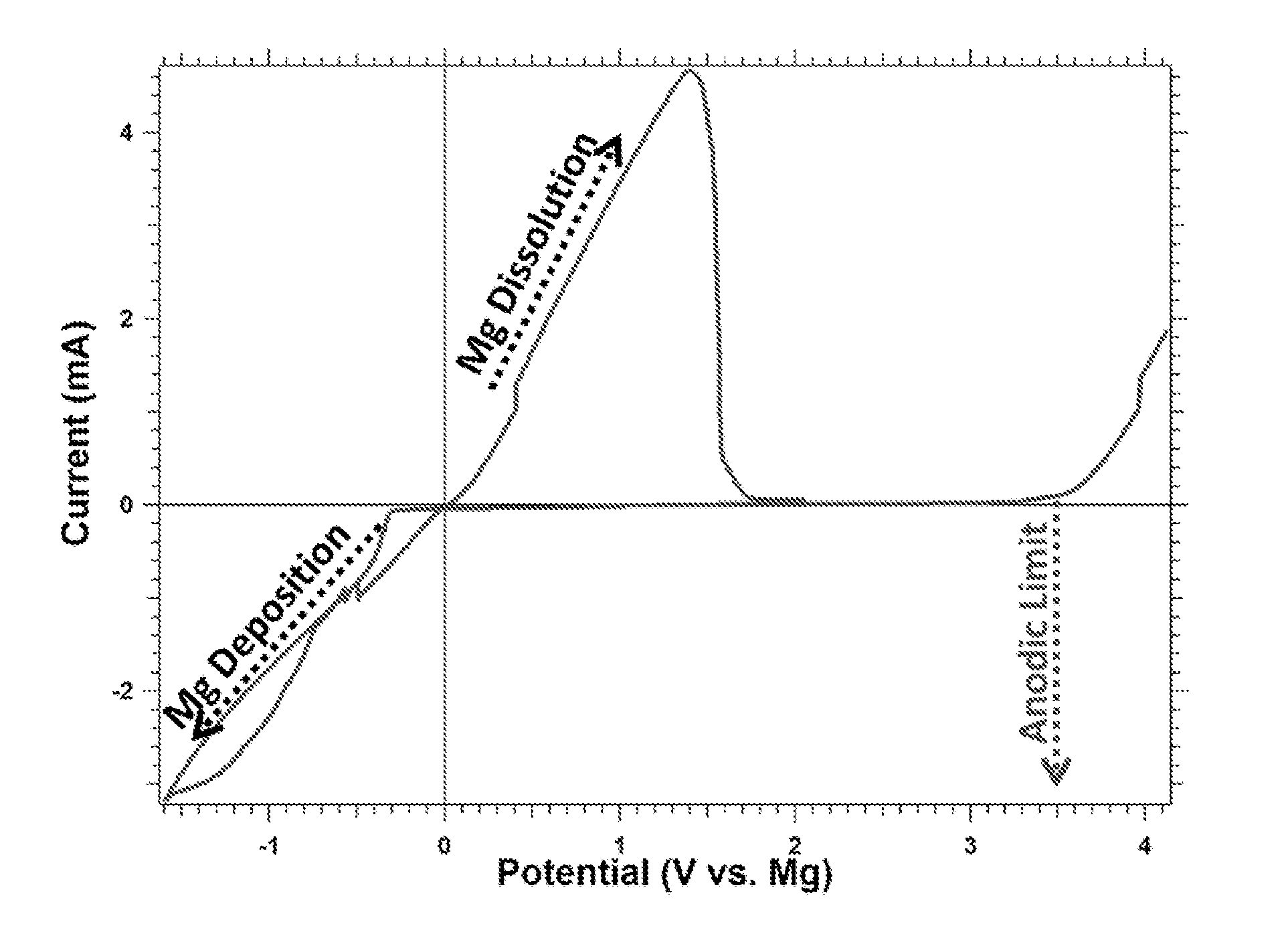

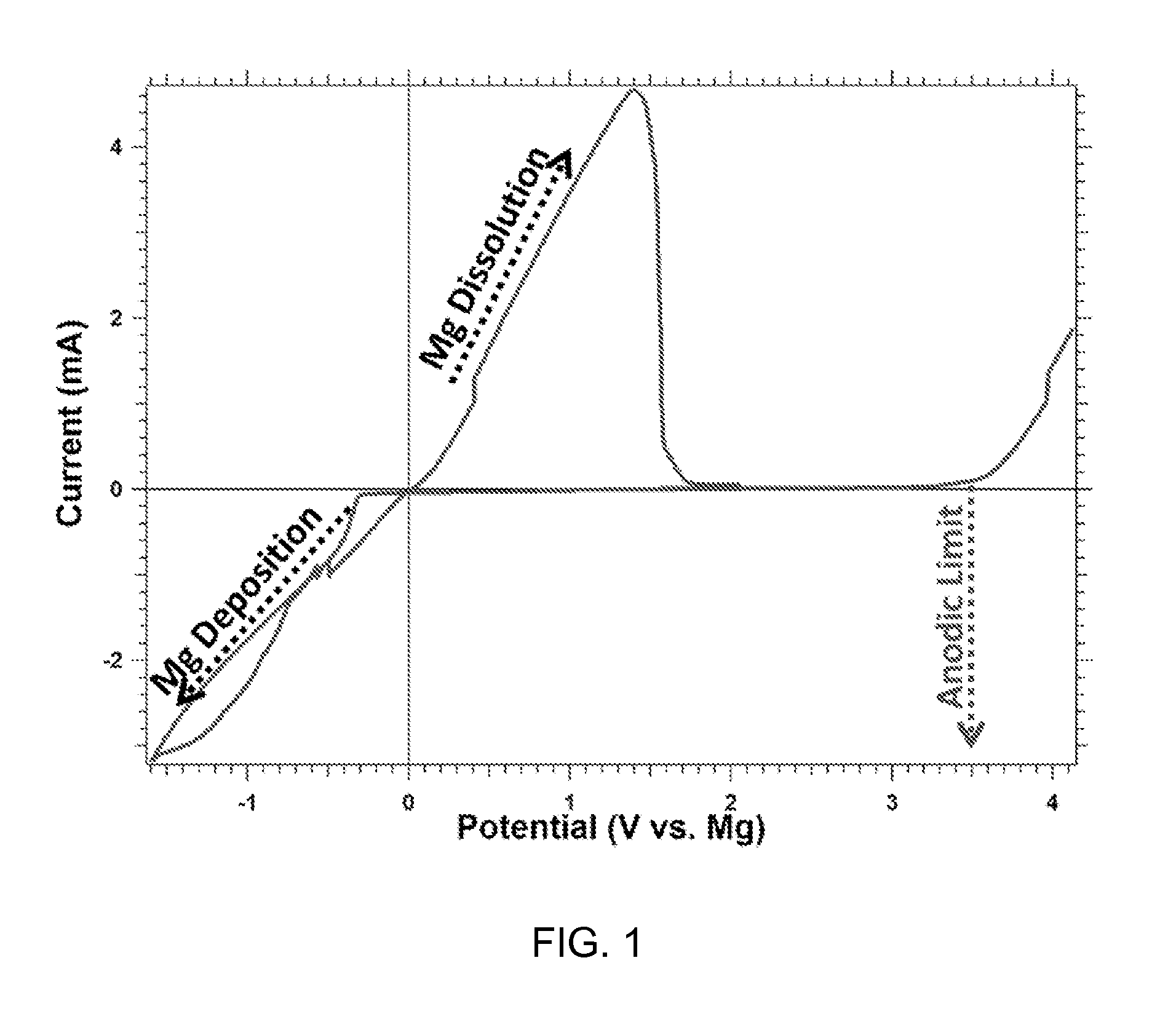

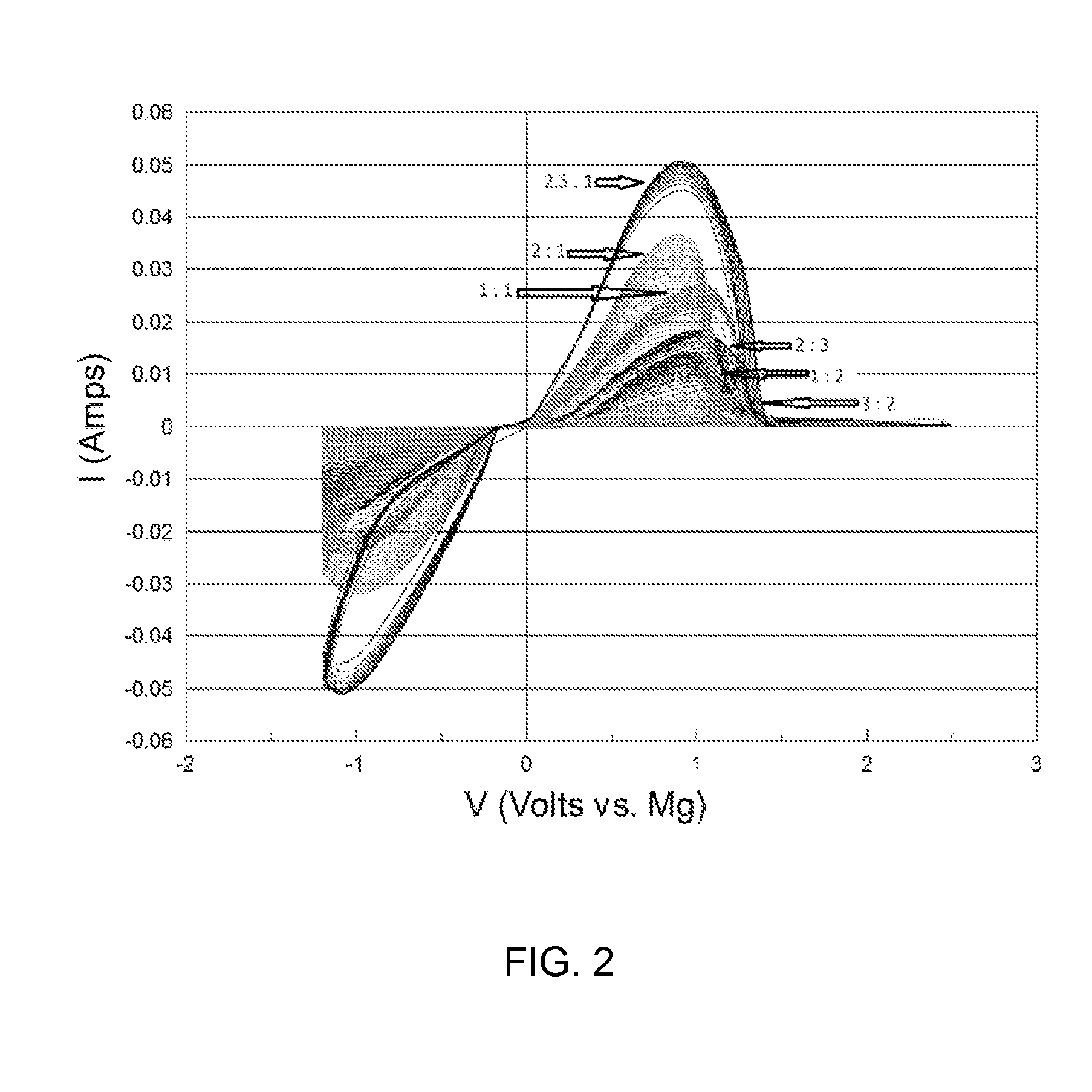

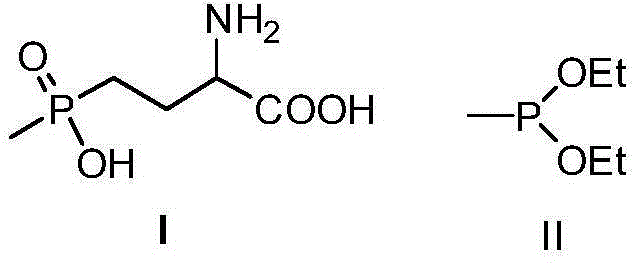

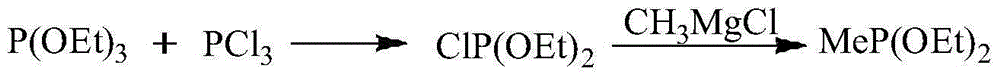

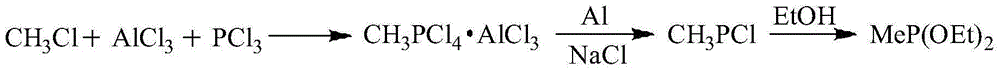

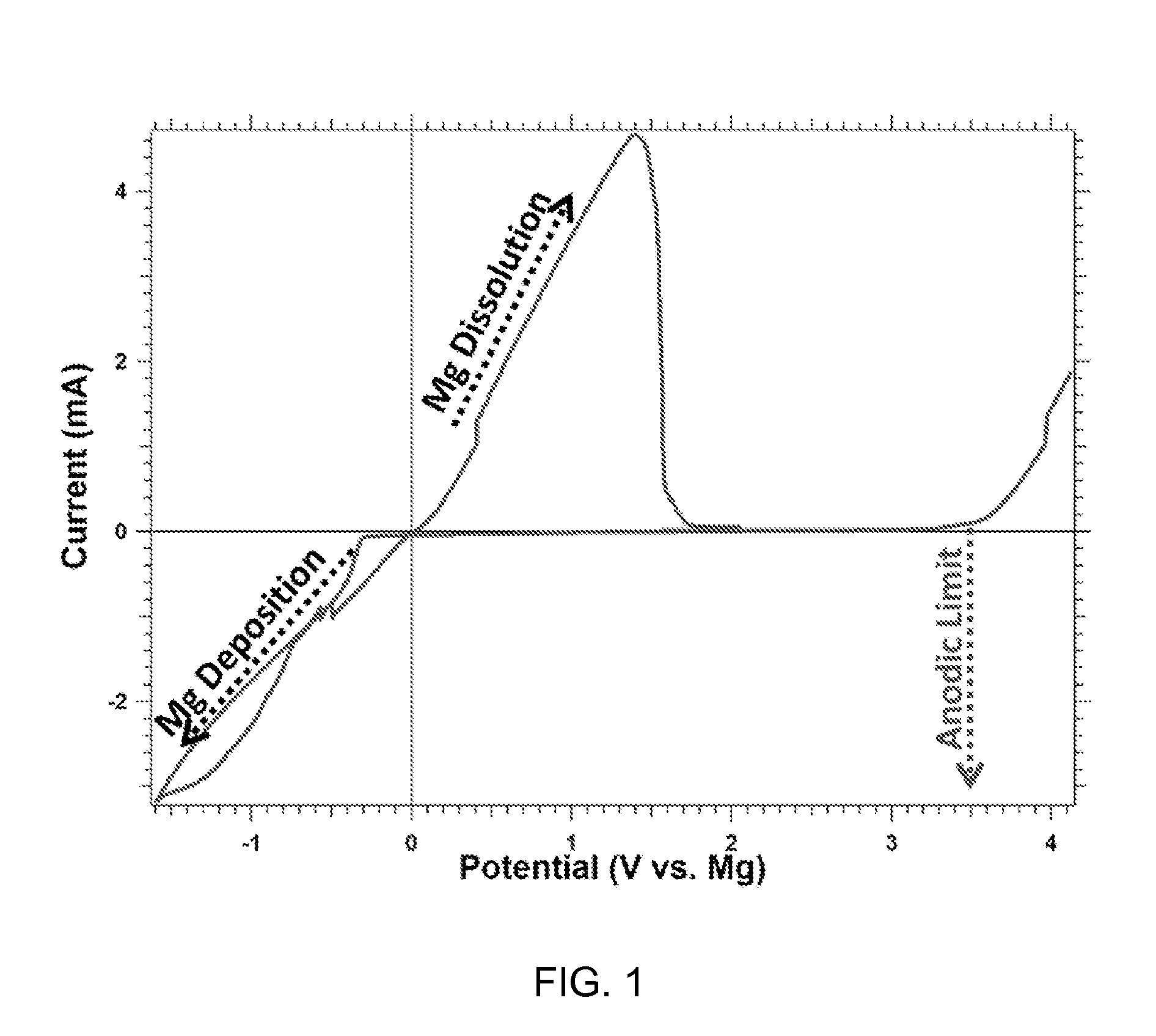

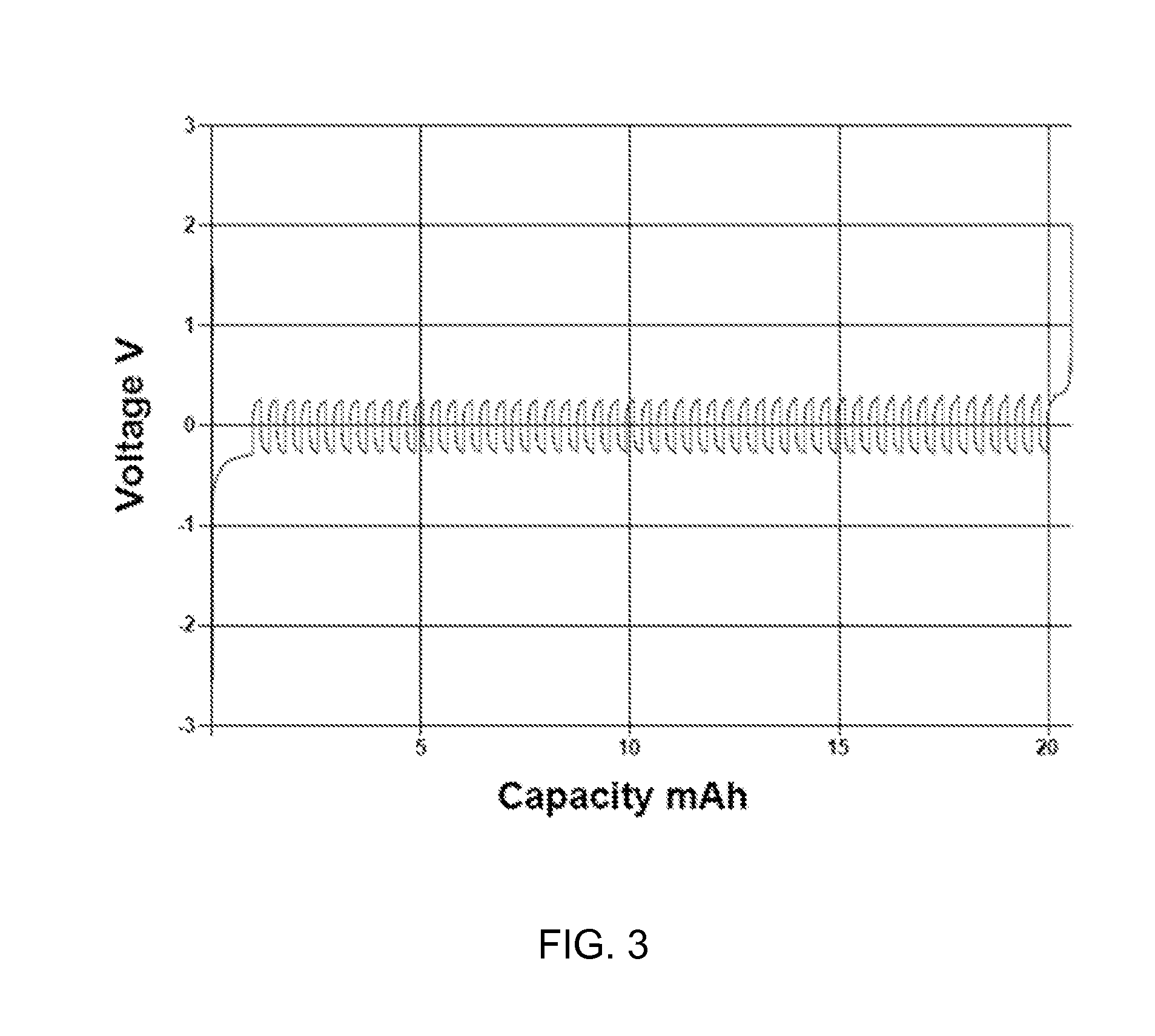

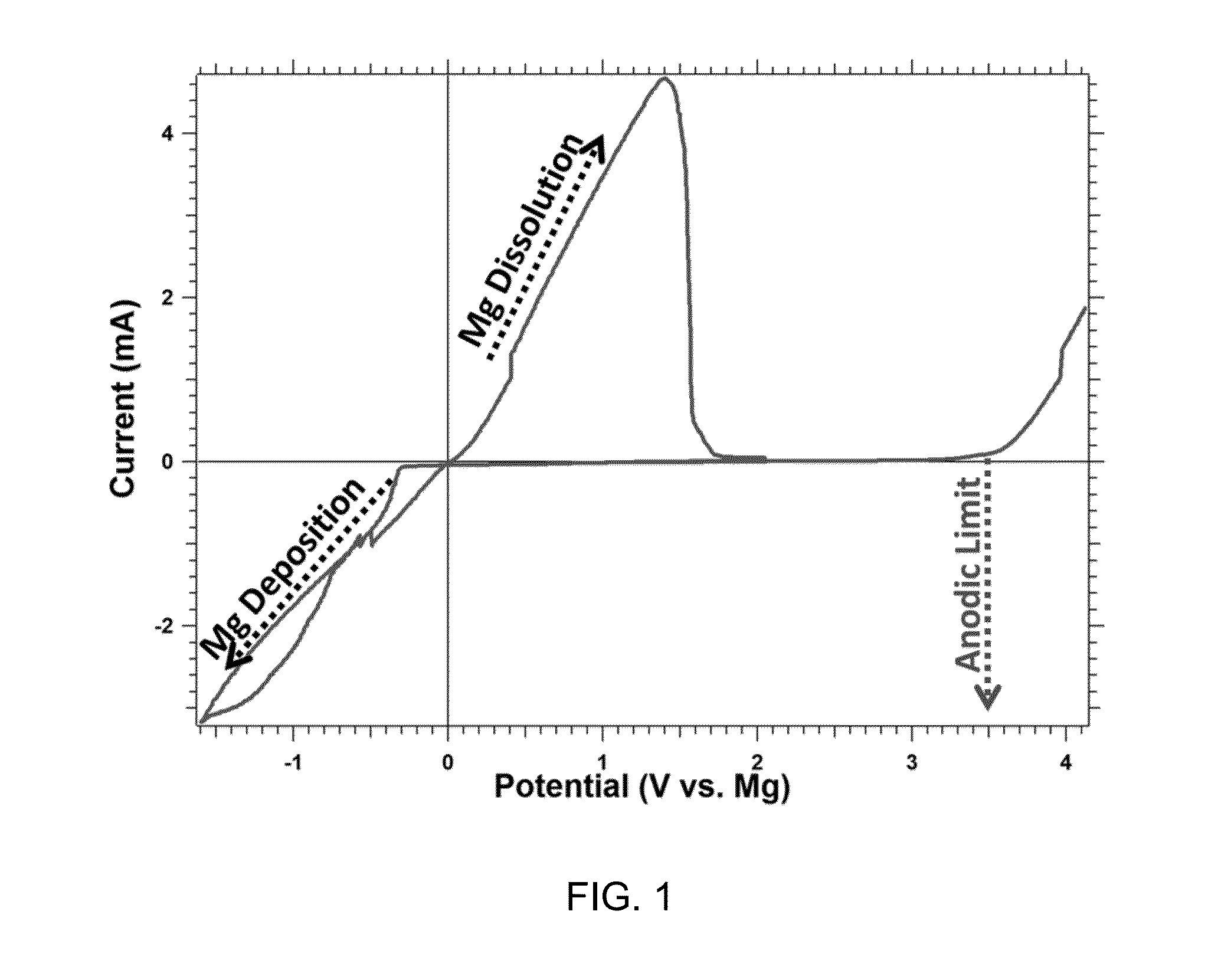

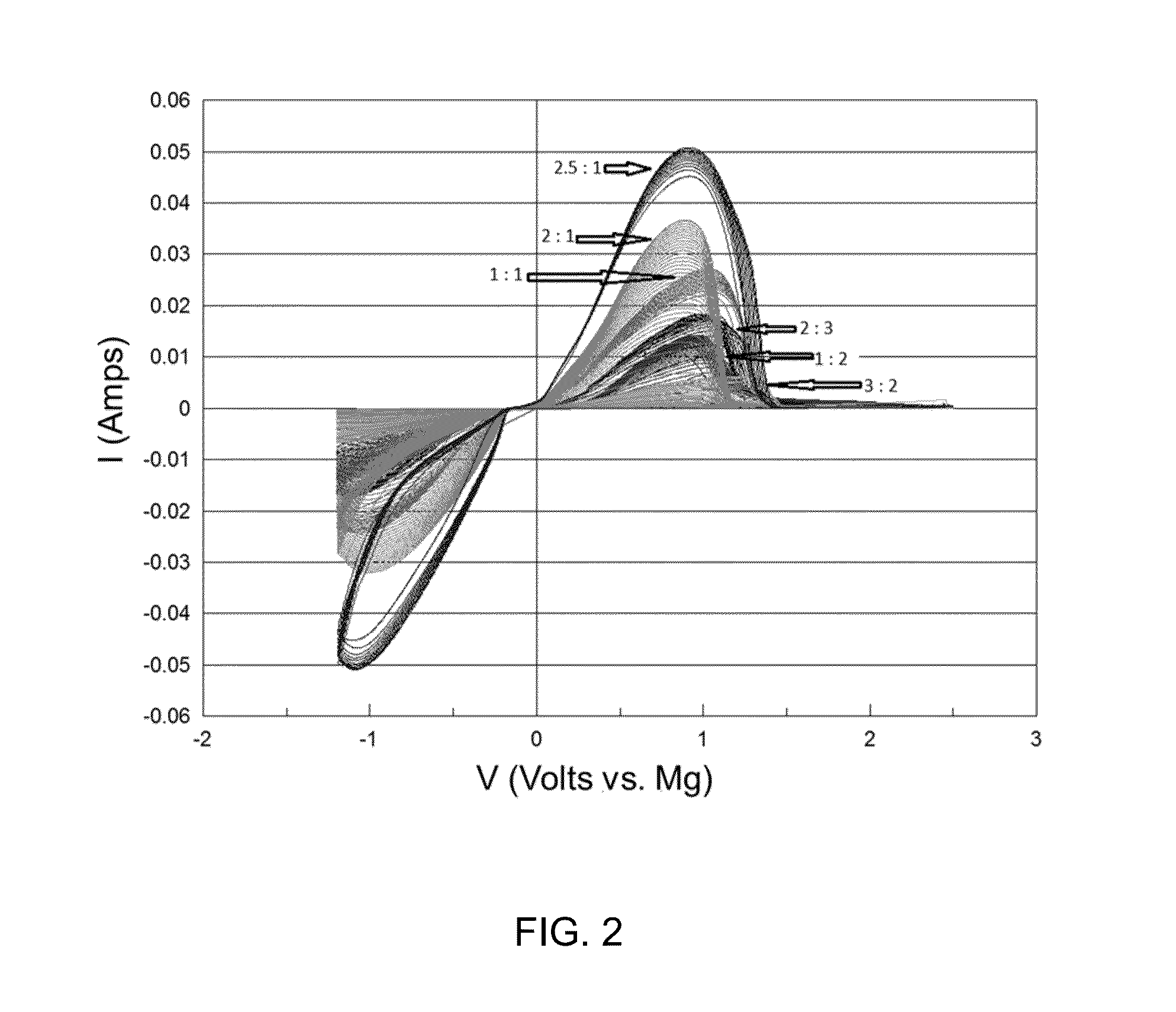

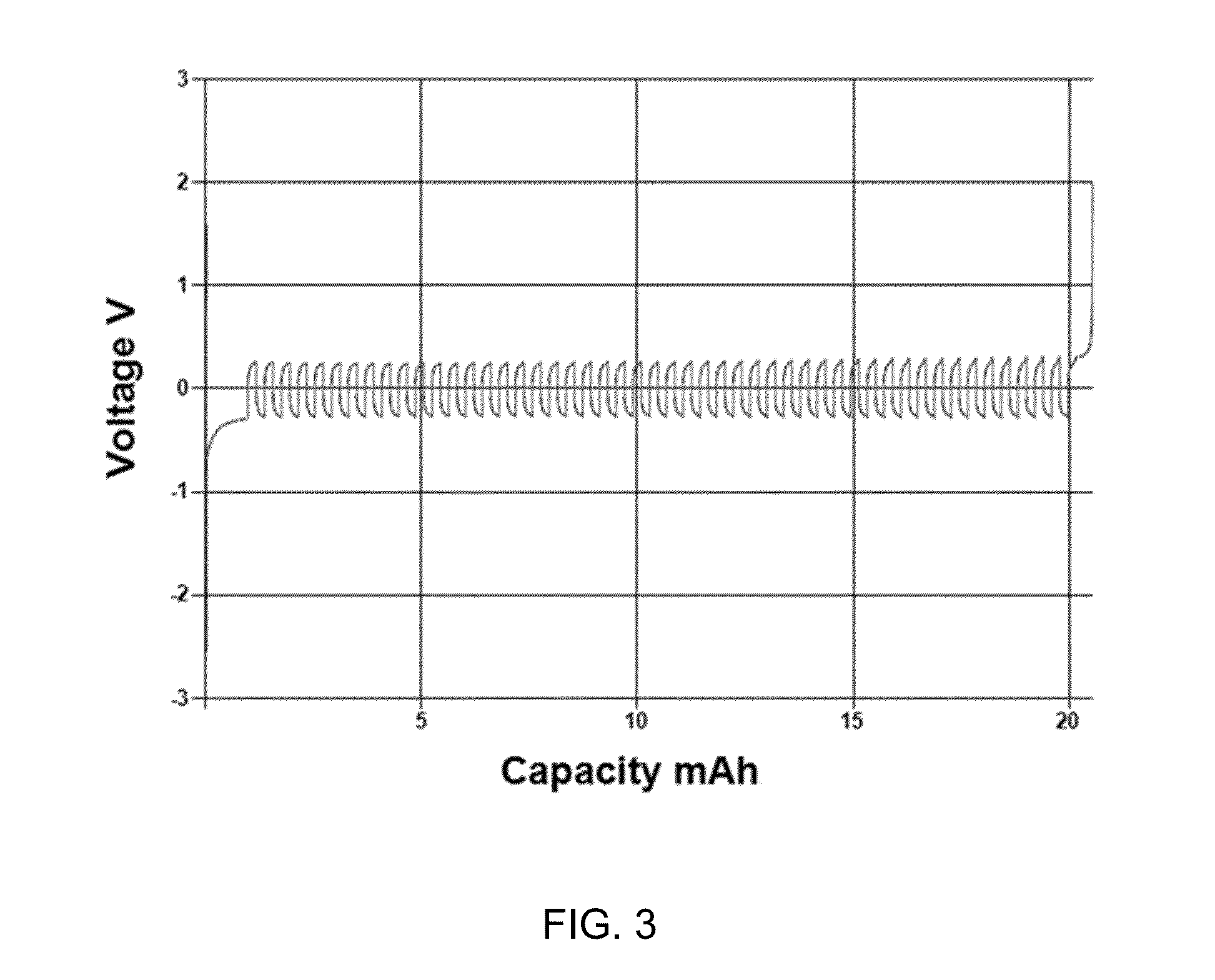

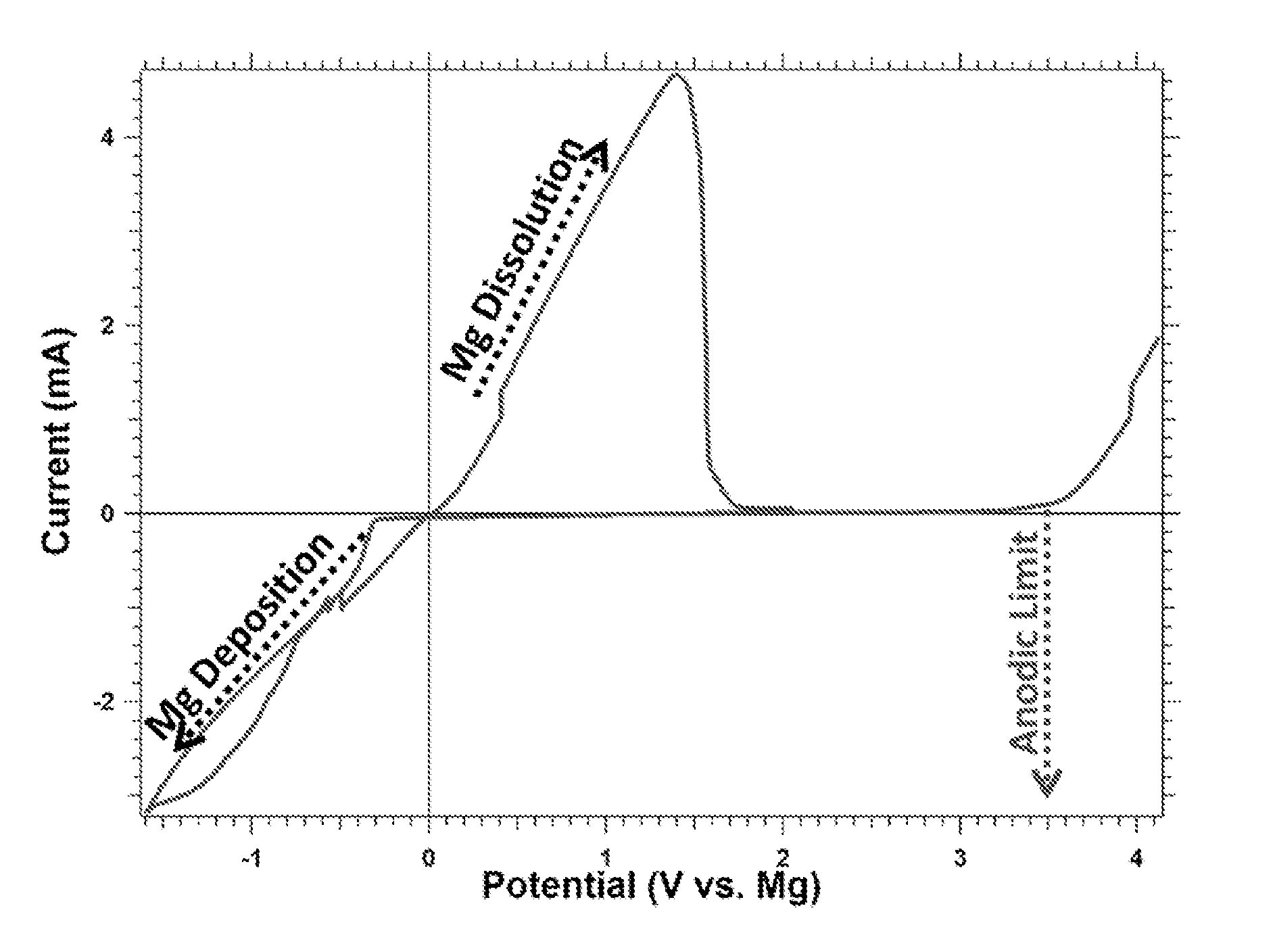

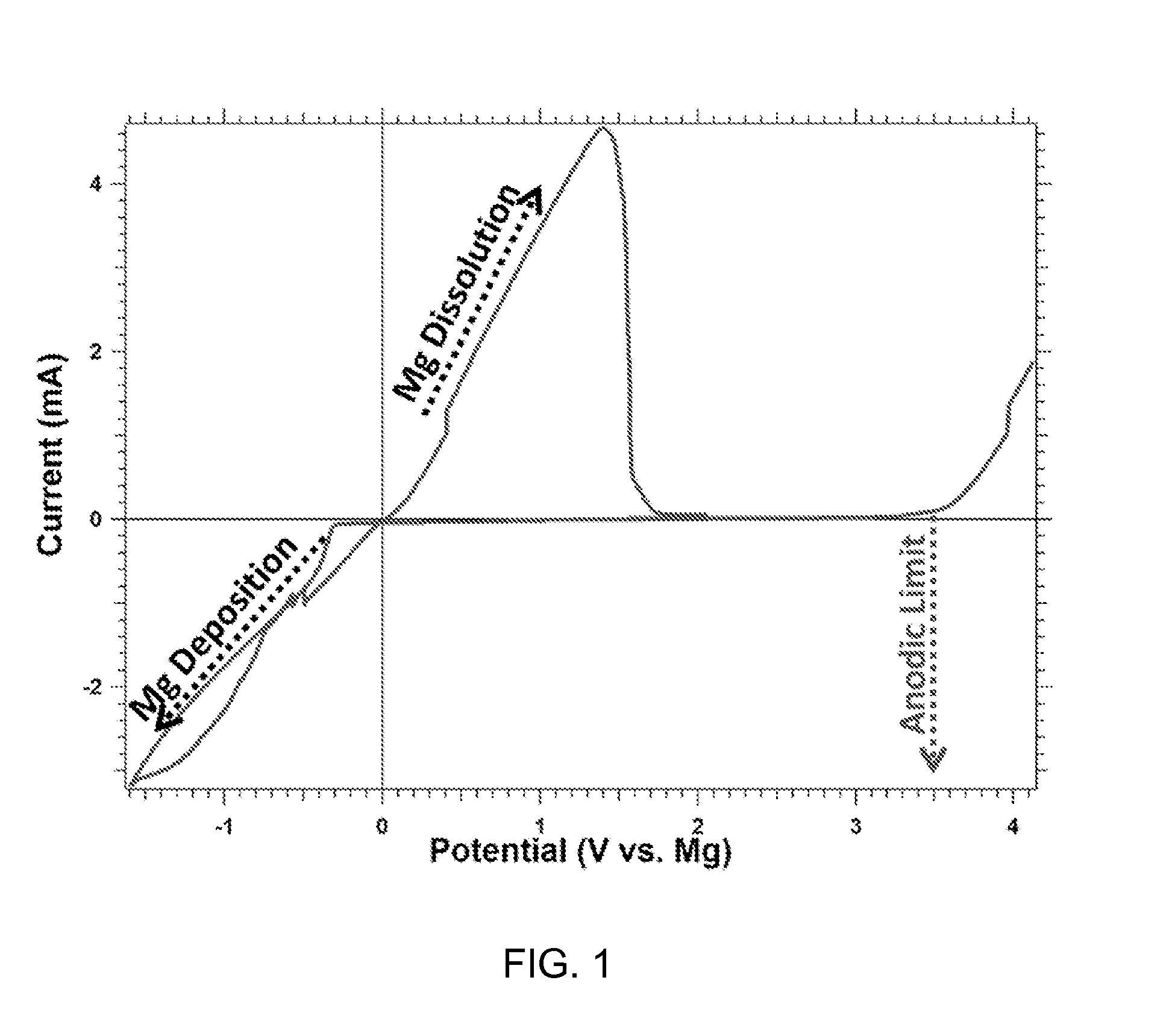

A rechargable magnesium battery having an non-aqueous electrolyte is provided. The properties of the electrolyte include high conductivity, high Coulombic efficiency, and an electrochemical window that can exceed 3.5 V vs. Mg / Mg+2. The use of the electrolyte promotes the electrochemical deposition and dissolution of Mg without the use of any Grignard reagents, other organometallic materials, tetraphenyl borate, or tetrachloroaluminate derived anions. Other Mg-containing electrolyte systems that are expected to be suitable for use in secondary batteries are also described.

Owner:PELLION TECH

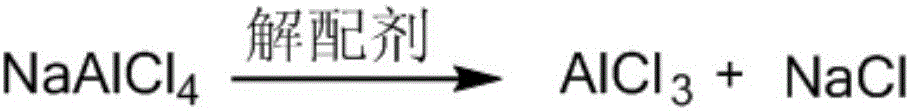

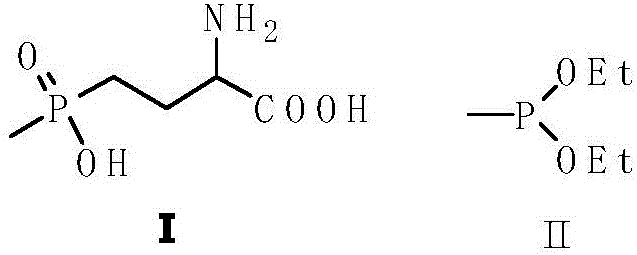

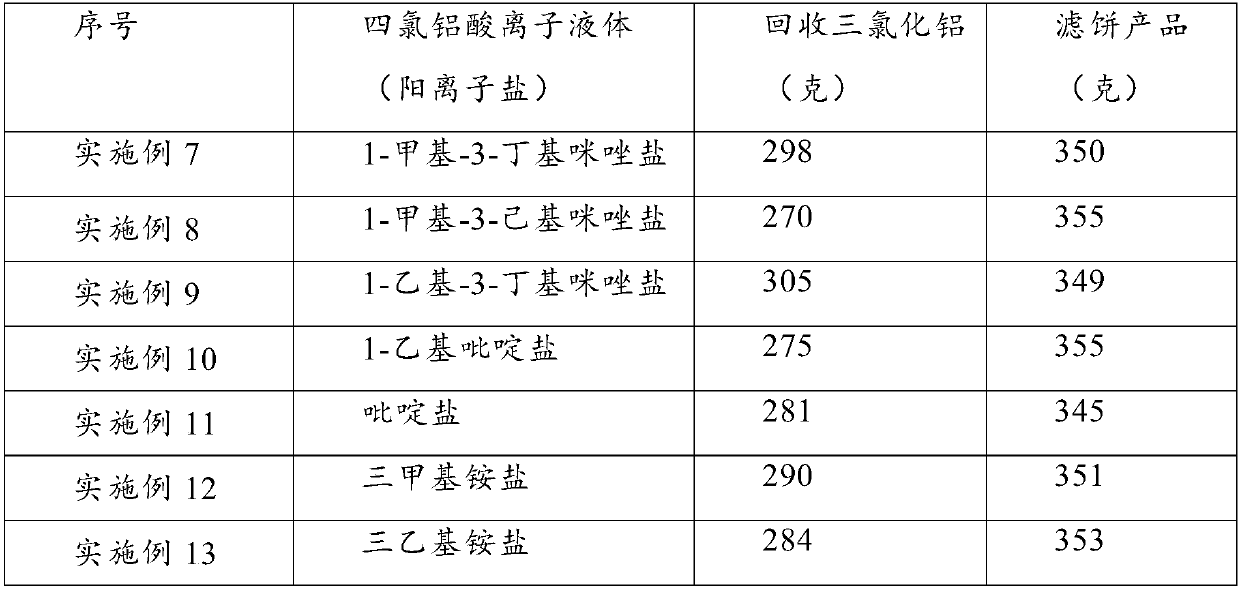

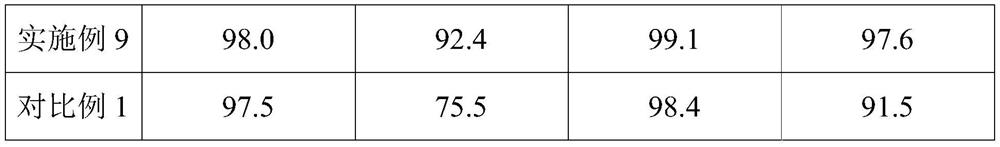

Recycling process of sodium tetrachloroaluminate in phosphinothricin production

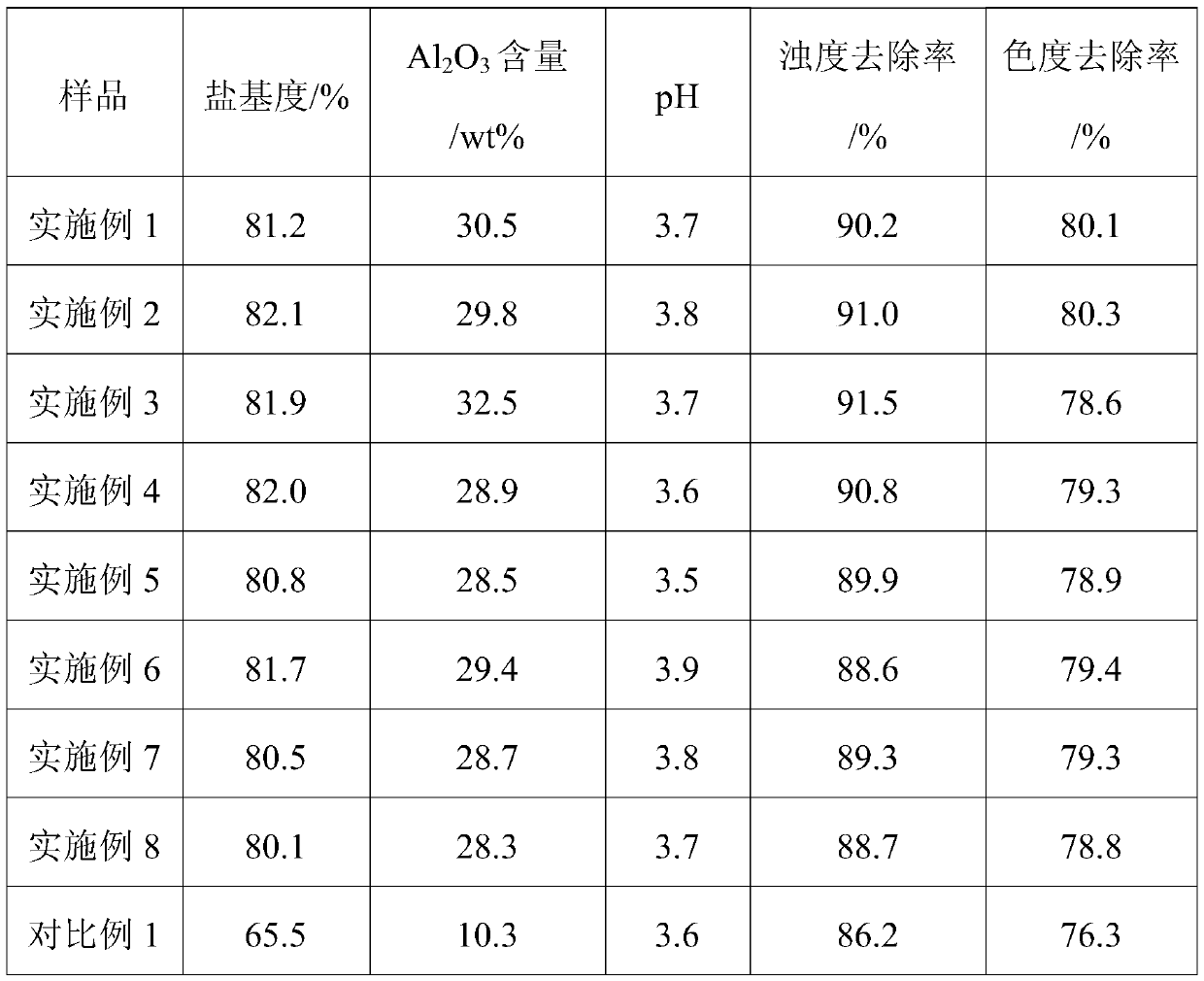

ActiveCN105217667ASolve processing problemsReduce pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSewage treatment

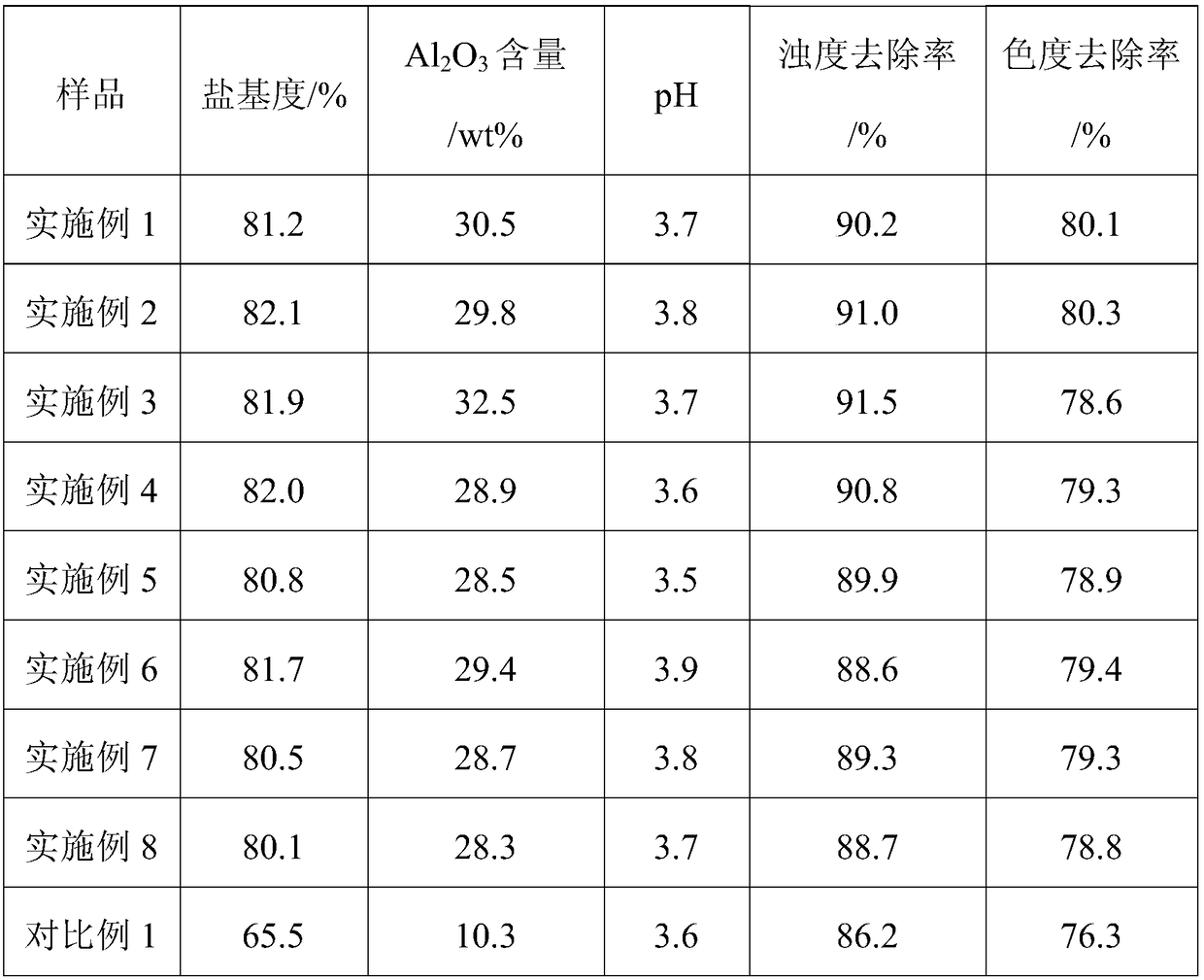

The invention discloses a recycling process of sodium tetrachloroaluminate in phosphinothricin production. The process comprises the following steps that 1, mismatching and precipitation are carried out; 2, solids are filtered; 3, cooling precipitation is carried out; 4, reutilization is carried out; 5, cyclic utilization is carried out; 6, aluminum polychlorid is prepared. Sodium tetrachloroaluminate solid waste is changed into treasure, alchlor obtained after mismatching is recycled, the problem of treatment of sodium tetrachloroaluminate solid waste is solved, pollution to environment is reduced, no three waste is discharged, the atom economy of a reaction is improved, and large-scale production of phosphinothricin is facilitated. A mismatching agent and a poor solvent adopted in the process are low in price and easy to obtain, the whole process is easy and convenient to operate, and especially suitable for industrial production. Further prepared polymerization alchlor can be adopted as a water purifying agent, and is wide in application range and especially suitable for sewage treatment of chemical plants.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Non-aqueous electrolyte for high voltage rechargeable magnesium batteries

InactiveUS20140099557A1Improve conductivityEasy to depositOrganic electrolyte cellsSecondary cellsGrignard reagentMetallic materials

An electrolyte for use in electrochemical cells is provided. The properties of the electrolyte include high conductivity, high Coulombic efficiency, and an electrochemical window that can exceed 3.5 V vs. Mg / Mg+2. The use of the electrolyte promotes the electrochemical deposition and dissolution of Mg without the use of any Grignard reagents, other organometallic materials, tetraphenyl borate, or tetrachloroaluminate derived anions. Other Mg-containing electrolyte systems that are expected to be suitable for use in secondary batteries are also described.

Owner:PELLION TECH

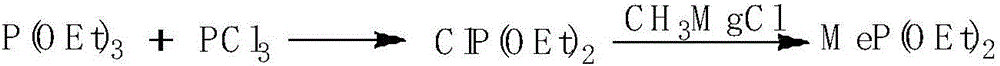

Method for preparing aluminum polychlorid from byproduct generated in methyl diethyl phosphate production

ActiveCN109052444AResolve disposal issuesHigh value-added productsAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideDiethyl phosphate

The invention provides a method for preparing aluminum polychlorid from byproducts generated in methyl diethyl phosphate production. The method comprises the following steps: (1) dispersing byproductsolid dregs into a solvent, analyzing, and collecting a solution; (2) cooling the solution with water, and separating aluminum chloride hydrate crystal; (3) hydrolyzing and polymerizing the aluminum chloride hydrate crystal, and aging, thereby obtaining the aluminum polychlorid. By adopting the method, solid dregs rich in sodium tetrachloroaluminate are adopted as a raw material, an inorganic polymeric flocculant, namely the aluminum polychlorid, is successfully prepared through steps of simple processes, and not only is the problem of waste disposal solved, but also a high additional value product can be successfully made.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

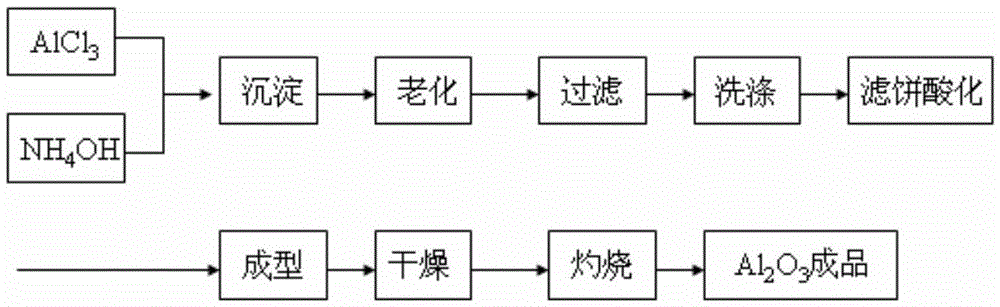

Preparation method of porous activated aluminum oxide adsorbing material

InactiveCN104445323AEliminate the effects ofSolve processing problemsOther chemical processesAlkali metal chloridesDiasporeTetrachloroaluminate

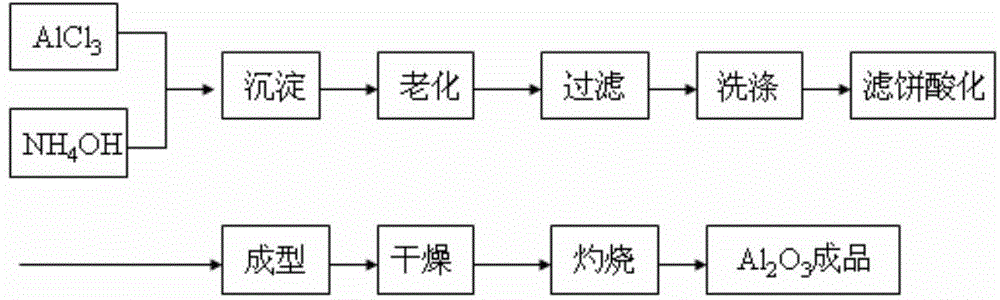

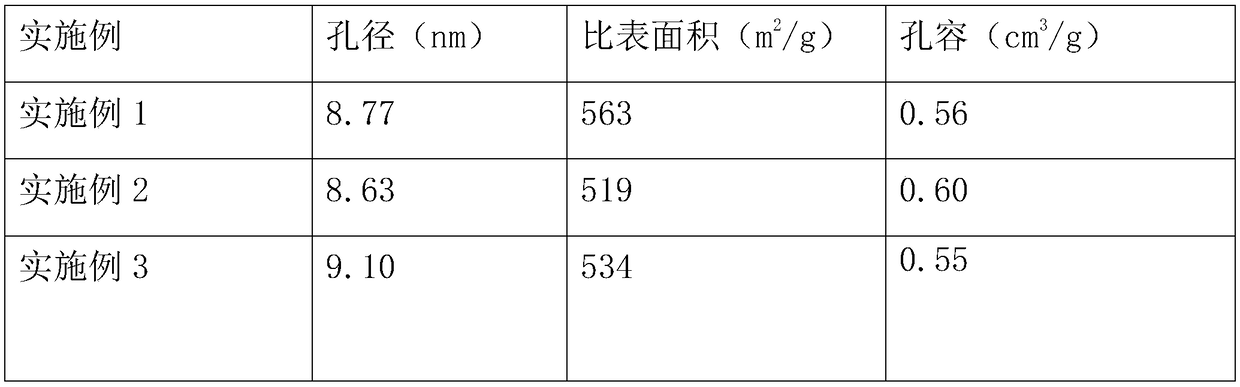

The invention relates to a preparation method of a porous activated aluminum oxide adsorbing material. The preparation method comprises the following steps: (1) dissolving and hydrolyzing solid sodium tetrachloroaluminate by using an ethanol water solution; (2) adding water into an obtained solution to generate aluminum trichloride hexahydrate; (3) adding ammonia water for reaction to generate hydrated alumina suspension liquid, and ageing to obtain alpha-diaspore; (4) peptizing by using acid to obtain sol, dropwise adding the sol into an oil-ammonia column by adopting a dripping method, allowing the sol to retract to form balls under the effect of a surface tensile force in oil, putting the balls into ammonia water, neutralizing and ageing to form hard gel ball-like substances, washing away oil ammonia by using water and drying; and (5) baking to obtain the porous activated aluminum oxide adsorbing material. The preparation method disclosed by the invention can be used for solving the problems of wastewater treatment, improving cyclic utilization of resources, realizing value maximization and increasing the additional value of byproducts; the porous activated aluminum oxide adsorbing material is good in thermal stability at high temperature, large in specific surface area, good in adsorption performance, simple in production process, convenient to operate, low in cost and basically free of environmental pollution from aspect of production technology.

Owner:武汉铂莱材料科技有限公司

Non-aqueous electrolyte for high voltage rechargeable magnesium batteries

InactiveUS8951676B2Improve conductivityEasy to depositOrganic electrolyte cellsSecondary cellsGrignard reagentElectrical battery

An electrolyte for use in electrochemical cells is provided. The properties of the electrolyte include high conductivity, high Coulombic efficiency, and an electrochemical window that can exceed 3.5 V vs. Mg / Mg+2. The use of the electrolyte promotes the electrochemical deposition and dissolution of Mg without the use of any Grignard reagents, other organometallic materials, tetraphenyl borate, or tetrachloroaluminate derived anions. Other Mg-containing electrolyte systems that are expected to be suitable for use in secondary batteries are also described.

Owner:PELLION TECH

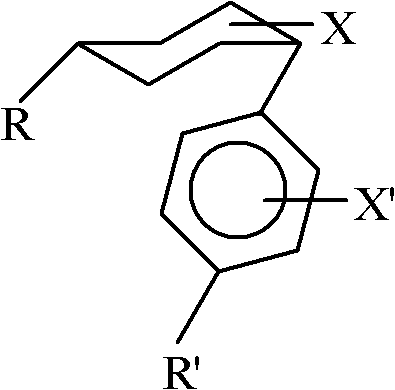

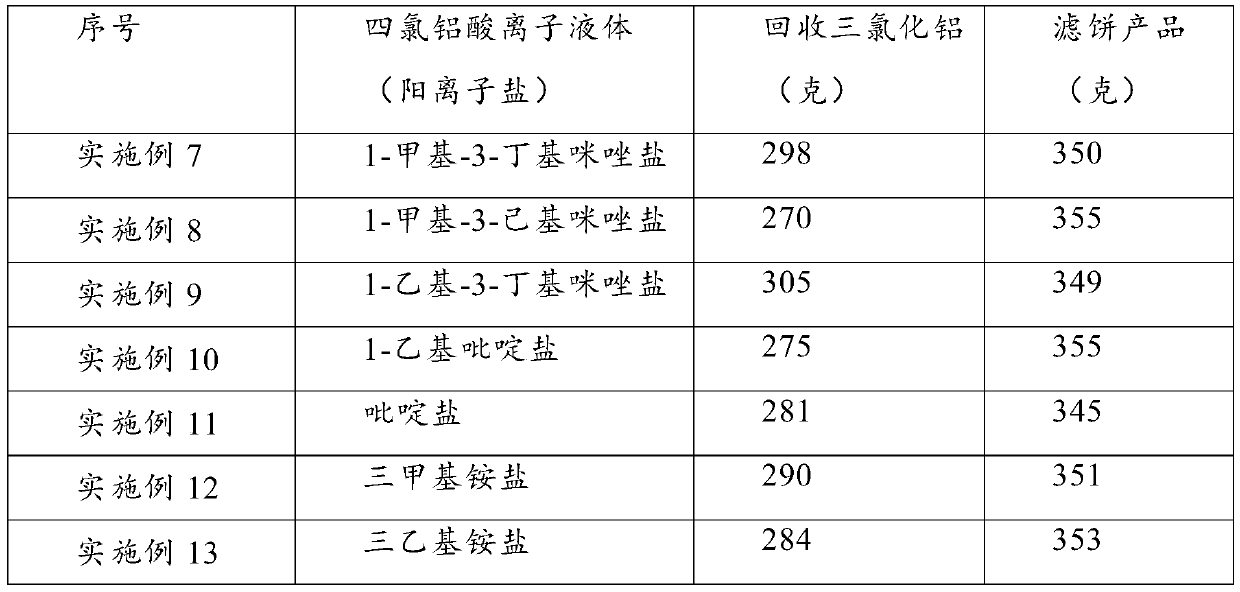

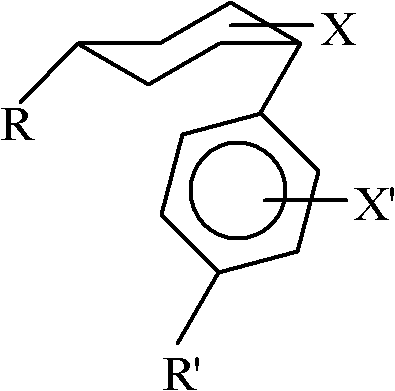

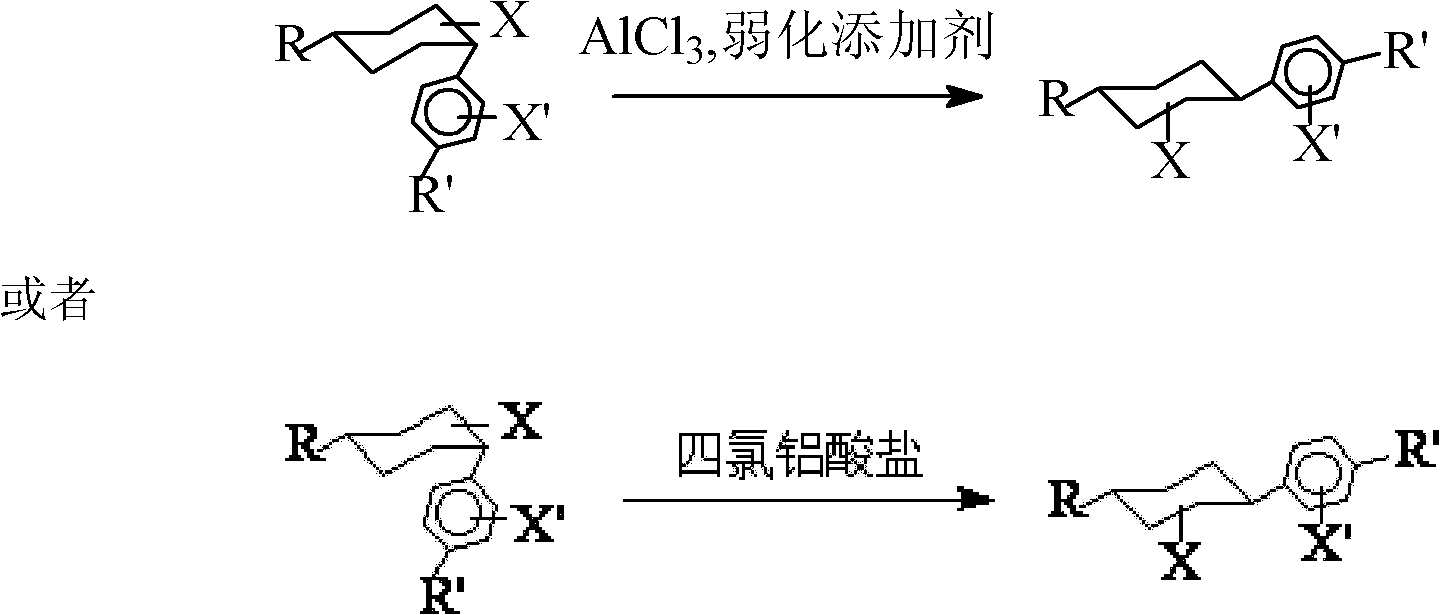

Method for converting cis-substituted cyclohexyl in organic molecules into trans-substituted cyclohexyl

ActiveCN102408284AWide applicabilityRich varietyHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsIsomerizationReaction temperature

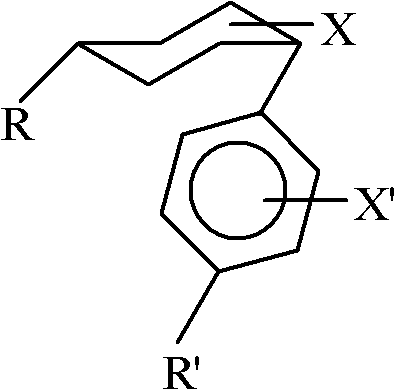

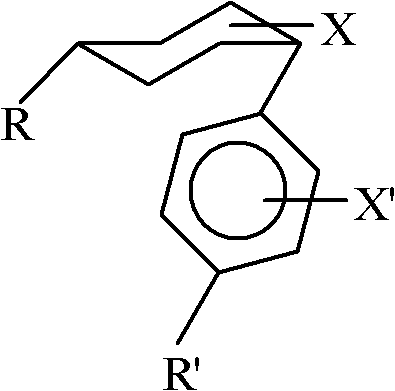

The invention relates to a method for converting cis-substituted cyclohexyl into trans-substituted cyclohexyl. The cis-substituted cyclohexyl has a structural formula shown in the specifications, wherein R and R' are the same or different and are an H atom, fatty hydrocarbyl with 1 to 10 carbon atoms, or aromatic hydrocarbyl with 1 to 10 carbon atoms; X and X' are the same or different and are an H element, 1 to 3 halogens, cyan, alkyl, alkoxy, trifluoromethyl or trifluoromethoxy; a catalyst converted from an isomer is weakened aluminum trichloride of which the activity is weakened by a weakening additive, or tetrachloroaluminate; and the reaction temperature is between -20 and +50 DEG C. The conversion method is simple and practicable, other isomerization side reactions in the cyclohexyl conversion process can be effectively inhibited when cyclohexyl conversion reaction is performed, a few isomerization byproducts are generated, yield is high, and a wide application prospect is achieved.

Owner:江苏广域化学有限公司

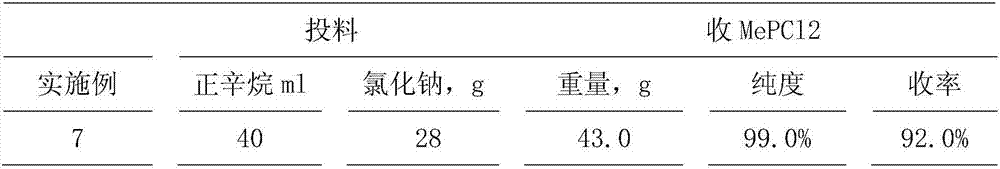

Method for preparing dichloro monoalkyl phosphine

The invention discloses a method for preparing dichloro-alkylphosphine, which uses sodium chloride to decomplex the binary complex of dichloro-alkylaluminum or alkyl aluminum sesquichloride and phosphorus trichloride When adding the alkane solvent, the free dichloro-alkylphosphine enters the alkane solvent, and the alkane solution of the dichloro-alkylphosphine is separated from the newly generated sodium tetrachloroaluminate NaAlCl by solid filtration; the target product dichloro-alkyl The mixture of phosphine and alkane solvent can be separated by distillation, or directly enter the next application process without separation. The decomposition of the traditional dichloro-alkylphosphine high-temperature distillation is avoided, the yield is increased and the waste residue is reduced.

Owner:南京奥格美化学研究所有限公司

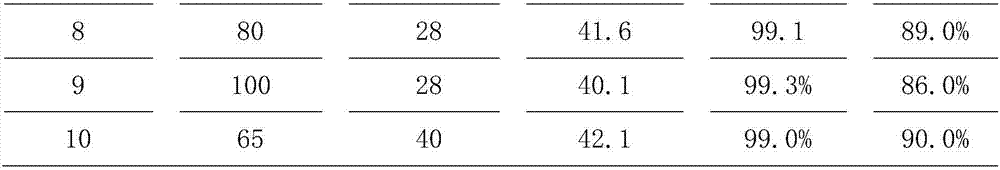

Treatment method of sodium tetrachloroaluminate solid residues

ActiveCN111689508ANo cross contaminationLow costGroup 5/15 element organic compoundsAluminium chloridesAluminium chlorideOrganic solvent

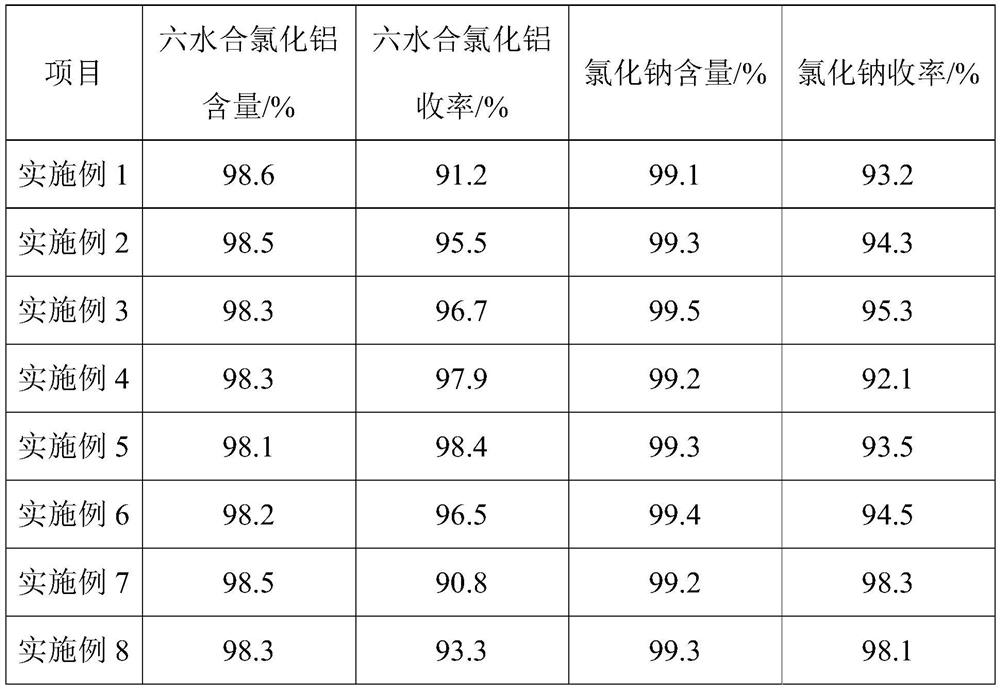

The invention relates to a treatment method of sodium tetrachloroaluminate solid residues. The treatment method comprises the following steps: (1) mixing sodium tetrachloroaluminate solid residues with water for dissociation, then adding a separating agent to separate out aluminum chloride hexahydrate, or directly mixing the sodium tetrachloroaluminate solid residues with the separating agent fordissociation, separating out aluminum chloride hexahydrate, and then carrying out primary solid-liquid separation to obtain an aluminum chloride hexahydrate solid and primary filtrate; and (2) carrying out concentration crystallization and secondary solid-liquid separation on the primary filtrate to obtain a sodium chloride solid and a secondary filtrate. According to the treatment method, an organic solvent does not need to be introduced, cross contamination does not exist, and the cost can be reduced; the aluminum chloride and the sodium chloride which are obtained by dissociating the sodiumtetrachloroaluminate solid residues are fully recycled, so that the high resource utilization of the sodium tetrachloroaluminate solid residues is realized, the obtained secondary filtrate can be returned to a solid residue dissociation stage to provide a separating agent, the concept of circular economy is embodied, and the method has the advantages of simple process flow, simplicity and convenience in operation and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

High voltage rechargeable magnesium cells having a non-aqueous electrolyte

InactiveUS20130252114A1Improve conductivityEasy to depositOrganic electrolyte cellsSecondary cellsGrignard reagentMetallic materials

A electrochemical cell having an non-aqueous electrolyte is provided. The properties of the electrolyte include high conductivity, high Coulombic efficiency, and an electrochemical window that can exceed 3.5 V vs. Mg / Mg+2. The use of the electrolyte promotes the electrochemical deposition and dissolution of Mg without the use of any Grignard reagents, other organometallic materials, tetraphenyl borate, or tetrachloroaluminate derived anions. Other Mg-containing electrolyte systems that are expected to be suitable for use in secondary batteries are also described.

Owner:PELLION TECH

A kind of sodium tetrachloroaluminate recycling process in the production of glufosinate

ActiveCN105217667BSolve processing problemsReduce pollutionAluminium chloridesWater/sewage treatment by flocculation/precipitationSolventPollution

The invention discloses a recycling process of sodium tetrachloroaluminate in phosphinothricin production. The process comprises the following steps that 1, mismatching and precipitation are carried out; 2, solids are filtered; 3, cooling precipitation is carried out; 4, reutilization is carried out; 5, cyclic utilization is carried out; 6, aluminum polychlorid is prepared. Sodium tetrachloroaluminate solid waste is changed into treasure, alchlor obtained after mismatching is recycled, the problem of treatment of sodium tetrachloroaluminate solid waste is solved, pollution to environment is reduced, no three waste is discharged, the atom economy of a reaction is improved, and large-scale production of phosphinothricin is facilitated. A mismatching agent and a poor solvent adopted in the process are low in price and easy to obtain, the whole process is easy and convenient to operate, and especially suitable for industrial production. Further prepared polymerization alchlor can be adopted as a water purifying agent, and is wide in application range and especially suitable for sewage treatment of chemical plants.

Owner:ANHUI COSTAR BIOCHEM CO LTD

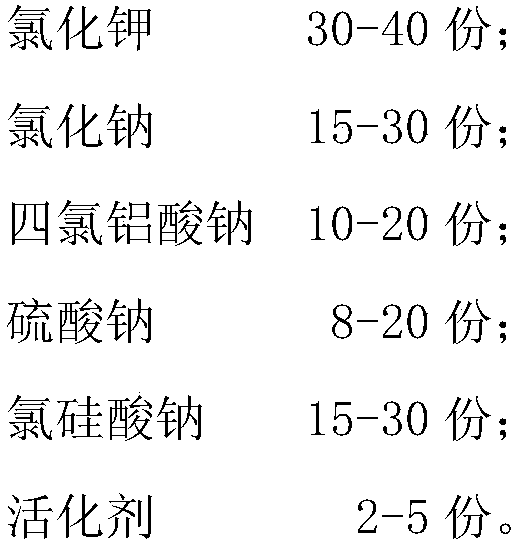

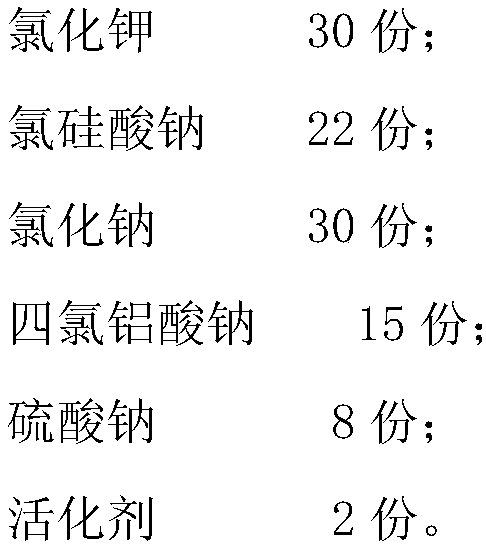

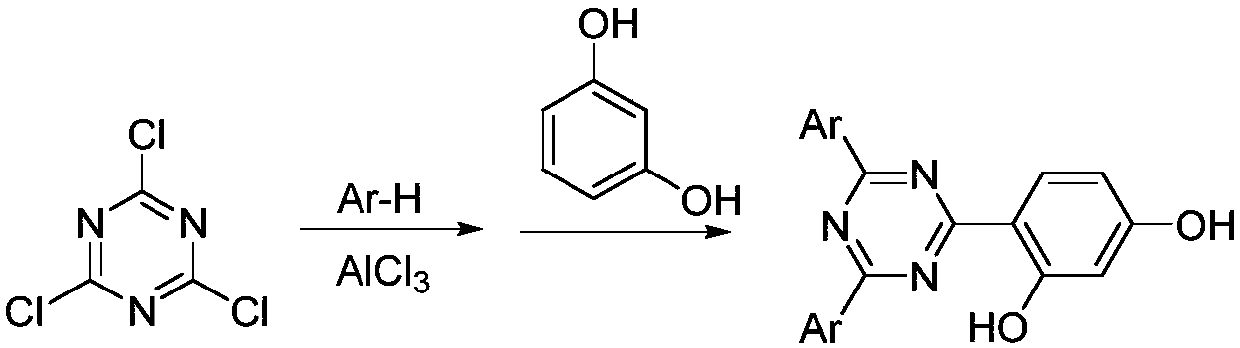

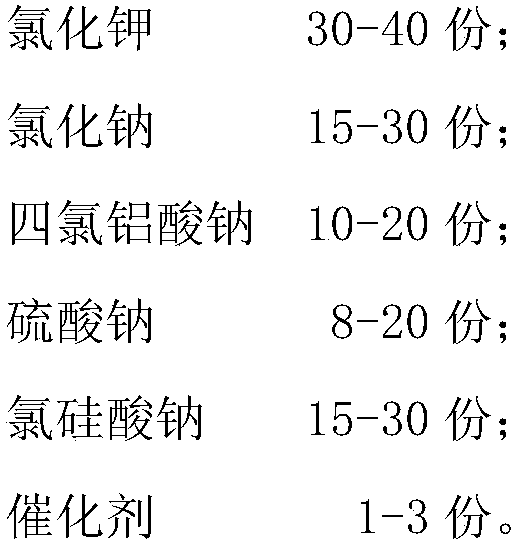

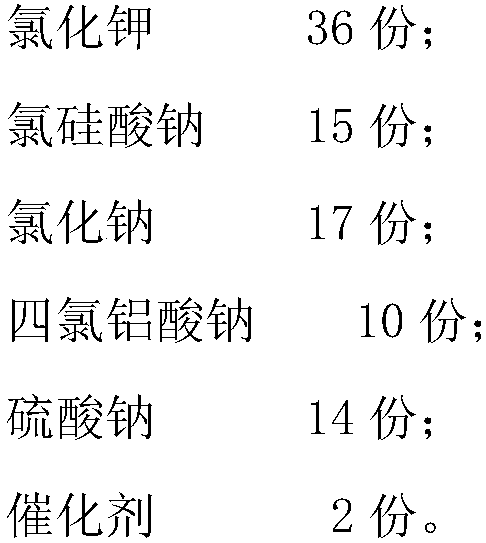

Refining agent for metal smelting, preparation method and refining technology

InactiveCN108660331APromote decompositionImprove refining efficiencyLead smeltingAtmospheric pollution

The invention relates to the technical field of aluminum and aluminum alloy purifying and refining treatment, in particular to a refining agent for metal smelting, a preparation method and a refiningtechnology. The refining agent for metal smelting aims to remove impurities of molten aluminum in the aluminum alloy refining process, so that the product quality is improved, and atmospheric pollution is avoided. The refining agent for metal smelting comprises, by weight, 30-40 parts of potassium chloride, 15-30 parts of sodium chloride, 10-20 parts of sodium tetrachloroaluminate, 8-20 parts of sodium sulfate, 15-30 parts of chloride sodium silicate and 2-5 parts of activating agent. According to the refining agent for metal smelting, the activating agent is added to the refining agent, the activating agent can promote sodium tetrachloroaluminate in the refining agent to decompose and reduce the interfacial tension between the refining agent and oxide inclusion at the same time, so that the oxide inclusion can smoothly float on the surface of the melt and then is removed, and therefore the product quality is improved.

Owner:湖北新金洋资源股份公司

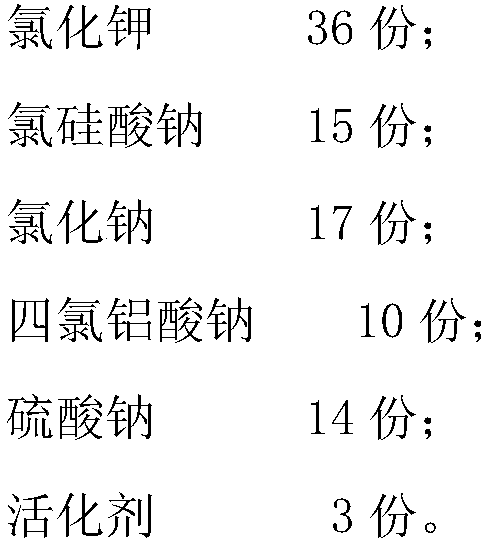

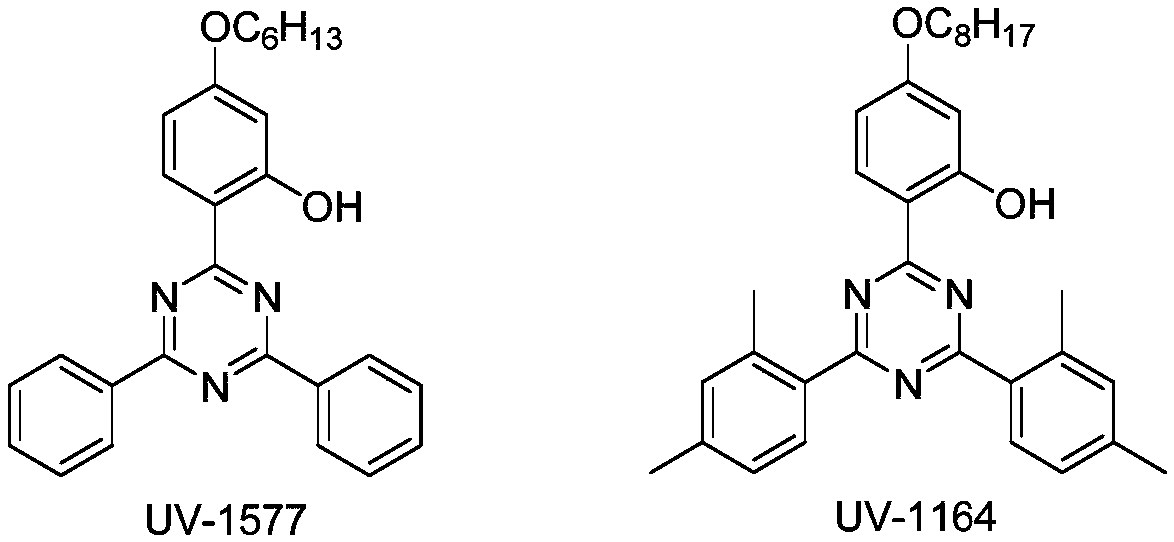

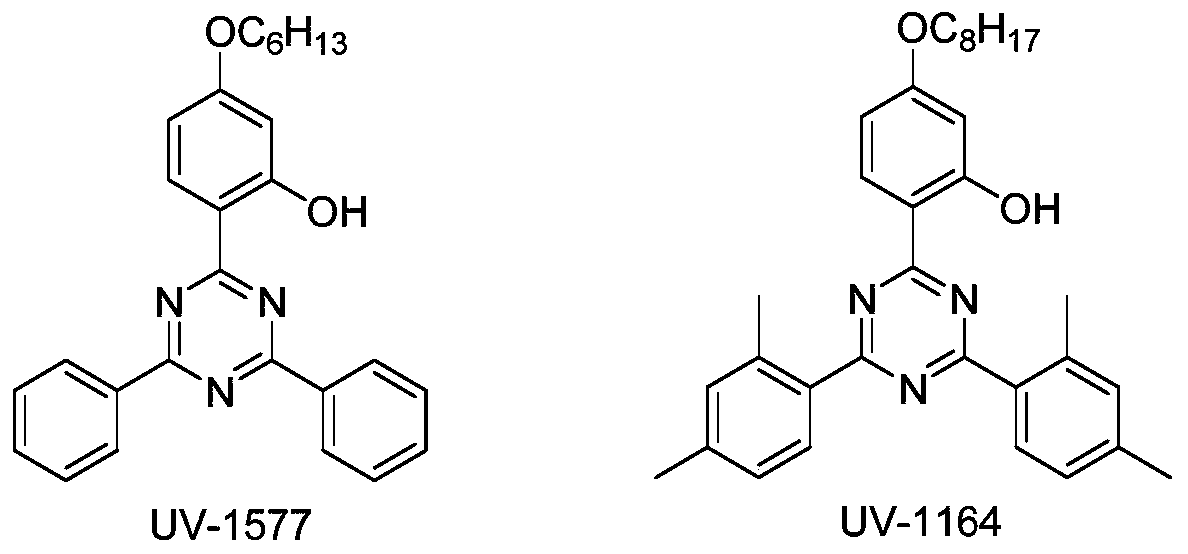

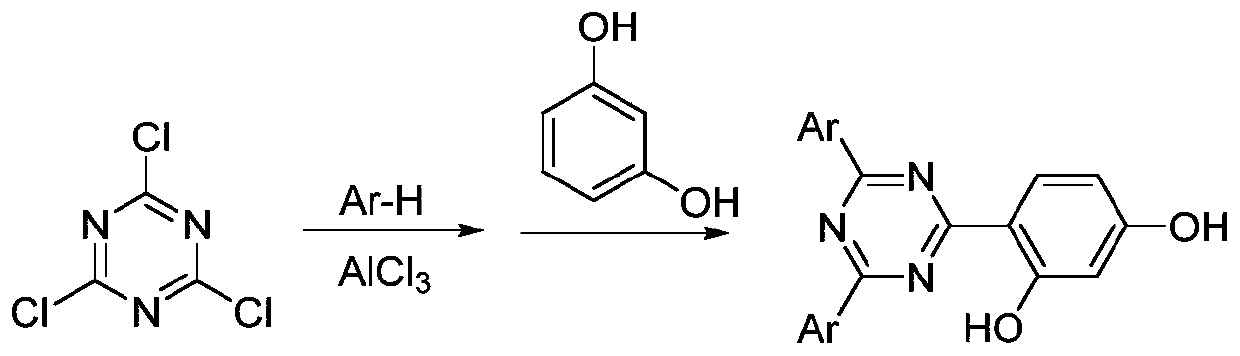

Method of recycling catalyst used in Friedel-Crafts process for producing aryl-s-triazine ultraviolet absorber

ActiveCN107746389AEliminate waste waterImprove cleaner productionOrganic chemistryChlorobenzeneUltraviolet

The invention discloses a method of recycling a catalyst used in Friedel-Crafts process for producing an aryl-s-triazine ultraviolet absorber. The method includes the following steps: 1) with chlorobenzene as a solvent, performing a Friedel-Crafts reaction to cyanuric chloride and aromatic hydrocarbon under a catalyst, AlCl3, to prepare a reaction solution which contains an intermediate of the aryl-s-triazine ultraviolet absorber; 2) adding a tetrachloroaluminate ionic liquid, as an extract agent, to the reaction solution so as to separate the intermediate of the aryl-s-triazine ultraviolet absorber from the AlCl3 or tetrachloroaluminate ions, and recycling the extracted and separated AlCl3 or tetrachloroaluminate ions as the catalyst or the extract agent for producing the aryl-s-triazineultraviolet absorber via the Friedel-Crafts process. In the method, the tetrachloroaluminate ionic liquid is used as the extract agent to separate the intermediate from the catalyst phase AlCl3, so that the catalyst, AlCl3, used in the Friedel-Crafts process can be recycled. The method eliminates waste water containing the AlCl3 without reduction on product yield, thus significantly improving clean production performance.

Owner:JIANGSU KAITENG PHARMA RAW MATERIALS CO LTD

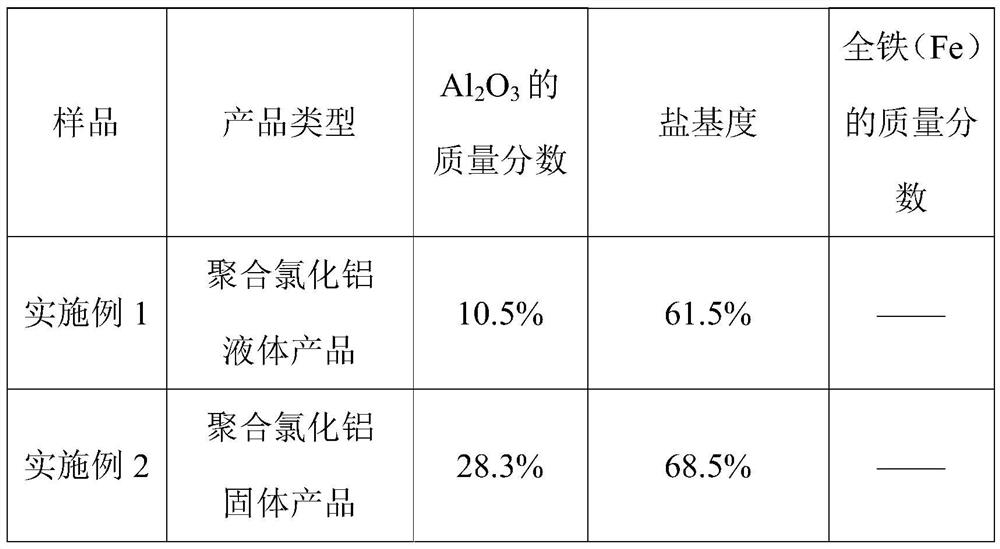

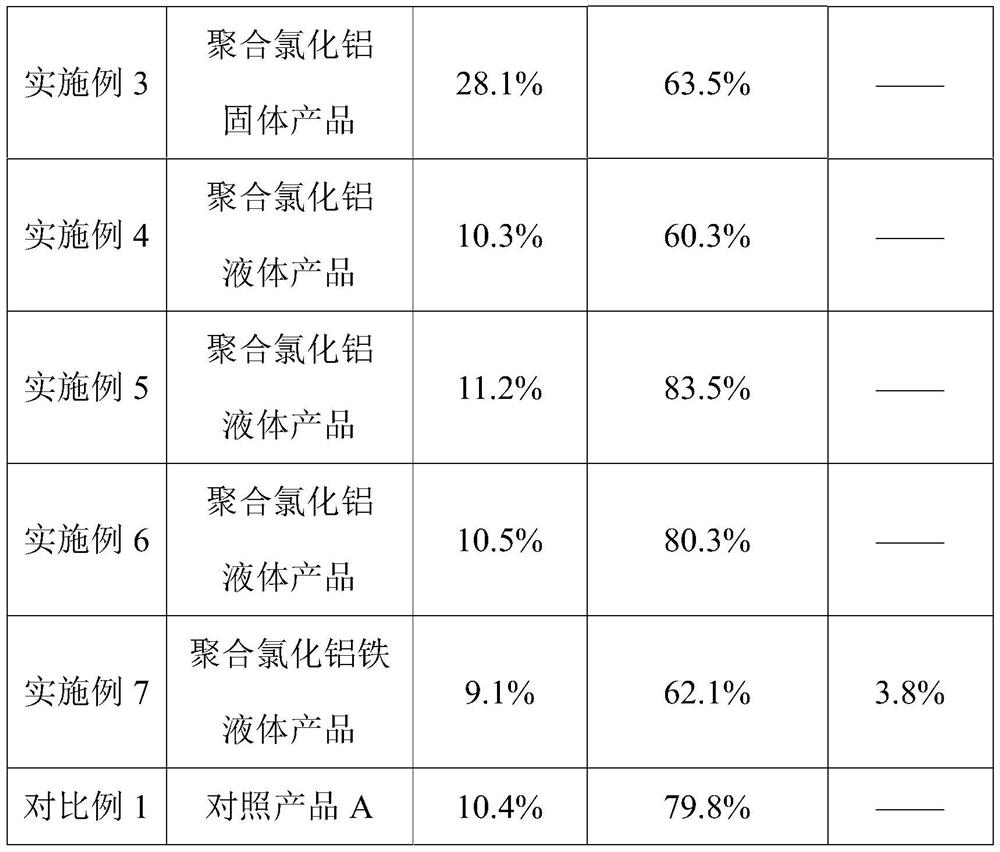

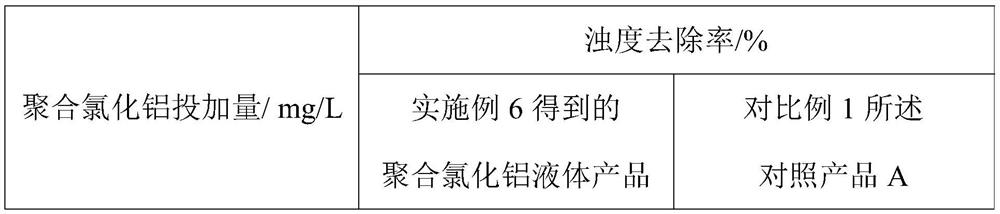

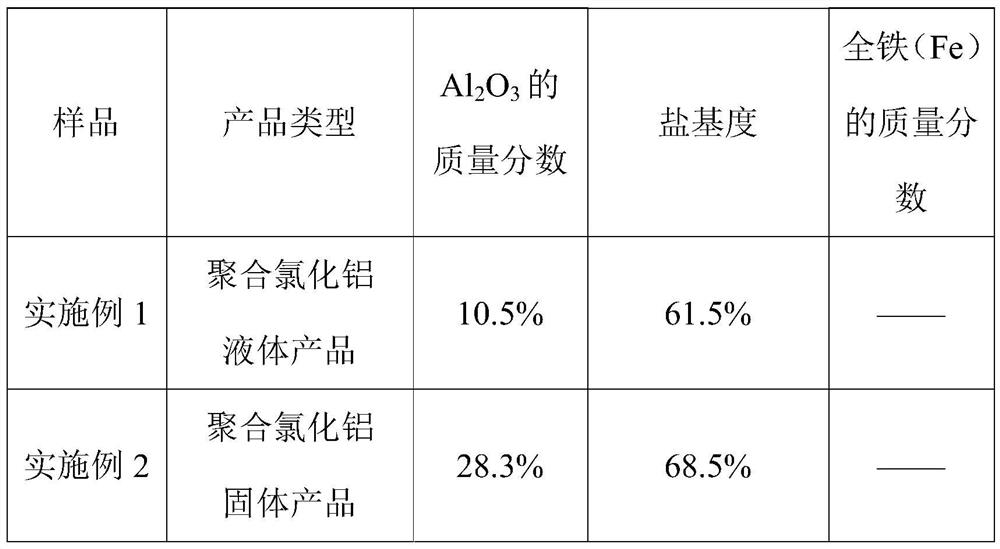

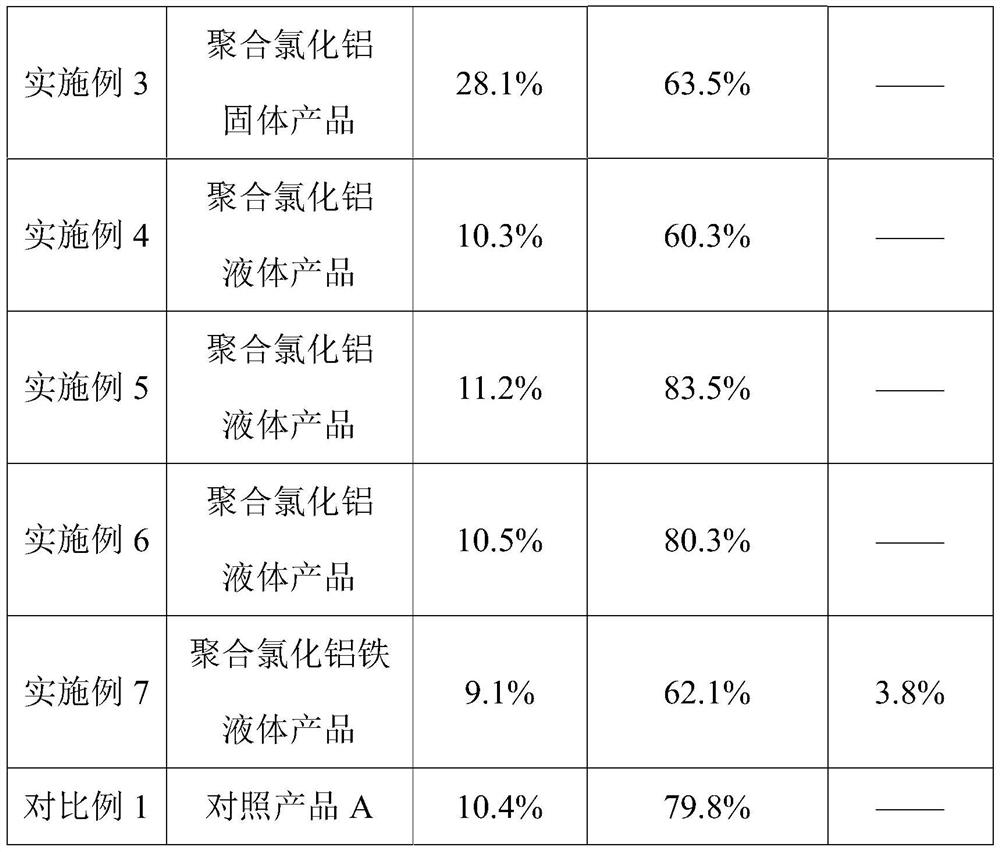

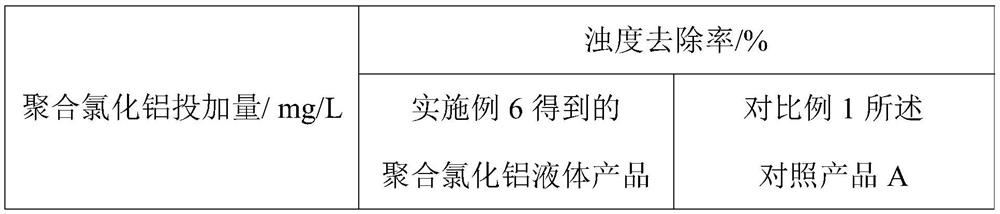

Treatment method for solid sodium tetrachloroaluminate residue

ActiveCN111804704AResolve disposal issuesIncrease added valueSolid waste disposalAluminium chlorideLiquid product

The invention relates to a treatment method for solid sodium tetrachloroaluminate residue. The treatment method comprises the following steps: mixing the solid sodium tetrachloroaluminate residue withwater and dissociating at first; then adding alkali and carrying out polymerization reaction; then carrying out concentration and crystallization, and solid-liquid separation to obtain a sodium chloride solid and a concentrated mother solution; and then curing the obtained concentrated mother solution to obtain a polyaluminum chloride liquid product. According to the treatment method, aluminum chloride and sodium chloride which are obtained by dissociating the solid sodium tetrachloroaluminate residue are adequately recovered, so that the problem of disposal for the solid waste is solved, andthe polyaluminum chloride liquid product with a high additional value is prepared, the mass fraction of Al2O3 is not less than 10%, the basicity of Al2O3 is not less than 60%, and the index requirements of the national standards GB 15892-2009 are met; and according to the treatment method, an organic solvent does not need to be introduced, so that cross contamination is avoided, and the cost canbe lowered, and the treatment method has the advantages of being simple in process flow, simple and convenient to operate, low in equipment investment, and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

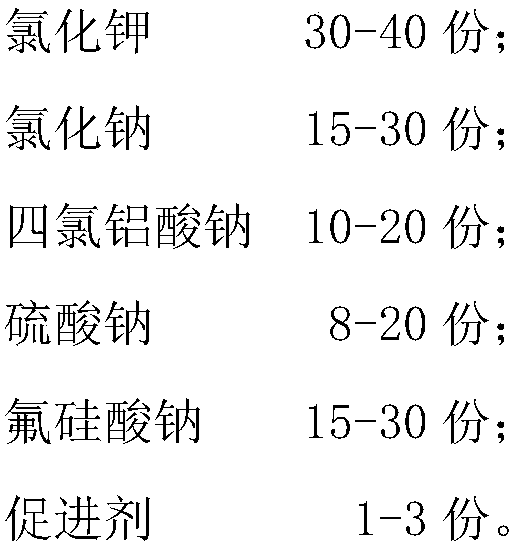

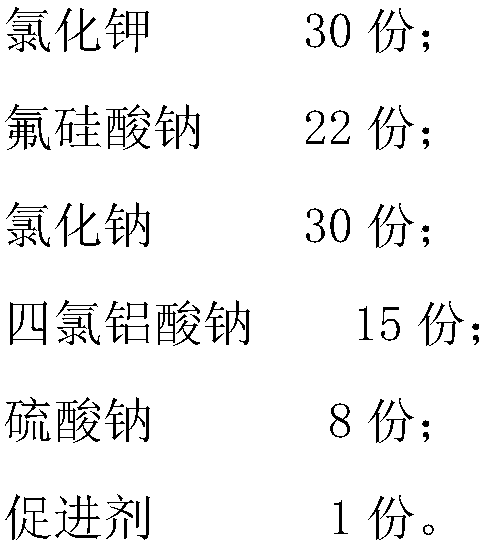

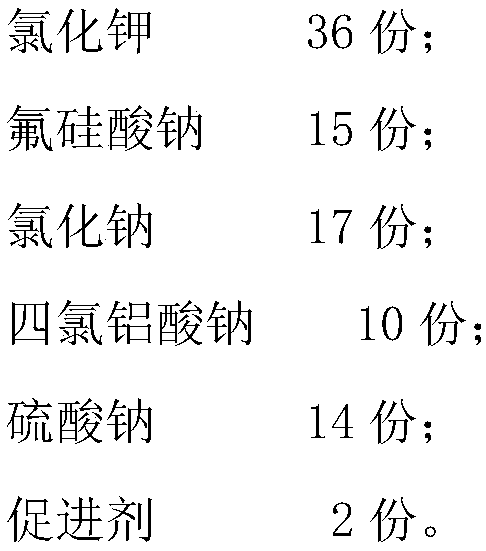

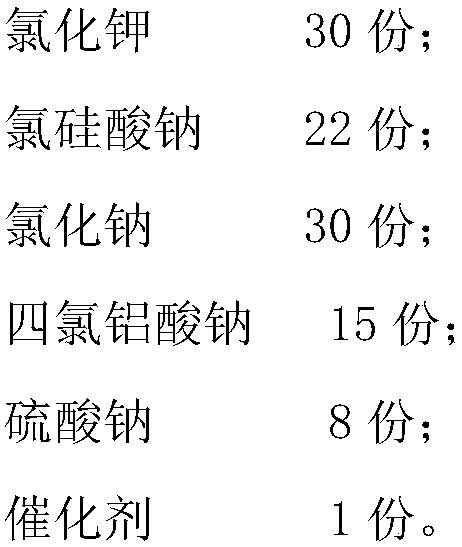

Refining agent for aluminum alloy as well as preparation method and refining process

The invention relates to the technical field of aluminum and aluminum alloy purification and refining treatment, in particular to a refining agent for aluminum alloy as well as a preparation method and a refining process, and aims at removing impurities in molten aluminum in the aluminum alloy refining process so as to improve the product quality. The refining agent for the aluminum alloy comprises, by weight, 30-40 parts of potassium chloride, 15-30 parts of sodium chloride, 10-20 parts of sodium tetrachloroaluminate, 8-20 parts of sodium sulfate, 15-30 parts of sodium fluosilicate and 1-3 parts of accelerants. According to the refining process, the accelerants are added into the refining agent, and can promote decomposition of the sodium tetrachloroaluminate in the refining agent, and meanwhile, the interface tension between the refining agent and oxide inclusions is reduced, and therefore, the oxide inclusions can smoothly float on the liquid surface and then are removed, and the product quality is improved.

Owner:湖北新金洋资源股份公司

Method for producing sodium tetrachloroaluminate by using TiCl4-containing material

The invention discloses a method for producing sodium tetrachloroaluminate by using a TiCl4-containing material. The method is characterized by comprising the following steps: adding sodium chloride and a reducing agent into the TiCl4-containing material and evaporating TiCl4 by isolating air at 130 to 300 DEG C; and performing vacuum distillation on residues, obtained after the TiCl4 is evaporated, at 200 to 600 DEG C and recovering aluminum in the form of sodium tetrachloroaluminate. The method has the advantages that the process is simple; the production cost is low, the obtained sodium tetrachloroaluminate has high purity; the TiCl4 obtained by recovery has few impurities; and environmental friendliness is realized.

Owner:CENT SOUTH UNIV

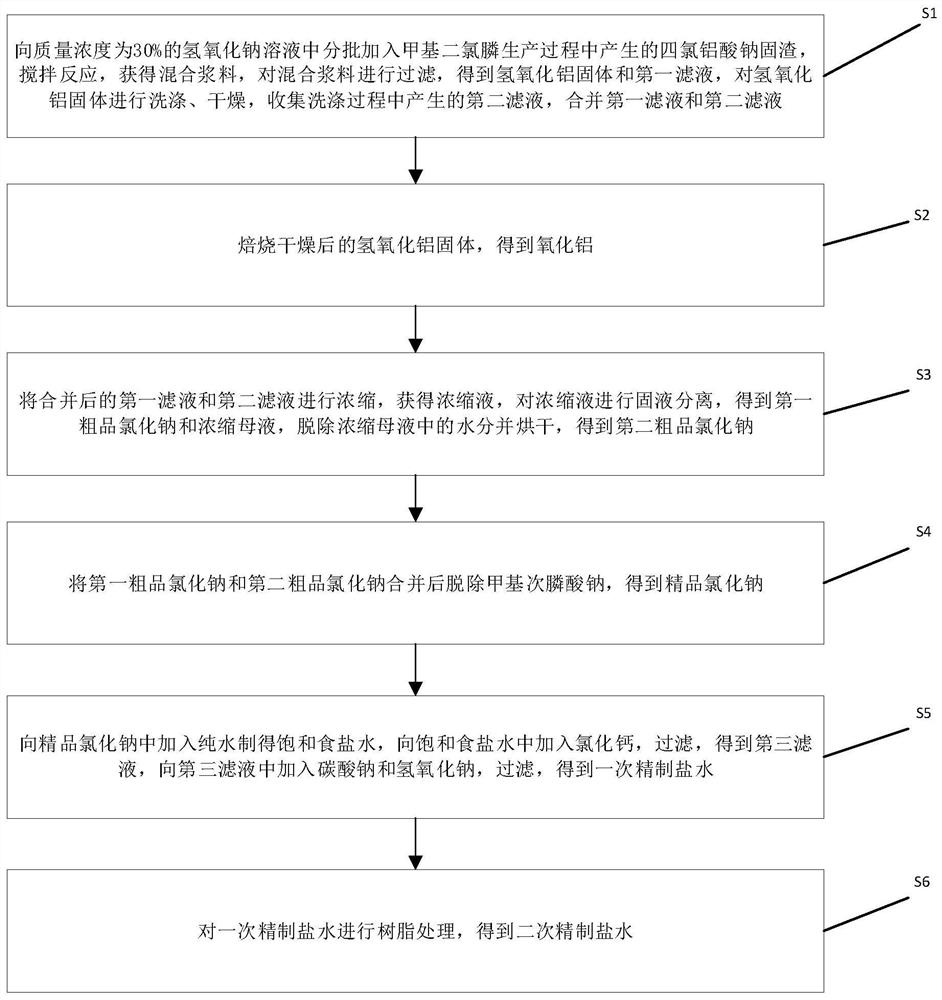

Treatment method of sodium tetrachloroaluminate generated in production process of methyl dichlorophosphine

ActiveCN112794868AAchieve removalSodium methylphosphinate content is smallGroup 5/15 element organic compoundsAluminium chloridesAluminium hydroxideProcess engineering

The invention provides a treatment method of sodium tetrachloroaluminate generated in a production process of methyl dichlorophosphine, wherein the treatment method comprises the steps: adding sodium tetrachloroaluminate solid slag into a sodium hydroxide solution, stirring for reaction to obtain mixed slurry, filtering to obtain aluminum hydroxide solid and first filtrate, washing and drying the aluminum hydroxide solid, and collecting second filtrate generated in the washing process; roasting the aluminum hydroxide solid to obtain aluminum oxide; concentrating the first filtrate and the second filtrate to obtain a concentrated solution, carrying out solid-liquid separation to obtain a first crude sodium chloride product and a concentrated mother solution, removing moisture in the concentrated mother solution, and drying to obtain a second crude sodium chloride product; combining the first crude sodium chloride and the second crude sodium chloride and heating to remove impurities, and thus obtaining refined sodium chloride; and adding pure water into the refined sodium chloride to prepare a saturated saline solution, adding calcium chloride, filtering to obtain third filtrate, adding sodium carbonate and sodium hydroxide into the third filtrate, filtering to obtain a primary refined saline solution, and performing resin treatment to obtain a secondary refined saline solution.

Owner:HONGHU YITAI TECH CO LTD

Treatment method of sodium tetrachloroaluminate

InactiveCN111921153AWater/sewage treatment by flocculation/precipitationSodium bicarbonateEnvironmental engineering

The invention relates to a treatment method of sodium tetrachloroaluminate. The treatment method is characterized by comprising the following steps: 1) crushing sodium tetrachloroaluminate blocky crystals; 2) adding a certain amount of hot water, and carrying out a reaction at a temperature of 50-100 DEG C, 3) after the reaction is finished, adding an alkali metal hydroxide or sodium bicarbonate to neutralize HCl, and 4) transferring the harmless substance obtained in the step 3) into a wastewater sedimentation tank. The product treated by the treatment method of sodium tetrachloroaluminate isharmless and environmentally friendly.

Owner:浙江安力能源有限公司

Environment-friendly refining agent, preparation method and refining process

InactiveCN108504884APromote decompositionImprove refining efficiencyAir quality improvementDecompositionAtmospheric pollution

The invention relates to the technical field of purification and refining treatment of aluminum and alloys thereof, in particular to an environment-friendly refining agent, a preparation method and arefining process and aims to remove impurities in molten aluminum in the aluminum alloy refining process so as to improve the product quality and avoid atmospheric pollution. The environment-friendlyrefining agent is prepared from components in parts by weight as follows: 30-40 parts of potassium chloride, 15-30 parts of sodium chloride, 10-20 parts of sodium tetrachloroaluminate, 8-20 parts of sodium sulfate, 15-30 parts of sodium silicate chloride and 1-3 parts of a catalyst. An accelerant is added to the refining agent, the accelerant can promote decomposition of sodium tetrachloroaluminate in the refining agent, besides, interfacial tension between the refining agent and oxide inclusions is reduced, so that the oxide inclusions can smoothly float on the liquid level to be further removed, and the product quality is improved.

Owner:湖北新金洋资源股份公司

A kind of method that contains ticl4 material to produce sodium tetrachloroaluminate

InactiveCN103466673BEfficient separationEasy to separateAluminium chloridesImpurityTetrachloroaluminate

The invention discloses a method for producing sodium tetrachloroaluminate by using a TiCl4-containing material. The method is characterized by comprising the following steps: adding sodium chloride and a reducing agent into the TiCl4-containing material and evaporating TiCl4 by isolating air at 130 to 300 DEG C; and performing vacuum distillation on residues, obtained after the TiCl4 is evaporated, at 200 to 600 DEG C and recovering aluminum in the form of sodium tetrachloroaluminate. The method has the advantages that the process is simple; the production cost is low, the obtained sodium tetrachloroaluminate has high purity; the TiCl4 obtained by recovery has few impurities; and environmental friendliness is realized.

Owner:CENT SOUTH UNIV

Production process of high-purity vanadium pentoxide for vanadium-nitrogen alloy

PendingCN114162868AHigh yieldHigh purityChemical industryVanadium oxidesAluminium chlorideWater chlorination

The invention discloses a production process of high-purity vanadium pentoxide for a vanadium-nitrogen alloy, and relates to the technical field of vanadium pentoxide purification. When the high-purity vanadium pentoxide for producing the vanadium-nitrogen alloy is used, industrial-grade vanadium pentoxide is used as a vanadium source, the chlorinating agent obtained by blending aluminum chloride and sodium chloride is firstly used for carrying out two-stage heating chlorination to obtain vanadium oxytrichloride, and then ultrasonic spraying ammonification is carried out, so that the specific surface area of a precipitate is increased while agglomeration of the precipitate is avoided; meanwhile, tail gas containing ammonia gas is recycled and introduced into ultrasonic spraying ammoniation equipment, so that the production process of the high-purity vanadium pentoxide for the vanadium-nitrogen alloy is more energy-saving and environment-friendly; liquid sodium tetrachloroaluminate generated in the preparation process of vanadium oxytrichloride effectively controls volatilization of aluminum chloride, so that aluminum chloride and a vanadium source are in full contact for chlorination, the yield and purity of vanadium oxytrichloride are improved, and the yield and purity of high-purity vanadium pentoxide are further improved.

Owner:江西林力高新材料有限公司

A kind of treatment method of sodium tetrachloroaluminate solid slag

ActiveCN111804704BResolve disposal issuesIncrease added valueSolid waste disposalAluminium chlorideLiquid product

The invention relates to a treatment method of sodium tetrachloroaluminate solid slag. The treatment method firstly mixes sodium tetrachloroaluminate solid slag with water for dissociation, then adds alkali to carry out polymerization reaction, and then carries out concentrated crystallization, solid-liquid Separating to obtain solid sodium chloride and concentrated mother liquor, and then aging the obtained concentrated mother liquor to obtain a liquid product of polyaluminum chloride. The treatment method of the present invention fully recovers the aluminum chloride and sodium chloride obtained by dissociating the solid slag of sodium tetrachloroaluminate, which not only solves the problem of solid waste disposal, but also prepares high value-added polyaluminum chloride Liquid product, Al 2 o 3 The mass fraction is ≥10%, and the basicity is ≥60%, which meets the index requirements of the national standard GB 15892-2009; the treatment method does not need to introduce organic solvents, does not have cross-contamination, and can reduce costs, and has the advantages of simple process flow, It has the advantages of simple operation and less investment in equipment.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

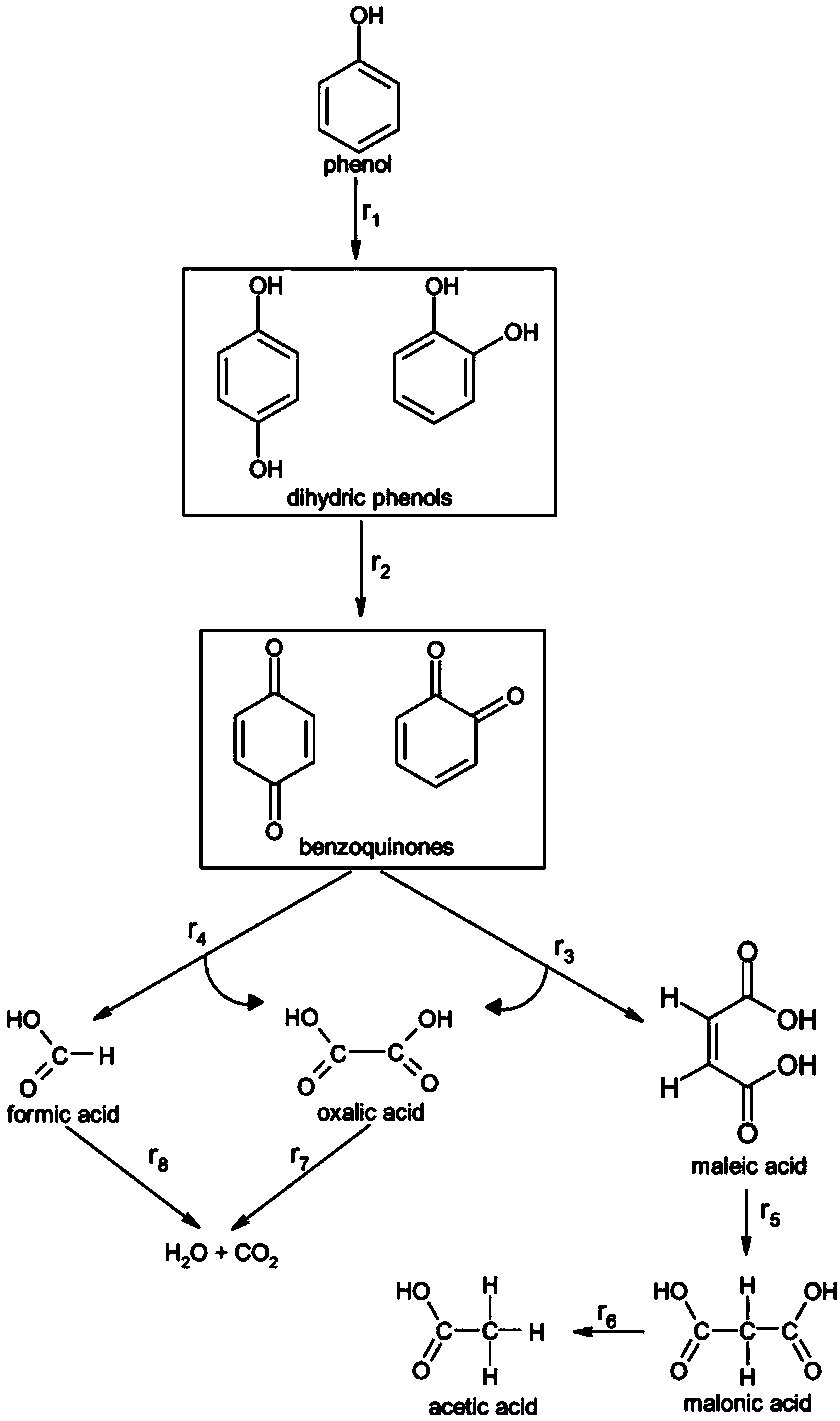

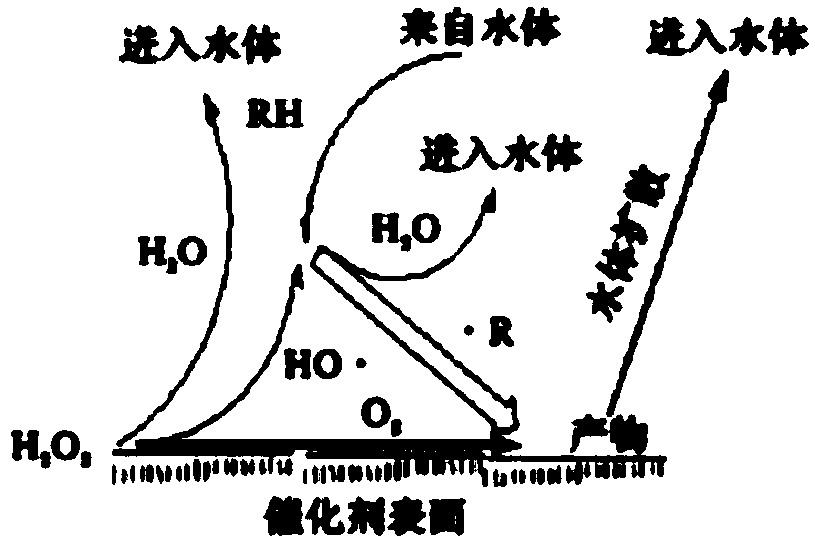

A kind of heterogeneous fenton-like catalyst and preparation method thereof and application in degrading phenol-containing wastewater

InactiveCN106391035BImprove adhesionHigh porosityWater treatment compoundsWater contaminantsSlurryCordierite

The invention discloses a heterogeneous Fenton catalyst, a preparation method thereof and application of the heterogeneous Fenton catalyst to degradation of phenolic wastewater. The preparation method includes the steps of dissolving sodium tetrachloroaluminate with ethanol water; filtering to obtain filtrate B, adding deionized water and ammonium hydroxide into the filtrate B, and hydrolyzing to obtain liquid C; adding urea and a saturated ferrous sulfate water solution into the liquid C so as to obtain coating slurry; immersing cordierite monolith ceramics carriers into the coating slurry for surface coating, adding the cordierite monolith ceramics carriers subjected to surface coating into a mixed water solution of FeSO4 7H2O, Ce(NO3)3 6H2O and cyanuric acid to obtain thick liquid, subjecting the thick liquid to solid-liquid separation to obtain a solid D, and roasting prior to rapid cooling so as to obtain the heterogeneous Fenton catalyst applied to degradation of the phenolic wastewater. The preparation method has the advantage that a catalyst preparation method is changed to stop active ingredients from loss so as to make the catalyst high in catalytic activity, stable in catalytic performance and recyclable.

Owner:BENGBU COLLEGE

A kind of treatment method of sodium tetrachloroaluminate solid slag

ActiveCN111689508BNo cross contaminationLow costGroup 5/15 element organic compoundsAluminium chloridesAluminium chlorideOrganosolv

The invention relates to a treatment method of sodium tetrachloroaluminate solid slag. The treatment method comprises the following steps: (1) mixing sodium tetrachloroaluminate solid slag with water for dissociation, and then adding a separating agent to separate out chlorine hexahydrate Aluminum chloride, or sodium tetrachloroaluminate solid slag is directly mixed with a separating agent for dissociation, and aluminum chloride hexahydrate is separated out, and then aluminum chloride hexahydrate solid and a filtrate are obtained through a solid-liquid separation; (2) The first filtrate is concentrated and crystallized, and the second solid-liquid separation is carried out to obtain sodium chloride solid and the second filtrate. The treatment method does not need to introduce an organic solvent, and there is no cross-contamination, and the cost can be reduced; and the aluminum chloride and sodium chloride obtained by dissociating the solid slag of sodium tetrachloroaluminate are fully recovered, and the sodium tetrachloroaluminate is realized. The high resource utilization of solid slag can also return the obtained secondary filtrate to the solid slag dissociation stage to provide a separating agent, which embodies the concept of circular economy and has the advantages of simple process flow and easy operation.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

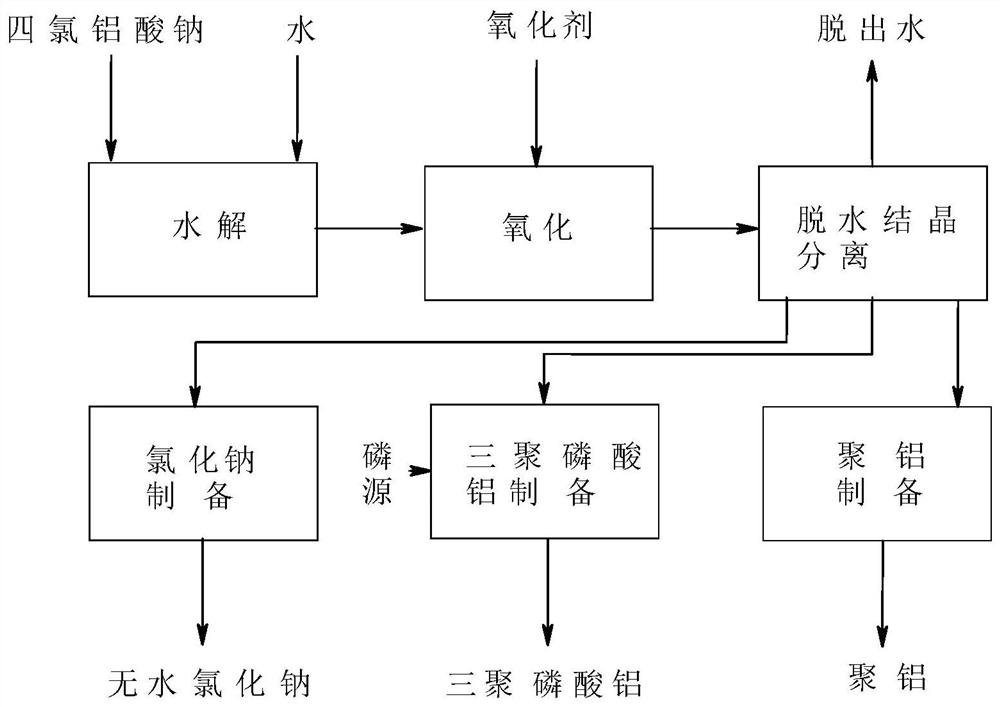

A kind of recovery processing method of sodium tetrachloroaluminate catalyst composition

ActiveCN112456462BAvoid bringing inLarge market capacityAluminium chloridesAlkali metal chloridesAluminium chloridePtru catalyst

The invention discloses a method for recovering and treating a sodium tetrachloroaluminate catalyst composition. The sodium tetrachloroaluminate is added into water, and the temperature rises to react to generate aluminum trichloride and sodium chloride; the aluminum trichloride, sodium chloride The mixture is controlled at a certain temperature, and an oxidizing agent is added for oxidation treatment; after the treatment, dehydration, crystallization, filtration, washing and separation are carried out to obtain aluminum trichloride and sodium chloride; the obtained aluminum trichloride is used to prepare polyaluminum chloride, The obtained sodium chloride is used to prepare anhydrous sodium chloride. In the present invention, the by-product sodium tetrachloroaluminate can be separated into sodium chloride and aluminum trichloride by hydrolysis, and there is no need to add other organic dissolving agents during the treatment process, thereby avoiding the introduction of organic impurities; the present invention obtains The products such as polyaluminum chloride, sodium chloride, and aluminum tripolyphosphate have a large market capacity, are easy to sell, and can also produce good economic benefits.

Owner:JIANGSU YOUTH CHEM

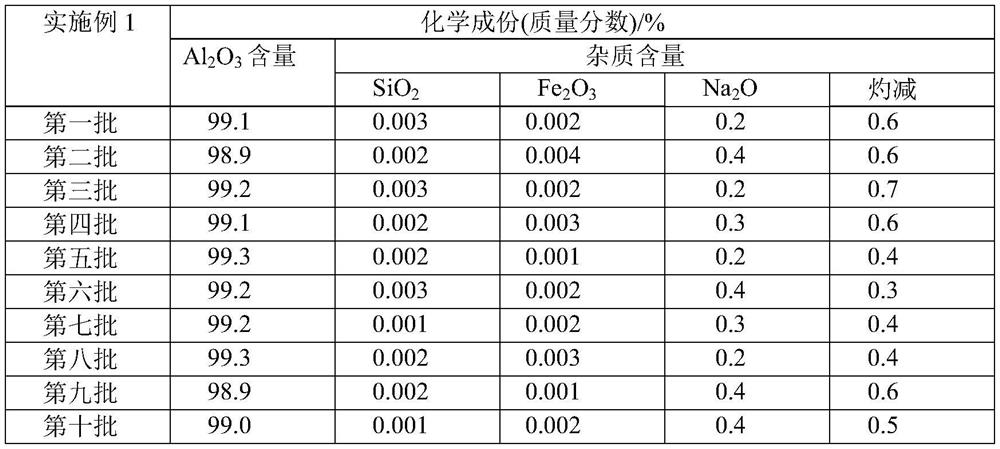

Preparation method of high-purity sodium tetrachloroaluminate for sodium salt battery

InactiveCN110817913ALow costEasy to controlAluminium compoundsSecondary cellsMetallic aluminumEngineering

The invention relates to a preparation method of high-purity sodium tetrachloroaluminate as a second electrolyte of a sodium salt battery. The method comprises the following steps: uniformly mixing anhydrous aluminum trichloride, anhydrous sodium chloride and metal aluminum; adding the anhydrous aluminum trichloride, anhydrous sodium chloride and metal aluminum after uniform mixing into a reactorand introducing high-purity nitrogen and performing heating; opening a top lid of the reactor after all the materials are liquefied, performing continuous stirring and then closing the top lid of thereactor, and continuously keeping the temperature; transferring a supernatant in the reactor into a material storage tank heated to 170-250 DEG C in advance after the reaction is completed; connectingthe material storage tank maintained at 170-250 DEG C into a vacuum purification apparatus, and performing purification on a product for 0.5-2 h; and cooling the material storage tank and introducingan inert gas for sealing and storage to obtain the final high-purity sodium tetrachloroaluminate crystal product. The purity of sodium tetrachloroaluminate prepared by the method of the invention canreach 99.5% or more, and can meet requirements for electrolyte purity of the sodium salt battery.

Owner:浙江安力能源有限公司

Method for recycling catalyst in aryl-s-triazine ultraviolet absorber prepared by Friedel-Crafts method

ActiveCN107746389BEliminate waste waterImprove cleaner productionOrganic chemistryChlorobenzeneUltraviolet lights

Owner:JIANGSU KAITENG PHARMA RAW MATERIALS CO LTD

Method for converting cis-substituted cyclohexyl in organic molecules into trans-substituted cyclohexyl

ActiveCN102408284BWide applicabilityRich varietyHydrocarbon by isomerisationOrganic-compounds/hydrides/coordination-complexes catalystsIsomerizationReaction temperature

Owner:江苏广域化学有限公司

Method for preparing polyaluminum chloride by using by-products produced in the production of diethyl methyl phosphite

ActiveCN109052444BResolve disposal issuesHigh value-added productsAluminium chloridesWater/sewage treatment by flocculation/precipitationDiethyl phosphateAluminium chloride

The invention provides a method for preparing aluminum polychlorid from byproducts generated in methyl diethyl phosphate production. The method comprises the following steps: (1) dispersing byproductsolid dregs into a solvent, analyzing, and collecting a solution; (2) cooling the solution with water, and separating aluminum chloride hydrate crystal; (3) hydrolyzing and polymerizing the aluminum chloride hydrate crystal, and aging, thereby obtaining the aluminum polychlorid. By adopting the method, solid dregs rich in sodium tetrachloroaluminate are adopted as a raw material, an inorganic polymeric flocculant, namely the aluminum polychlorid, is successfully prepared through steps of simple processes, and not only is the problem of waste disposal solved, but also a high additional value product can be successfully made.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Preparation method of activated alumina porous adsorption material

InactiveCN104445323BEliminate the effects ofSolve processing problemsOther chemical processesAlkali metal chloridesDiasporeTetrachloroaluminate

The invention relates to a preparation method of a porous activated aluminum oxide adsorbing material. The preparation method comprises the following steps: (1) dissolving and hydrolyzing solid sodium tetrachloroaluminate by using an ethanol water solution; (2) adding water into an obtained solution to generate aluminum trichloride hexahydrate; (3) adding ammonia water for reaction to generate hydrated alumina suspension liquid, and ageing to obtain alpha-diaspore; (4) peptizing by using acid to obtain sol, dropwise adding the sol into an oil-ammonia column by adopting a dripping method, allowing the sol to retract to form balls under the effect of a surface tensile force in oil, putting the balls into ammonia water, neutralizing and ageing to form hard gel ball-like substances, washing away oil ammonia by using water and drying; and (5) baking to obtain the porous activated aluminum oxide adsorbing material. The preparation method disclosed by the invention can be used for solving the problems of wastewater treatment, improving cyclic utilization of resources, realizing value maximization and increasing the additional value of byproducts; the porous activated aluminum oxide adsorbing material is good in thermal stability at high temperature, large in specific surface area, good in adsorption performance, simple in production process, convenient to operate, low in cost and basically free of environmental pollution from aspect of production technology.

Owner:武汉铂莱材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com