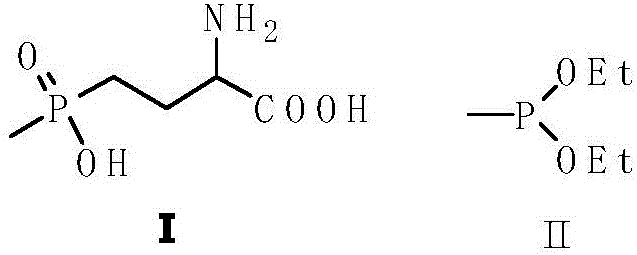

A kind of sodium tetrachloroaluminate recycling process in the production of glufosinate

A technology of sodium tetrachloroaluminate and glufosinate, which is applied in the fields of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc., to reduce pollution, realize no discharge of three wastes, and improve atomic economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

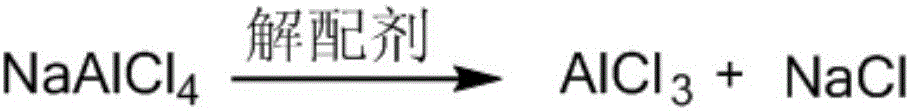

[0030] 1) Decomposition of sodium tetrachloroaluminate and recovery of aluminum trichloride

[0031] Add 300ml of methanol and 300ml of methyl tert-butyl ether to 200g of sodium tetrachloroaluminate, heat to 80°C, filter while hot, the filter cake is sodium chloride, and the filtrate is methanol solution of aluminum trichloride, slowly cool down , stirred overnight, a large amount of white aluminum trichloride solids were separated out, filtered and dried to obtain 133.2 g of aluminum trichloride with a yield of 95%;

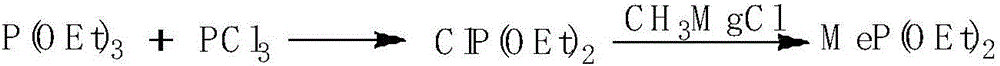

[0032] 2) Recycling of aluminum trichloride

[0033] In a 1L autoclave, add 100.0g (0.75mol) of aluminum trichloride prepared in 1), 134.0g (0.97mol) of phosphorus trichloride, 500ml of 1,1,2,2-tetrachloroethane, and pass chlorine Methane to 1Mpa, heat up to 80°C, react for 4 hours, cool down, filter, and dry to obtain 228.3g of white sandy solid with a yield of 95%;

[0034] Cycles

1

2

3

4

Ligand Yield (%)

95

90

85

60 ...

Embodiment 2

[0038] 1) Decomposition of sodium tetrachloroaluminate and recovery of aluminum trichloride

[0039] Add 300ml of ethanol and 300ml of tert-butyl ether to 200g of solid waste, heat to 85°C, filter while hot, the filter cake is sodium chloride, and the filtrate is methanol solution of aluminum trichloride, slowly cool down, stir overnight, and precipitate A large amount of white aluminum trichloride solids were filtered and dried to obtain 126.9 g of aluminum trichloride with a yield of 90%;

[0040] 2) Recycling of aluminum trichloride

[0041] In a 1L autoclave, add 100.0g (0.75mol) of aluminum trichloride prepared in 1), 134.0g (0.97mol) of phosphorus trichloride, 500ml of 1,1,2,2-tetrachloroethane, and pass chlorine Methane to 1Mpa, heat up to 80°C, react for 4 hours, cool down, filter, and dry to obtain 216.3g of white sandy solid with a yield of 90%;

[0042] 3) Preparation of polyaluminum chloride

[0043] Slowly add saturated sodium hydroxide solution dropwise to the...

Embodiment 3

[0045] 1) Decomposition of sodium tetrachloroaluminate and recovery of aluminum trichloride

[0046] Add 300ml of isopropanol and 300ml of tert-butyl ether to 200g of solid waste, heat to 90°C, filter while hot, and the filter cake is sodium chloride. The filtrate is the methanol solution of aluminum trichloride. Slowly lower the temperature and stir overnight, a large amount of white aluminum trichloride solids are precipitated, filtered and dried to obtain 119.9 g of aluminum trichloride with a yield of 86%.

[0047] 2) Recycling of aluminum trichloride

[0048] In a 1L autoclave, add 100.0g (0.75mol) of aluminum trichloride prepared in 1), 134.0g (0.97mol) of phosphorus trichloride, 500ml of 1,1,2,2-tetrachloroethane, and pass chlorine Methane was raised to 1Mpa, and the temperature was raised to 80°C. After reacting for 4 hours, the temperature was lowered, filtered, and dried to obtain 230.3g of white sandy solid, with a yield of 96%.

[0049] 3) Preparation of polyalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com