A kind of treatment method of sodium tetrachloroaluminate solid slag

A sodium tetrachloroaluminate and treatment method technology, applied in the field of inorganic chemistry, can solve problems such as difficult separation, complex process, and high cost, and achieve the effects of cost reduction, simple process flow, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

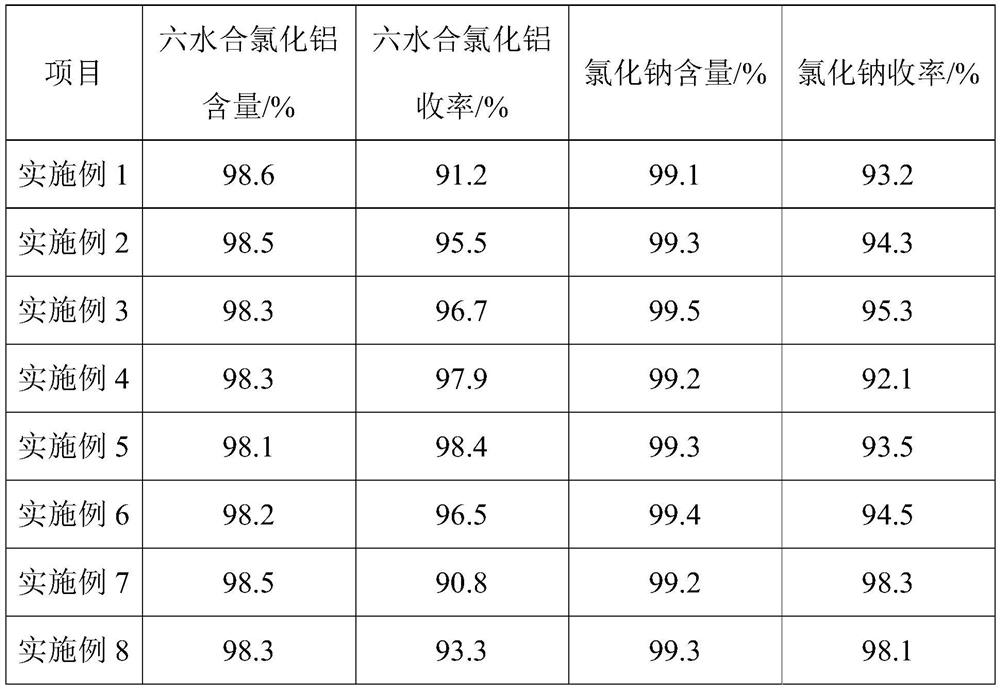

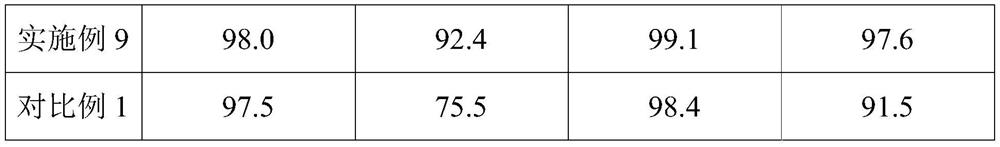

Examples

Embodiment 1

[0052] This embodiment provides a treatment method for sodium tetrachloroaluminate solid slag. The sodium tetrachloroaluminate solid slag is derived from the preparation of formazan by using methyl chloride, phosphorus trichloride, aluminum powder and aluminum trichloride as main raw materials. In the production process of phosphine dichloride, the content of sodium tetrachloroaluminate in the solid slag is 95%, and the treatment method comprises the following steps:

[0053] (1) adding 100 g of solid slag with a sodium tetrachloroaluminate content of 95% into 400 g of water for dissociation, dissociated for 1 h at 80° C., and then feeding 70 g of hydrogen chloride gas, that is, the mass ratio of solid slag and hydrogen chloride is 1: 0.7, aluminum chloride hexahydrate is separated out, and then aluminum chloride hexahydrate solid and primary filtrate are obtained through a solid-liquid separation;

[0054] Among them, 121.5g of aluminum chloride hexahydrate solid was obtained...

Embodiment 2

[0057] This embodiment provides a treatment method for sodium tetrachloroaluminate solid slag, which is the same as in Example 1, and the treatment method includes the following steps:

[0058] (1) adding 100 g of solid slag with a sodium tetrachloroaluminate content of 95% into 400 g of water for dissociation, dissociated for 1 h at 80° C., and then feeding 100 g of hydrogen chloride gas, that is, the mass ratio of solid slag and hydrogen chloride is 1: 1.0, aluminum chloride hexahydrate is precipitated, and then aluminum chloride hexahydrate solid and primary filtrate are obtained through a solid-liquid separation;

[0059] Among them, 127.6g of aluminum chloride hexahydrate solid was obtained from a solid-liquid separation, and dried at 60°C for 8 hours by vacuum drying to obtain 116.0g of aluminum chloride hexahydrate product;

[0060] (2) The primary filtrate obtained in step (1) is concentrated and crystallized under normal pressure, and sodium chloride solids are precip...

Embodiment 3

[0062] This embodiment provides a treatment method for sodium tetrachloroaluminate solid slag, which is the same as in Example 1, and the treatment method includes the following steps:

[0063] (1) adding 100 g of solid slag with a sodium tetrachloroaluminate content of 95% into 400 g of water for dissociation, dissociated for 1 h at 80° C., and then feeding 150 g of hydrogen chloride gas, that is, the mass ratio of solid slag and hydrogen chloride is 1: 1.5, aluminum chloride hexahydrate is precipitated, and then aluminum chloride hexahydrate solid and primary filtrate are obtained through a solid-liquid separation;

[0064] Among them, 131.1g of aluminum chloride hexahydrate solid was obtained from a solid-liquid separation, and dried at 60°C for 8 hours by vacuum drying to obtain 117.6g of aluminum chloride hexahydrate;

[0065] (2) The primary filtrate obtained in step (1) was concentrated and crystallized under normal pressure, and sodium chloride solids were precipitated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com