Environment-friendly refining agent, preparation method and refining process

An environmentally friendly, refining agent technology, applied in the direction of air quality improvement, etc., can solve the problems of polluted atmosphere, the impact of the final product aluminum ingot quality, low impurity removal efficiency, etc., to improve the ability to absorb impurities, shorten the refining time, improve The effect of refining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

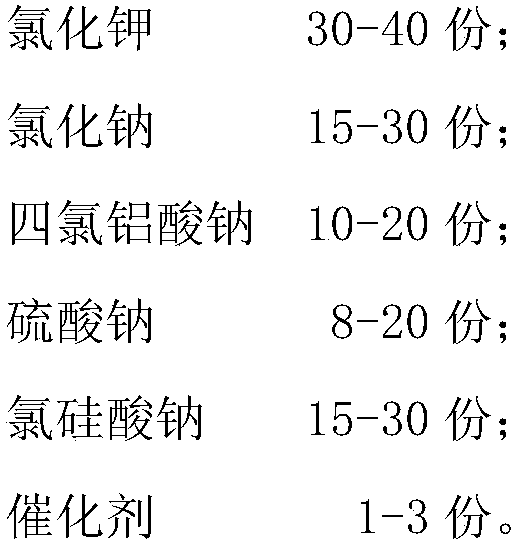

[0040] 1. The content of each component of the environment-friendly refining agent is as follows:

[0041]

[0042] In this embodiment, the catalyst is potassium alginate.

[0043] Two, the preparation method of this environment-friendly type refining agent is:

[0044] S1: Pretreatment, mix potassium chloride, sodium chlorosilicate, sodium chloride, sodium tetrachloroaluminate and sodium sulfate of the above-mentioned components, stir and heat to 250°C;

[0045] S2: Microwave treatment is performed on the catalyst, and the temperature of the microwave treatment is controlled at 170°C;

[0046] S3: After fully stirring and mixing the mixture obtained in S1 and the material obtained in S2, put it into a sintering furnace and sinter at 300-305°C;

[0047] S4: Pulverize the mixture obtained in S3 with a pulverizer, and granulate with a granulator to obtain an environment-friendly refining agent.

[0048] 3. The refining process of using this environment-friendly refining ag...

Embodiment 2

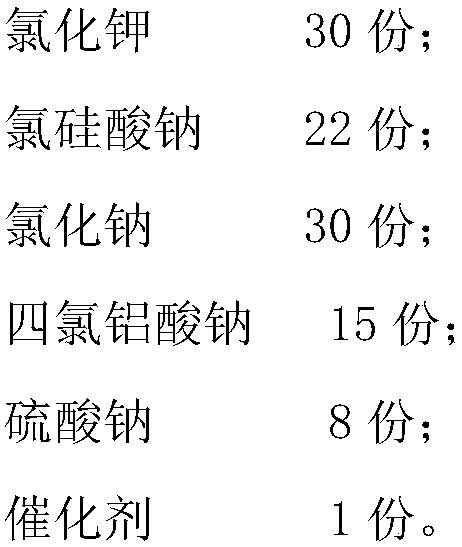

[0057] 1. The content of each component of the environment-friendly refining agent is as follows:

[0058]

[0059] In this embodiment, the catalyst is potassium alginate.

[0060] Two, the preparation method of this environment-friendly type refining agent is:

[0061] S1: Pretreatment, mix potassium chloride, sodium chlorosilicate, sodium chloride, sodium tetrachloroaluminate and sodium sulfate of the above components, stir and heat to 260°C;

[0062] S2: Microwave treatment is performed on the catalyst, and the temperature of the microwave treatment is controlled at 150°C;

[0063] S3: After fully stirring and mixing the mixture obtained in S1 and the material obtained in S2, put it into a sintering furnace and sinter at 305-310°C;

[0064] S4: Pulverize the mixture obtained in S3 with a pulverizer, and granulate with a granulator to obtain an environment-friendly refining agent.

[0065] 3. The refining process of using this environment-friendly refining agent to refin...

Embodiment 3

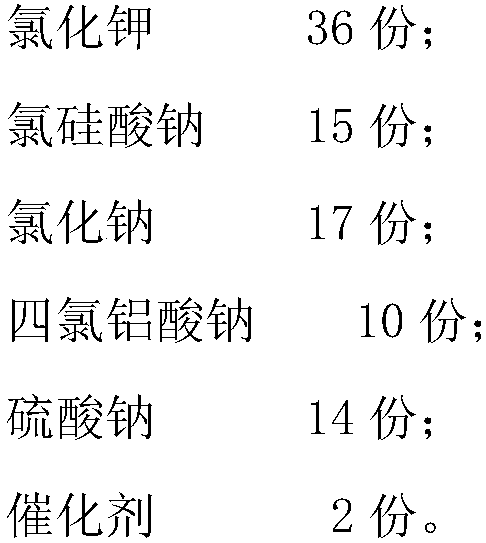

[0074] 1. The content of each component of the environment-friendly refining agent is as follows:

[0075]

[0076] In this embodiment, the catalyst is sodium alginate.

[0077] Two, the preparation method of this environment-friendly type refining agent is:

[0078] S1: Pretreatment, mix potassium chloride, sodium chlorosilicate, sodium chloride, sodium tetrachloroaluminate and sodium sulfate of the above components, stir and heat to 270°C;

[0079] S2: Microwave treatment is performed on the catalyst, and the temperature of the microwave treatment is controlled at 180°C;

[0080] S3: After fully stirring and mixing the mixture obtained in S1 and the material obtained in S2, put it into a sintering furnace and sinter at 300-310°C;

[0081] S4: Pulverize the mixture obtained in S3 with a pulverizer, and granulate with a granulator to obtain an environment-friendly refining agent.

[0082] 3. The refining process of using this environment-friendly refining agent to refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com