Preparation method of activated alumina porous adsorption material

A technology of porous adsorption material and activated alumina, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, chemical instruments and methods, alkali metal chloride, etc. Waste, environmental pollution and other problems, to achieve the effect of maximizing value, convenient operation and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

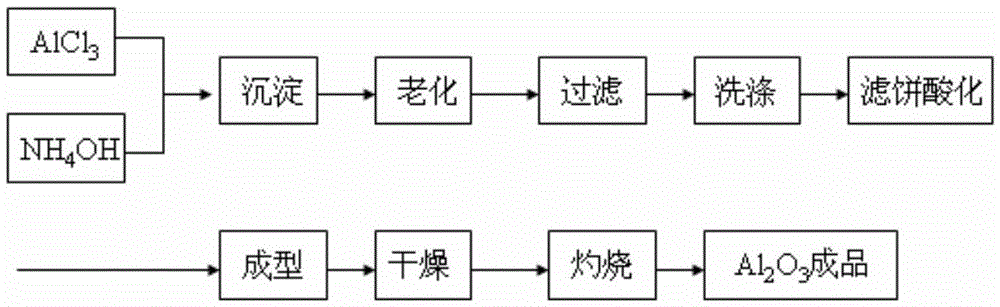

Method used

Image

Examples

Embodiment 1

[0022] (1) 19.2 g of solid sodium tetrachloroaluminate was dissolved and hydrolyzed with an excessive amount of ethanol aqueous solution, and insoluble sodium chloride was recovered by filtration. The reaction temperature of this process is 25°C, and at the same time, it needs to be fully stirred, and the stirring speed is 300rpm;

[0023] (2) adding an appropriate amount of water to the resulting ethanol solution to generate aluminum chloride hexahydrate insoluble in ethanol;

[0024] (3) Aluminum trichloride hexahydrate reacts with ammonia water to form a hydrated alumina suspension: age the suspension in the range of pH = 8.0 for 2.5 hours to make it into α-gibbsite, and then wash until there is no chloride ion.

[0025] (4) Dissolve α-diaspore with acid peptization into a sol with better fluidity, drop it into the oil ammonia column by dropwise addition, shrink into balls in the oil under the action of surface tension, then enter the ammonia water, and neutralize After ag...

Embodiment 2

[0029] (1) 19.2 g of solid sodium tetrachloroaluminate was dissolved and hydrolyzed with an excessive amount of ethanol aqueous solution, and insoluble sodium chloride was recovered by filtration. The reaction temperature of this process is 35°C, and at the same time, it needs to be fully stirred, and the stirring speed is 400rpm;

[0030] (2) adding an appropriate amount of water to the resulting ethanol solution to generate aluminum chloride hexahydrate insoluble in ethanol;

[0031] (3) Reaction of aluminum trichloride hexahydrate and ammonia water to form a hydrated alumina suspension: aging the suspension in the range of pH=8.5 for 3 hours to make it into α-gibbsite, and then washing until there is no chloride ion.

[0032] (4) Dissolve α-diaspore with acid peptization into a sol with better fluidity, drop it into the oil ammonia column by dropwise addition, shrink into balls in the oil under the action of surface tension, then enter the ammonia water, and neutralize Aft...

Embodiment 3

[0036] (1) 19.2 g of solid sodium tetrachloroaluminate was dissolved and hydrolyzed with an excessive amount of ethanol aqueous solution, and insoluble sodium chloride was recovered by filtration. The reaction temperature of this process is 45°C, and at the same time, it needs to be fully stirred, and the stirring speed is 500rpm;

[0037] (2) adding an appropriate amount of water to the resulting ethanol solution to generate aluminum chloride hexahydrate insoluble in ethanol;

[0038] (3) Aluminum trichloride hexahydrate reacts with ammonia water to form a hydrated alumina suspension: the suspension is aged in the range of pH=9.0 for 5 hours to make it into α-gibbsite, and then washed until there is no chloride ion.

[0039] (4) Dissolve α-diaspore with acid peptization into a sol with better fluidity, drop it into the oil ammonia column by dropwise addition, shrink into balls in the oil under the action of surface tension, then enter the ammonia water, and neutralize After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com