A kind of heterogeneous fenton-like catalyst and preparation method thereof and application in degrading phenol-containing wastewater

A technology for catalyst and phenol wastewater, which is applied in the application field of heterogeneous Fenton-like catalyst and its preparation and degradation of phenol-containing wastewater, can solve the problems of high cost of other treatment methods, unbearable for enterprises, poisoning, etc., and achieves increased overflow , Improve the removal rate, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for a heterogeneous Fenton-like catalyst, comprising the following steps:

[0032] (1) Dissolving and hydrolyzing the solid sodium tetrachloroaluminate with excess ethanol aqueous solution, filtering out insoluble sodium chloride, and obtaining filtrate A;

[0033] (2) Filtrate A is filtered by a ceramic membrane with a pore size of 50 nm, further purified, and impurities such as potassium, sodium, and zinc are removed, and the liquid B is obtained.

[0034] (3) Add deionized water to liquid B first, and then add ammonia water, so that the ratio of substances is: n(Al):n(H 2 O): n(OH -)=1:90:0.6, hydrolyzed at 20°C for 3 hours to obtain liquid C; liquid C is a clear and transparent high-quality pseudo-boehmite sol. During the catalyst preparation process, after the sol is made, let the newly formed sol stand for a period of time for aging. The aging time is 2 hours, and the pH is controlled at about 7 during aging. Aging is conducive to the format...

Embodiment 2

[0042] A kind of preparation method of heterogeneous Fenton catalyst, is characterized in that: comprise the following steps:

[0043] (1) Dissolving and hydrolyzing the solid sodium tetrachloroaluminate with excess ethanol aqueous solution, filtering out insoluble sodium chloride, and obtaining filtrate A;

[0044] (2) Filtrate A is filtered by a ceramic membrane with a pore size of 100nm to obtain liquid B;

[0045] (3) Add deionized water to liquid B first, then add ammonia water, so that the ratio of substances is: n(Al):n(H2O):n(OH - )=1:105:0.9, hydrolyze at 90°C for 4 hours to obtain liquid C, preferably let the newly formed liquid C stand for a period of time for aging.

[0046] (4) Add urea to liquid C and stir for 1.3 hours, then heat liquid C to 750°C, cool to room temperature, add saturated ferrous sulfate aqueous solution to liquid C, and stir for 30 minutes to obtain a coating slurry;

[0047] (5) Immerse the cordierite honeycomb ceramic carrier in the coating ...

Embodiment 3

[0052] A kind of preparation method of heterogeneous Fenton catalyst, is characterized in that: comprise the following steps:

[0053] (1) Dissolving and hydrolyzing the solid sodium tetrachloroaluminate with excess ethanol aqueous solution, filtering out insoluble sodium chloride, and obtaining filtrate A;

[0054] (2) Filtrate A is filtered by a ceramic membrane with a pore size of 85nm to obtain liquid B;

[0055] (3) Add deionized water to liquid B first, then add ammonia water, so that the ratio of substances is: n(Al):n(H2O):n(OH - )=1:100:0.8, hydrolyzed at 50°C for 3.5h to obtain liquid C;

[0056] (4) Add urea to liquid C and stir for 2 hours, then heat liquid C to 900°C, cool to room temperature, add saturated ferrous sulfate aqueous solution to liquid C, and stir for 20 minutes to obtain a coating slurry;

[0057] (5) Immerse the cordierite honeycomb ceramic carrier in the coating slurry for 3 minutes for surface coating, and after taking it out, blow out the excess...

PUM

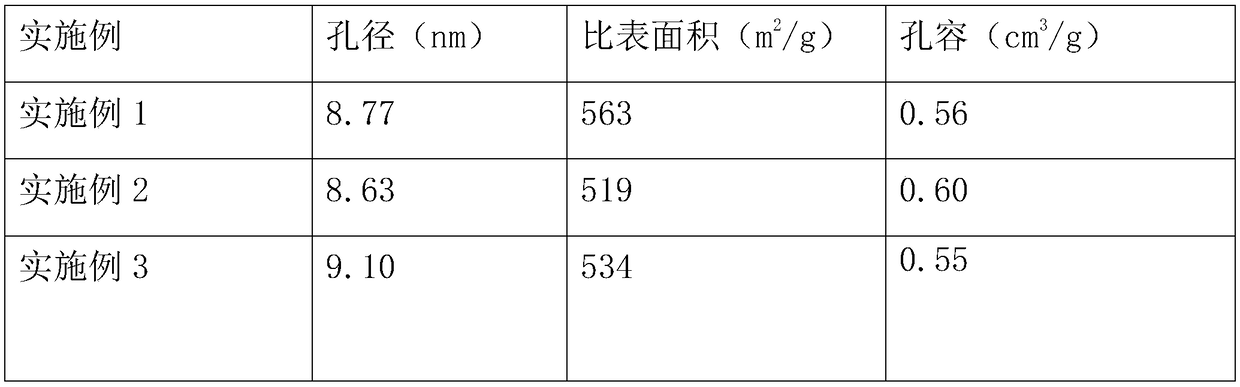

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com