A kind of recovery processing method of sodium tetrachloroaluminate catalyst composition

A sodium tetrachloroaluminate, recovery and treatment technology, applied in the direction of phosphorus compounds, alkali metal chlorides, chemical instruments and methods, etc., can solve the problems of high treatment cost, long process, complicated treatment process, etc., and achieve the goal of avoiding organic impurities The effect of bringing in, large market capacity, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

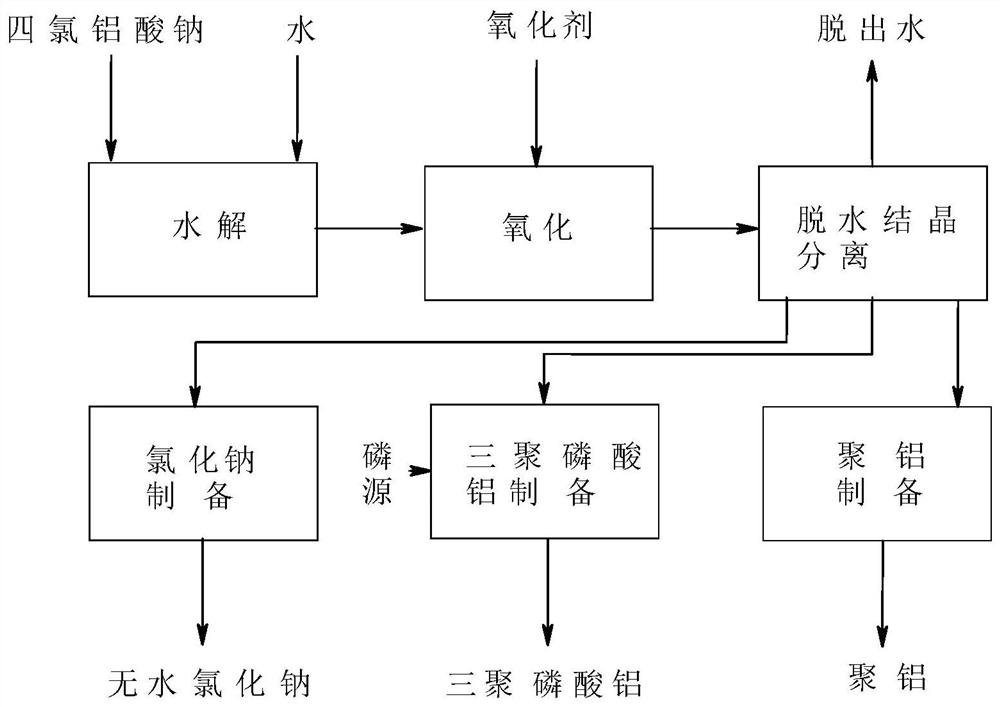

Method used

Image

Examples

Embodiment 1

[0031] A kind of recycling treatment method of sodium tetrachloroaluminate catalyst composition, comprises the following steps:

[0032] (1) Add 1200ml of water into the glass bottle, add 300g of sodium tetrachloroaluminate into the water under vigorous stirring, the water temperature rises to 95°C, continue the reaction for 0.5 hours after the addition, and cool down after the reaction;

[0033] (2) The temperature was controlled at 40°C, 6g of 27.5% hydrogen peroxide was added dropwise, and the reaction was carried out at 40-50°C for 4 hours to obtain 1505.2g of the reaction-finished product;

[0034] (3) Distill the product at the end of the reaction, distill at -0.09MPa at 60°C for 10h for dehydration, remove 500g of water, cool down to 20°C at the end of the distillation, suction filter and wash after 3 hours of crystallization to obtain 67g of sodium chloride wet base, a filtrate 938.2g;

[0035] Distill 938.2g of filtrate once, distill at -0.09MPa at 60°C for 4h to deh...

Embodiment 2

[0041] A kind of recycling treatment method of sodium tetrachloroaluminate catalyst composition, comprises the following steps:

[0042] (1) Add 1200ml of water into the glass bottle, add 300g of sodium tetrachloroaluminate into the water under vigorous stirring, the water temperature rises to 95°C, continue the reaction for 0.5 hours after the addition, and cool down after the reaction;

[0043] (2) The temperature is controlled at 30°C, 18.6g of ozone with a concentration of 10% is introduced, and the reaction is carried out at 20-35°C for 6 hours to obtain 1500g of the reaction-finished product;

[0044] (3) Distill the product at the end of the reaction, distill at -0.09MPa at 60°C for 10h for dehydration, remove 500g of water, cool down to 20°C at the end of the distillation, suction filter and wash after 3 hours of crystallization to obtain 67g of sodium chloride wet base, a filtrate 933g;

[0045] Distill 933g of filtrate once, distill at -0.09MPa at 60°C for 4h to deh...

Embodiment 3

[0051] A kind of recycling treatment method of sodium tetrachloroaluminate catalyst composition, comprises the following steps:

[0052] (1) Add 1200ml of water into the glass bottle, add 300g of sodium tetrachloroaluminate into the water under vigorous stirring, the water temperature rises to 95°C, continue the reaction for 0.5 hours after the addition, and cool down after the reaction;

[0053] (2) The temperature is controlled at 40°C, 18.6g of ozone with a concentration of 10% is introduced, and the reaction is carried out at 20-35°C for 6 hours to obtain 1500g of the reaction-finished product;

[0054] (3) Distill the product at the end of the reaction, distill at -0.09MPa at 60°C for 10h for dehydration, remove 500g of water, cool down to 20°C at the end of the distillation, suction filter and wash after 3 hours of crystallization to obtain 67g of sodium chloride wet base, a filtrate 933g;

[0055] Distill 933g of filtrate once, distill at -0.09MPa at 60°C for 4h to deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com