Method for preparing aluminum polychlorid from byproduct generated in methyl diethyl phosphate production

A technology of diethyl methyl phosphite and polyaluminum chloride, applied in the direction of aluminum chloride, chemical instruments and methods, aluminum halide, etc., to achieve the effects of reducing acid consumption, high basicity, and reducing the formation of aluminum sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

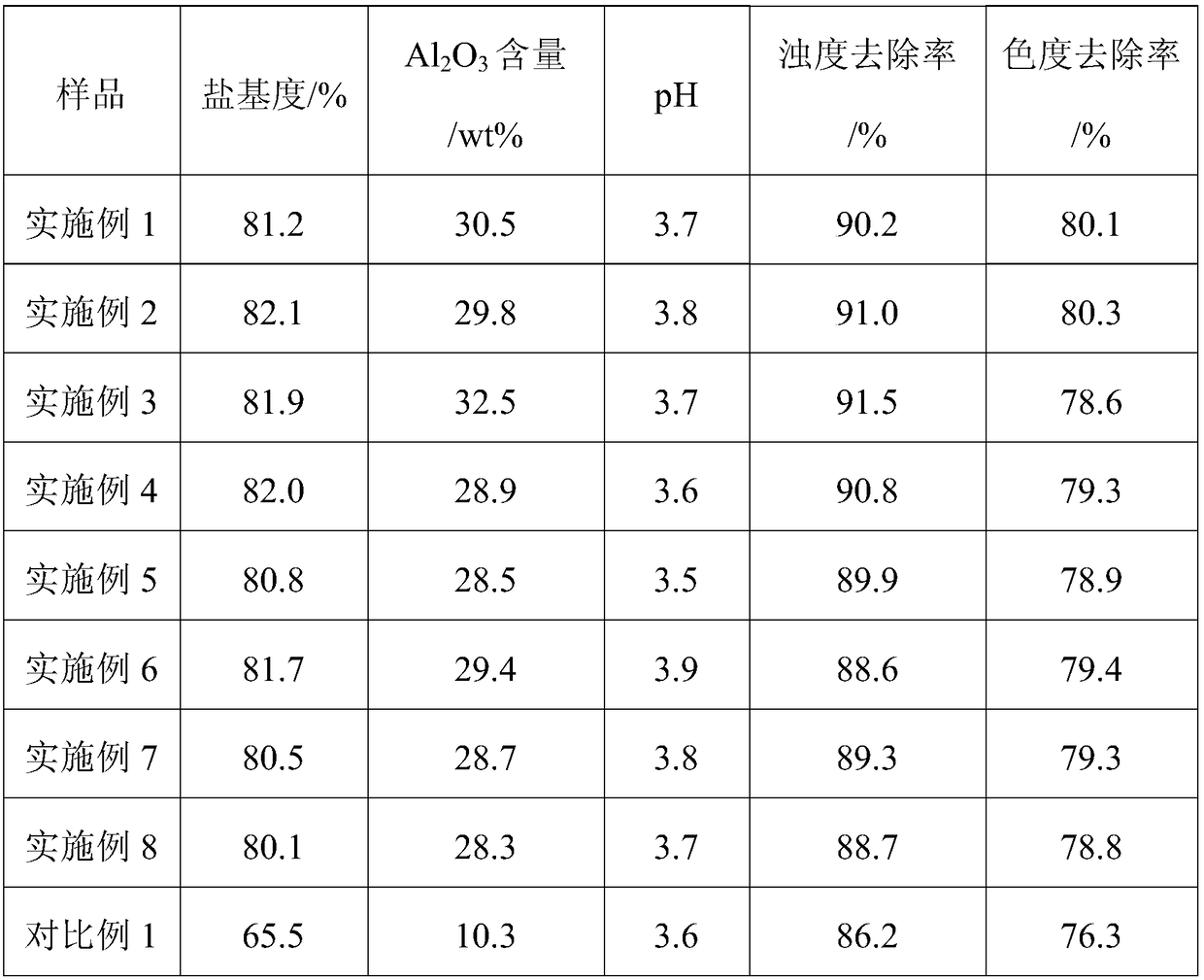

Examples

Embodiment 1

[0052] A kind of method that utilizes methyl diethyl phosphite to produce by-product to prepare polyaluminum chloride comprises the steps:

[0053] (1) Add 200 g of the by-product solid residue into 1000 mL of methanol, analyze at 50 ° C, filter while hot to remove the precipitated sodium chloride, and collect the solution;

[0054] (2) add 40g water in the solution and cool to make aluminum chloride hydrate crystallize and separate out, filter to obtain aluminum chloride hydrate, and filtrate is reused as solvent;

[0055] (3) Dissolve aluminum chloride hydrate in water so that the concentration of aluminum chloride is 60g / L, then add calcium aluminate powder in 5 times for hydrolysis polymerization reaction, control the reaction temperature at 50°C, when the pH value of the solution is 3.7 , aged at 50°C for 4h, and finally dried to obtain polyaluminum chloride.

Embodiment 2

[0057] A kind of method that utilizes methyl diethyl phosphite to produce by-product to prepare polyaluminum chloride comprises the steps:

[0058] (1) Add 200 g of the by-product solid residue into 800 mL of ethanol, analyze at 70° C., filter while hot to remove the precipitated sodium chloride, and collect the solution;

[0059] (2) add 80g water in the solution and cool to make aluminum chloride hydrate crystallize and separate out, filter to obtain aluminum chloride hydrate, and filtrate is reused as solvent;

[0060] (3) Dissolve aluminum chloride hydrate in water so that the concentration of aluminum chloride is 100g / L, then add calcium aluminate powder in 4 times for hydrolysis polymerization reaction, control the reaction temperature at 60°C, when the pH value of the solution is 3.9 , aged at 55°C for 3h, and finally dried to obtain polyaluminum chloride.

Embodiment 3

[0062] A kind of method that utilizes methyl diethyl phosphite to produce by-product to prepare polyaluminum chloride comprises the steps:

[0063] (1) Add 200 g of by-product solid residue into 900 mL of n-butanol, analyze at 100 ° C, filter while hot to remove the precipitated sodium chloride, and collect the solution;

[0064] (2) add 70g water in the solution and cool to make aluminum chloride hydrate crystallize and separate out, filter to obtain aluminum chloride hydrate, and filtrate is reused as solvent;

[0065] (3) Dissolve aluminum chloride hydrate in water so that the concentration of aluminum chloride is 90g / L, then add calcium aluminate powder in 2 times for hydrolysis polymerization reaction, control the reaction temperature at 80°C, when the pH value of the solution is 3.8 , aged at 65°C for 1h, and finally dried to obtain polyaluminum chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com