Household Garbage Disposal System

A domestic waste and treatment system technology, which is applied in the field of waste-derived fuel domestic waste treatment system, can solve the problems that odor and dust cannot be collected and disposed reasonably, and domestic waste is difficult to handle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

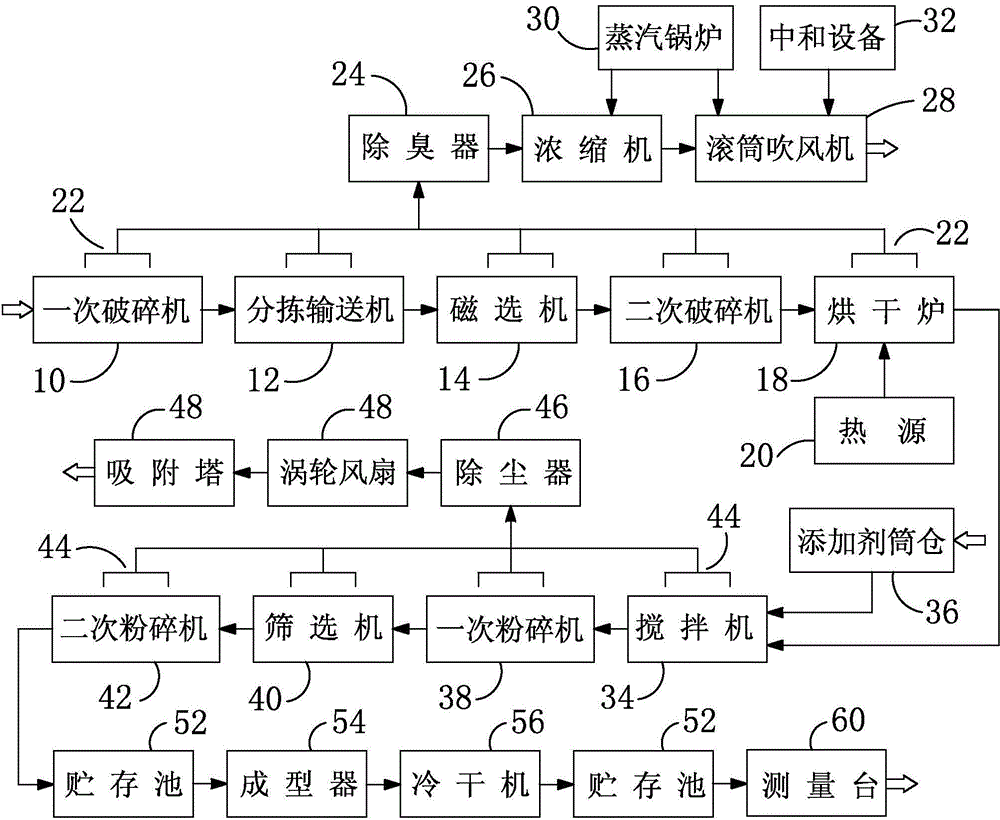

[0052] The present invention is the same as the positioning of domestic garbage mentioned by other existing technologies. That is, household waste is generally composed of organic waste such as food waste, sewage residue, and animal excrement, and inorganic waste such as paper, resin, metal, and glass. As we all know, there are many ways to deal with this domestic waste, but from the perspective of resource reuse, the method of using domestic waste to produce combustible waste-derived fuel is also well received. The present invention aims to provide a domestic waste treatment system for producing waste-derived fuel from domestic waste.

[0053] Therefore, the treatment object of the present invention is the same as mentioned above, which is domestic waste composed of organic waste such as food waste, sewer residue, animal manure, and inorganic waste such as paper, metal or glass.

[0054] The technical process of the domestic waste treatment system of the present invention is...

Embodiment 2

[0089] A domestic waste treatment system, which utilizes domestic waste composed of food waste, sewer residues, animal manure and other organic wastes and paper, metal or glass and other inorganic wastes to produce useful waste-derived fuels, characterized in that the domestic waste The processing equipment of the processing system includes:

[0090] A primary crusher 10 for crushing collected domestic waste into broken objects;

[0091] Installed under the primary crusher, the sorting conveyor 12 manually sorts large pieces of glass, stones and other non-combustible substances from the broken objects;

[0092] Installed under the sorting conveyor 12, a magnetic separator 14 for sorting magnetic substances from broken objects;

[0093] Installed below the magnetic separator 14, the secondary crusher 16 that breaks the broken objects of domestic garbage into small pieces again;

[0094] Installed below the secondary crusher 16, a drying furnace 18 for drying the small pieces ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com