Method for preparing high-purity calcium fluoride product from acid fluoride-containing wastewater

A technology for calcium fluoride and wastewater, applied in chemical instruments and methods, water treatment parameter control, calcium/strontium/barium fluoride, etc., can solve problems such as difficult large-scale application, complicated process, and high treatment cost, and achieve good results Economic and environmental benefits, good application prospects, and good solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

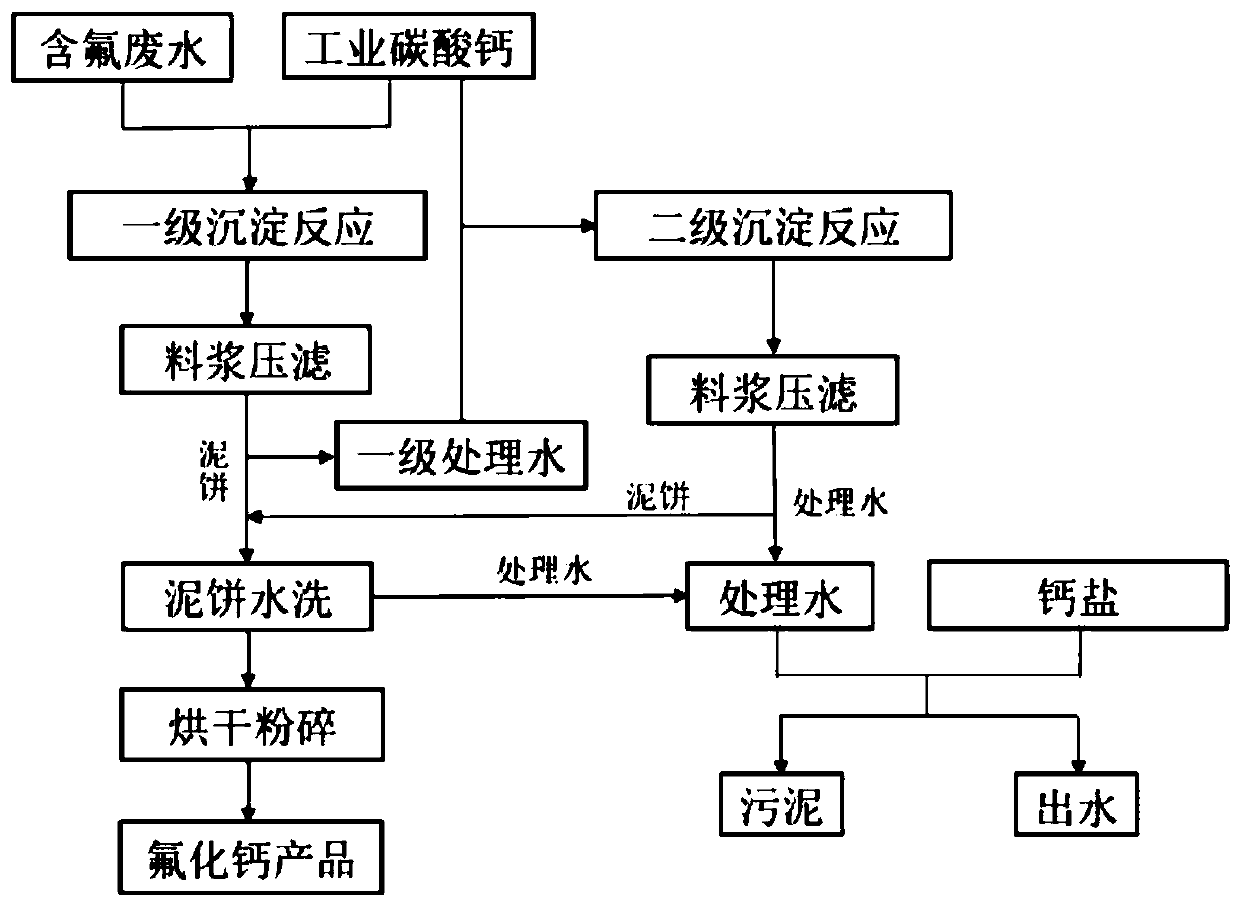

[0027] The method of the invention is used to treat the fluorine-containing waste water discharged in the production process of a certain photovoltaic industry. The specific processing steps are as figure 1 Shown:

[0028] (1) Primary precipitation reaction: add acidic fluorine-containing wastewater with a pH value of 2 to 3 and industrial calcium carbonate into the primary precipitation reaction kettle, the molar ratio of calcium to fluorine is 1:1, control the reaction pH to 5 to 6, and stir After 2 hours of reaction, press filter the mud, collect the first-level mud cake into the mud cake storage tank, and carry out the second precipitation reaction with the first-level treated water;

[0029] (2) Secondary precipitation reaction: add the primary treated water and industrial calcium carbonate obtained from the primary precipitation reaction to the secondary precipitation reaction kettle, the molar ratio of calcium to fluorine is 1:1, the pH of the reaction is controlled to...

Embodiment 2

[0039] Using the method of the present invention to treat fluorine-containing wastewater discharged during the production process of a certain photovoltaic industry, the specific treatment steps are as follows:

[0040] (1) Primary precipitation reaction: add acidic fluorine-containing wastewater with a pH value of 1 to 2 and industrial calcium carbonate into a primary precipitation reaction kettle, the molar ratio of calcium to fluorine is 1.2:1, control the reaction pH to 5 to 6, and stir the reaction After 1 hour, press filter the mud, collect the first-level mud cake into the mud cake storage tank, and carry out the second precipitation reaction with the first-level treated water;

[0041] (2) Secondary precipitation reaction: Add the primary treated water and industrial calcium carbonate obtained from the primary precipitation reaction into the secondary precipitation reaction kettle, the molar ratio of calcium to fluorine is 1.2:1, the pH of the reaction is controlled to ...

Embodiment 3

[0051] Using the method of the present invention to treat fluorine-containing wastewater discharged during the production process of a certain photovoltaic industry, the specific treatment steps are as follows:

[0052] (1) Primary precipitation reaction: add acidic fluorine-containing wastewater with a pH value of 1 to 2 and industrial calcium carbonate into a primary precipitation reaction kettle, the molar ratio of calcium to fluorine is 1.2:1, control the reaction pH to 5 to 6, and stir the reaction After 1 hour, press filter the mud, collect the first-level mud cake into the mud cake storage tank, and carry out the second precipitation reaction with the first-level treated water;

[0053] (2) Secondary precipitation reaction: Add the primary treated water and industrial calcium carbonate obtained from the primary precipitation reaction to the secondary precipitation reaction kettle, the molar ratio of calcium to fluorine is 1:1, the pH of the reaction is controlled to be 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com