Multifunctional liquid biological fertilizer and production method therefor

A production method and microbial fertilizer technology, applied in the direction of organic fertilizers, can solve the problems of affecting the survival of microorganisms, bacterial colonization, heavy resource consumption, etc., and achieve the effects of reducing environmental pollution, improving nutritional conditions, and reducing morbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

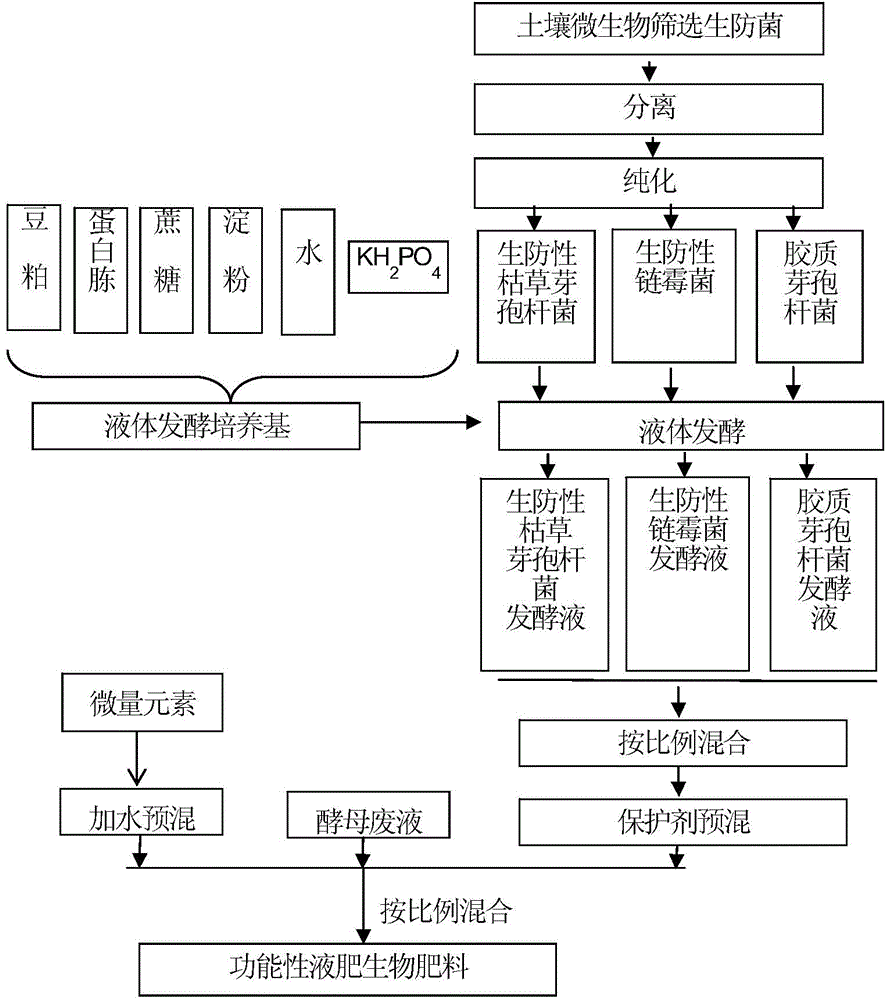

Method used

Image

Examples

Embodiment 1

[0048] 1. Compound microbial bacterial liquid: the formula of the strain fermentation medium is 40% of yeast waste liquid, 3% of bacterial liquid, and inorganic nutrients. Bacillus subtilis fermentation broth: Streptomyces fermentation broth: jelly-like Bacillus fermentation broth is mixed according to the ratio of 3:2:2, and the effective number of viable bacteria in the composite microbial broth is 5.2×10 9 individual / ml.

[0049] The fermentation process of the Bacillus subtilis and Bacillus peptiformis is as follows: inoculate the seed tank with 1-2% inoculation amount, and inoculate the fermentation liquid in the seed tank to the fermenter with 3-5% inoculum amount; Culture conditions: culture at 28±1°C for 24-48 hours, ventilation rate 1:0.5-1:1.6, anti-foaming agent vegetable oil 0.8% or silicone oil 0.04%, stirring speed 200-400rpm; after 24 hours, the bacterial liquid The bacterial count by plate counting is greater than or equal to 70-110×10 8 cfu / mL;

[0050] Str...

Embodiment 2

[0059] 1. Compound microbial bacterial liquid: the formula of the strain fermentation medium is 40% of yeast waste liquid, 3% of bacterial liquid, and inorganic nutrients. Bacillus subtilis fermentation broth: Streptomyces fermentation broth: jelly-like Bacillus fermentation broth is mixed according to the ratio of 3:1:3.5, and the effective number of viable bacteria in the composite microbial broth is 5.5×10 9 individual / ml.

[0060] Fermentation condition is the same as embodiment one. C / N is 2:1.

[0061] 2. Raw material formula: see Table 5. Trace elements and protective agent are the same as example one.

[0062] Table 5 Liquid compound microbial fertilizer raw material addition formula

[0063]

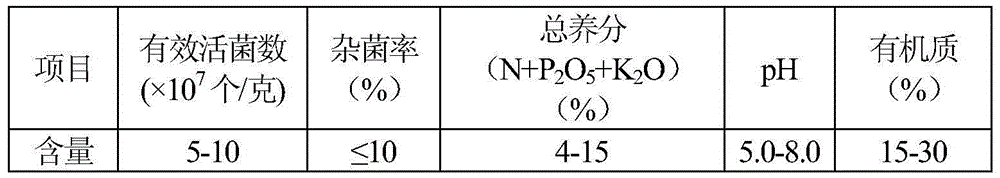

[0064] 3. Mixing and compounding: the same as Example 1. The technical indicators of the liquid compound microbial fertilizer are shown in Table 6.

[0065] Table 6 Technical indicators of liquid compound microbial fertilizer

[0066]

[0067] 4. Sub-loading into wa...

Embodiment 3

[0069] 1. Compound microbial bacterial liquid: the formula of the strain fermentation medium is 40% of yeast waste liquid, 3% of bacterial liquid, and inorganic nutrients. Bacillus subtilis fermentation broth: Streptomyces fermentation broth: jelly-like Bacillus fermentation broth is mixed according to the ratio of 3:2:2, and the effective number of viable bacteria in the composite microbial broth is 5.8×10 9 individual / ml.

[0070] The fermentation process of the Bacillus subtilis and Bacillus peptiformis is as follows: inoculate the seed tank with 2% inoculation amount, and inoculate the fermentation liquid in the seed tank with 3-5% inoculum amount to the fermenter; the culture conditions of the seed tank and the fermenter : Cultivate at 28±1°C for 24-48 hours, the ventilation rate is 1:0.5-1:1.6, the defoamer uses vegetable oil 1% or silicone oil 0.04%, the stirring speed is 200-400rpm; after 24 hours, pass the bacterial liquid through the plate Count the amount of bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com