Treatment method of sodium tetrachloroaluminate generated in production process of methyl dichlorophosphine

A technology of sodium tetrachloroaluminate and methyl dichlorophosphine, applied in aluminum chloride, chemical instruments and methods, aluminum halide, etc., can solve the problems of high cost, inability to completely remove organic phosphine-containing substances, complicated processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

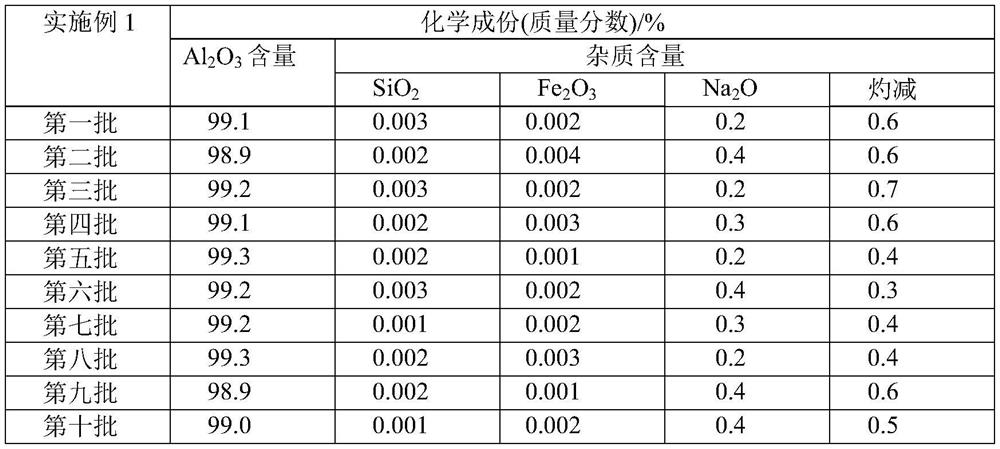

Embodiment 1

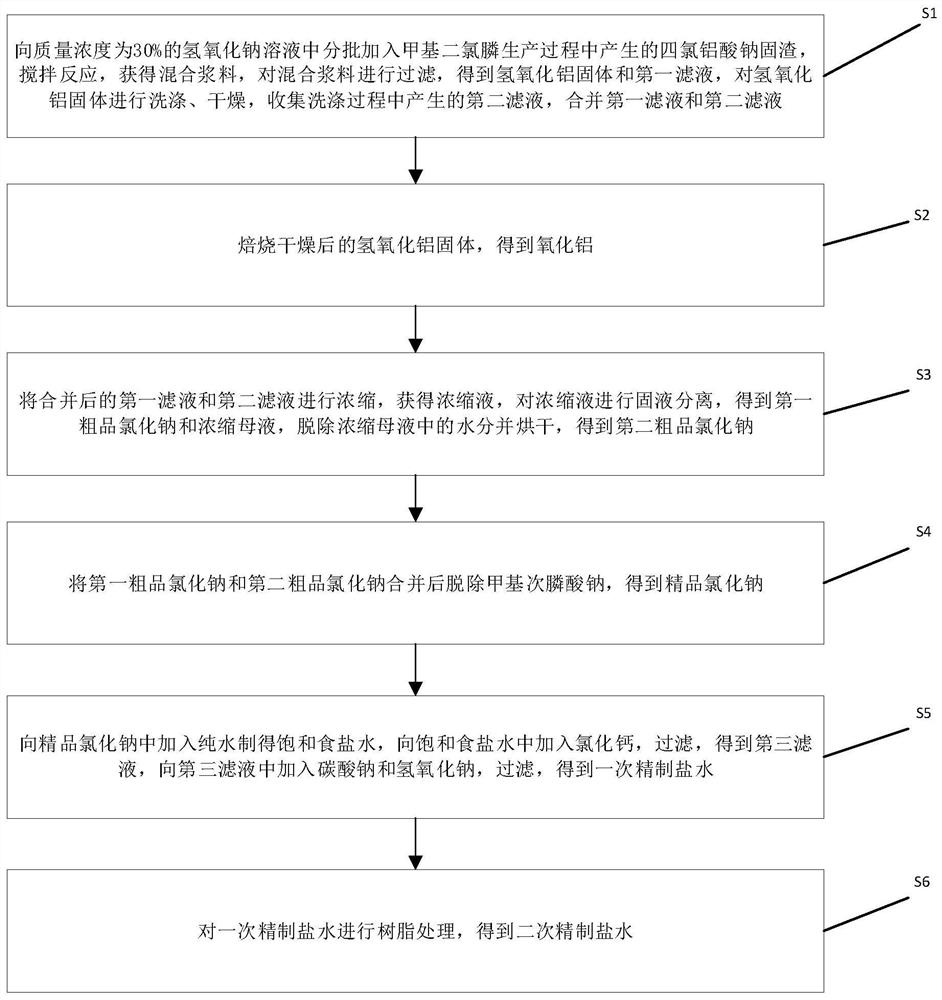

[0050] refer to figure 1 , the present embodiment 1 provides a treatment method for sodium tetrachloroaluminate produced in the production process of methyl dichlorophosphine, comprising the following steps:

[0051] (1) Add a sodium hydroxide solution with a mass concentration of 30% in the reactor, feed circulating water at about 20°C into the jacket of the reactor, and put into the tetrachloroaluminic acid produced in the production process of methyl dichlorophosphine in batches Sodium solid slag, the molar ratio of sodium hydroxide to sodium tetrachloroaluminate is 2.98:1, control the opening of the circulating water and the speed of adding sodium tetrachloroaluminate solid slag to maintain the temperature in the reactor at about 60 ° C, four After adding the sodium chloroaluminate solid slag, keep stirring and reacting at room temperature for 1 hour to obtain the mixed slurry. The pH value of the mixed slurry is measured to be 7.2. Unload the material from the reaction ke...

Embodiment 2

[0071] This embodiment 2 provides a treatment method for sodium tetrachloroaluminate produced in the production process of methyl dichlorophosphine, comprising the following steps:

[0072] (1) Add a sodium hydroxide solution with a mass concentration of 25% in the reactor, feed circulating water at about 20°C into the jacket of the reactor, and put into the tetrachloroaluminic acid produced in the production process of methyl dichlorophosphine in batches Sodium solid residue, the molar ratio of sodium hydroxide to sodium tetrachloroaluminate is 3:1, control the opening of the circulating water and the speed of adding sodium tetrachloroaluminate to maintain the temperature in the reactor at about 70 ° C, four After the addition of sodium chloroaluminate, keep stirring at room temperature for 1.5 hours to obtain the mixed slurry, measure the pH value of the mixed slurry to be 7, discharge the material from the reaction kettle to the flat filter, and use the flat filter to filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com