Preparation method for tin-coated copper composite powder

A composite powder and mixed powder technology, applied in the field of powder metallurgy, can solve the problems of high powder hardness, increased pressure and mold wear, powder performance influence, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of tin-coated copper composite powder, the steps are as follows:

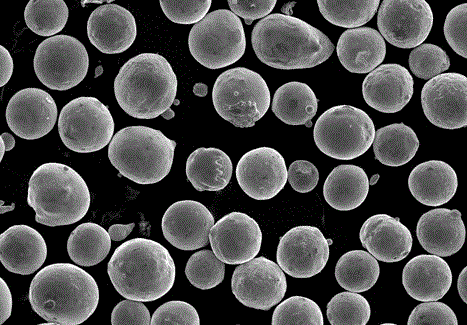

[0029] (1) Prepare powder, weigh a certain mass of copper powder and tin powder, and manually stir and pre-mix. Among them, the content of tin powder is 10%, the balance is copper powder, 0.5% of stearic acid is added, and stearic acid is added to play a lubricating effect. Copper powder is atomized copper powder, the particle size of copper powder is larger, and the particle size of tin powder is smaller. The particle size of the copper powder is -100 mesh, and the particle size of the tin powder is -300 mesh.

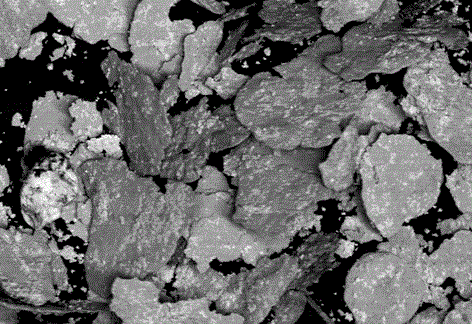

[0030] (2) Pretreatment, put the copper and tin powder weighed in step (1) into a ball mill for ball milling, and use a planetary ball mill to dry in a vacuum drying oven at 65°C for 4 hours to prepare a 'flaky' Copper-tin mixed powder, stainless steel balls are used as grinding balls, absolute ethanol is used as grinding medium, the mass ratio of grinding balls to raw mat...

Embodiment 2

[0034] (1) Prepare powder, weigh a certain mass of copper powder and tin powder, and manually stir and pre-mix. The content of tin powder is 12%, the balance is copper powder, and 0.5% stearic acid is added. Copper powder is electrolytic copper powder, the particle size of copper powder is larger, and the particle size of tin powder is smaller. The particle size of the copper powder is -100 mesh, and the particle size of the tin powder is -300 mesh.

[0035] (2) Pretreatment, put the copper and tin powder weighed in step (1) into a ball mill for ball milling, and use a rolling ball mill to dry in a vacuum drying oven at 65°C for 4 hours to prepare 'flaky' copper The tin mixed powder uses stainless steel balls as grinding balls, absolute ethanol as the grinding medium, the mass ratio of grinding balls to raw material powder is 5:1, and the ball milling time is 10 minutes. ;

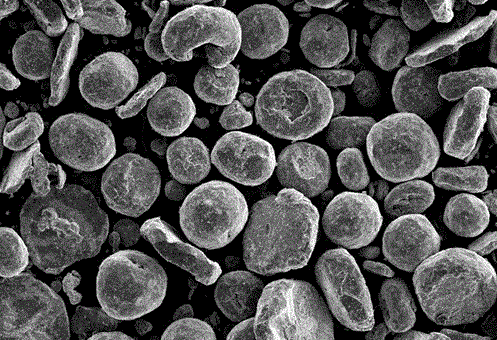

[0036] (3) Annealing, put the powder pretreated in step (2) into a tube furnace, and anneal at 220°C...

Embodiment 3

[0039] (1) Prepare powder, weigh a certain mass of copper powder and tin powder, and manually stir and pre-mix. The content of tin powder is 8%, the balance is copper powder, and 0.5% stearic acid is added.

[0040] (2) Pretreatment, put the copper and tin powder weighed in step (1) into a ball mill for ball milling, and use a high-energy ball mill to dry in a vacuum oven at 65°C for 4 hours to prepare 'flaky' copper The tin mixed powder uses stainless steel balls as grinding balls, absolute ethanol as the grinding medium, the mass ratio of grinding balls to raw material powder is 4:1, and the ball milling time is 20 minutes. ;

[0041] (3) Annealing, put the powder pretreated in step (2) into a tube furnace, and anneal at 180°C for 90 minutes in a hydrogen atmosphere;

[0042] (4) Shaping treatment, move the powder in step (3) into the spheroidizing equipment, the rotating speed is 3600r / min, the processing time is 15min, and the tin-clad copper composite powder is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com