Phase change energy storage composite microcapsule and manufacturing method thereof

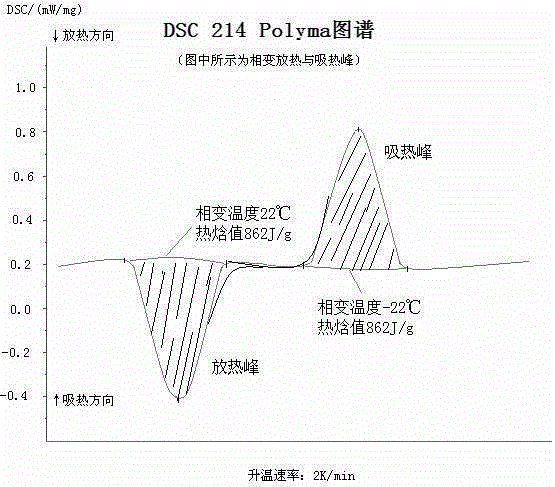

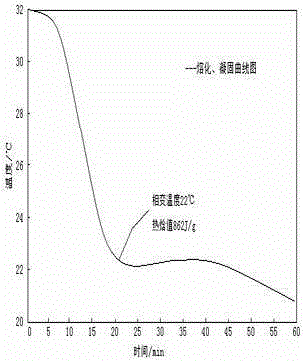

A composite microcapsule, phase change energy storage technology, applied in the field of phase change energy storage materials and their preparation, can solve the problems of phase change enthalpy decay, supercooling, non-uniform melting and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of phase-change energy storage composite microcapsule is processed according to the following steps:

[0022] (1) Weigh 500g of anhydrous calcium chloride and 500g of water to make a solution;

[0023] (2) Weigh 700g of calcium hydroxide and add it to step (1) for mixing;

[0024] (3) Weigh 50g of stearic acid and add it to step (2), add 10g of OP-10 emulsifier at the same time, emulsify and disperse, and make a slurry;

[0025] (4) Disperse the slurry obtained in step (3) in liquid paraffin, and at the same time add 700 g of ammonium carbonate and stir thoroughly to prepare phase change energy storage composite microcapsules with a particle size of 1 mm.

[0026] (5) Filter to separate excess liquid paraffin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com