Compatilizer for PP/PS extrusion molding and preparation method thereof

A technology of extrusion molding and compatibilizer, which is applied in the field of PP/PS extrusion molding compatibilizer and its preparation, can solve the problems of extrusion expansion and unfavorable processing, and achieve the improvement of elongation, increase of yield, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 150g of styrene, 50g of maleic anhydride, and 2g of DCP and mix them evenly, then add them together with 900g of PP, 25g of fumed silica, and 0.3g of antioxidant 1010 into a high-speed mixer and mix for 3 minutes, then set aside; The temperature of each heating zone of the screw extruder is: the first zone: 100°C, the second zone: 140°C, the third zone: 160°C, the fourth zone: 190°C, the fifth zone: 200°C, the sixth zone: 210°C ℃, the seventh zone: 220℃, the eighth zone: 230℃, the ninth zone: 220℃, the head temperature: 245℃; wait for the temperature to reach the set temperature and then stabilize for 30 minutes; extrude the mixture from the twin-screw Add to the feeding port of the main machine, slowly turn on the speed of the main machine to 100r / min; then turn on the feeding frequency to 4.5Hz. During the extrusion process, let the material stay in the screw area for 1.5 minutes to make it fully react. PP / PS compatibilizer 1 was obtained.

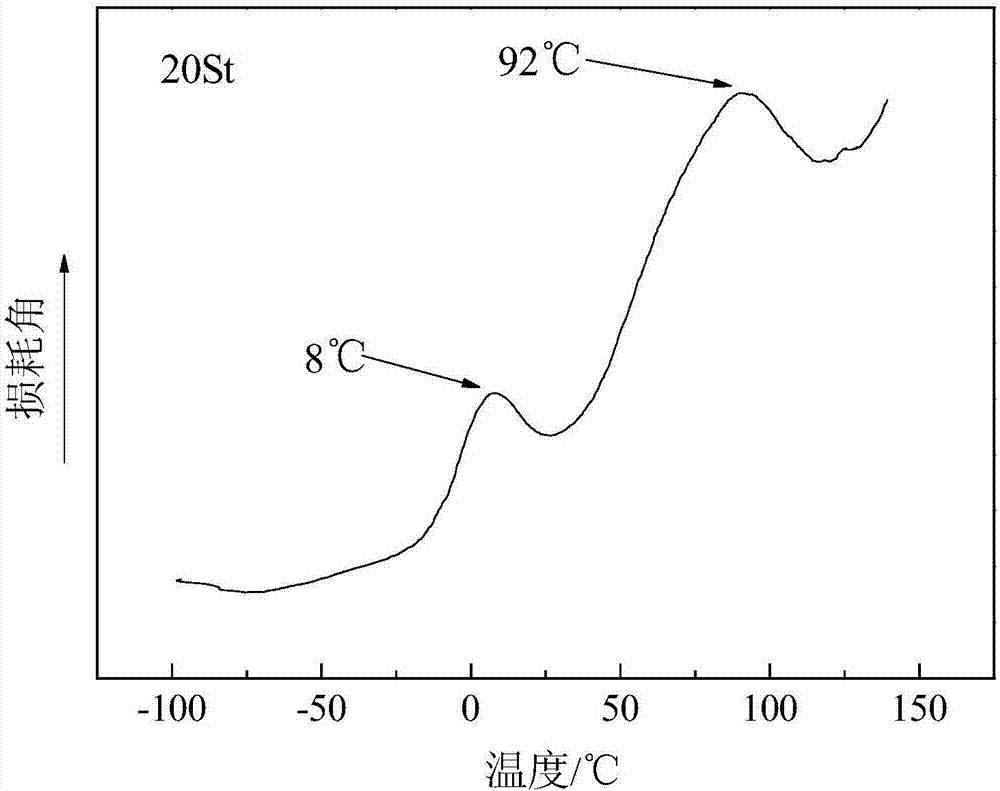

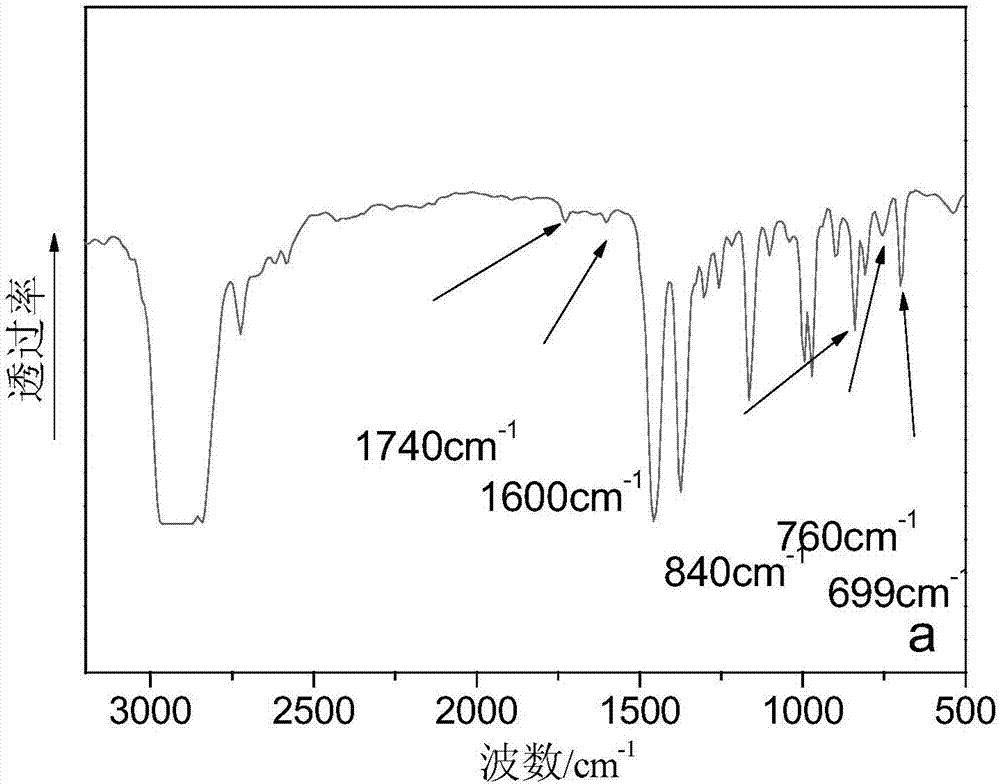

[0024] figure 1 I...

Embodiment 2

[0027] Weigh 250g of styrene, 50g of butyl acrylate, and 1.5g of DCP and mix them evenly, then add them together with 700g of PP, 50g of fumed silica, and 0.2g of antioxidant 1010 into a high-speed mixer and mix for 4 minutes, then set aside; set the twin-screw The temperature of each heating zone of the extruder is: the first zone: 100°C, the second zone: 140°C, the third zone: 160°C, the fourth zone: 190°C, the fifth zone: 200°C, the sixth zone: 210°C , the seventh zone: 220°C, the eighth zone: 230°C, the ninth zone: 220°C, the head temperature: 245°C; wait for the temperature to reach the set temperature and then stabilize for 30 minutes; put the mixture from the twin-screw extruder Add from the main feeding port, slowly turn on the speed of the main engine at 80r / min; then turn on the feeding frequency at 4.5Hz. During the extrusion process, let the material stay in the screw area for 1.8 minutes to make it fully react. PP / PS compatibilizer 2 was obtained.

Embodiment 3

[0029] Weigh 150g of styrene, 150g of butyl acrylate, and 2g of DCP and mix them evenly, then add them together with 700g of PP, 30g of molecular sieve, and 0.3g of antioxidant 1010 into a high-speed mixer and mix for 4 minutes, then set aside; set the twin-screw extruder to heat each The interval temperature is: first zone: 100°C, second zone: 140°C, third zone: 160°C, fourth zone: 190°C, fifth zone: 200°C, sixth zone: 210°C, seventh zone: 220°C, the eighth zone: 230°C, the ninth zone: 220°C, the head temperature: 245°C; wait for the temperature to reach the set temperature and then stabilize for 30 minutes; add the compound from the main feeding port of the twin-screw extruder, Slowly turn on the speed of the host machine at 80r / min; then turn on the feeding frequency at 4.5Hz. During the extrusion process, let the material stay in the screw area for 1.8 minutes to make it fully react. PP / PS compatibilizer 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com