Preparation method of isocyanate modified polyether silicone oil nonionic emulsion and product and application thereof

A technology of polyether silicone oil and isocyanate, which is applied in textiles and papermaking, fiber treatment, carbon fiber, etc. It can solve the problems of poor storage stability, unstable storage of amino-modified silicone oil, hairiness, etc., and achieve reduced surface tension and good emulsion stability. , Lubrication effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 172.48g of dried octamethylcyclotetrasiloxane and 26.70g of end-capping agent 1,1,3,3-tetramethyldisiloxane into a four-port open reaction kettle equipped with a thermometer and agitator and 3.00 g of concentrated sulfuric acid were reacted in an oil bath at 45° C. for 7 hours under the protection of nitrogen. Then add 10.20g of sodium bicarbonate to continue the reaction for 2 hours to neutralize the catalyst. After the reaction, carry out suction filtration, and place the filtrate in an oil bath at 120°C for vacuum rotary evaporation to remove unreacted substances. Terminal hydrogen silicone oil.

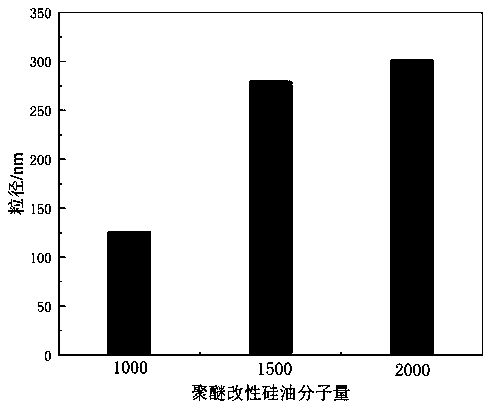

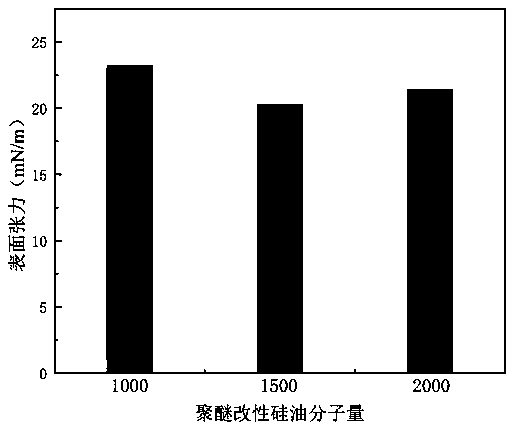

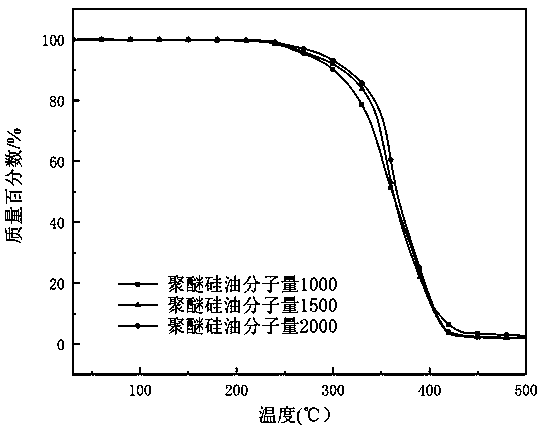

[0045] Dry the ethylene glycol monoallyl ether with anhydrous sodium sulfate for more than 7 hours, and then pour the ethylene glycol monoallyl ether into the reaction kettle. Put 1000 molecular weight double-ended hydrogen-containing silicone oil into another reaction kettle, pass nitrogen gas into the oil bath at 120°C to remove water for 2 hours, cool to 60°C, add p...

Embodiment 2

[0047] Add 180.47g of dried octamethylcyclotetrasiloxane and 17.75g of end-capping agent 1,1,3,3-tetramethyldisiloxane into a four-port open reaction kettle equipped with a thermometer and agitator and 3.00 g of concentrated sulfuric acid were reacted in an oil bath at 45° C. for 7 hours under the protection of nitrogen. Then add 10.20g of sodium bicarbonate to continue the reaction for 2 hours to neutralize the catalyst. Suction filtration is performed after the reaction, and the filtrate is placed in an oil bath at 120° C. for vacuum rotary evaporation to remove unreacted substances. Terminal hydrogen silicone oil.

[0048] Dry the ethylene glycol monoallyl ether with anhydrous sodium sulfate for more than 7 hours, and then pour the ethylene glycol monoallyl ether into the reaction kettle. Put 1500 molecular weight double-ended hydrogen-containing silicone oil into another reaction kettle, pass nitrogen gas into the oil bath at 120°C to remove water for 2 hours, cool to 60°...

Embodiment 3

[0050] Add 186.12g of dried octamethylcyclotetrasiloxane and 13.40g of end-capping agent 1,1,3,3-tetramethyldisiloxane into a four-port open reaction kettle equipped with a thermometer and agitator and 3.00 g of concentrated sulfuric acid were reacted in an oil bath at 45° C. for 7 hours under the protection of nitrogen. Then add 10.20g of sodium bicarbonate and continue to react for 2 hours to neutralize the catalyst. After the reaction, carry out suction filtration, and place the filtrate in an oil bath at 120°C for vacuum rotary evaporation to remove unreacted substances. Terminal hydrogen silicone oil.

[0051] Dry the ethylene glycol monoallyl ether with anhydrous sodium sulfate for more than 7 hours, and then pour the ethylene glycol monoallyl ether into the reaction kettle. Put 2000 molecular weight double-ended hydrogen-containing silicone oil into another reaction kettle, pass nitrogen gas into an oil bath at 120°C to remove water for 2 hours, cool to 60°C, add plati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com