System and method for treating maize straws

A corn stalk and straw technology, applied in the field of corn stalk processing system, can solve the problems of reducing biomass oil and biomass gas yield, increasing pyrolysis energy consumption, affecting the quality of biomass charcoal, etc., and achieving resource utilization , Reduce pyrolysis cost, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

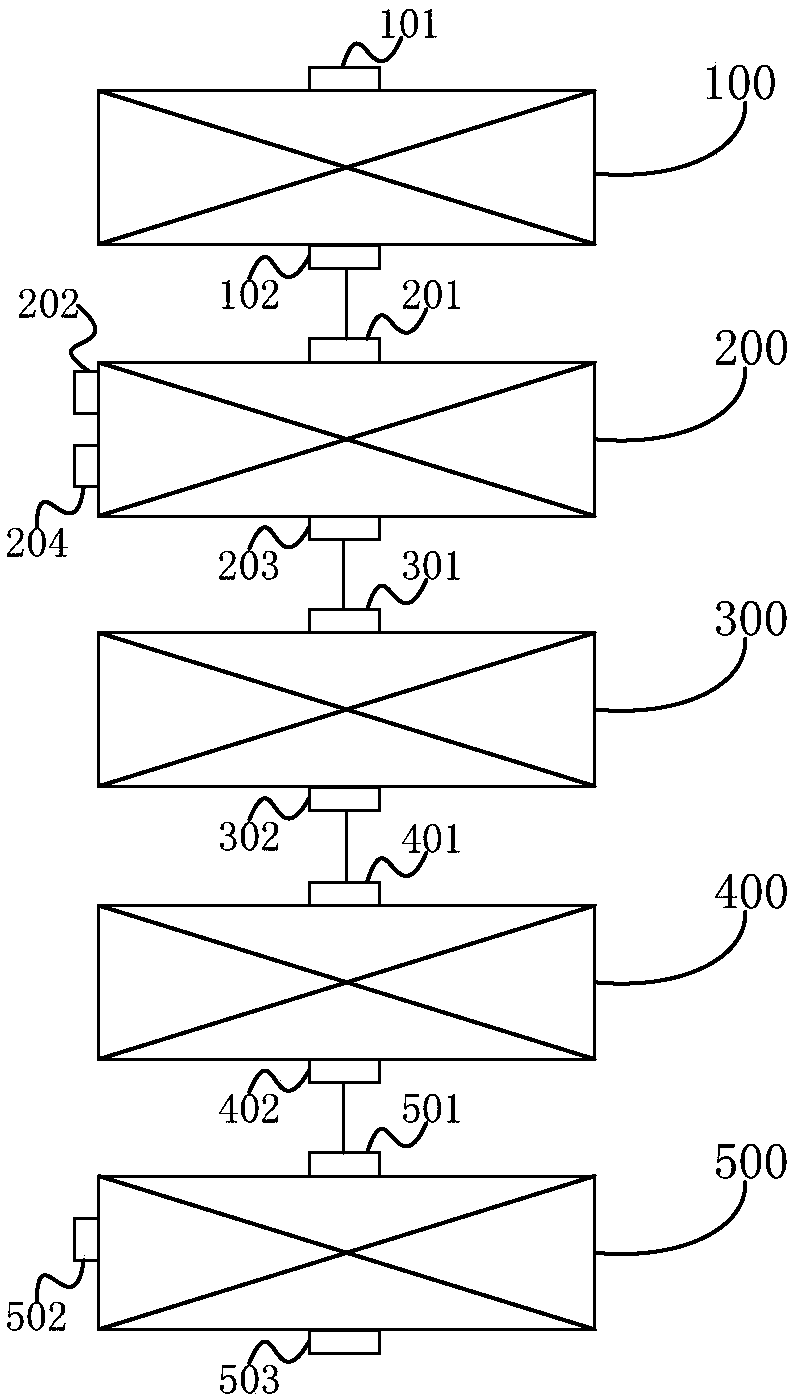

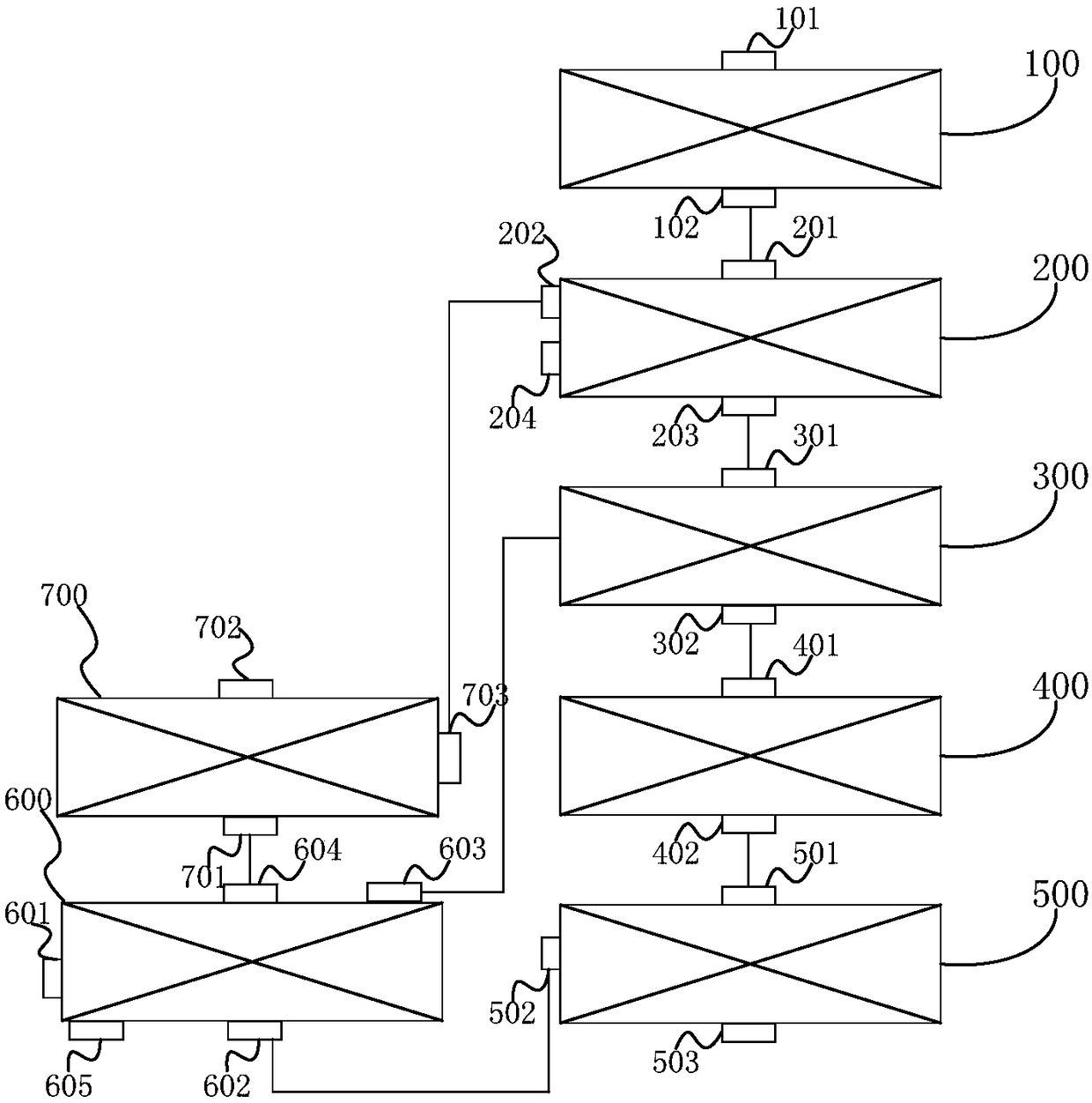

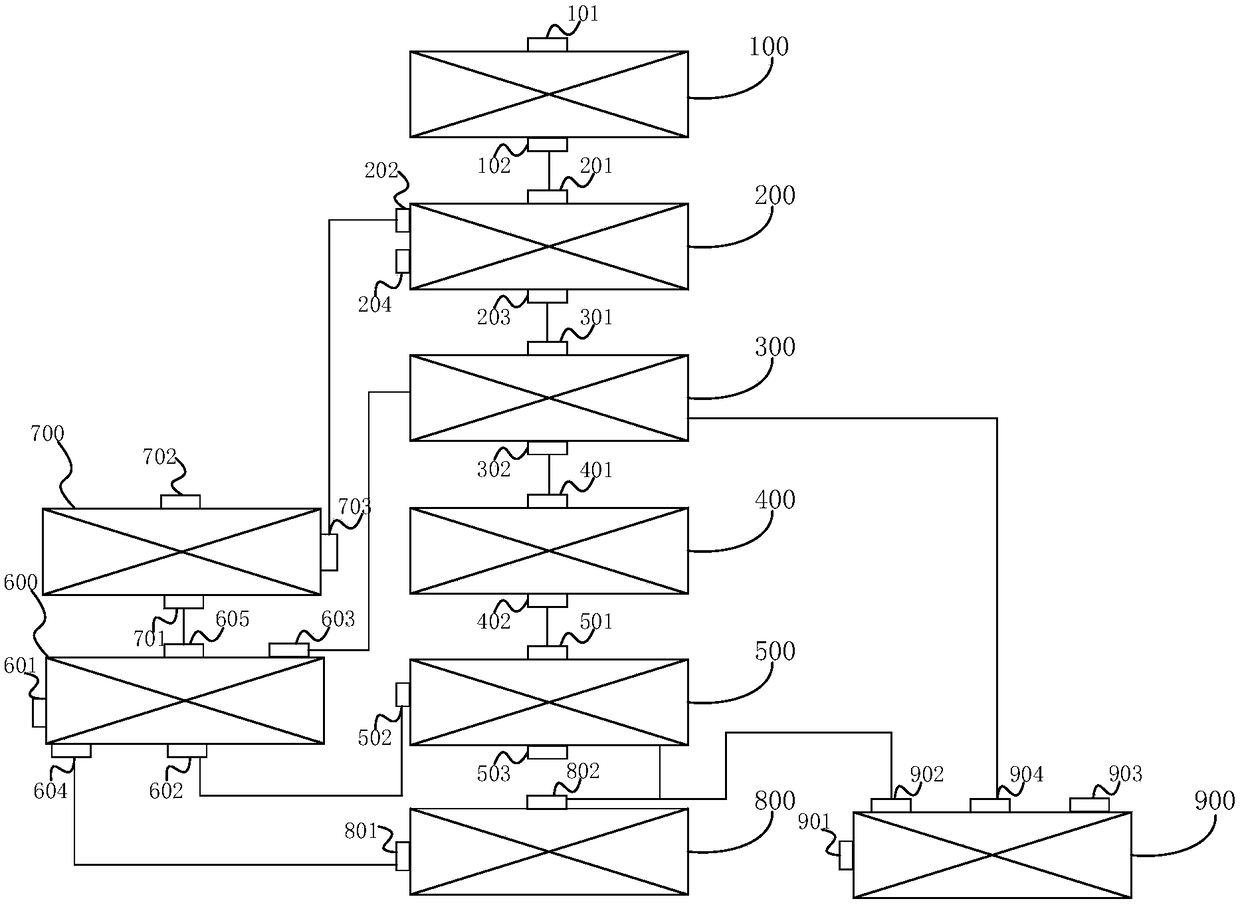

[0094] refer to Figure 9 , the corn stalks are supplied to the crusher for crushing treatment to obtain corn stalk granules (particle size greater than 8 mesh), and then the corn stalk granules are supplied to the stirring tank and mixed with wood vinegar to obtain the corn stalks after acid leaching and waste acid (Based on 1kg of corn stalk particles, the amount of wood vinegar is 15L, and the acid leaching time is 6 hours). After acid leaching, the corn stalks are supplied to the dryer for drying treatment (drying temperature is 60°C, and the drying time is not less than 20min) , to obtain dry corn stalks (moisture content lower than 40%); dry corn stalks are supplied to the granulator for briquetting to obtain briquettes of straw (the briquettes of straw are 30mm wide, 300mm high, and 40mm long, and the briquettes of straw after extrusion Block moisture content 3 ), straw briquettes are supplied to the rotary bed pyrolysis furnace for pyrolysis treatment (pyrolysis treatm...

Embodiment 2

[0096] refer to Figure 9 , the corn stalks are supplied to the crusher for crushing treatment to obtain corn stalk granules (particle size greater than 8 mesh), and then the corn stalk granules are supplied to the stirring tank and mixed with wood vinegar to obtain the corn stalks after acid leaching and waste acid (Based on 1 kg of corn stalk particles, the amount of wood vinegar is 20L, and the acid leaching time is 4 hours). After acid leaching, the corn stalks are supplied to the dryer for drying treatment (the drying temperature is 90°C, and the drying time is not less than 20 minutes) , to obtain dry corn stalks (moisture content lower than 40%); dry corn stalks are supplied to the granulator for briquetting to obtain briquettes of straw (the briquettes of straw are 30mm wide, 300mm high, and 50mm long, and the briquettes of straw after extrusion Block moisture content 3 ), straw briquettes are supplied to the rotary bed pyrolysis furnace for pyrolysis treatment (pyroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com