Improved structure of circuit anti-interference device

An anti-interference device and circuit technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as cracks, affect the accuracy of the test, and do not meet the economic cost efficiency, achieve proper design, and improve the pass rate. , the effect of saving material and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

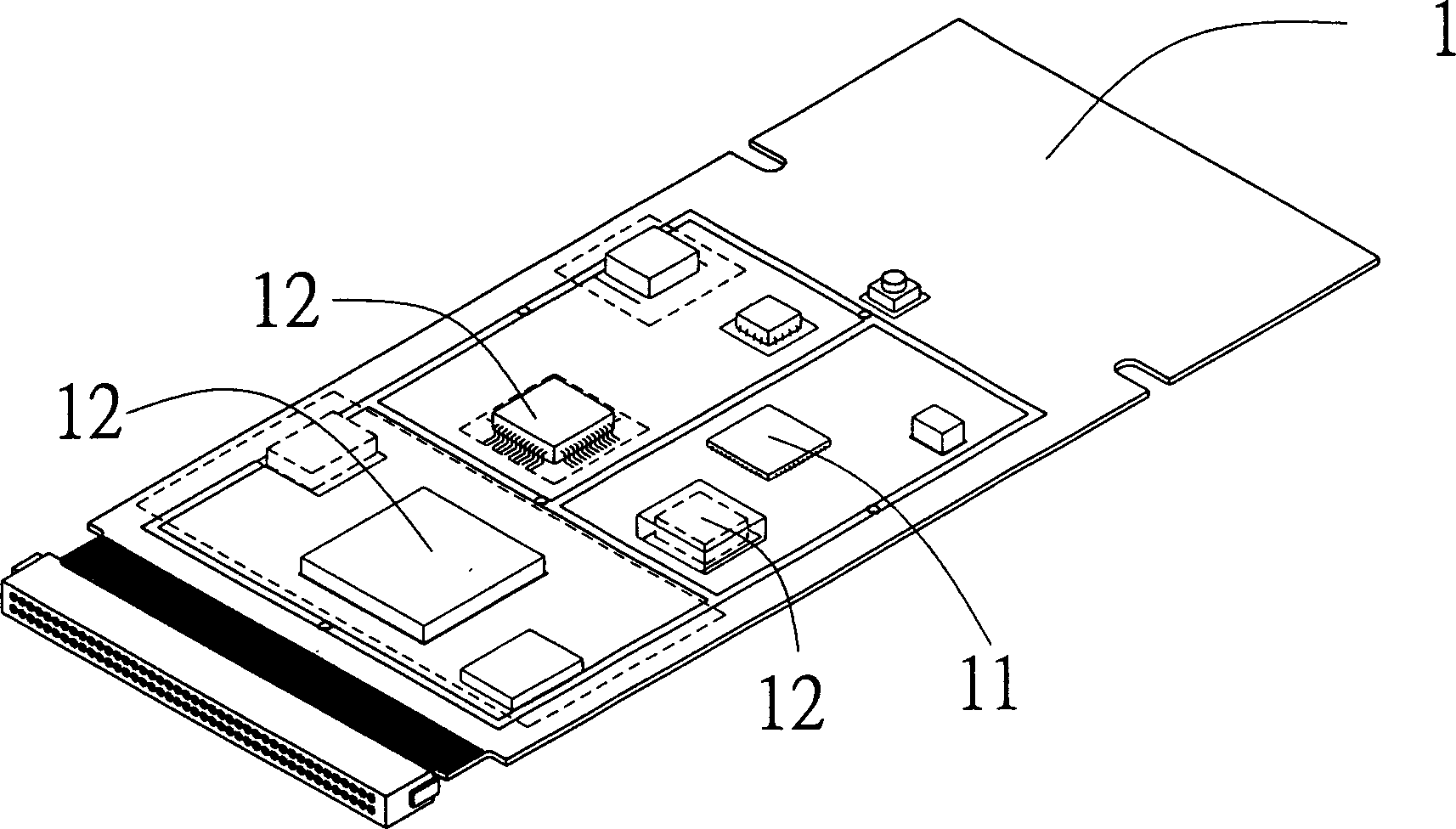

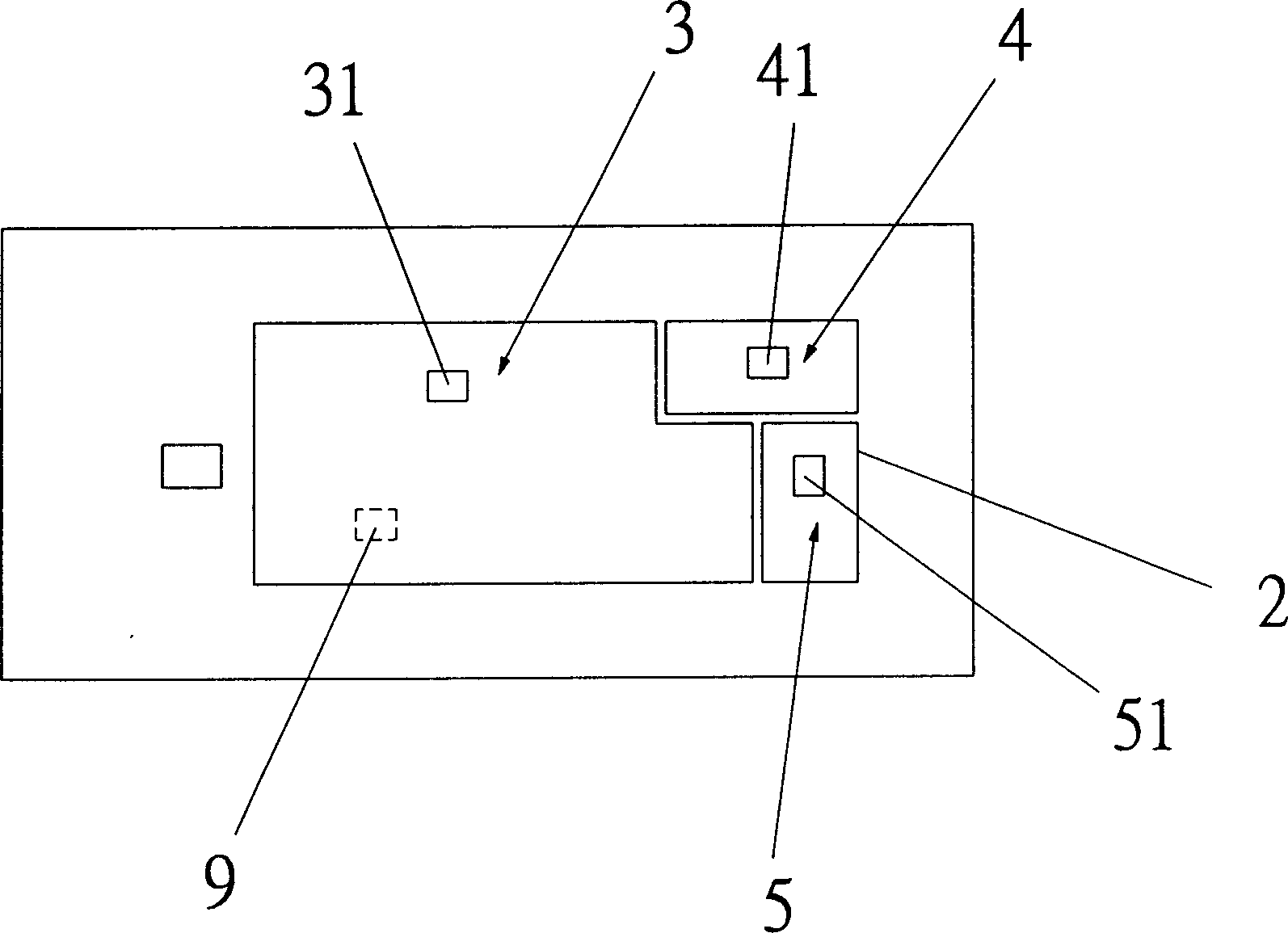

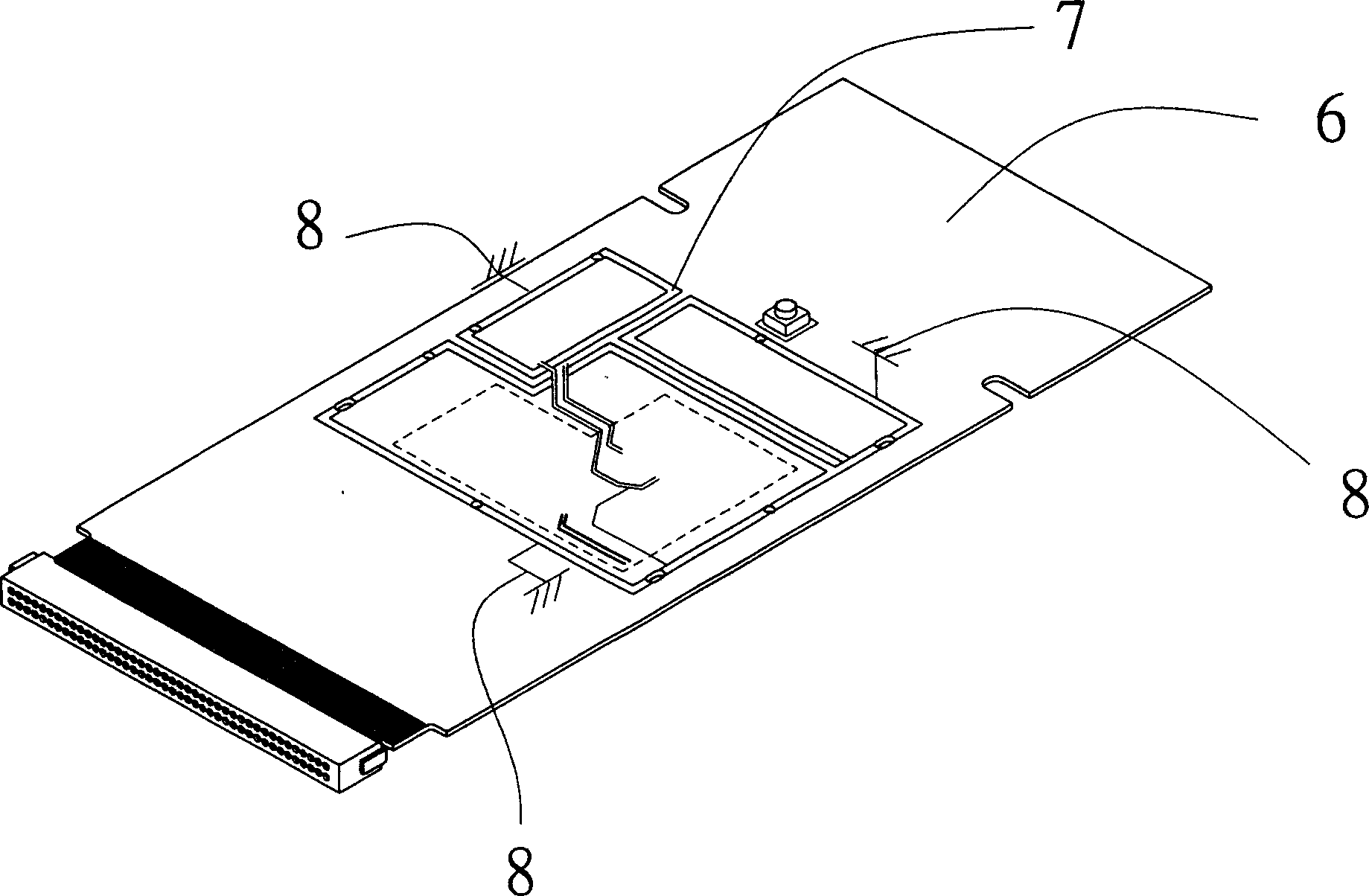

Embodiment Construction

[0022] Such as figure 2 As shown, the present invention is mainly divided into several frequency domain blocks such as high frequency region 3, intermediate frequency region 4 and low frequency region 5 with several frame lines 2 during circuit design, so that each oscillation source (such as: high Frequency oscillation source 31, intermediate frequency oscillation source 41, and low frequency oscillation source 51) belong to the relevant circuit components, each according to the attribute of high or low frequency, each placed in the corresponding frequency domain block, and after the surface treatment operation, that is, in the circuit On the board 6, the pre-divided frequency domain blocks are formed into independent copper wire frames 7 (such as image 3 As shown), with the help of the copper wire frame, the individual signals are respectively introduced into the ground terminal 8, so as to prevent the oscillation sources of different properties (such as: high frequency os...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com