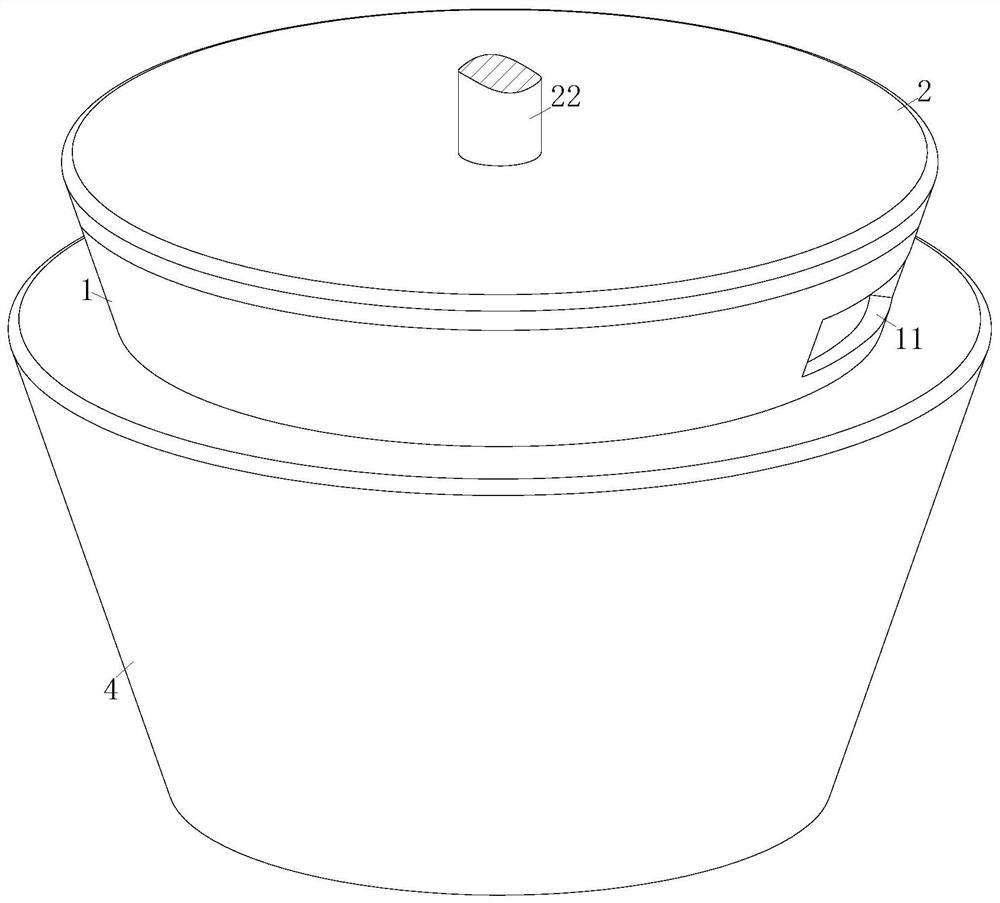

Aluminum profile smelting furnace

A technology for smelting furnaces and aluminum profiles, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of low production efficiency, uneven heating of outer layer materials, and melting of inner layer materials, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

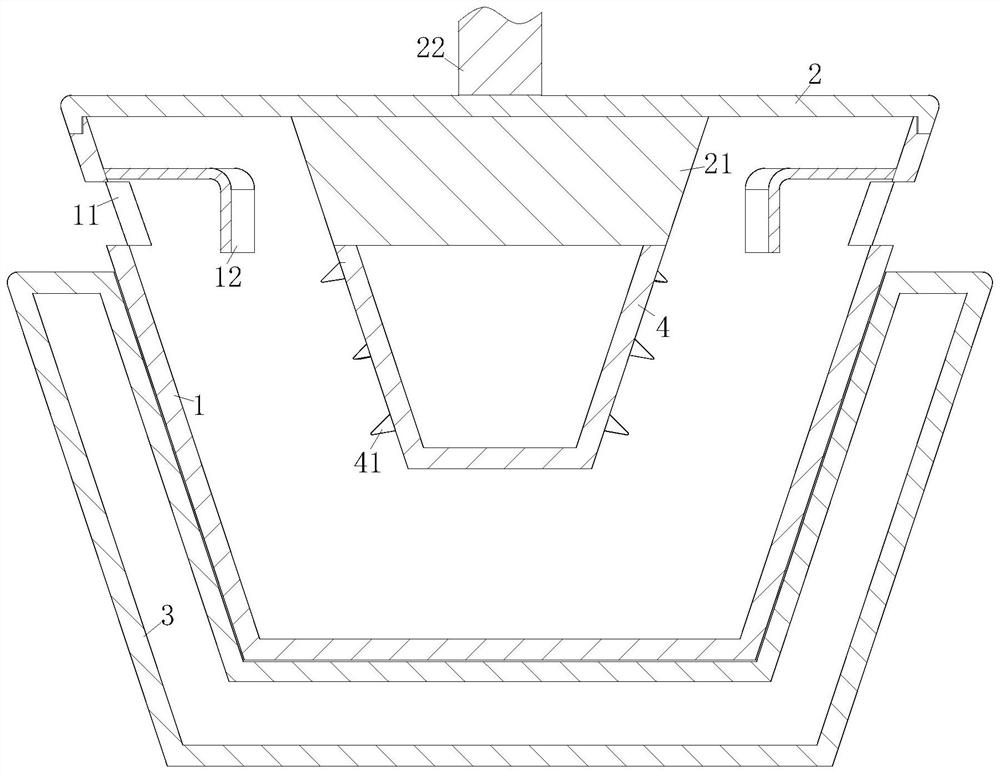

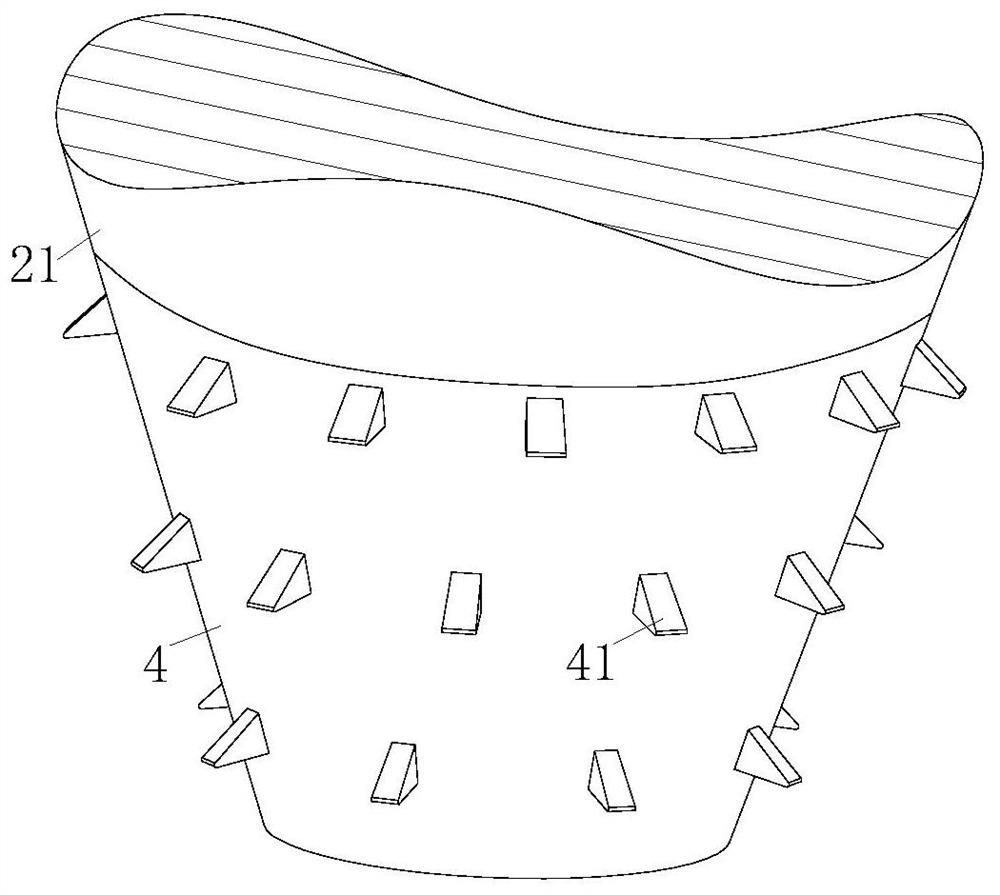

[0029] As an embodiment of the present invention, a material guide plate 12 is fixedly installed on the inner surface of the side wall of the furnace body 1 close to the top of the feed port 11, and the material guide plate 12 is vertically positioned near the side wall of the second heating chamber 4. Below; the height of the material guide plate 12 is greater than the height of the feed port 11.

[0030] When working, when the material is transported into the interior of the furnace body 1 from the feed port 11 on the side wall of the furnace body 1, the material enters the feed port 11 and is first blocked by the material guide plate 12, and finally falls again under the guidance of the material guide plate 12. to the side wall of the inclined furnace body 1 and roll down, avoiding that when the external material conveying speed is too high, the material no longer tilts and rolls down along the side wall of the furnace body 1, but breaks away from the slope of the side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com