Apparatus and method for heat treatment of metallic work pieces

A technology for metal workpieces and workpieces, which is applied in the field of equipment in the form of air furnaces, can solve problems such as impossible heat treatment, and achieve the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

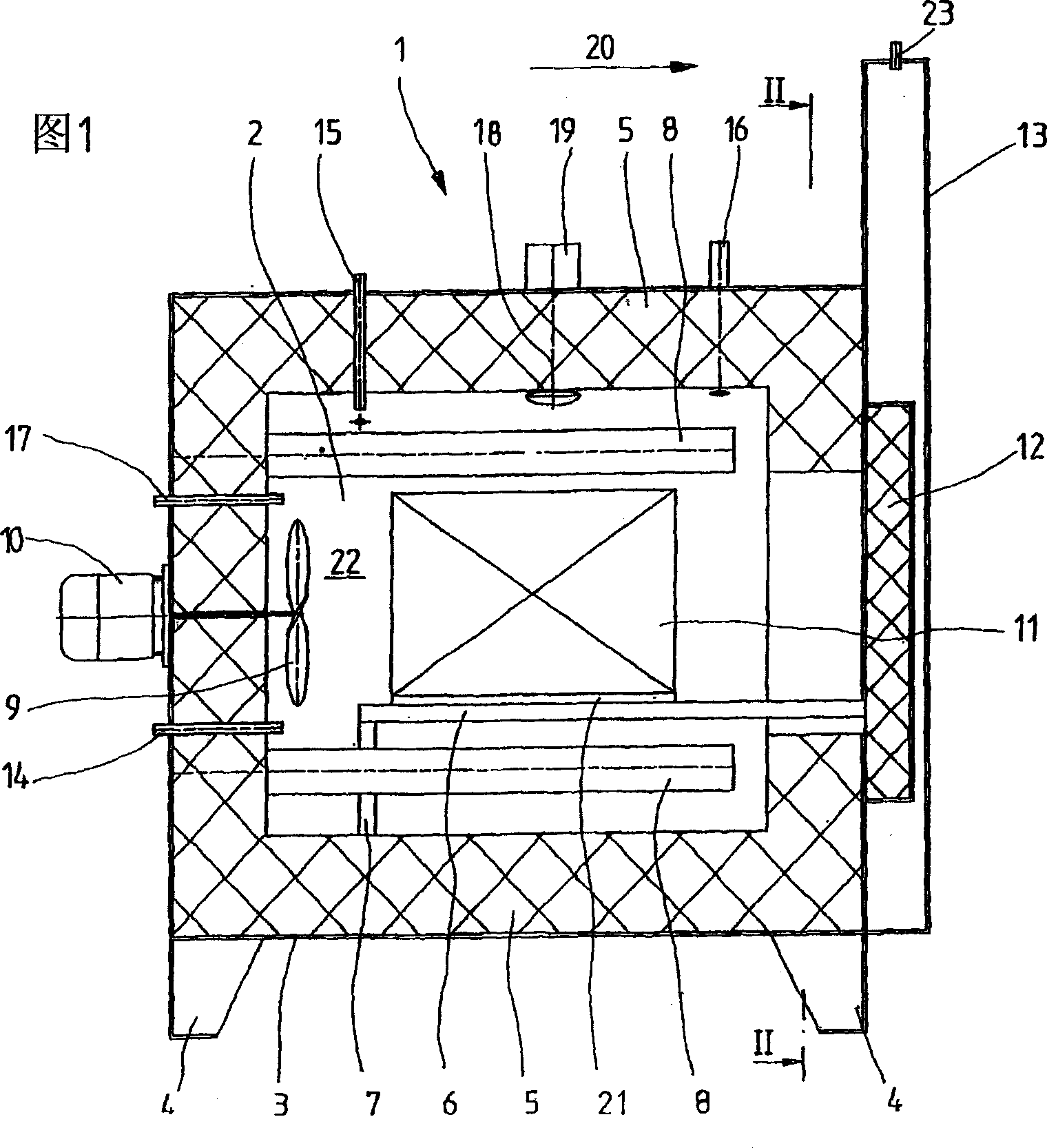

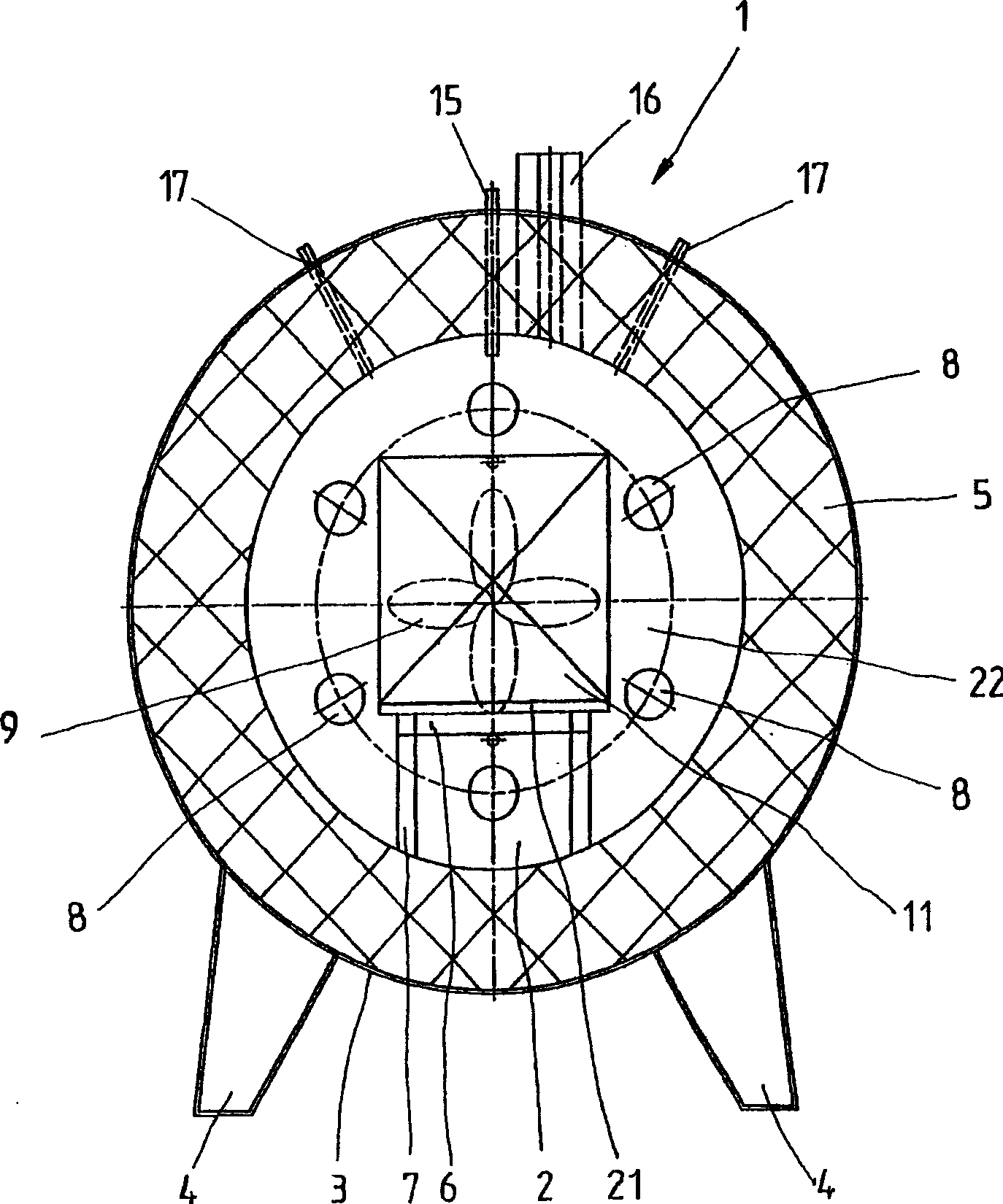

[0063] Figure 1 and figure 2 A furnace according to a preferred embodiment of the invention is shown. This is not limiting and is merely used to illustrate the functionality of the invention. same parts as in Figure 1 and figure 2 are marked with the same reference numerals.

[0064] The furnace 1 consists of a steel housing 3 which has correspondingly formed feet 4 for secure standing. A furnace chamber 2 is formed in a steel casing 3 and has a heat insulating layer 5 provided inside the steel casing 3 for heat insulation.

[0065] In order to circulate the air in the oven chamber, a gas circulation device in the form of a ventilation device 9 is provided in the oven chamber 2 . The ventilation device 9 is driven by a motor 10 which is accessible from the outside and is arranged outside the oven chamber 2 . In terms of drive technology, the motor 10 and the ventilation device 9 are connected via a drive shaft which is not described in detail.

[0066] The heating elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com