Graphene composite material helicopter rotor anti-icing and deicing device and manufacturing method

A technology for helicopter rotors and composite materials is applied in the field of anti-icing devices for rotor bases, which can solve the problems of difficulty in deicing and easy icing of rotor bases, and achieve the effects of reducing weight, improving strength, and improving heat transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

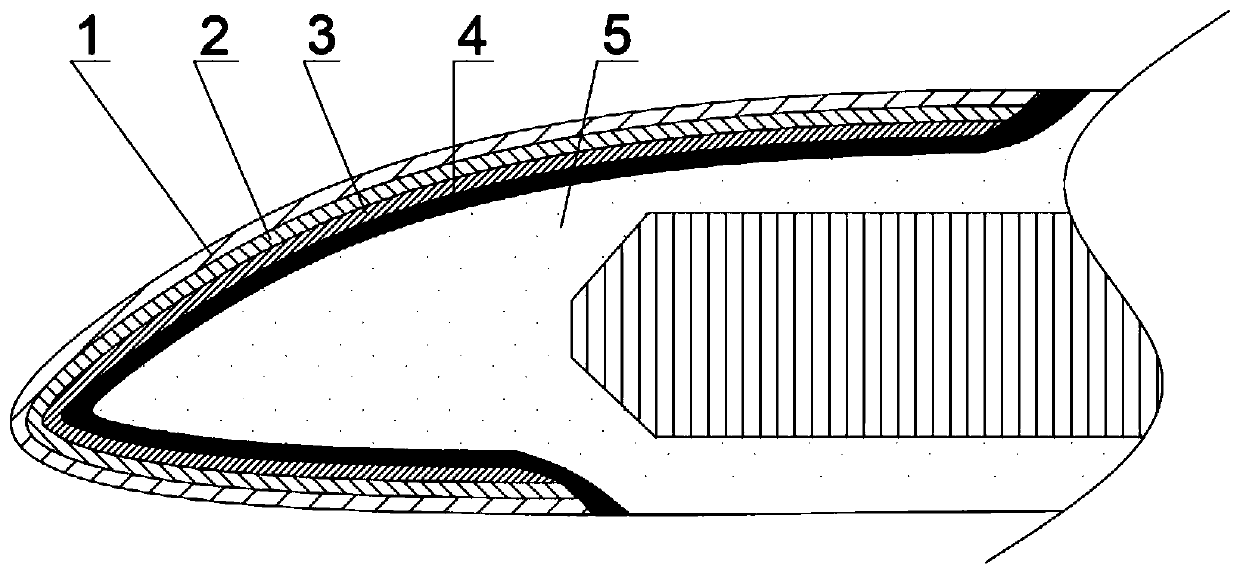

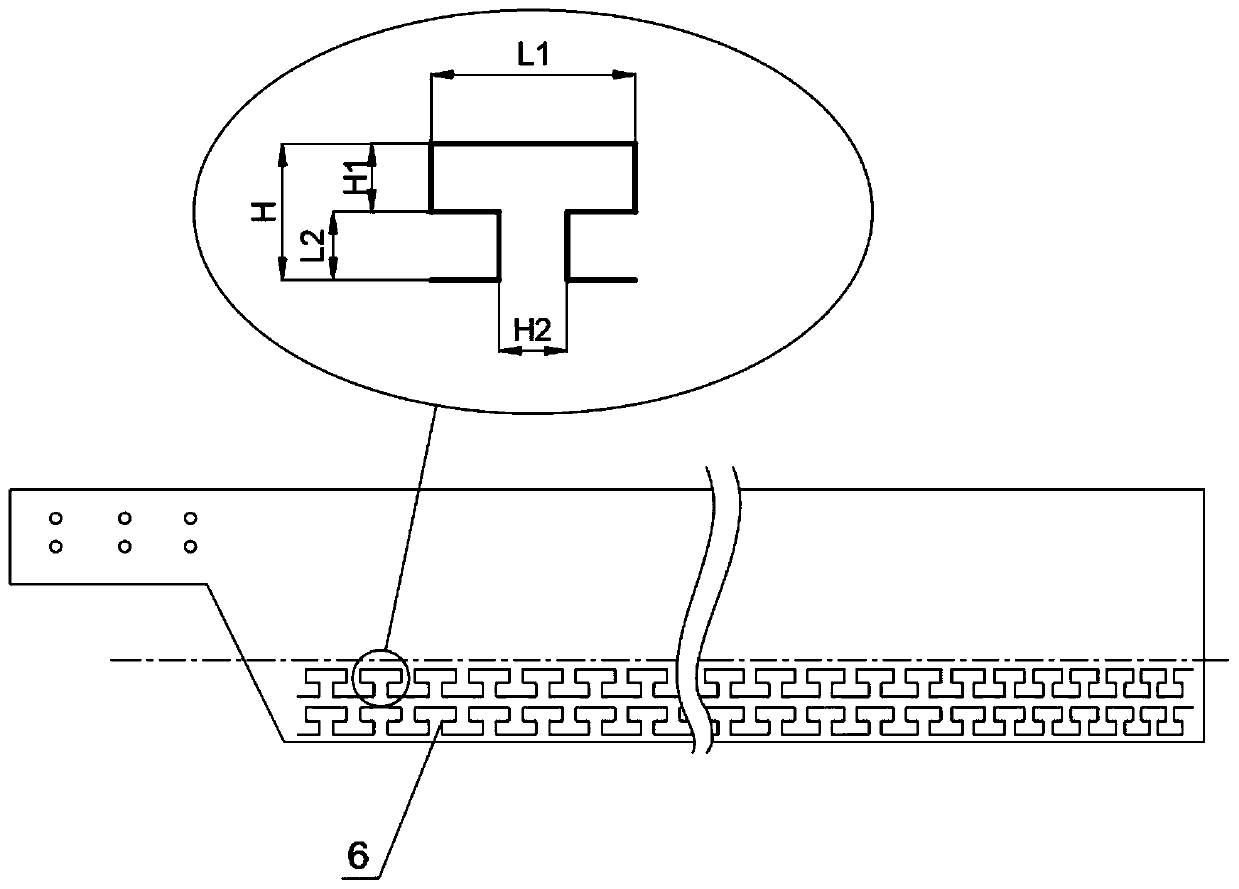

[0034] Please refer to figure 1 , a graphene composite material helicopter rotor anti-icing device, comprising skin 1, insulating heat transfer layer 2, heating layer 3 and insulating heat insulating layer 4, skin 1, insulating heat transfer layer 2, heating layer 3 and insulating insulation layer The thermal layer 4 is arranged sequentially from outside to inside along the chord direction; the skin 1, the insulating heat transfer layer 2, the heating layer 3 and the insulating heat insulating layer 4 are laminated to form an outer edge body, and the outer edge body is heated and solidified as a whole to form the shape of the leading edge of the rotor , the outer edge body is installed on the rotor base body 5. It can be understood that the graphene composite material helicopter rotor anti-icing device disclosed in this embodiment is arranged on the outer surface of the rotor of the helicopter, and the structure of the rotor base 5 is a technology known in the art, and its det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com