Landing rosin dissolution and separation device

A separation device, the technology of landing turpentine, applied in the direction of turpentine, natural resin refining, chemical instruments and methods, etc., can solve problems such as sticking to equipment, dissolution, affecting economic benefits, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

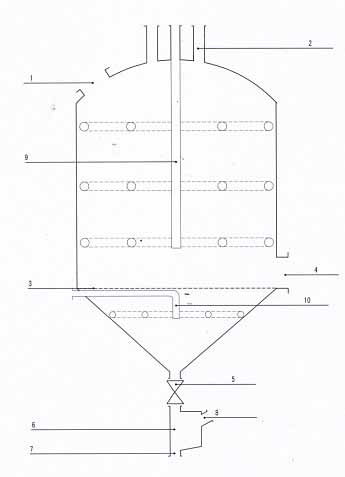

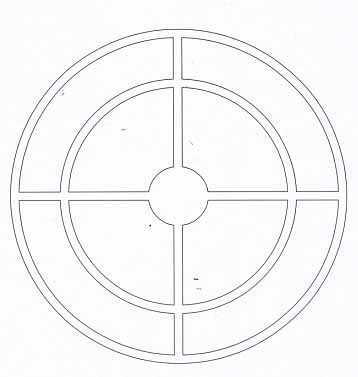

[0010] A floor-standing rosin melting and separating device, the device includes a cylindrical metal container with a conical bottom. Set a porous sieve plate 3, set a slag outlet 4 at the lower end of the cylinder and the upper edge of the sieve plate, set a gate valve 5 at the bottom of the funnel-shaped cone, set a turpentine and turpentine gas diversion tank 6 under the gate valve 5, and set a turpentine outlet 7 at the bottom of the tank , the top of the tank body is provided with a turpentine gas diversion inclined pipe 8, and the upper and lower steam injection systems 9 and 10 are established with the sieve plate in the container, and the steam pipes are arranged in a criss-cross pattern, and the opening angle of the injection holes is: limited by the level from 0 to negative 90 degrees. Its working process is: use steam to heat the ground rosin to make it melt under heat, and the melted rosin leaks to the bottom through the sieve plate and flows into the turpentine an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com