Processing method of pine resin

A processing method and technology of turpentine, applied in the field of turpentine processing, can solve the problems that the quality of rosin and turpentine cannot meet the production needs of downstream industries, the quality of rosin and turpentine products cannot meet the standards, and the impurity in turpentine cannot be removed well, etc., to achieve Conducive to dissolution and clarification, easy to remove impurities, and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

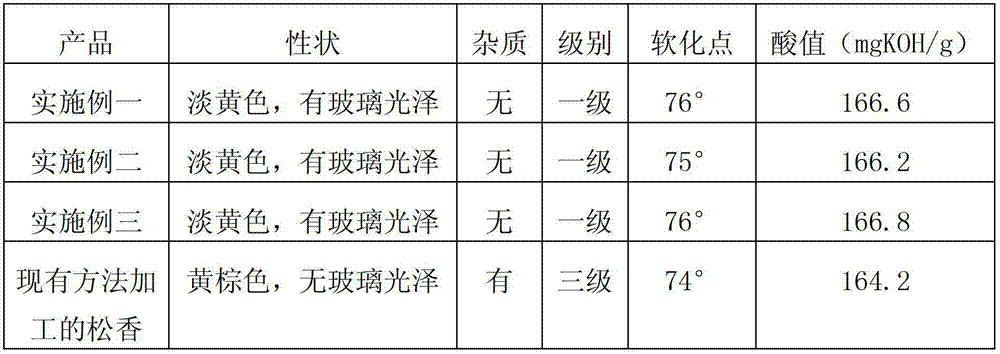

[0021] 100kg turpentine is dissolved with a dissolving solution composed of 28kg turpentine, 11.88kg water and 0.12kg oxalic acid, clarified after the dissolution is completed, and the clarified solution is filtered through a 60-mesh filter to obtain 130kg crude filtrate; add 0.26kg oxalic acid for acidification Wash, then add hot water at 80°C for washing, and after clarifying for 4 hours, carry out fine filtration through a 120-mesh filter to obtain a fine filtrate. The fine filtrate was placed in a rectification tower for distillation at a temperature of 170° C. to obtain 76 kg of rosin and 16 kg of turpentine respectively. Among them, the yield of rosin is 76%, and the yield of turpentine is 16%. The test results of the gained rosin finished product are shown in Table 1, and the test results of the gained turpentine finished product are shown in Table 2.

Embodiment 2

[0023] 100kg turpentine is dissolved with a dissolving solution composed of 32kg turpentine, 7.8kg water and 0.2kg oxalic acid, clarified after the dissolution is completed, and the clarified solution is filtered through a 60-mesh filter to obtain 132kg crude filtrate; add 0.132kg oxalic acid for acidification Wash, then add hot water at 70°C for washing, and after clarifying for 4 hours, carry out fine filtration through a 120-mesh filter to obtain a fine filtrate. The fine filtrate is placed in a rectification tower for distillation at a temperature of 175° C. to obtain 77 kg of rosin and 17 kg of turpentine. Among them, the yield of rosin is 77%, and the yield of turpentine is 17%. The test results of the gained rosin finished product are shown in Table 1, and the test results of the gained turpentine finished product are shown in Table 2.

Embodiment 3

[0025] 100kg turpentine is dissolved with a dissolving solution composed of 22.5kg turpentine, 7.38kg water and 0.12kg oxalic acid, clarified after the dissolution is completed, and the clarified solution is filtered through a 60-mesh filter to obtain 121kg crude filtrate; add 0.242kg oxalic acid for pickling, and then add hot water at 80°C for washing, and after clarifying for 4 hours, perform fine filtration through a 120-mesh filter to obtain a fine filtrate. The fine filtrate is placed in a rectification tower for distillation at a temperature of 172° C. to obtain 75 kg of rosin and 16 kg of turpentine. Among them, the yield of rosin is 75%, and the yield of turpentine is 16%. The test results of the gained rosin finished product are shown in Table 1, and the test results of the gained turpentine finished product are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com