Patents

Literature

52results about How to "Guaranteed production demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real-time material distribution method in mechanical product assembling process

InactiveCN101950387AEasy to manage on siteNo stack pressureLogisticsMaterial consumptionMaterial distribution

The invention discloses a real-time material distribution method in a mechanical product assembling process, which is characterized in that: according to the production plan on the same day, calculating to obtain all required parts; by considering the storage capability, the existing amount, the material lead time and the product cycle time of each part on each station, calculating a material distribution scheme; distributing the parts in time on small batches according to the obtained distribution scheme; simultaneously, tracking the on-site production situation by an MES system in real time; recording manufacturing product situation and the material consumption situation of each station; and timely feeding back production plan information and station inventory information. The method of the invention can realize on-time material distribution, feeds back and adjusts the distribution scheme in time according to real-time working condition, can improve production efficiency and lowers product cost.

Owner:HEFEI UNIV OF TECH

Method for breeding allogynogenetic crucian carp fry at low temperature

ActiveCN103563799AGuaranteed production demandImprove germination rateClimate change adaptationPisciculture and aquariaAnimal scienceBroodstock

The invention discloses a method for breeding allogynogenetic crucian carp fry at a low temperature. The method comprises the following steps of preparing a male and female parent fish dedicated culture pond, selecting and breeding male and female parent fishes, carrying out hasten parturition on the male and female parent fishes, enabling the male and female parent fishes to lay eggs and be fertilized, enabling fertilized eggs to unstick, hatching the fertilized eggs, demolding and breeding the fertilized eggs into small fry, and breeding the small fry into large-size allogynogenetic crucian carp summer flower fry by sending the small fry into the culture pond. According to the method disclosed by the invention, high-quality allogynogenetic crucian carp fry can be bred when the temperature is low in Spring, and the emergence rate and the survival rate of the allogynogenetic crucian carp fry are very high; the production demands of the allogynogenetic crucian carp fry can be ensured, and the economic benefit of an allogynogenetic crucian carp breeding user can be greatly increased; the sustainable development of an allogynogenetic crucian carp breeding industry and the whole ecological benefit, the economic benefit and the social benefit of a fish farming industry can be greatly increased.

Owner:潘洪强 +1

Aqueous acrylamide solution containing saccharide

InactiveUS7129217B2Reduce the amount requiredHigh viscosityBiocideSugar derivativesNitrile hydratase activityAqueous solution

Owner:MITSUBISHI CHEM CORP

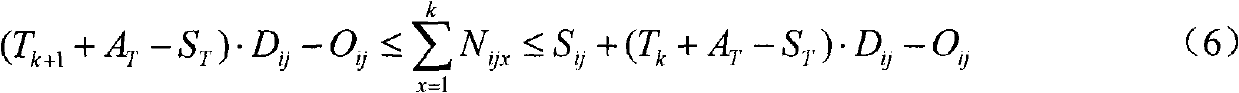

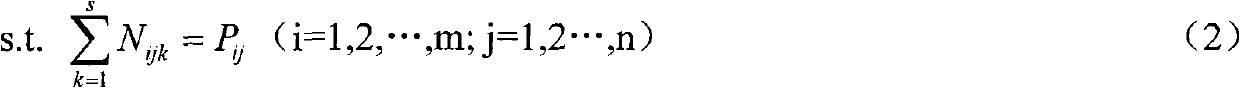

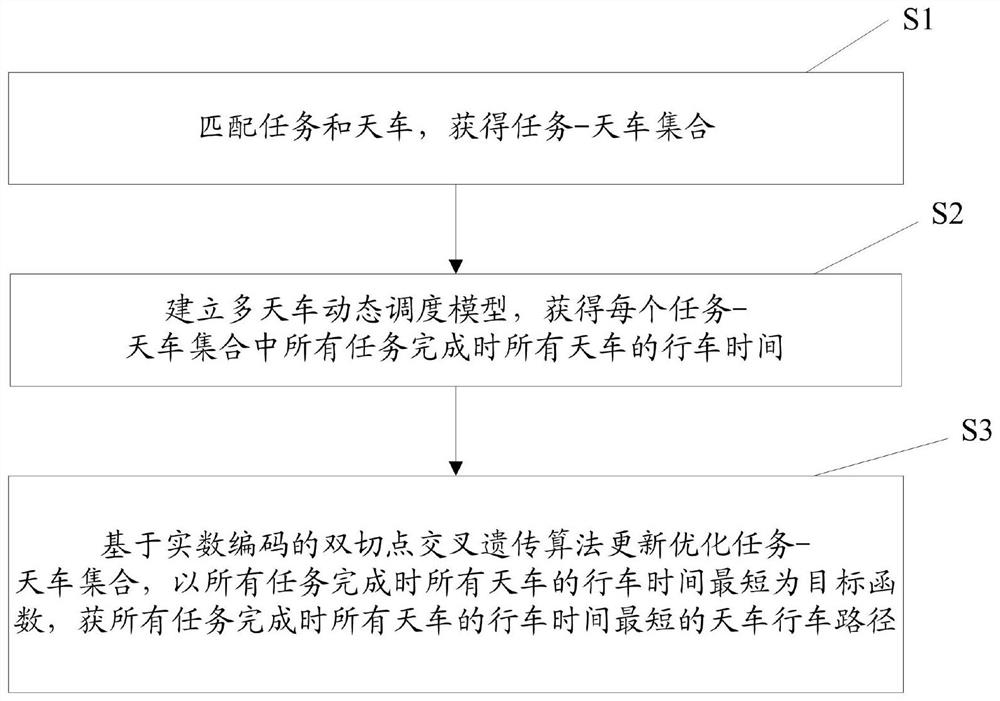

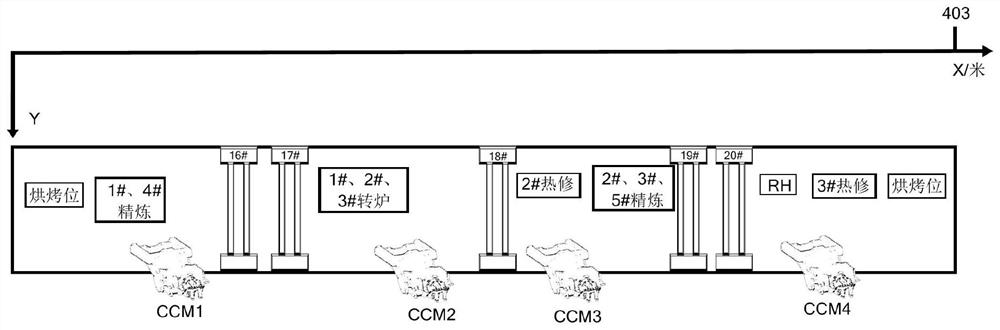

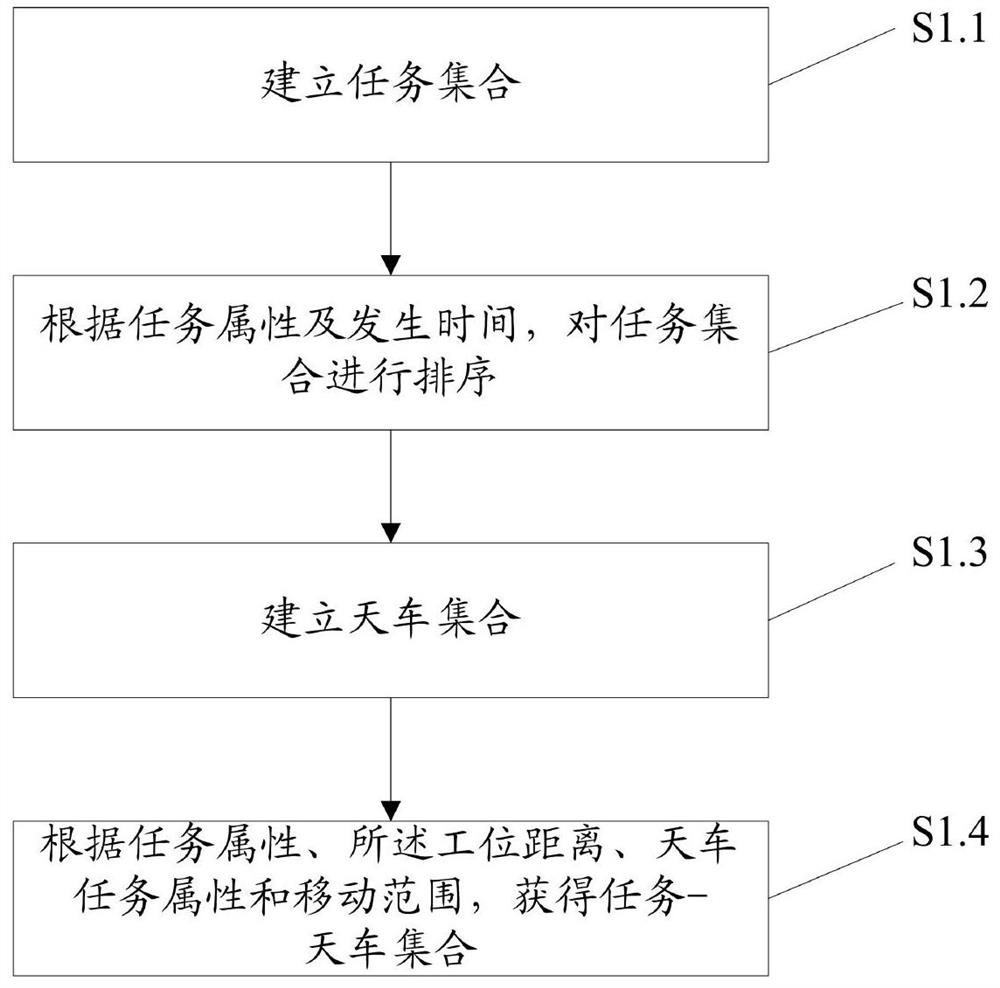

Multi-crown-block scheduling optimization method and system

InactiveCN112446642AImprove securityImprove efficiencyForecastingResourcesSteelmakingBlock scheduling

The invention relates to a multi-crown-block scheduling optimization method and system, and the method comprises the steps: building a multi-crown-block dynamic scheduling model through the matching of a task and crown blocks, calculating by a double-tangent-point cross genetic algorithm based on real number coding, obtaining an optimal driving scheme of multiple crown blocks in a steelmaking refining continuous casting production process, effectively reducing the invalid number of times of giving way to the crown blocks, and improving the efficiency. The effective operation rate of crown block driving is improved. The model, the algorithm and the rule provided by the invention have the advantages of strong universality, high convergence speed, balance of crown block workload and the like,and have great reference value for improving the crown block operation efficiency, shortening the molten steel waiting time of a station and the like.

Owner:大连英达士智能科技有限公司

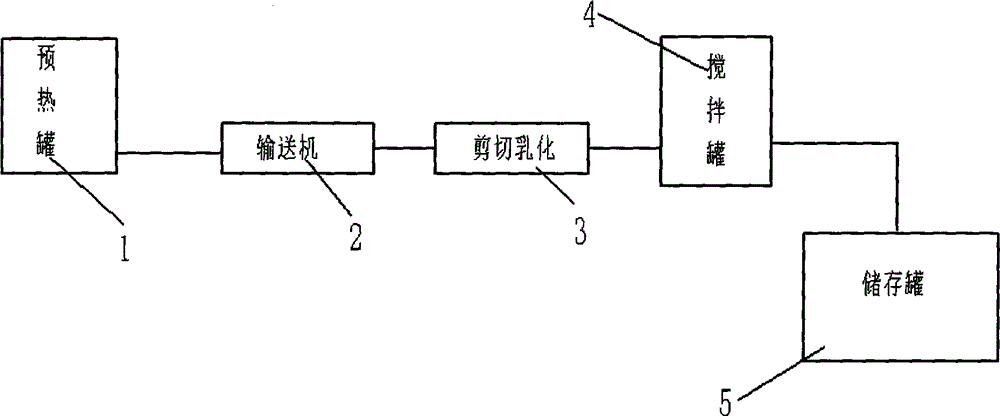

Warm-mix asphalt and production device thereof

ActiveCN105316991AEmission reductionLow costClimate change adaptationRoads maintainenceControl systemAsphalt

The invention discloses warm-mix asphalt and a production device thereof. The warm-mix asphalt is prepared from 70# matrix asphalt or SBS asphalt, a warm-mix modifier and other additives. A preparation method of the warm-mix asphalt includes the steps that the matrix asphalt is preheated, the modifier is added at the constant temperature of 140 DEG C, and the mixture is stirred at a low speed through a machine to obtain the warm-mix asphalt. The production device of the warm-mix asphalt comprises an asphalt preheating tank, a constant-temperature stirring tank, an asphalt storage tank and a motor control system, wherein the asphalt is preheated and stirred through the asphalt preheating tank and conveyed to the stirring tank at the constant temperature of 140 DEG C through a pressure system, the warm-mix modifier is added, stirring continues till the warm-mix asphalt is obtained, and finally the obtained warm-mix asphalt is conveyed to the asphalt storage tank. The warm-mix asphalt can obviously lower the emission of dust, waste and other pollutants and is low in construction temperature. The asphalt production device is simple in structure and low in cost, meets production requirements and saves energy.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

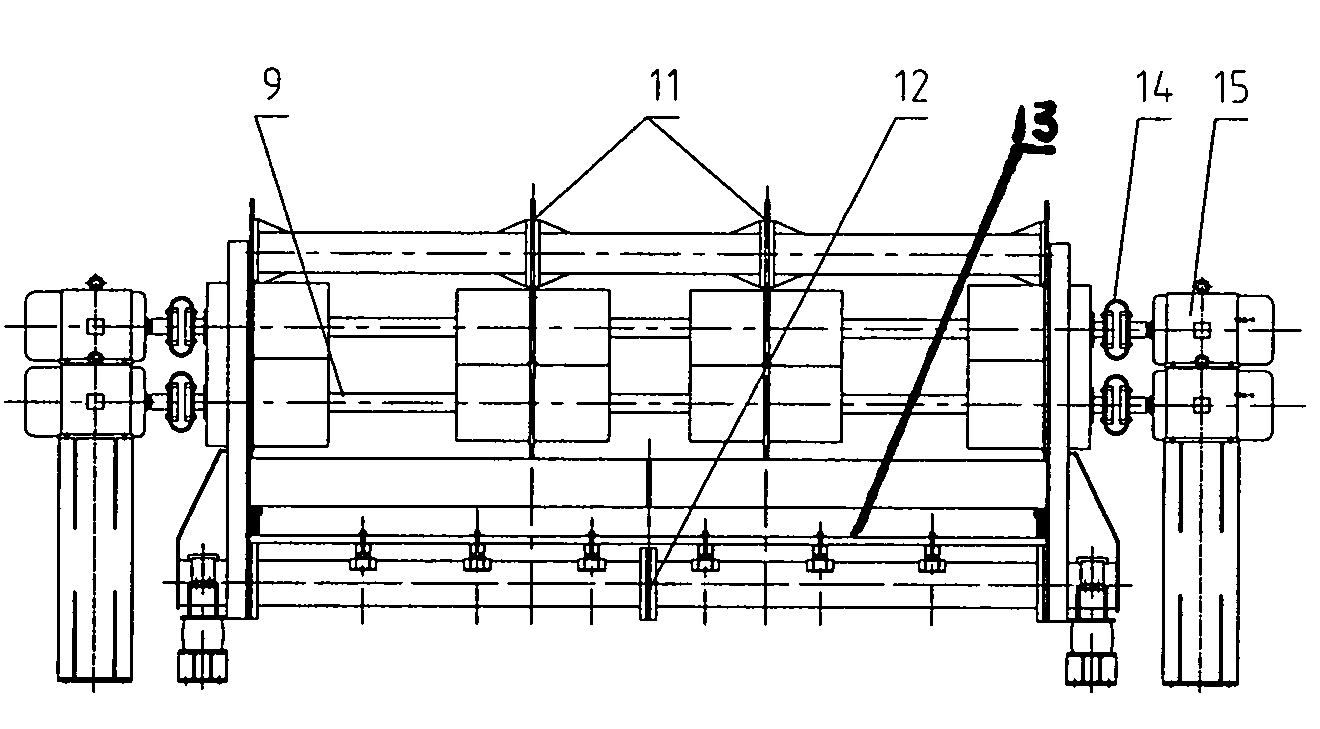

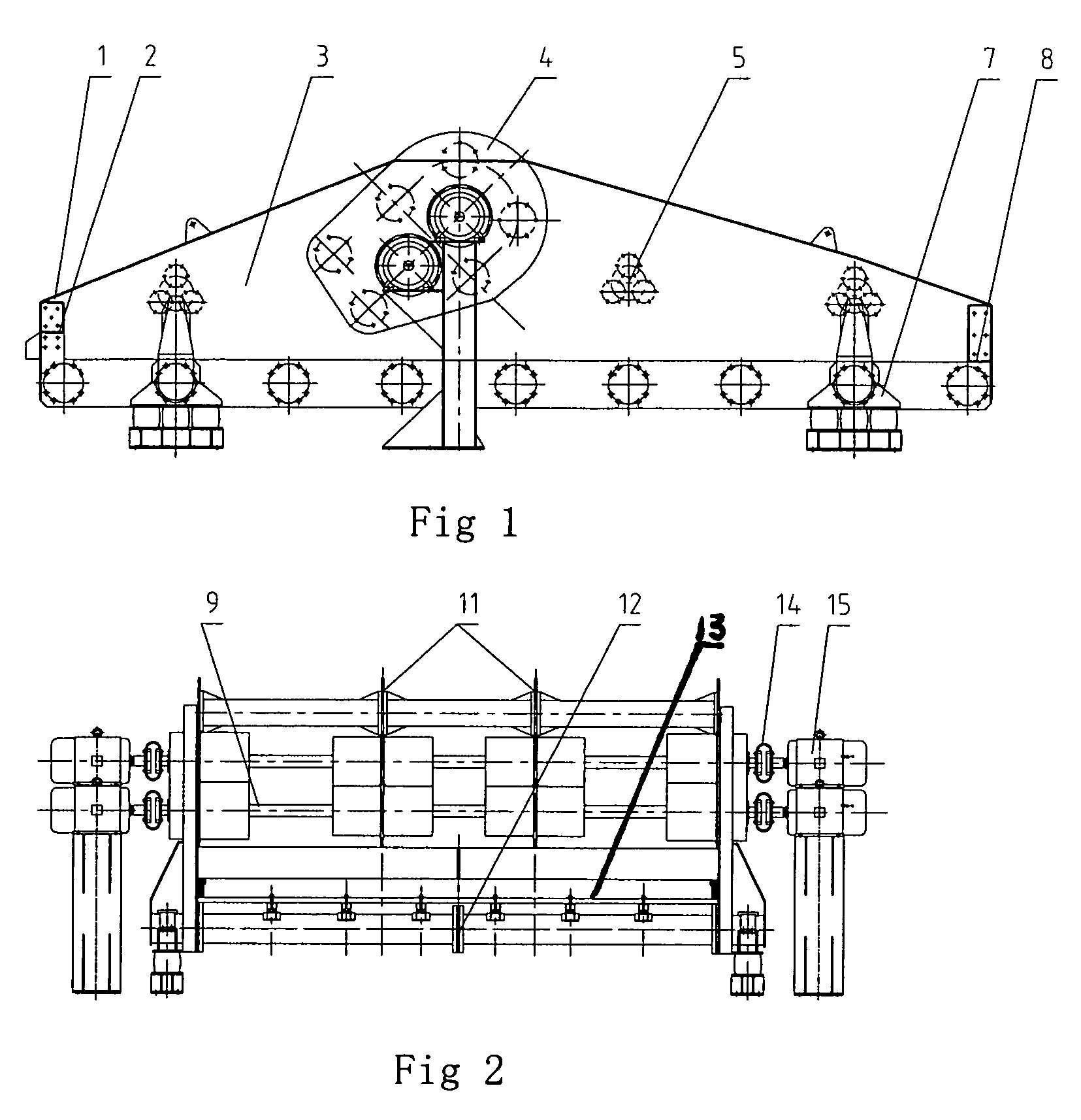

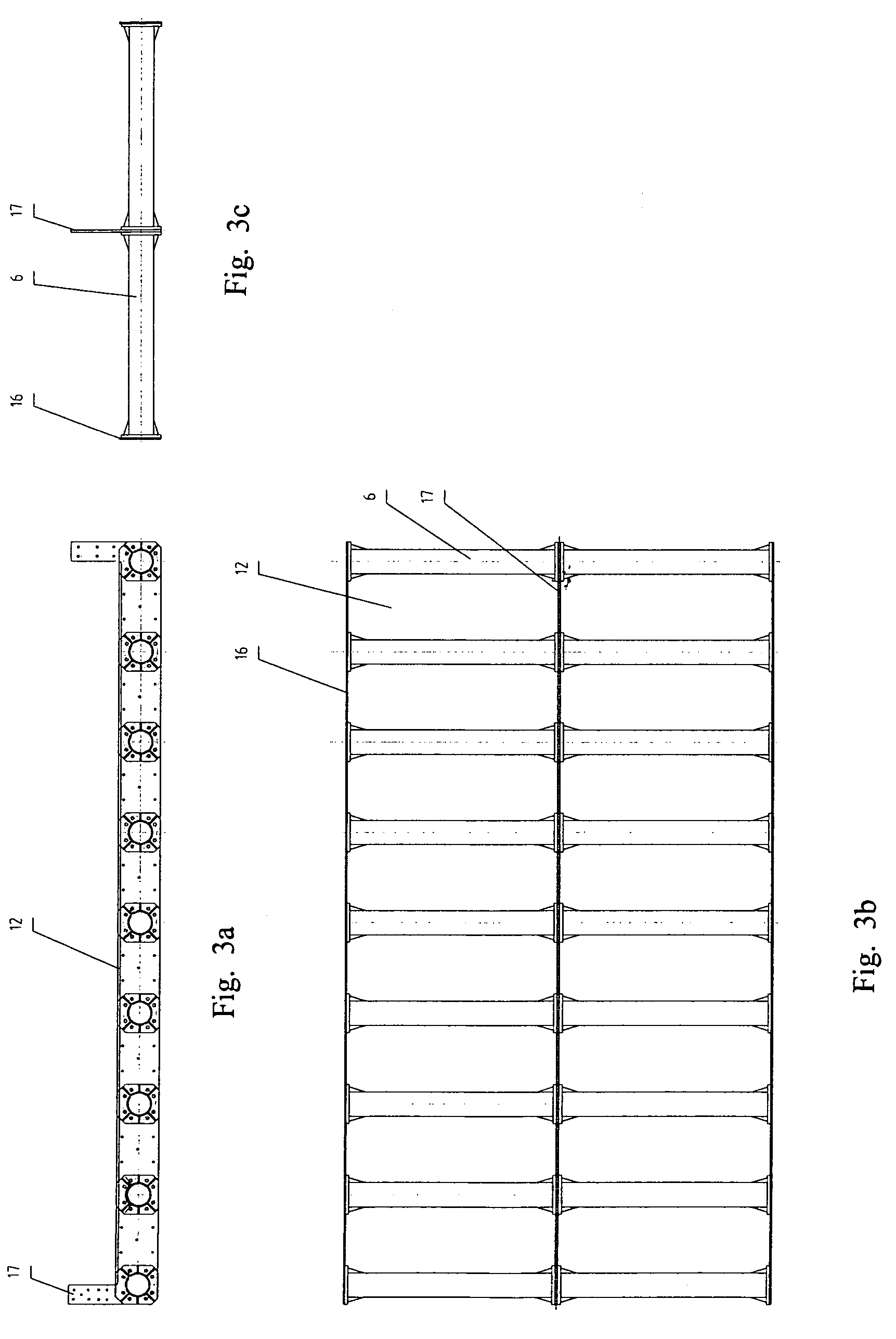

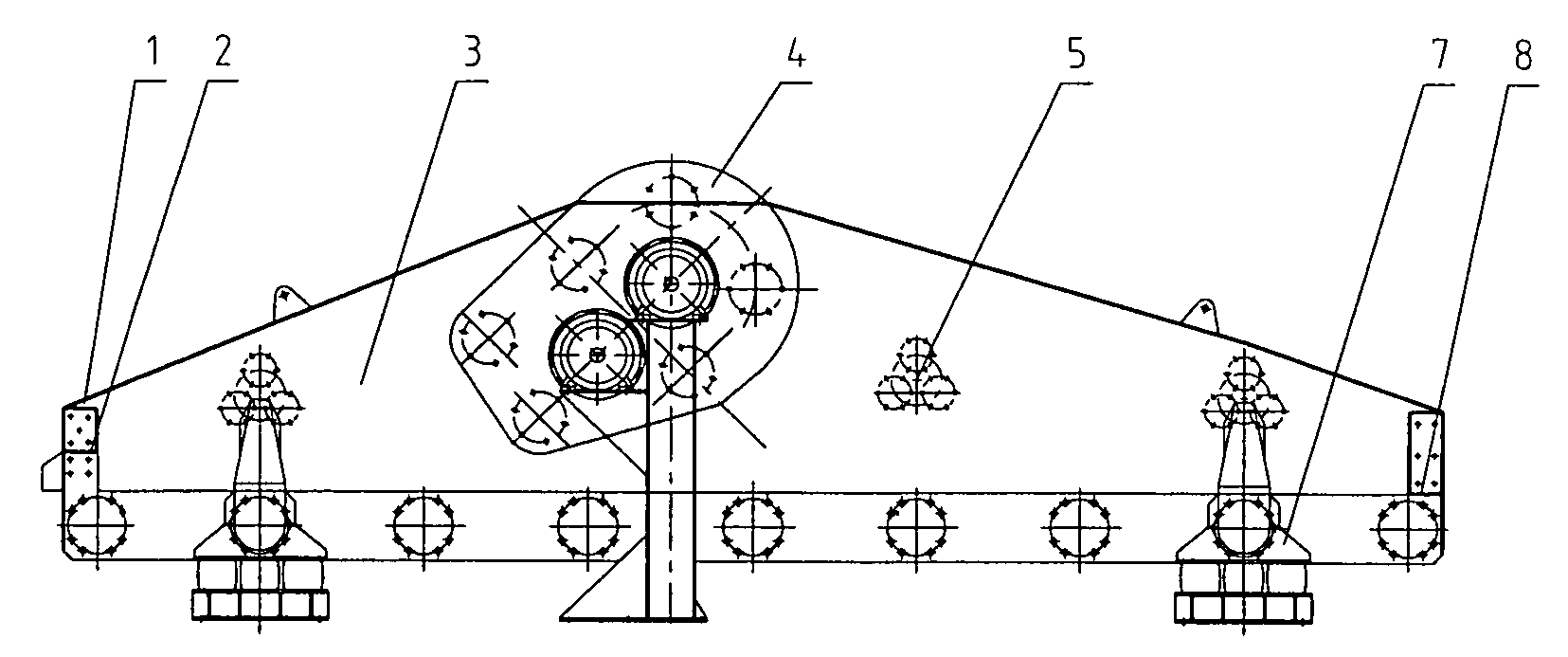

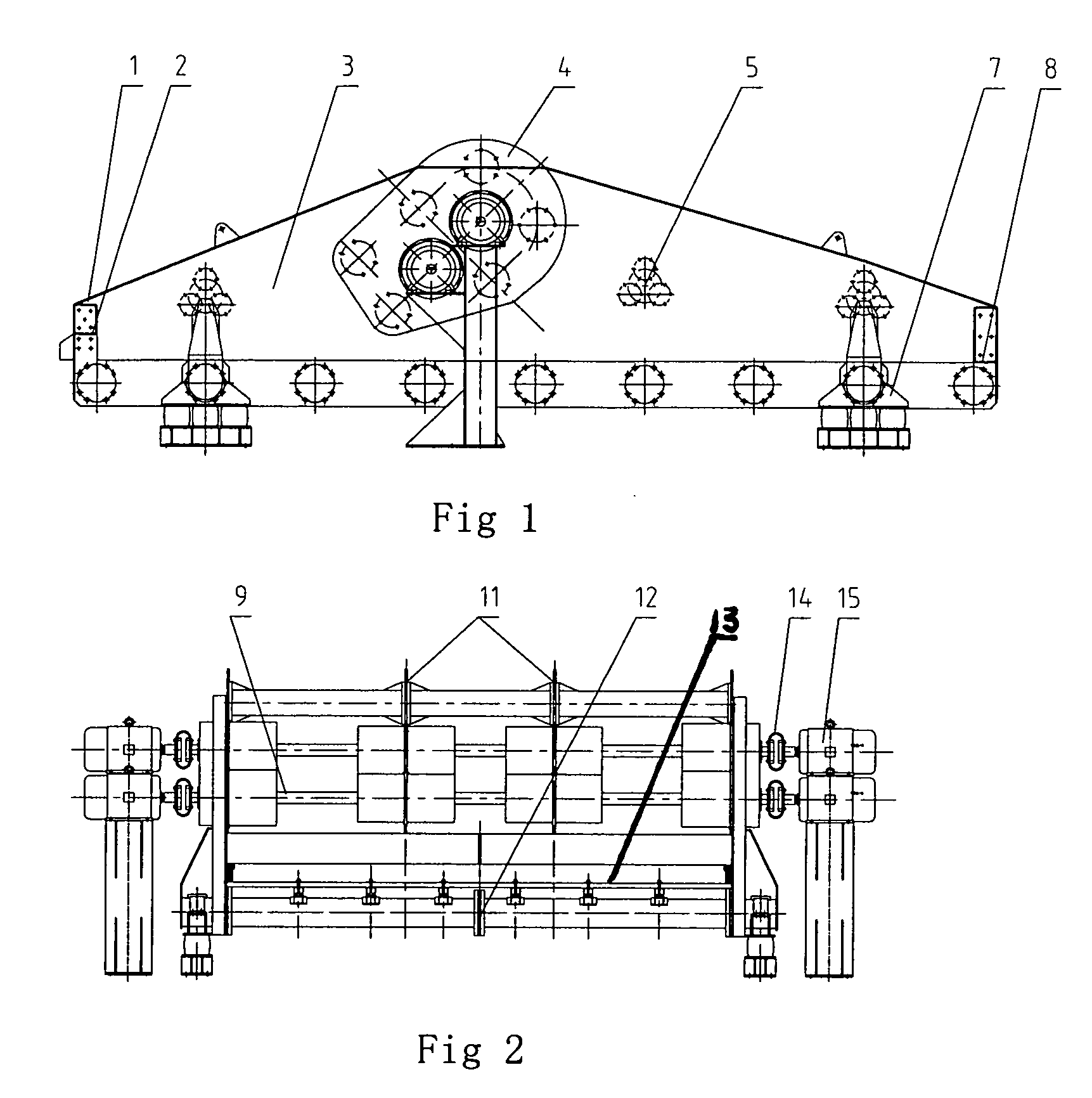

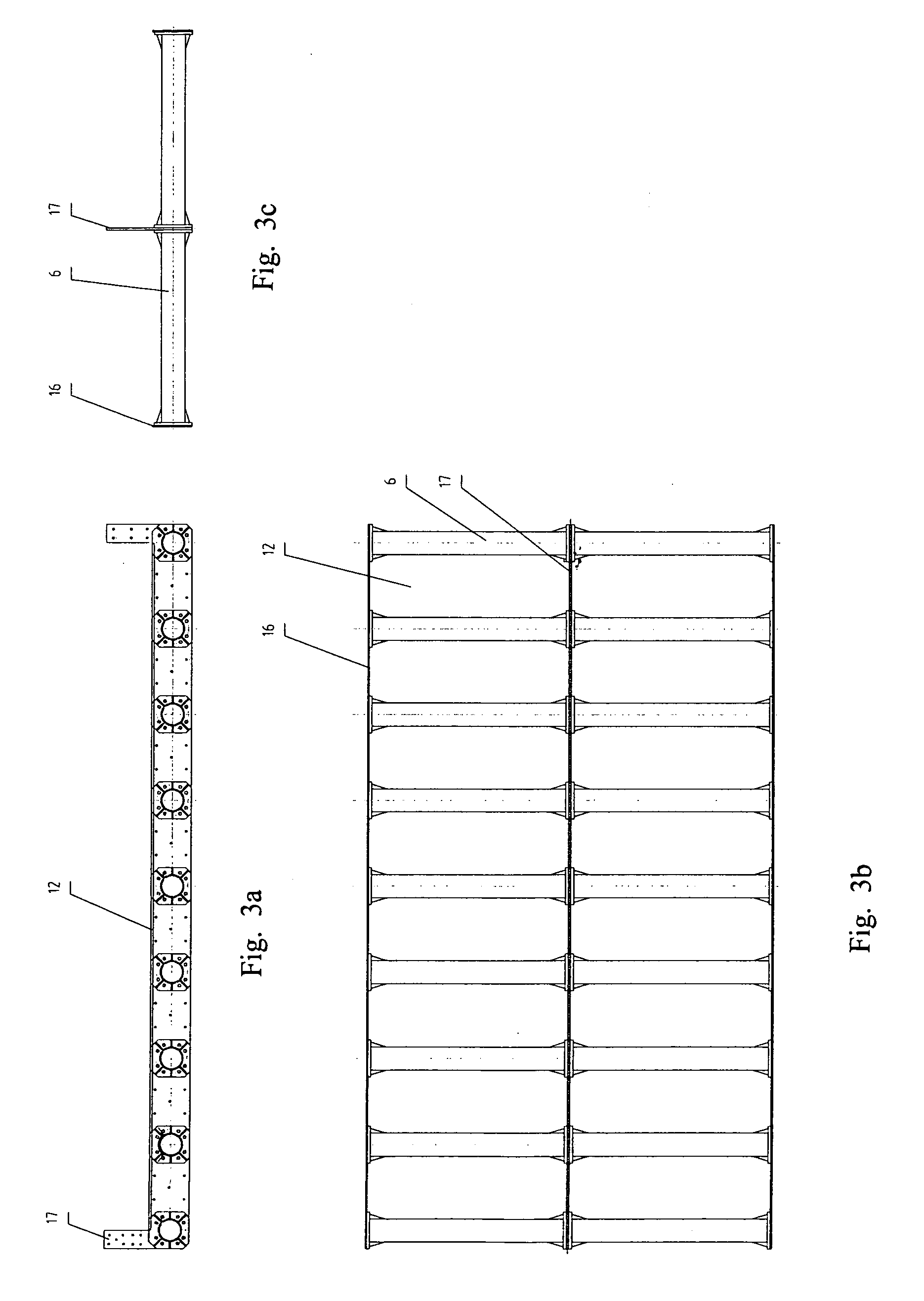

Extra-large vibrating screen with duplex statically indeterminate mesh beam

ActiveUS8074805B2Light weightReduce the excitation forceSievingScreeningStatically indeterminateCoupling

An extra-large vibrating screen with duplex statically indeterminate mesh beam excitation body and plate type combined bearing beam comprises plate type flat and rigid statically indeterminate combined bearing beam (12) arranged in a screen box (1), a plurality of Y-shaped statically indeterminate combined reinforcing beams (5) arranged on the side plates (3) of the screen box alternately, duplex statically indeterminate supporting plates (22) linking a plurality of mesh beams (21) to the statically indeterminate connecting plate (4) and the side plate (3) so as to form a container made of a beam system, the vibration exciters (10) in the statically indeterminate mesh beam unit comprising eight sets of vibration exciters, which are aligned in pair horizontally and linked together through universal couplings (9), and connected to the duplex statically indeterminate mesh beam excitation body (11) to form a highly rigid integral vibrating assembly. The vibrating screen is simple and reliable in structure, can vibrate smoothly, and therefore can be widely used in coal, metallurgical, chemical, and environmental protection industries.

Owner:CHINA UNIV OF MINING & TECH

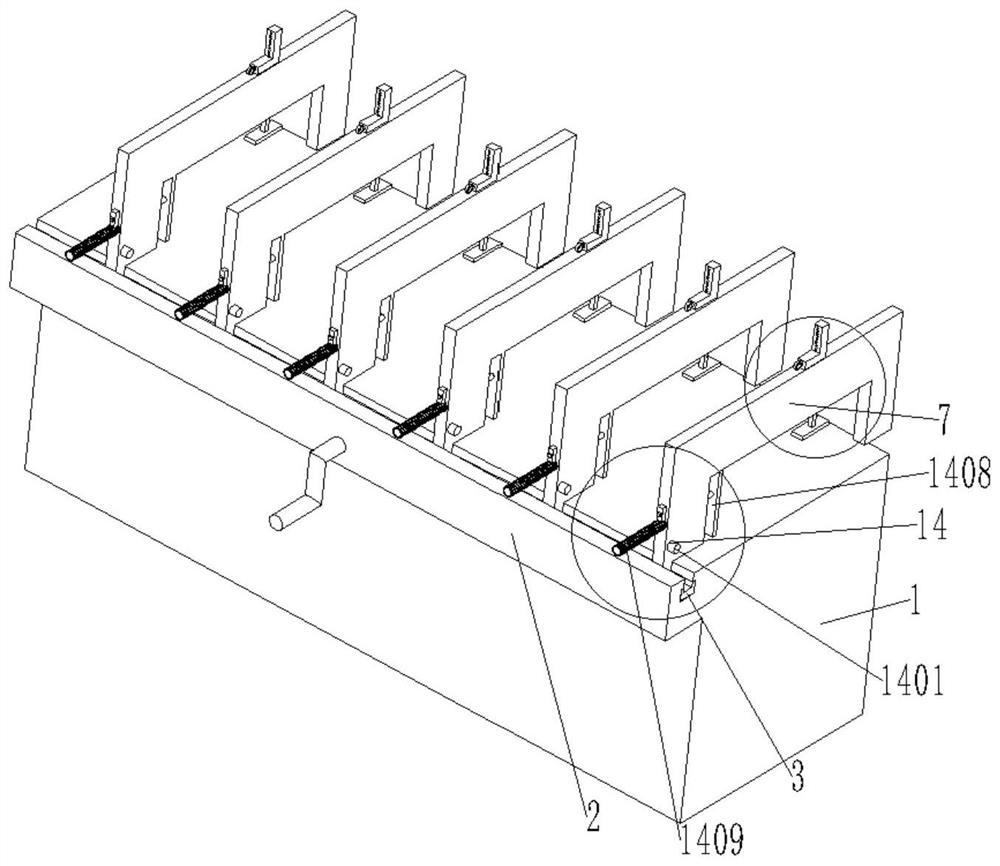

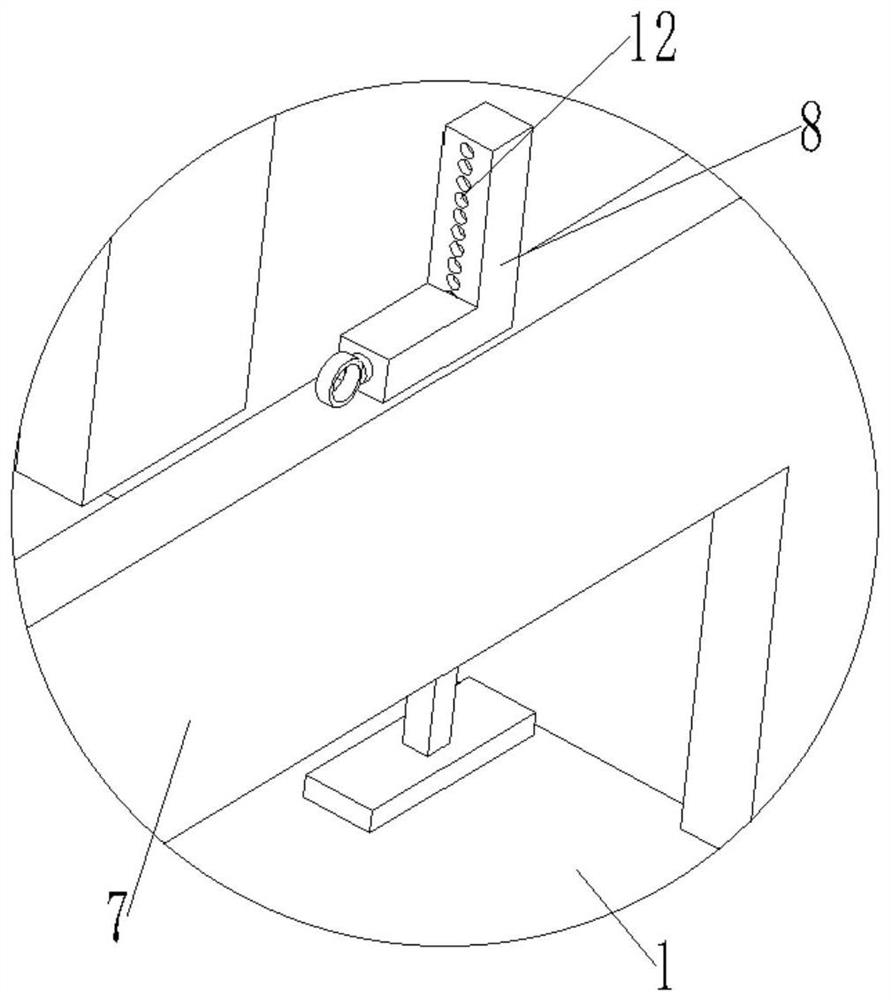

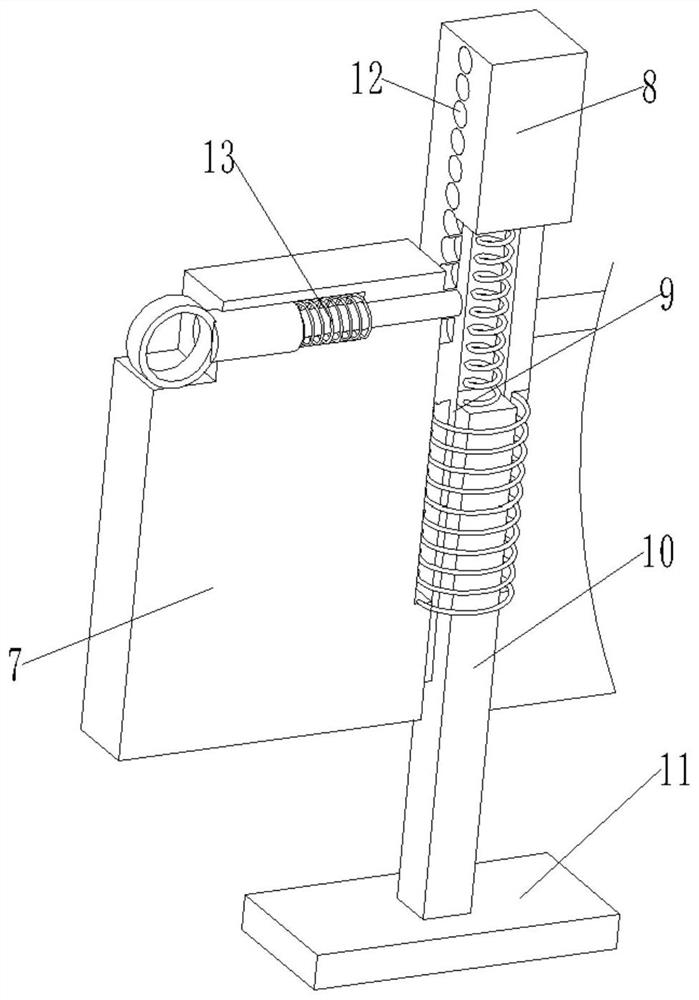

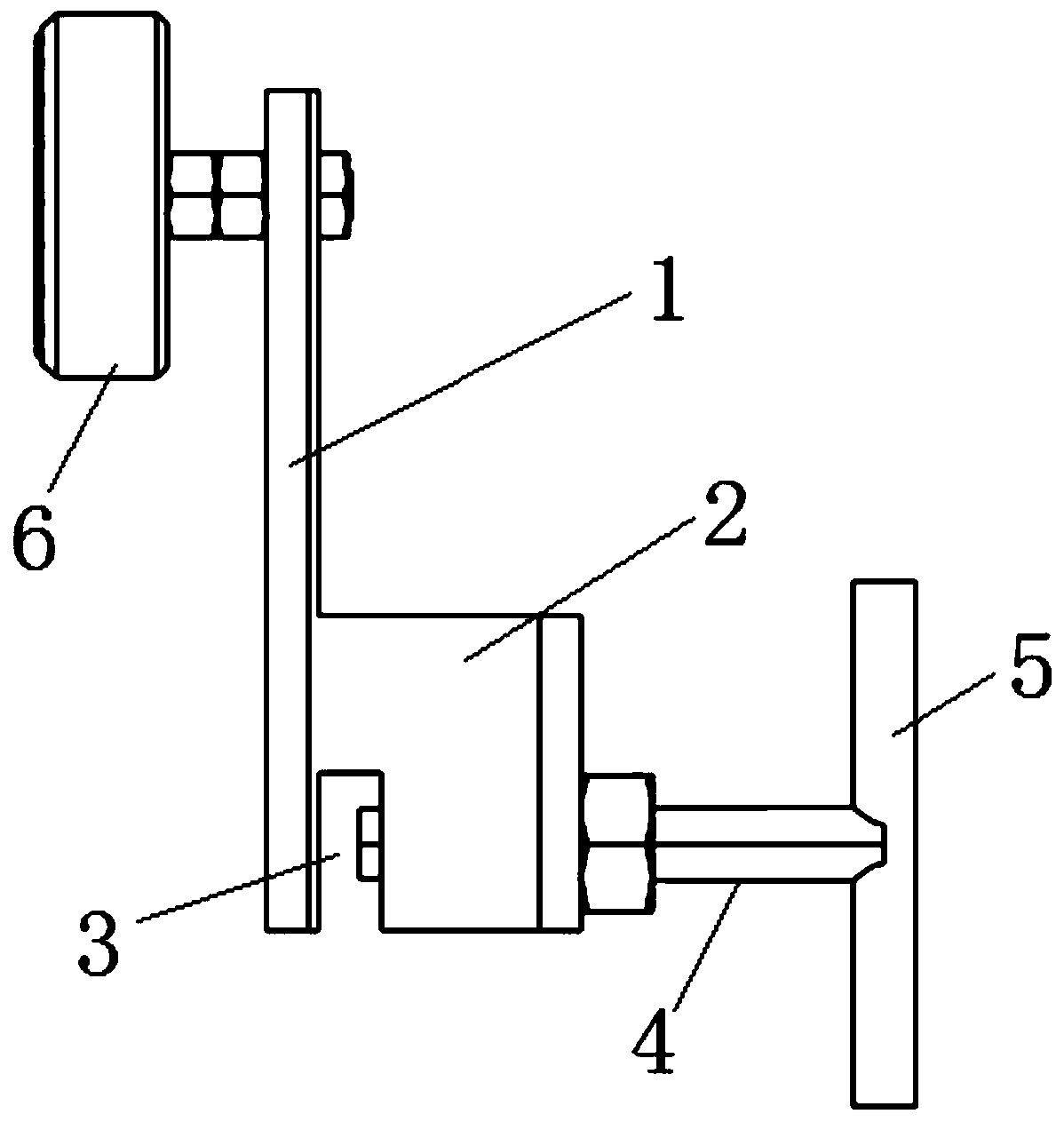

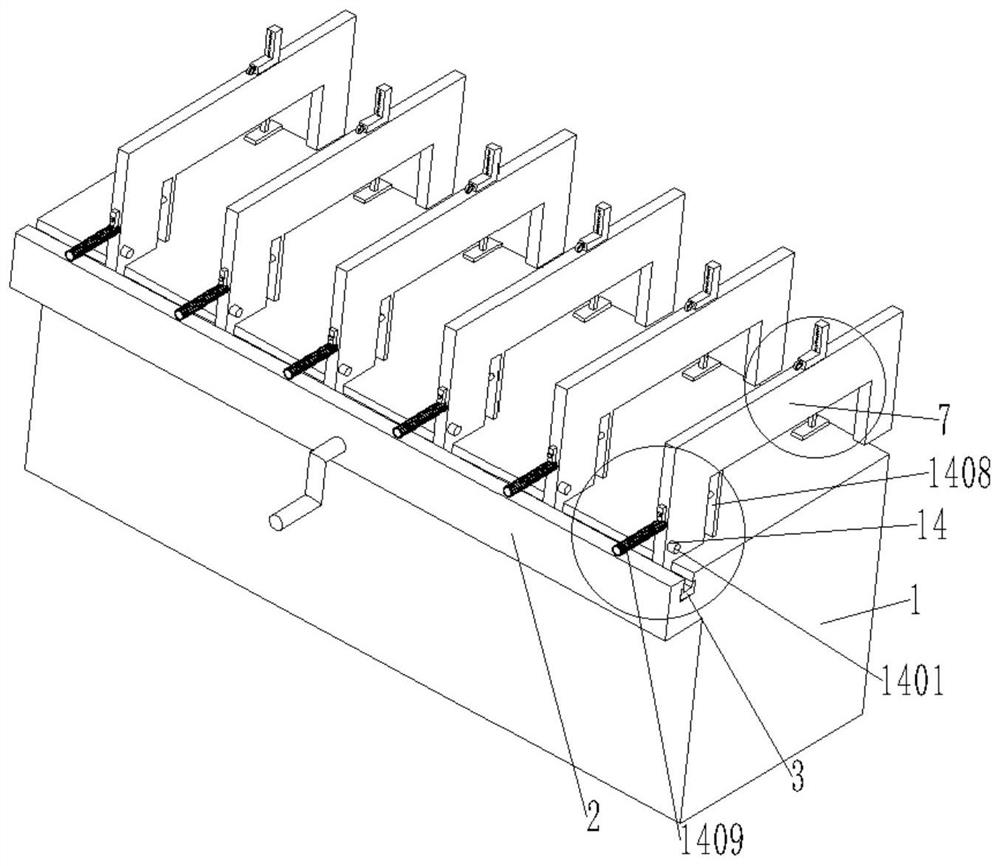

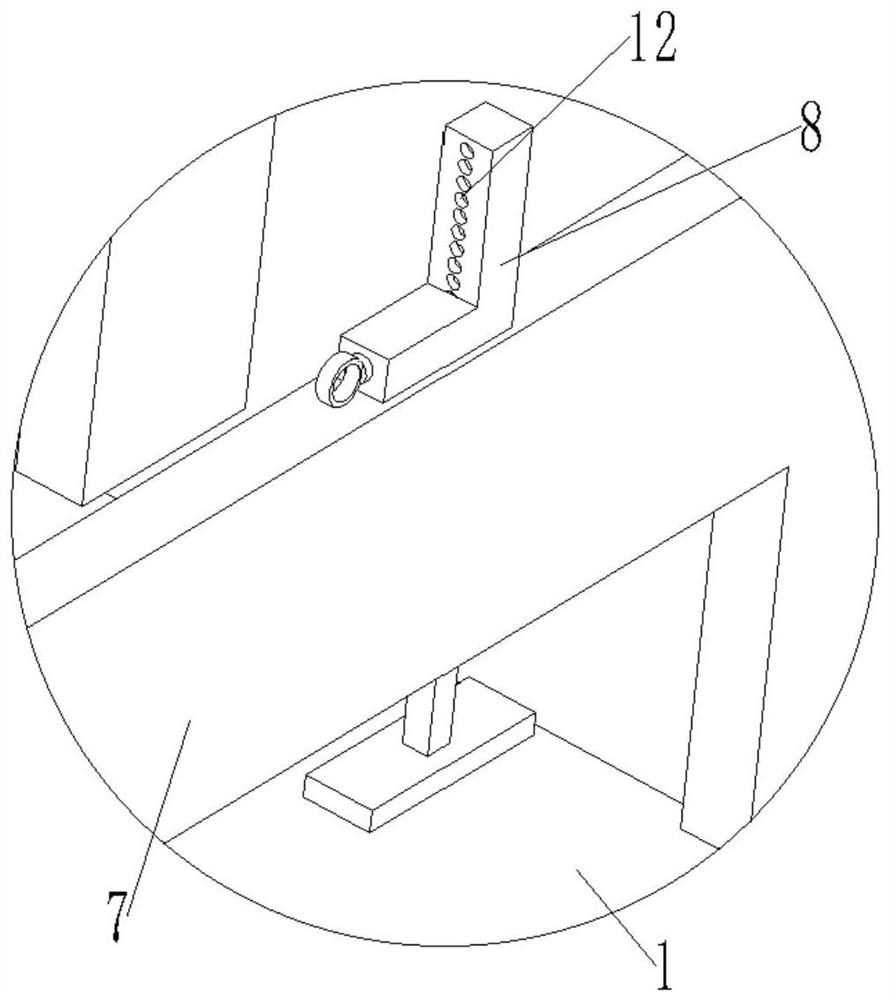

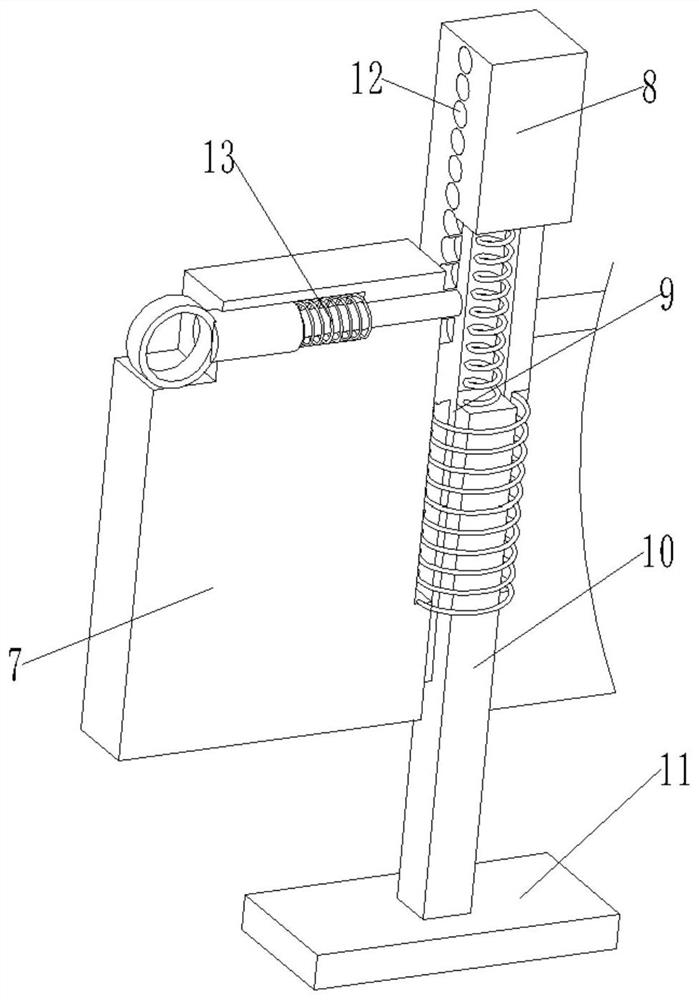

Positioning mechanism for aluminum profile cutting machining

ActiveCN111872486AAchieving horizontal positioning requirementsHigh positioning accuracyPositioning apparatusMetal-working holdersEconomic benefitsEngineering

The invention discloses a positioning mechanism for aluminum profile cutting machining. When the positioning mechanism is used for cutting aluminum profiles, an arranged positioning bracket is firstlyused for primarily positioning the aluminum profiles, and when equal-section cutting positions of the aluminum profiles are determined, the upper sides of the aluminum profiles are pressed through anarranged first positioning pressing plate, so that positioning in the vertical direction is achieved; and then one side of each aluminum profile is pressed and positioned through a second positioningpressing plate arranged in an auxiliary positioning mechanism, and a transverse positioning requirement of the aluminum profiles is met, so that the positioning accuracy, firmness and stability of the aluminum profiles during cutting work are improved, the cutting work of the aluminum profiles can be carried out more smoothly, the cutting quality of the aluminum profiles is guaranteed, the actualrequirements of production work are guaranteed, the production work quality is improved, and the economic benefits of the production work are guaranteed.

Owner:辽宁永壮铝业集团有限公司

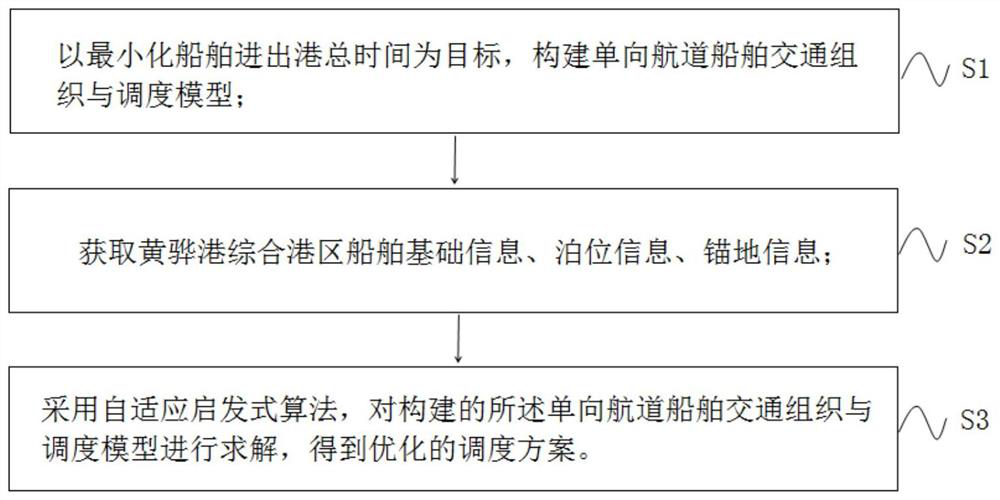

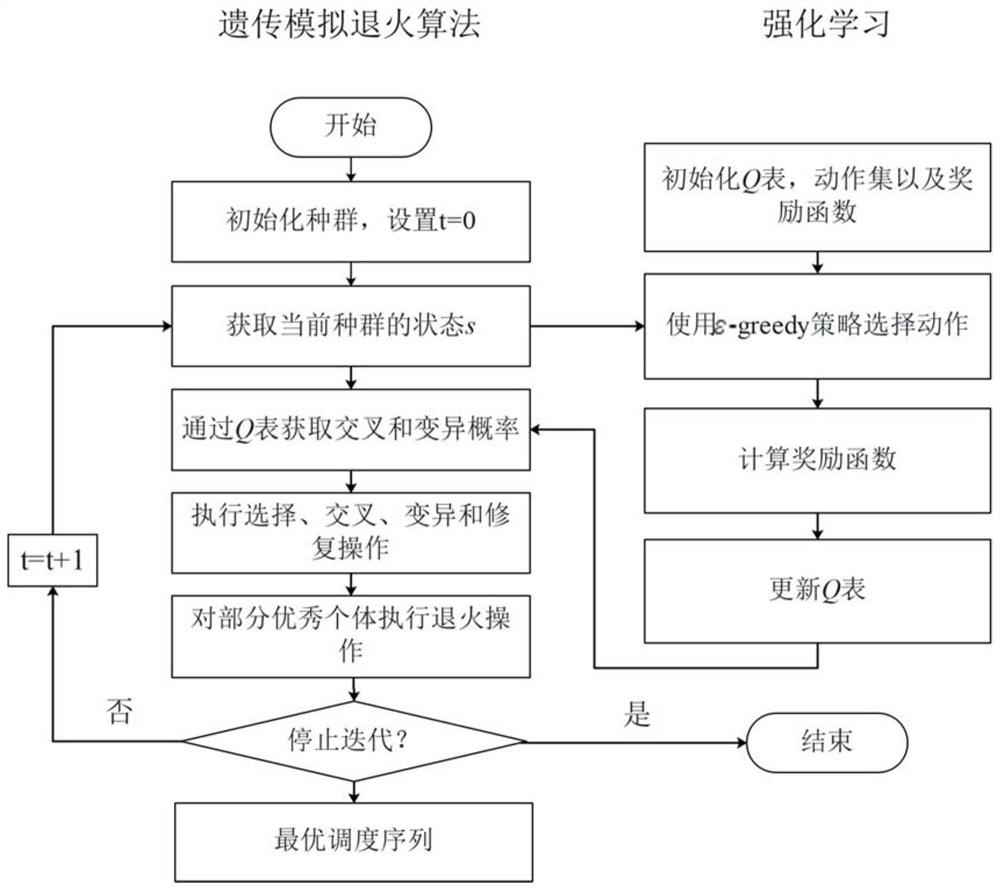

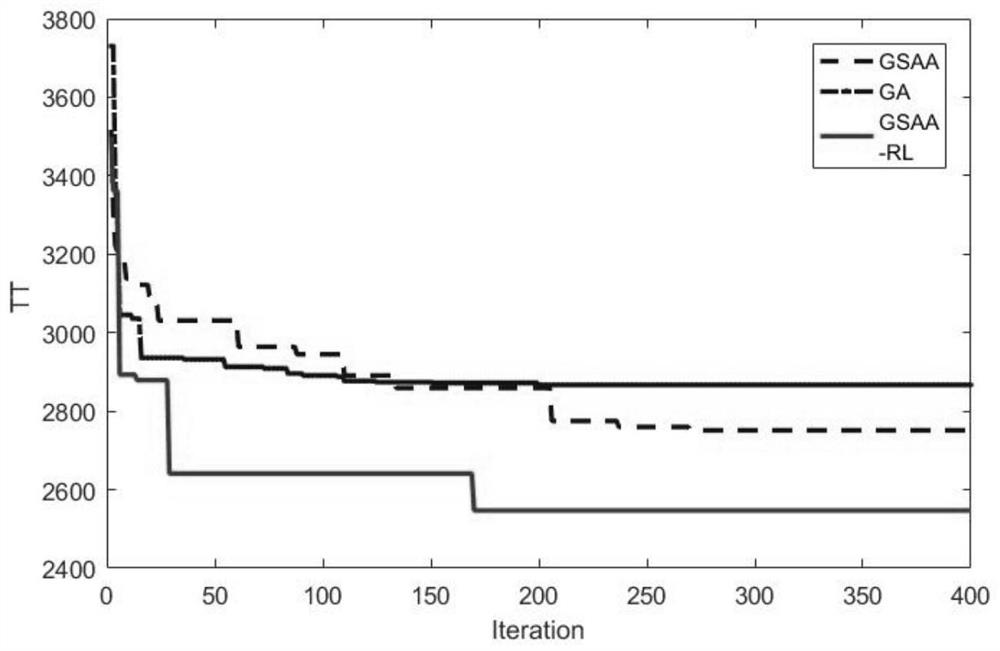

Self-adaptive heuristic algorithm for solving ship traffic organization and scheduling problem

PendingCN114037252AThe total time of entering and leaving the port is shortenedImprove the efficiency of port entry and exitResourcesGenetic algorithmsLocal optimumAlgorithm

The invention provides a self-adaptive heuristic algorithm for solving a ship traffic organization and scheduling problem. The self-adaptive heuristic algorithm comprises the following steps: establishing a one-way channel ship traffic organization and scheduling mathematical model with the goal of minimizing the total time of entering and leaving a port of a ship; obtaining ship basic information, berth information and anchoring ground information of the comprehensive harbor district of the Huanggang; using an adaptive heuristic algorithm (AHA) to solve the model. In the AHA, the genetic algorithm is used as a basic optimization model, and Q-learning is utilized to adaptively adjust crossover and mutation operators matched with ship numbers and port entering and leaving directions in the iteration process. Considering that the algorithm may fall into a local optimal solution, the invention introduces a simulated annealing algorithm to perform annealing operation on part of excellent individuals after genetic operation. According to the method, on the premise that safety is guaranteed, the total time for the ships to enter and leave the port is remarkably shortened, the ship dispatching efficiency of the one-way navigation port is improved, meanwhile, a new tool is provided for port ship traffic organization and dispatching optimization, and the defects of an existing ship traffic organization optimization method are overcome.

Owner:DALIAN MARITIME UNIVERSITY

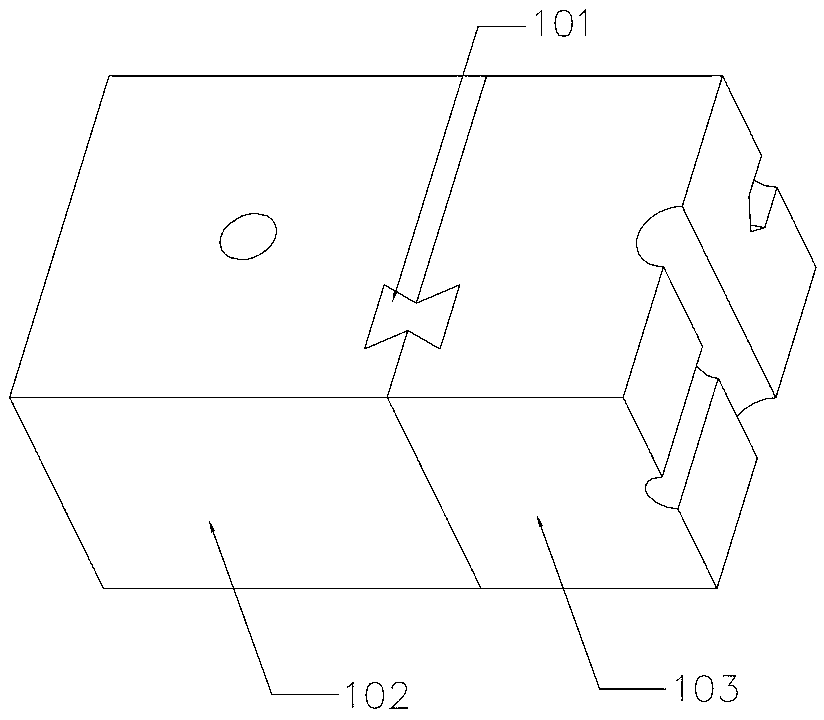

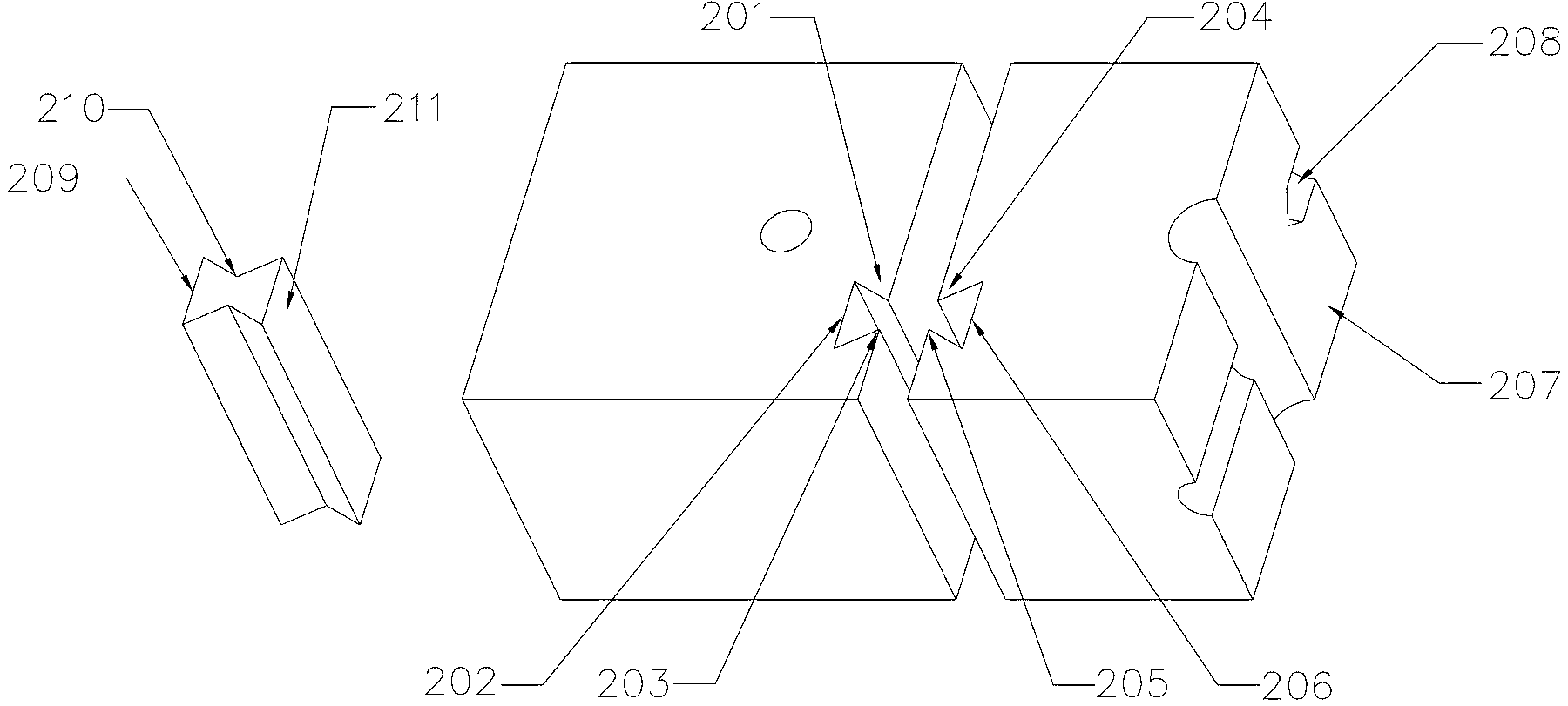

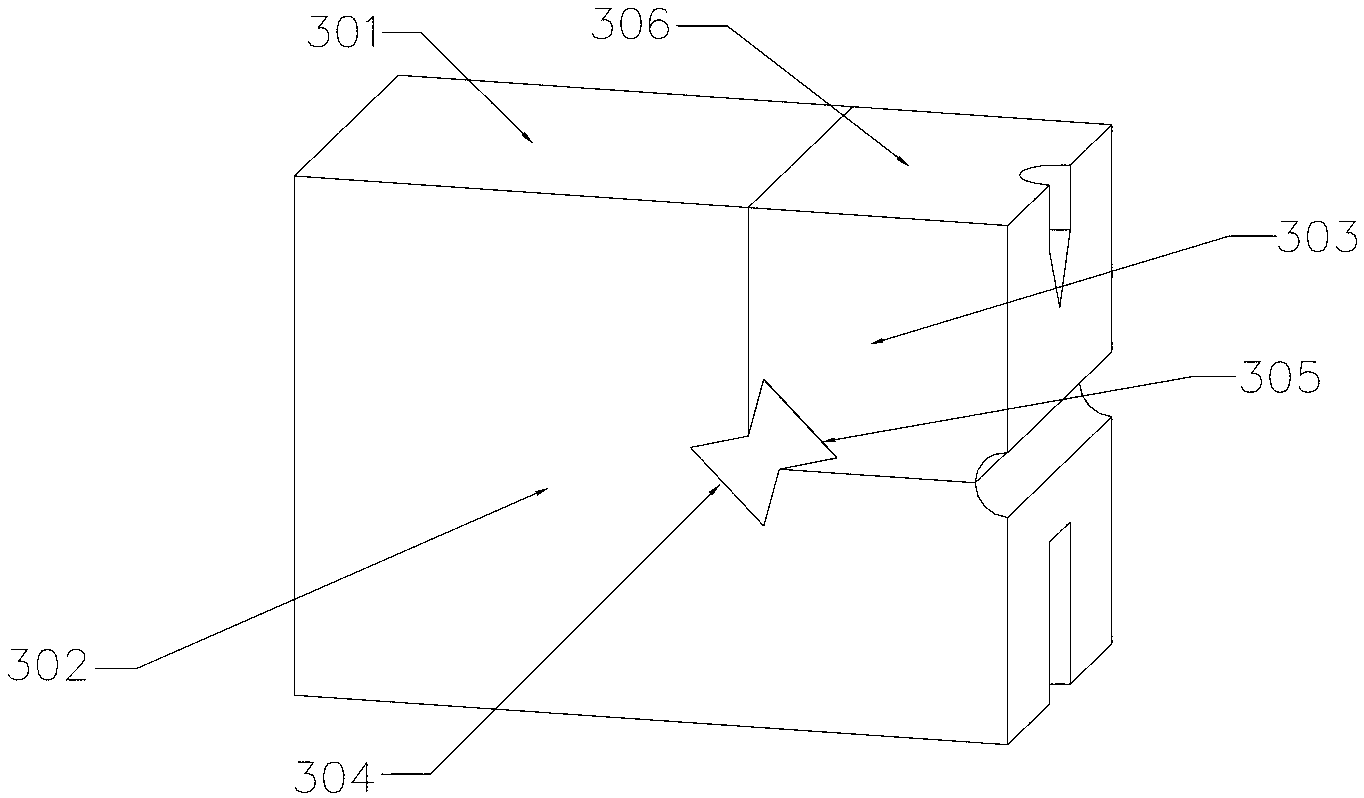

Forming mould for self drilling screws

The invention discloses a forming mould for self drilling screws. The forming mould comprises a first body and a second body, the first body is connected with the second body through a connector, a mould cavity is arranged on the second body, and material hardnesss of the first body is less than that of the second body. A first embedding groove is arranged at a first combination end of the first body, a second embedding groove is arranged at a second combination end of the second body, a first clamping portion and a second clamping portion are arranged on the connector, the first clamping portion and the second clamping portion are respectively matched with the first embedding groove and the second embedding groove, and the first clamping portion is connected with the second clamping portion through a center portion. Preferentially, the first embedding groove and the second embedding are respectively arranged on lower middle portions of the first body and the second body. By the aid of the forming mould, deformation of a mosaic structure caused by press mould impact force can be effectively avoided, and the forming mould is not easy to wear under transverse press mould impact force.

Owner:TAICANG SHOUYE AUTOMATIC CONTROL

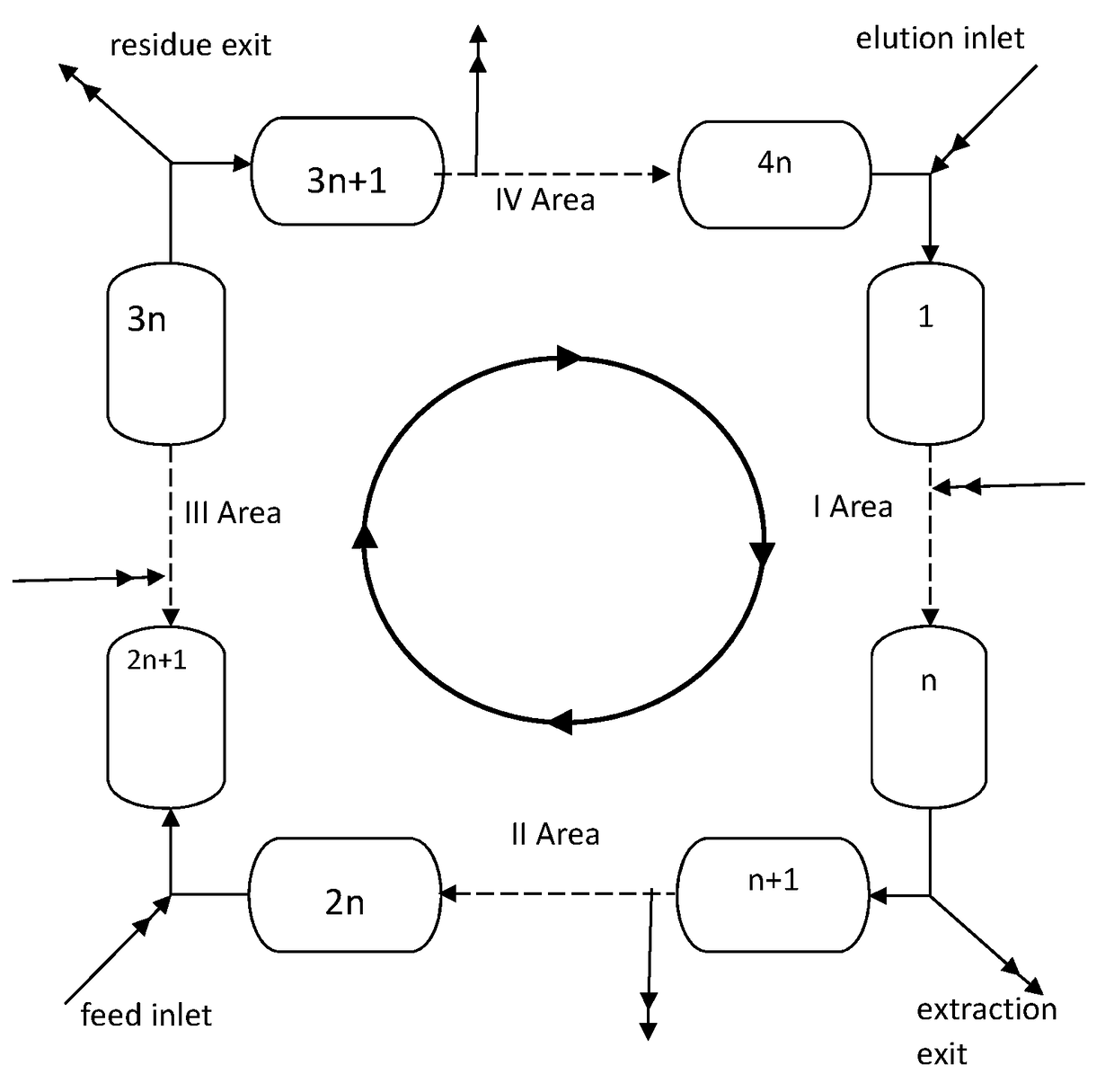

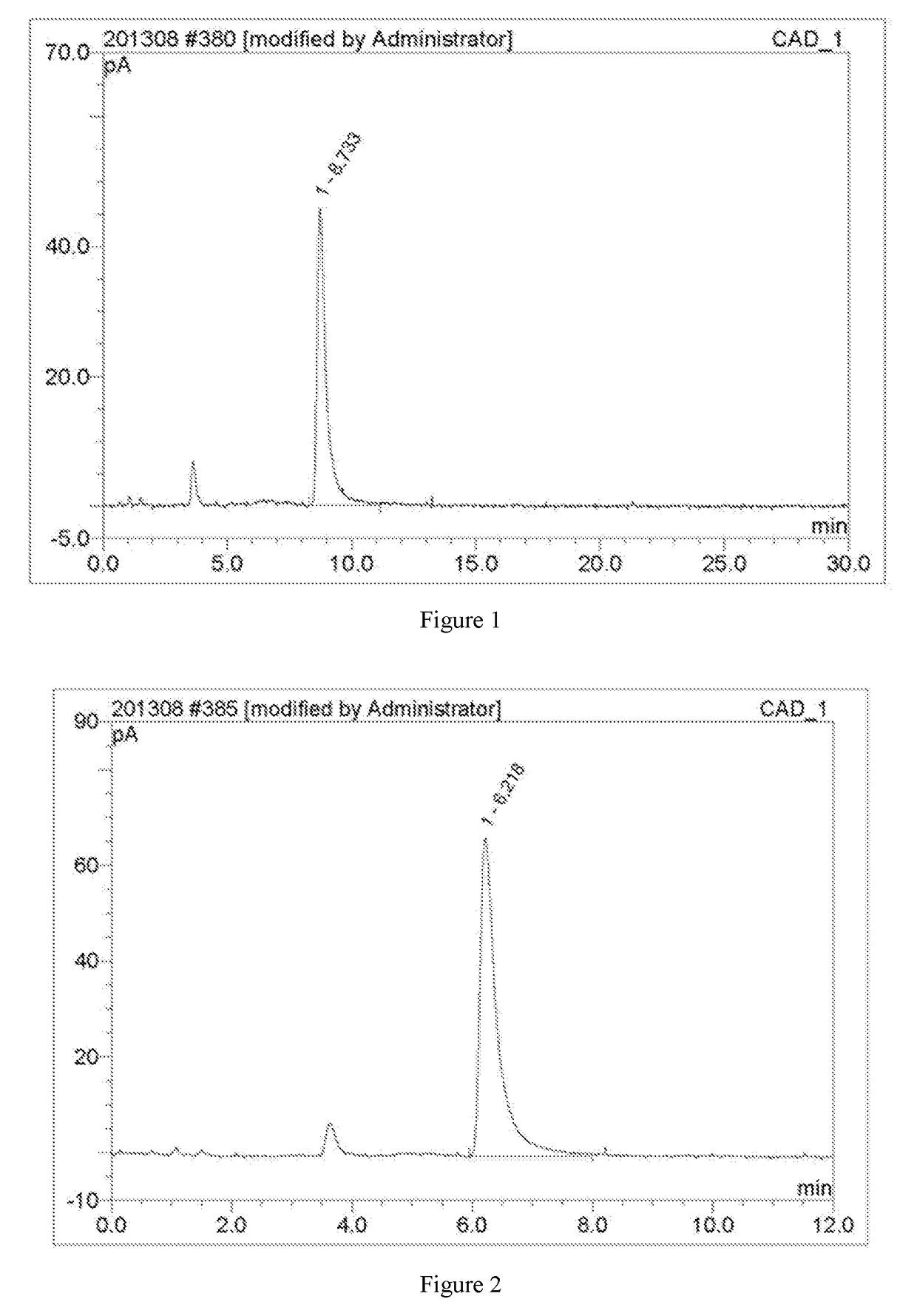

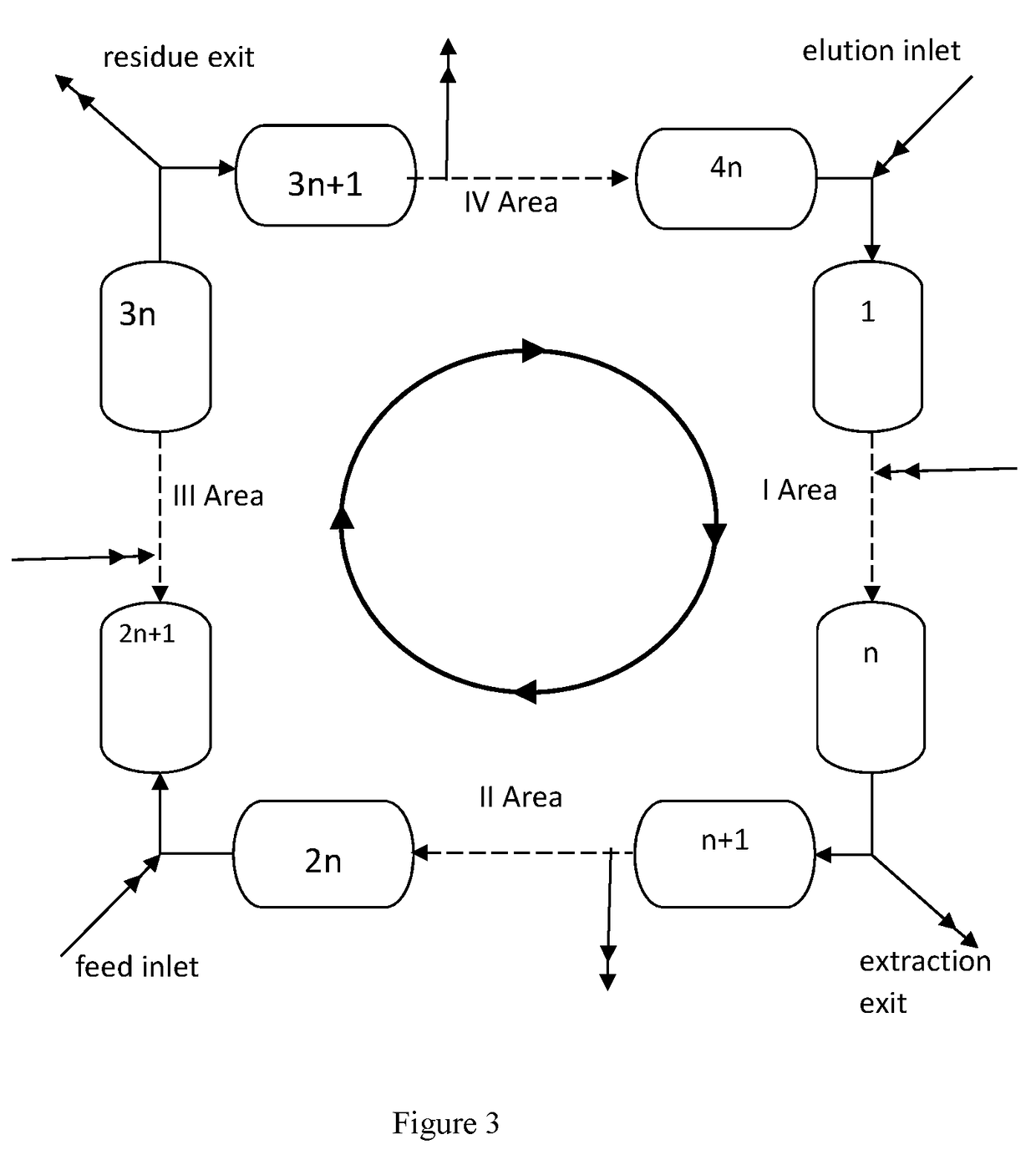

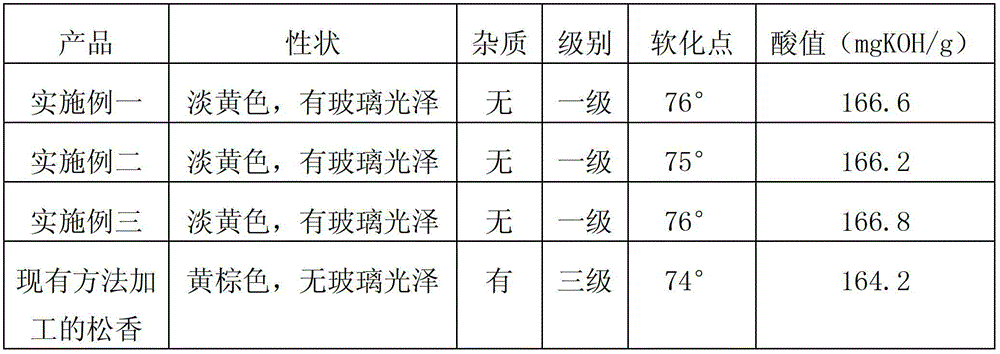

Technology for extracting and preparing high-purity raffinose from defatted wheat germ

ActiveUS20180051047A1High yieldGuaranteed production demandMembranesSemi-permeable membranesSimulated moving bedDesalination

The present invention discloses a process for preparing high-purity raffinose from defatted wheat germ comprising the steps of percolate extraction of raffinose from defatted wheat germ, decoloration by extraction from the abstraction liquid, electrodialysis desalination, impurity removal by simulated moving bed, concentration and crystallization, with the absolute purity of raffinose as high as 98% and the recovery up to 75%. The process is not only reliable and easy to operate, but also easy to realize industrial production and control the parameters.

Owner:ZHEJIANG UNIV

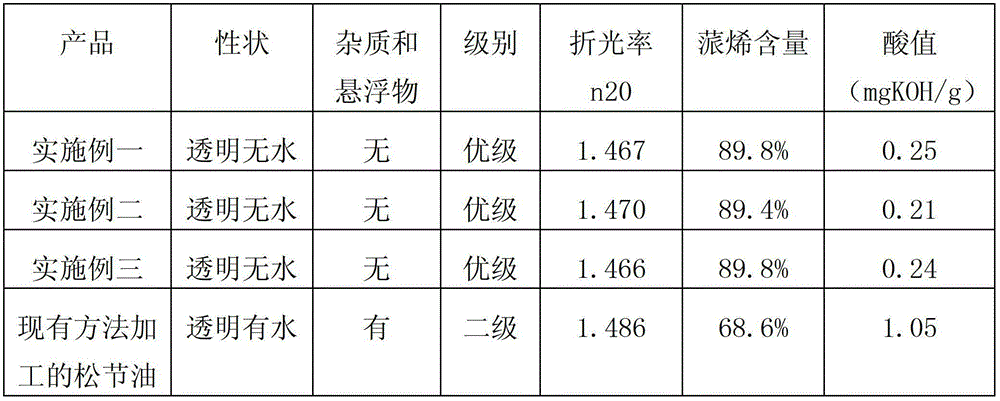

Processing method of pine resin

InactiveCN103087635BQuality improvementImprove solubilityTurpentine spiritsNatural resin purificationOxalateFiltration

The invention relates to a processing method of pine resin and belongs to the field of rosin production. The processing method of pine resin comprises the following steps of: a, dissolving, namely dissolving the pine resin by adopting a dissolving solution, wherein the dissolving solution comprises the following components in percentage by weight: 55-82% of turpentine oil, 17.5-44.5% of water and 0.1-0.5% of oxalic acid; b, clarifying and colating, namely placing the dissolved pine resin liquid in a transition pot to be clarified and then colating to obtain colature; c, acid washing, namely adding the oxalic acid for washing; d, washing, namely adding hot water for washing; e, clarifying and carrying out refined filtration, namely placing the pine resin liquid into the transition pot to be clarified and then carrying out refined filtration; and f, heating and distilling, namely placing the pine resin liquid in a rectifying tower to be subjected to the heating and distilling, so that rosin and turpentine oil finished products are respectively obtained. The processing method of rosin provided by the invention has the beneficial effect that the qualities of the rosin and turpentine oil obtained by processing pine resin are excellent, so that demand of downstream industries is met.

Owner:云南茶花林化有限公司

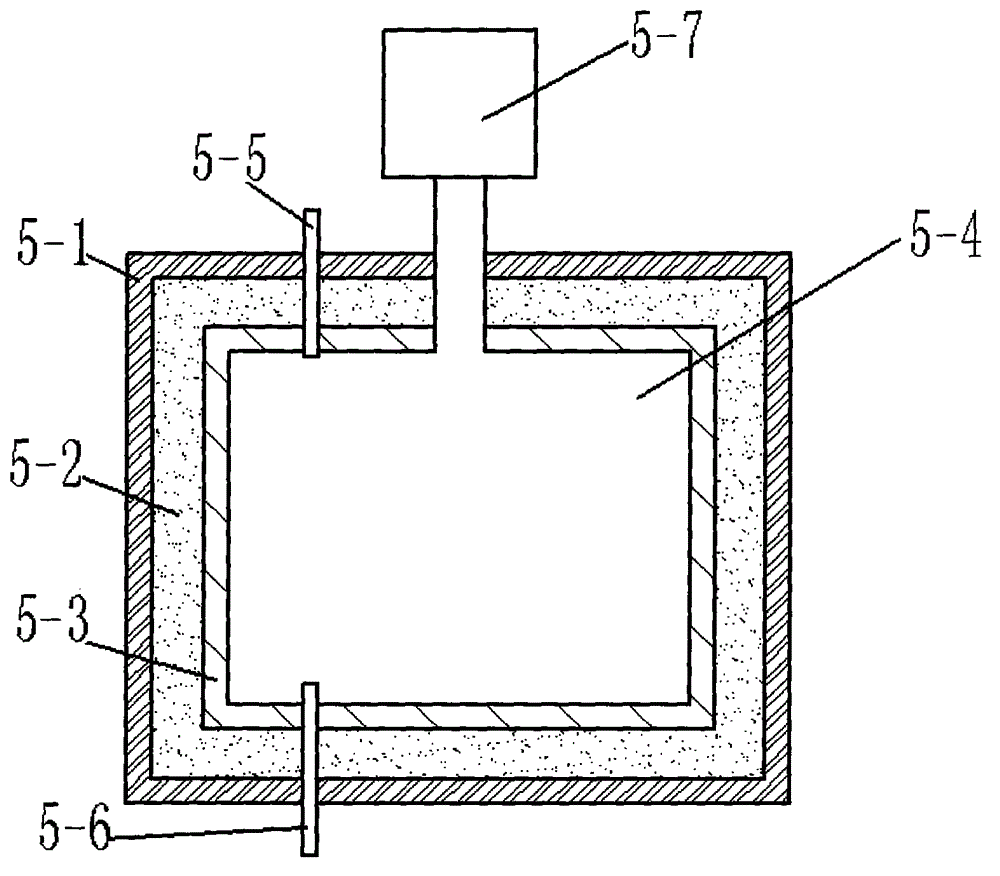

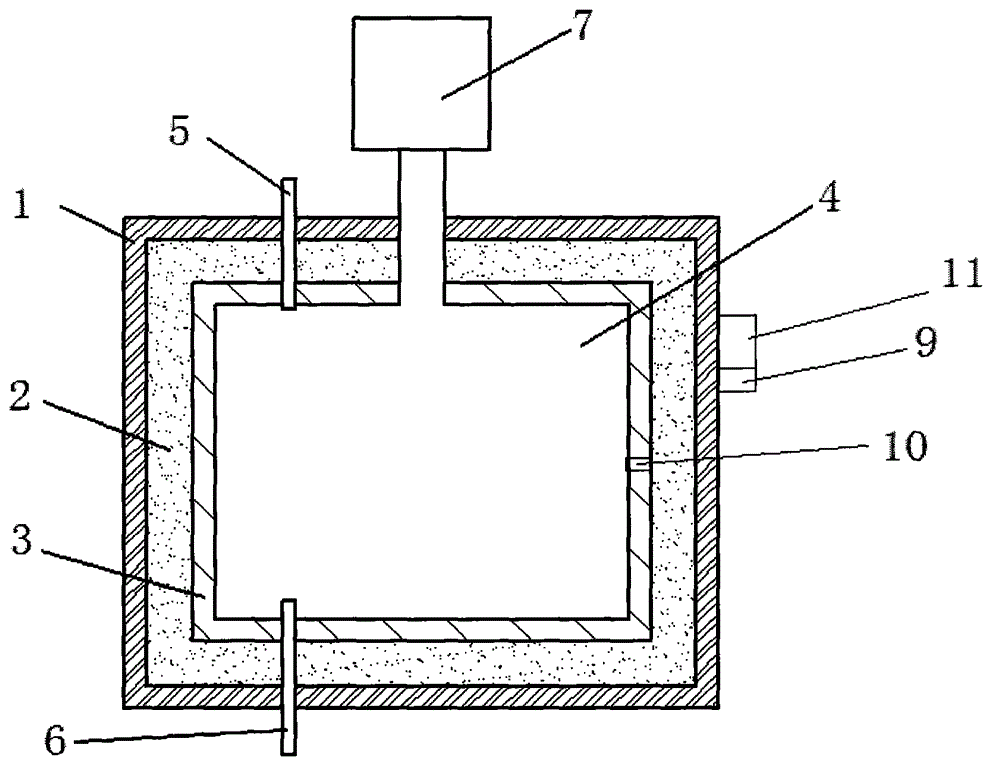

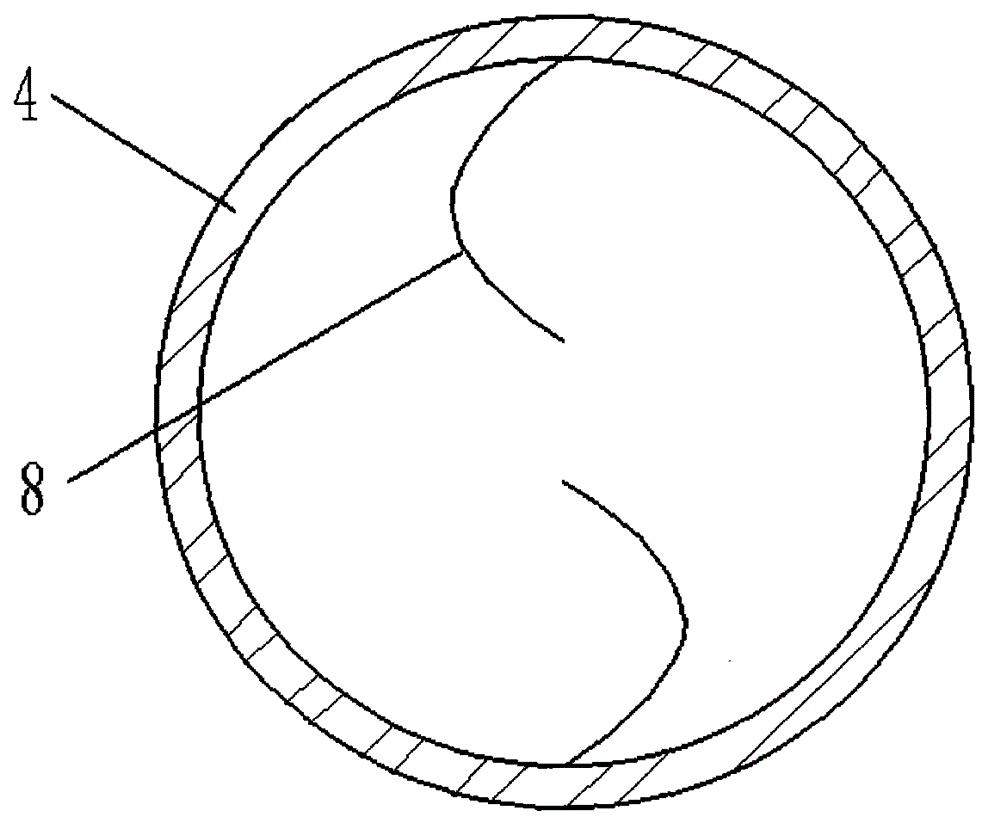

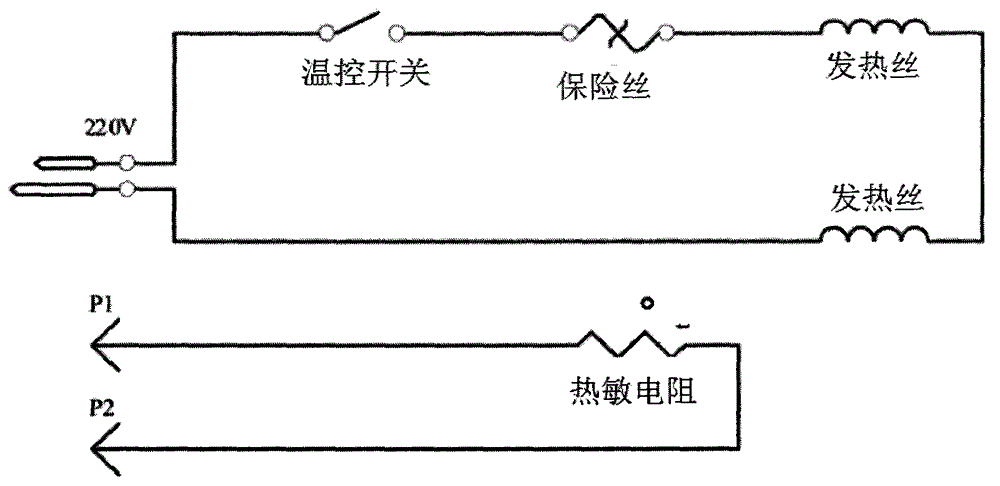

High-viscosity composite modified pitch and storing and heating device thereof

InactiveCN105316020AThermal storage stableGood high and low temperature performanceWorking-up pitch/asphalt/bitumen by meltingBuilding insulationsEngineeringTemperature monitoring

The invention discloses high-viscosity composite modified pitch and a storing and heating device thereof. The storing and heating device of the high-viscosity composite modified pitch is provided with a shell, a heating container and an inner container, a temperature indicator and a control switch of the heating container are installed on the shell, a temperature monitoring device is installed on the inner container, the temperature monitoring device is connected with the temperature indicator through a wire, and the temperature indicator is connected with the control switch. The high-viscosity composite modified pitch is prepared from, by weight, 85 parts of pitch and 15 parts of modified compounds. The prepared composite high-viscosity modified pitch has the advantages of being stable in heat storage and good in high temperature and low temperature performance; a large number of pitch raw materials are stored, preheating treatment is conducted on the pitch raw materials, the temperature of the pitch can be controlled accurately, the production requirement is guaranteed, and the energy is saved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Extra-Large Vibrating Screen With Duplex Statically Indeterminate Mesh Beam

ActiveUS20090026113A1Decrease massBending and torsion resistance be improveSievingScreeningCoalMesh grid

An extra-large vibrating screen with duplex statically indeterminate mesh beam excitation body and plate type combined bearing beam comprises plate type flat and rigid statically indeterminate combined bearing beam (12) arranged in a screen box (1), a plurality of Y-shaped statically indeterminate combined reinforcing beams (5) arranged on the side plates (3) of the screen box alternately, duplex statically indeterminate supporting plates (22) linking a plurality of mesh beams (21) to the statically indeterminate connecting plate (4) and the side plate (3) so as to form a container made of a beam system, the vibration exciters (10) in the statically indeterminate mesh beam unit comprising eight sets of vibration exciters, which are aligned in pair horizontally and linked together through universal couplings (9), and connected to the duplex statically indeterminate mesh beam excitation body (11) to form a highly rigid integral vibrating assembly. The vibrating screen is simple and reliable in structure, can vibrate smoothly, and therefore can be widely used in coal, metallurgical, chemical, and environmental protection industries.

Owner:CHINA UNIV OF MINING & TECH

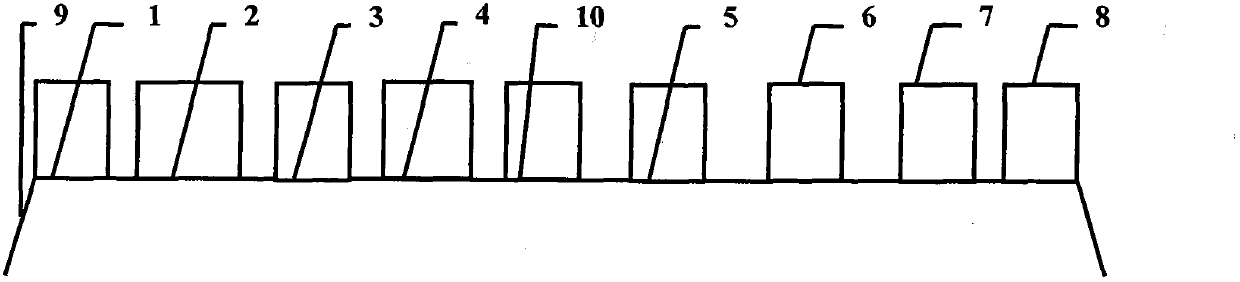

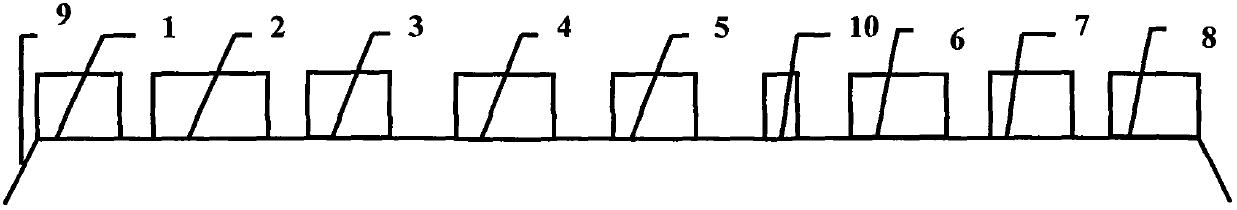

Rack of multi-cylinder long mesh paper machine for producing high filler paper

InactiveCN103669098AIncrease the lengthGuaranteed production demandPaper-making machinesPaper machine

The invention discloses a rack of a multi-cylinder long mesh paper machine for producing high filler paper. A flow pulp box mounting position, a mesh section mounting position, a press section mounting position, a front drying section mounting position, a sizing machine mounting position, a rear drying section mounting position, a calender mounting position and a paper rolling section mounting position are arranged on the rack in sequence, proper intervals are formed between positions, the overall length of the rack is increased by 10-25m relative to the overall length of the rack of a traditional multi-cylinder long mesh paper machine of the same width and speed, the length of the mesh section mounting position is relatively increased by 4-6m, and enhancing drying mounting positions can be arranged in front of and behind the sizing machine mounting position. The problem that the traditional rack cannot be used for mounting the multi-cylinder long mesh paper machine for producing the high filler paper is solved, and the demand for mounting the multi-cylinder long mesh paper machine for producing the high filler paper is met.

Owner:GUONENG PAPER IND +1

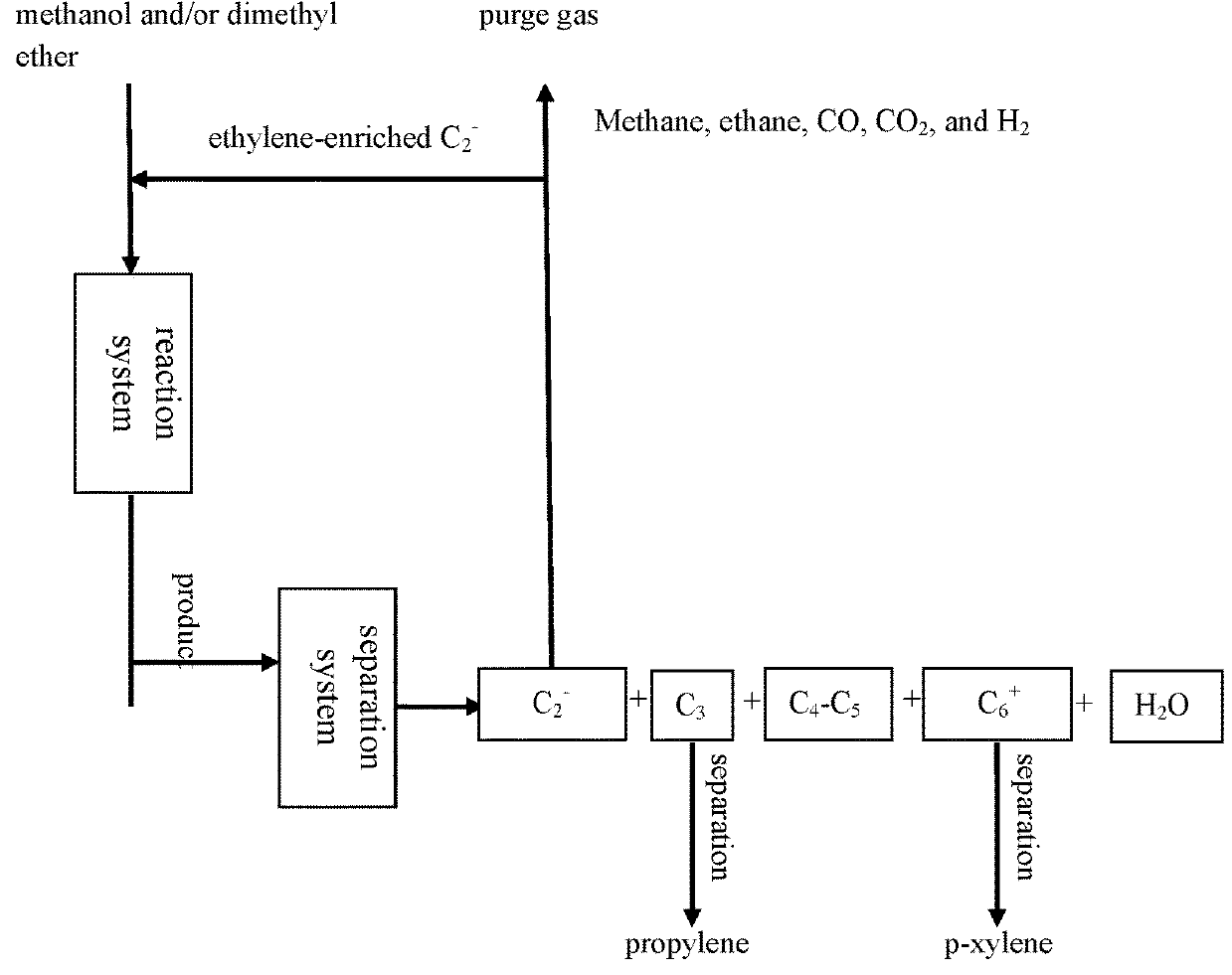

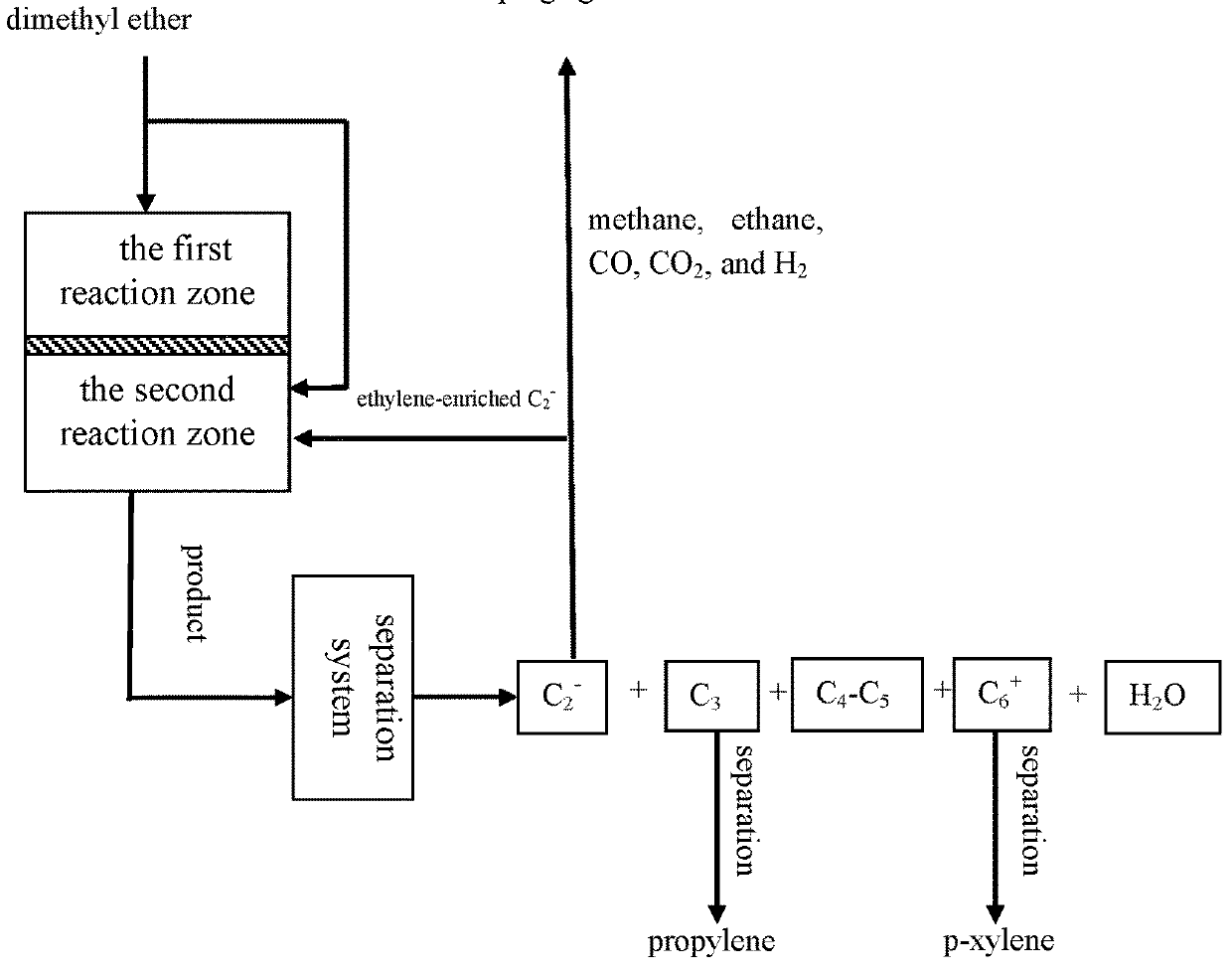

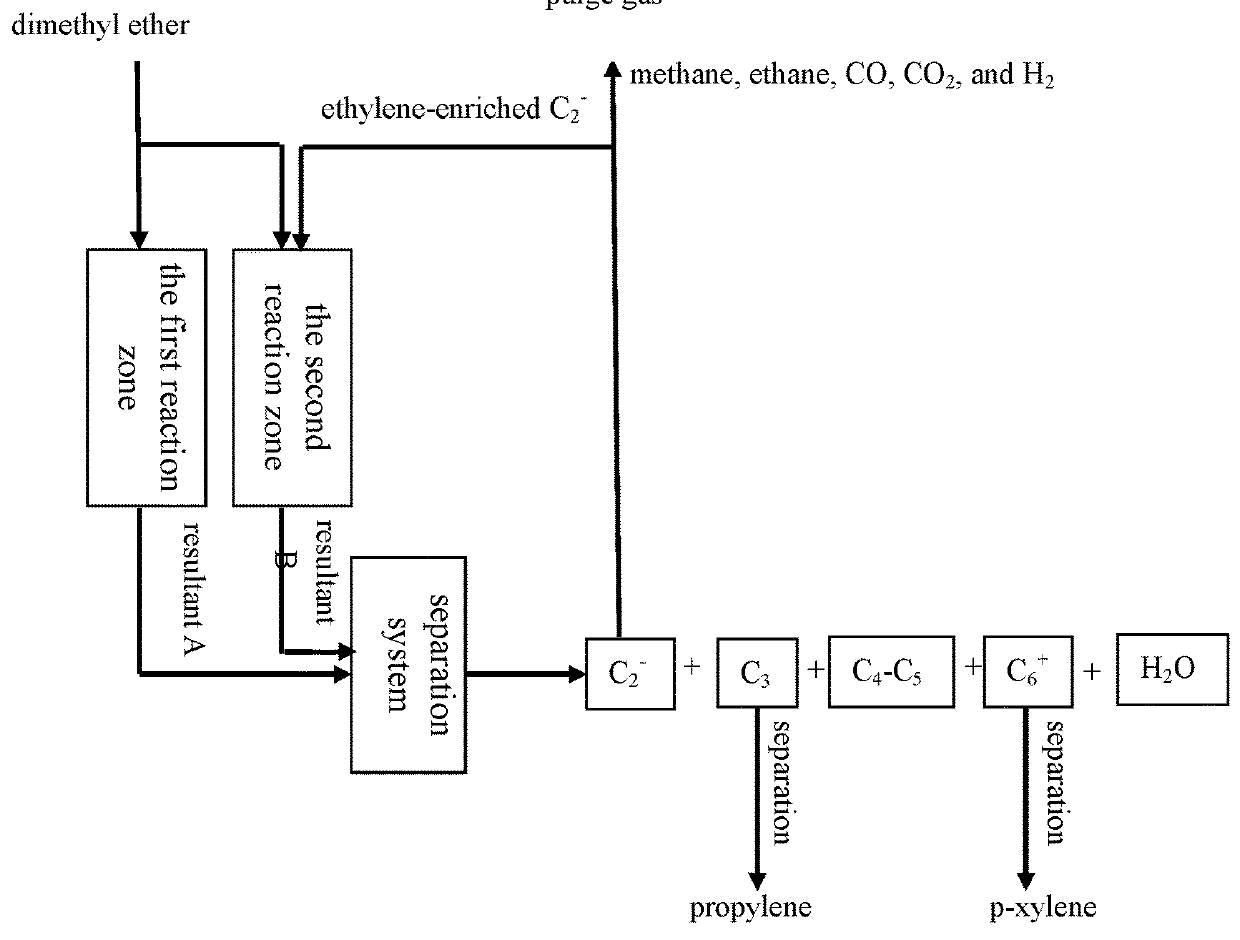

Method for preparing p-xylene and co-producing propylene with high selectivity

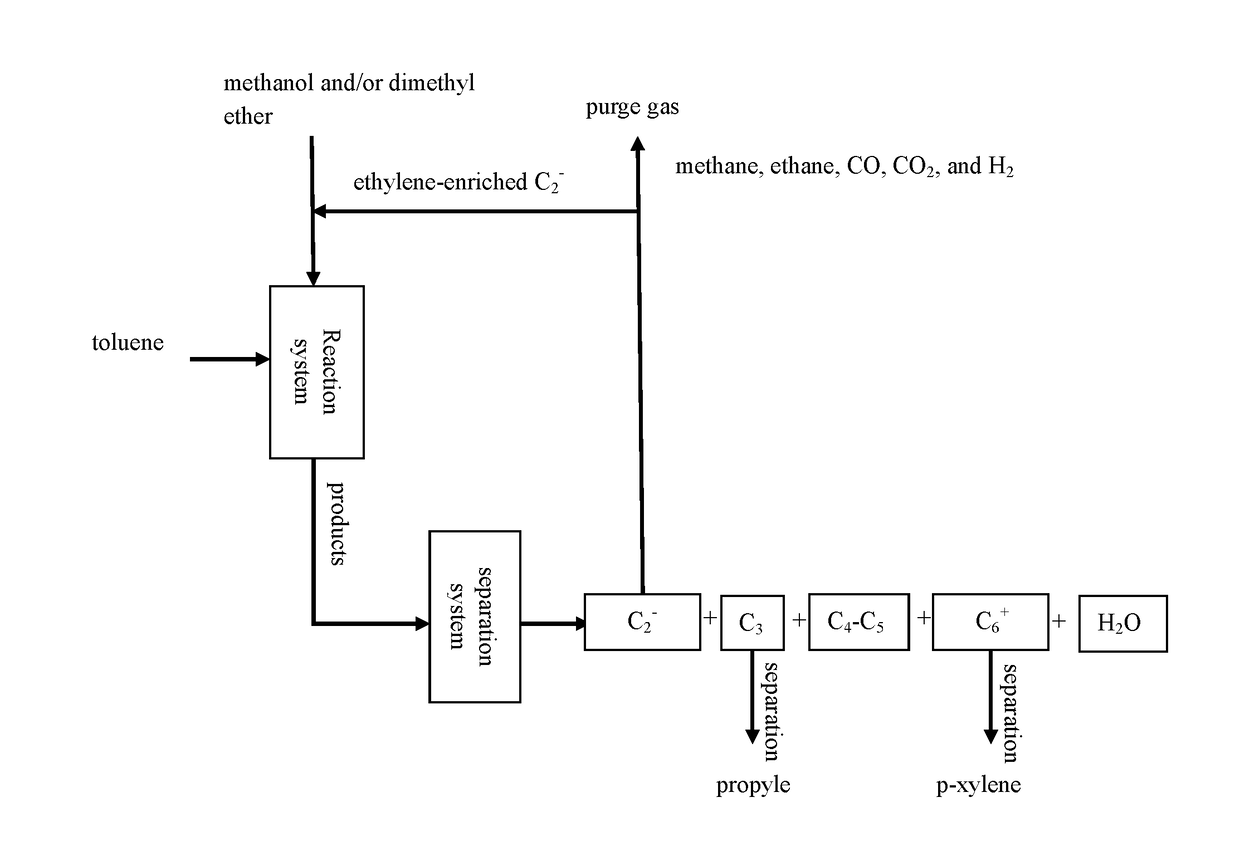

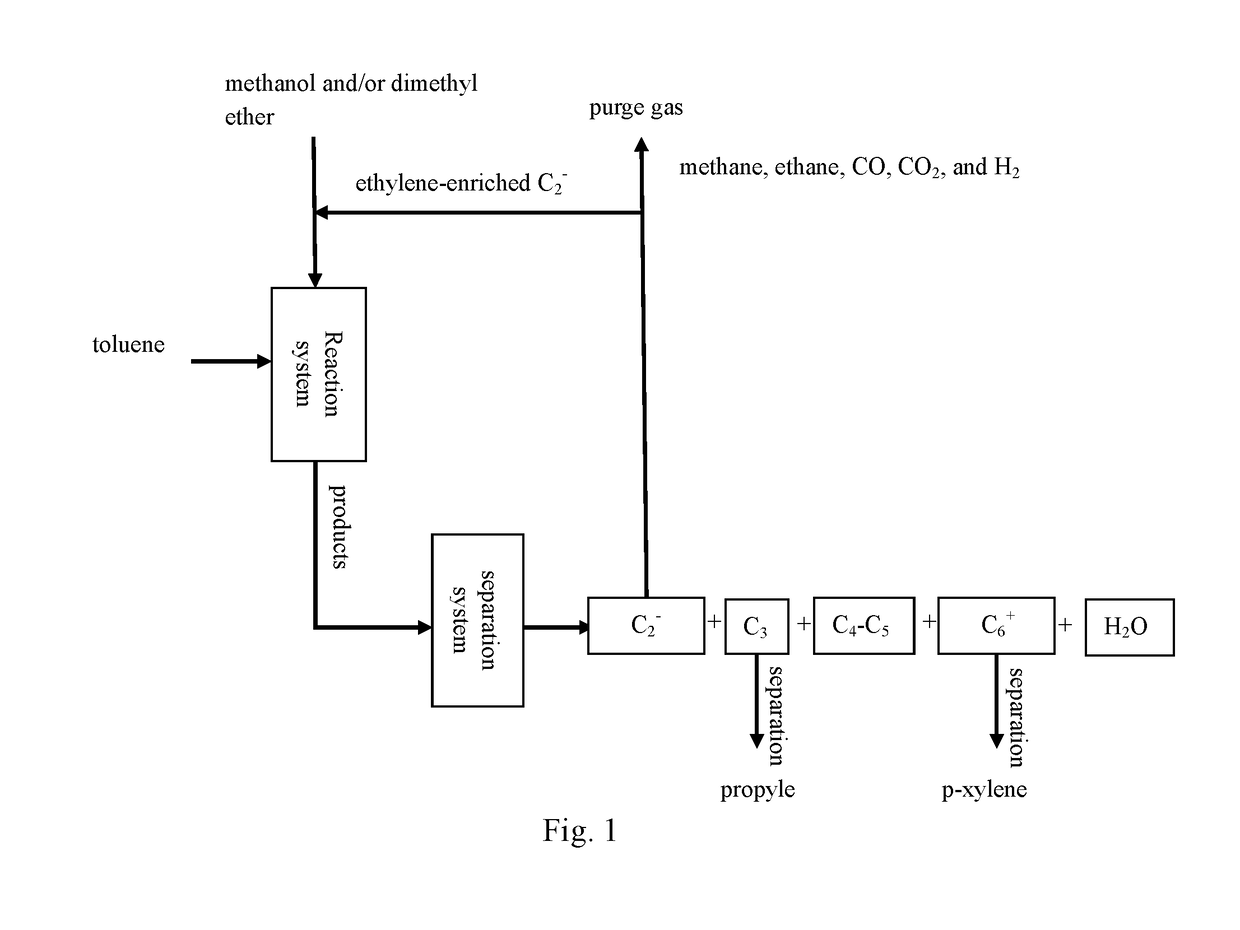

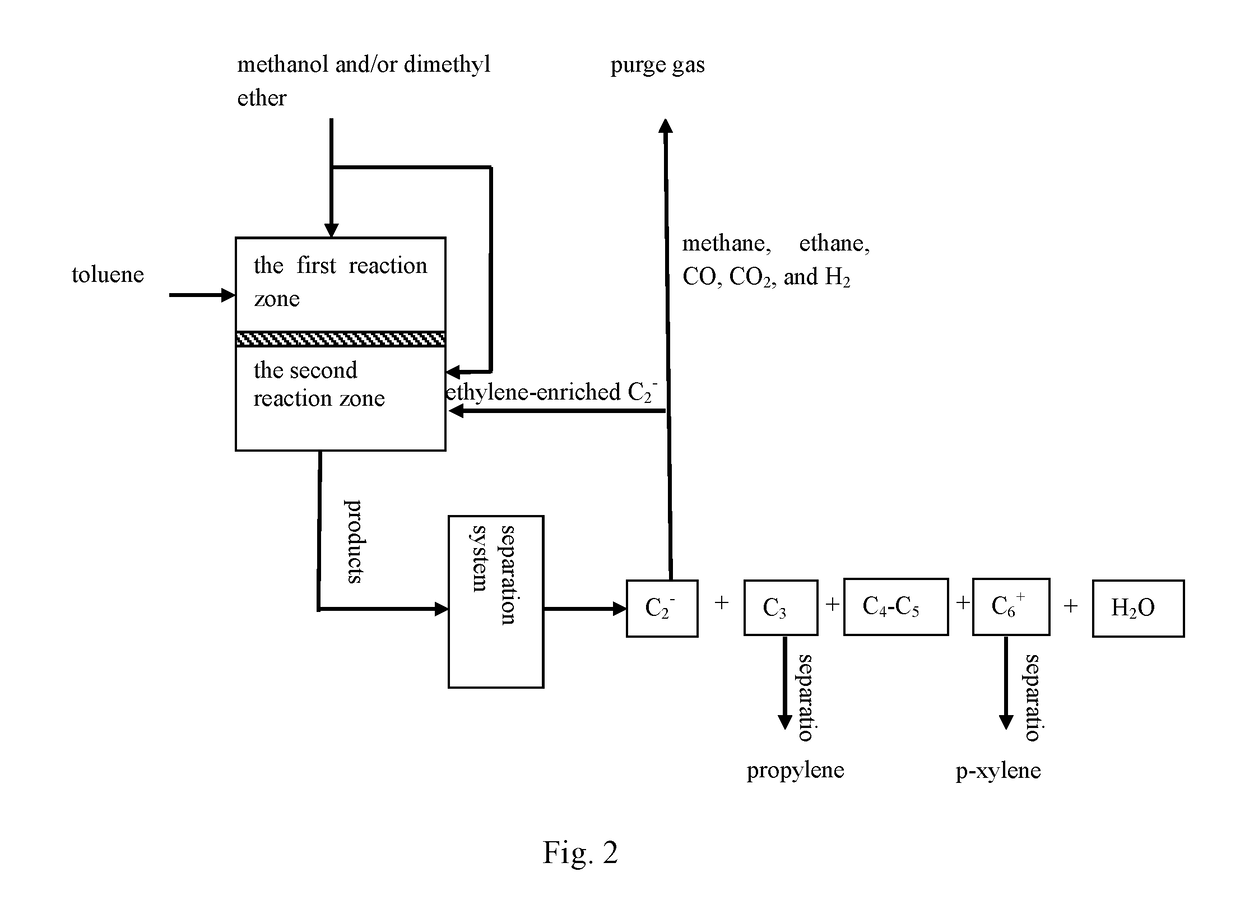

ActiveUS20170152197A1High selectivityImprove economyGroup 4/14 element organic compoundsMolecular sieve catalystsReaction systemEthylene

A method for preparing p-xylene and co-producing propylene with a high selectivity, comprising:a) bringing a raw material containing toluene and methanol and / or dimethyl ether into contact with a catalyst in a reaction system for reaction; returning an ethylene-enriched C2− component discharged from the reaction system to the reaction system, and continuing the reaction with the raw material on the catalyst to produce propylene;b) separating a C6+ component discharged from the reaction system to obtain a product p-xylene; andc) separating a C3 component discharged from the reaction system to obtain a product propylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

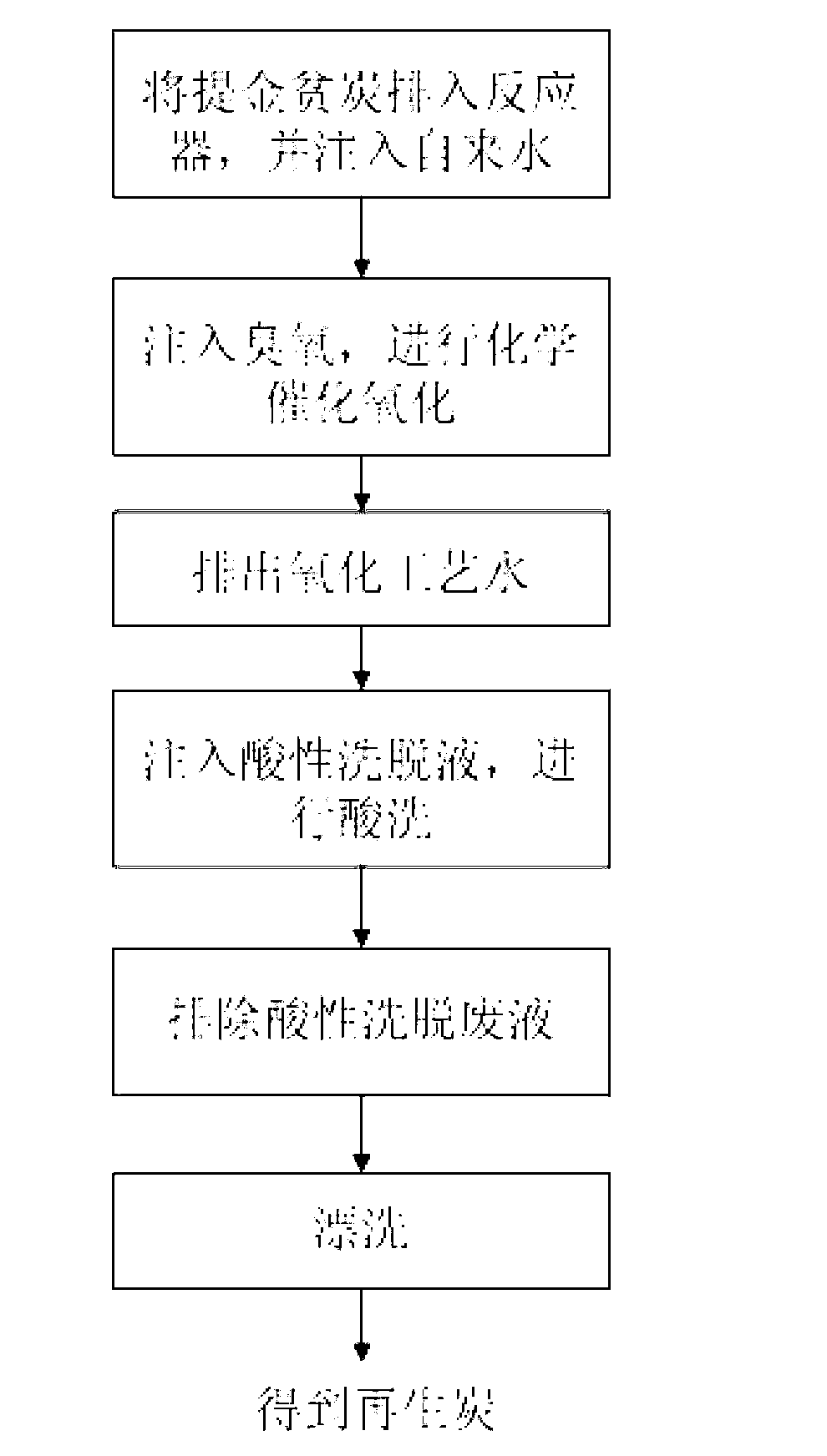

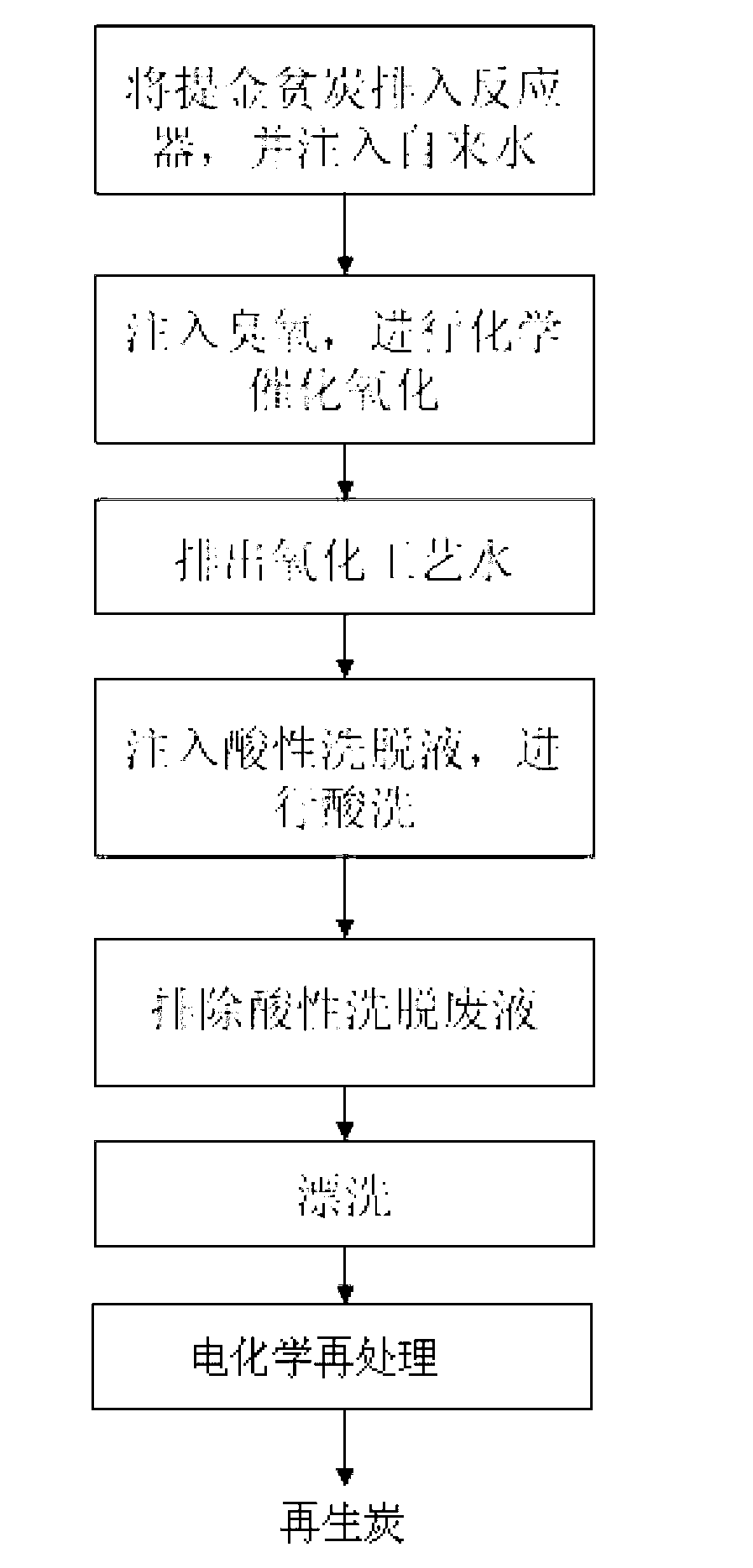

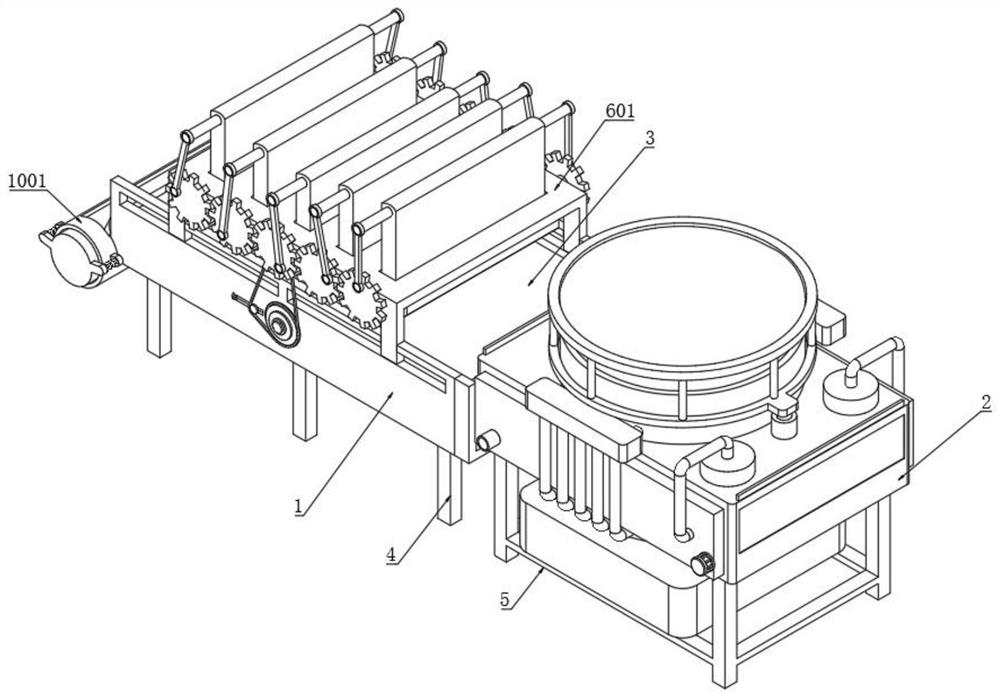

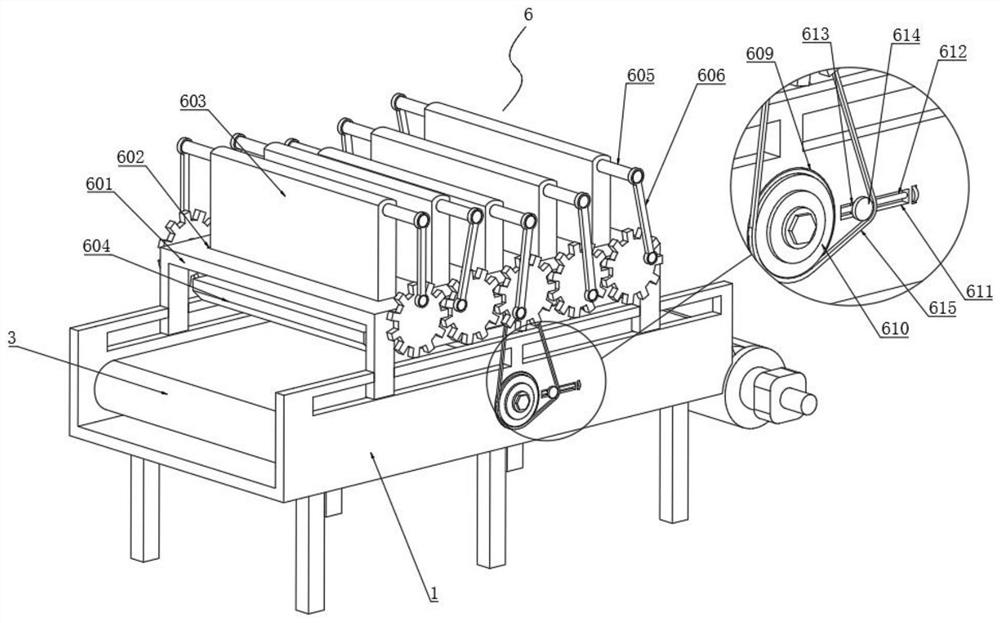

Normal temperature and normal pressure regeneration method for activated carbon for gold extraction

ActiveCN103301810ASave resourcesImprove the production efficiency of gold absorptionOther chemical processesCombustible gas purificationActivated carbonPhysical chemistry

The invention discloses a normal temperature and normal pressure regeneration method for activated carbon for gold extraction. According to the method, the problem of low economical property of a conventional high-temperature heat-method activated carbon regeneration reactor can be solved; high-efficiency activated carbon regeneration can be realized at normal temperature and normal pressure with low cost according to an advanced oxidization and chemical elution theory. The normal temperature and normal pressure regeneration method comprises the specific steps of: discharging the activated carbon for gold extraction to be regenerated into a reactor, and then injecting running water into the reactor; oxidizing the activated carbon in the reactor by injecting ozone into the reactor; after the oxidation is finished, discharging oxidation process water out of the reactor; chemically eluting the activated carbon in the reactor by an acidic eluting solution; after the chemical elution is finished, discharging the acidic eluting solution out of the reactor; and injecting running water into the reactor to rinse the activated carbon in the reactor, thus obtaining regenerated carbon.

Owner:辽宁排山楼黄金矿业有限责任公司

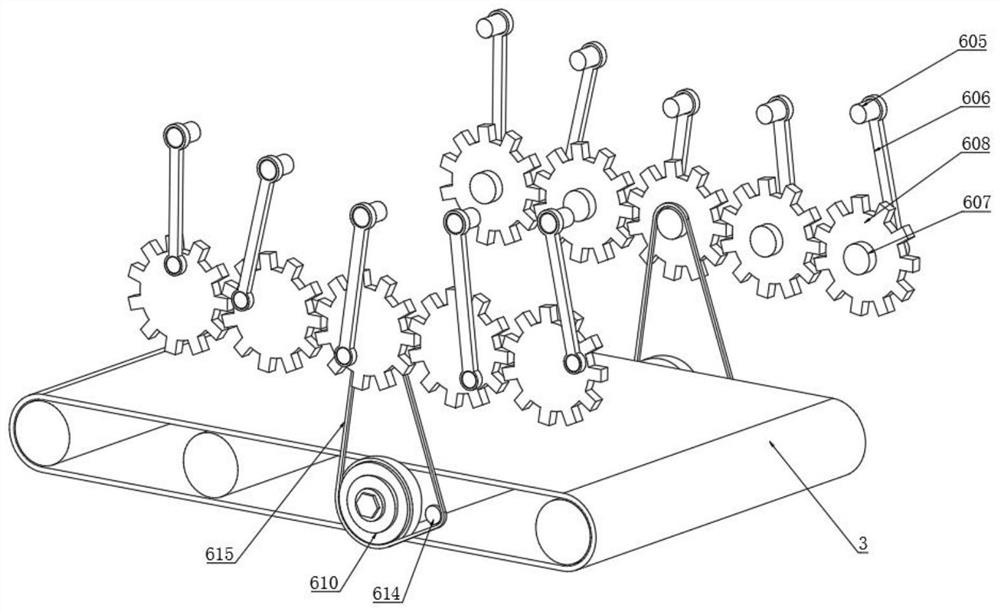

Environment-friendly agricultural economy recovery device

ActiveCN113070319AGuaranteed tightnessPrevent loosening and fallingSolid waste disposalTransportation and packagingAgricultural scienceDrive wheel

The invention discloses an environment-friendly agricultural economy recovery device. The environment-friendly agricultural economy recovery device comprises a rack, wherein one end of the rack is fixedly connected with a drying box; the top end of the rack is fixedly connected with a conveyor belt; the bottom end of the rack and the bottom end of the drying box are fixedly connected with supporting legs at equal intervals; the inner walls of the supporting legs at the bottom end of the drying box are fixedly connected with a bottom frame; and a beating and crushing mechanism is arranged at the central position of the top end of the rack. The environment-friendly agricultural economy recovery device is scientific and reasonable in structure and safe and convenient to use; the beating and crushing mechanism is arranged, and a driving wheel is driven by the conveyor belt, so that the driving wheel is matched with a belt to drive a transmission shaft and gears to rotate; through transmission between the gears, the gears pull a fixed rod, a movable plate and a pressing plate to move through a rotating plate together to beat passing waste materials and crush the dried waste materials, so that subsequent treatment is facilitated, and the convenience of the device is improved; and in addition, the position of the belt on the outer side of the driving wheel is adjusted as required.

Owner:HENGYANG NORMAL UNIV

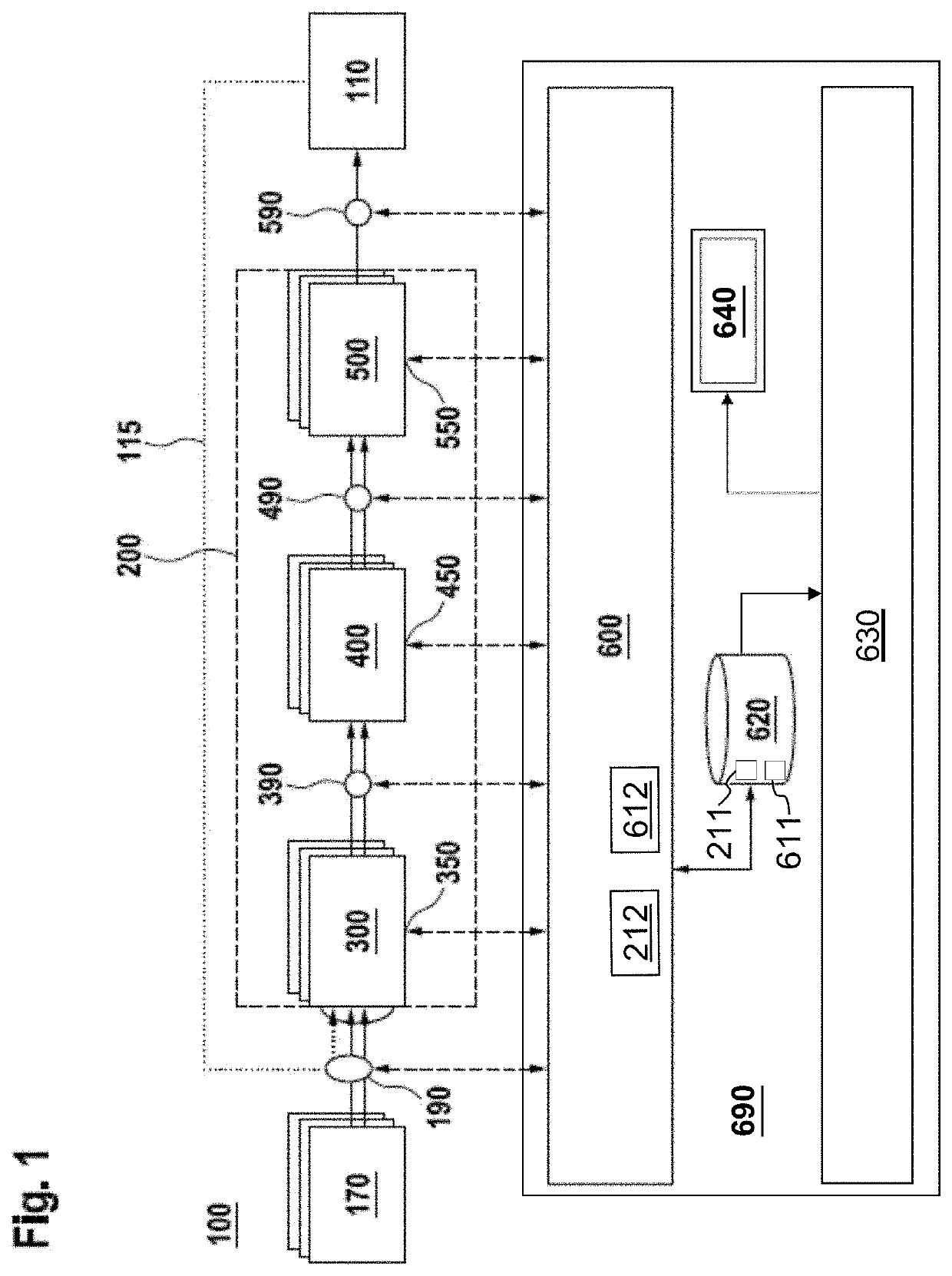

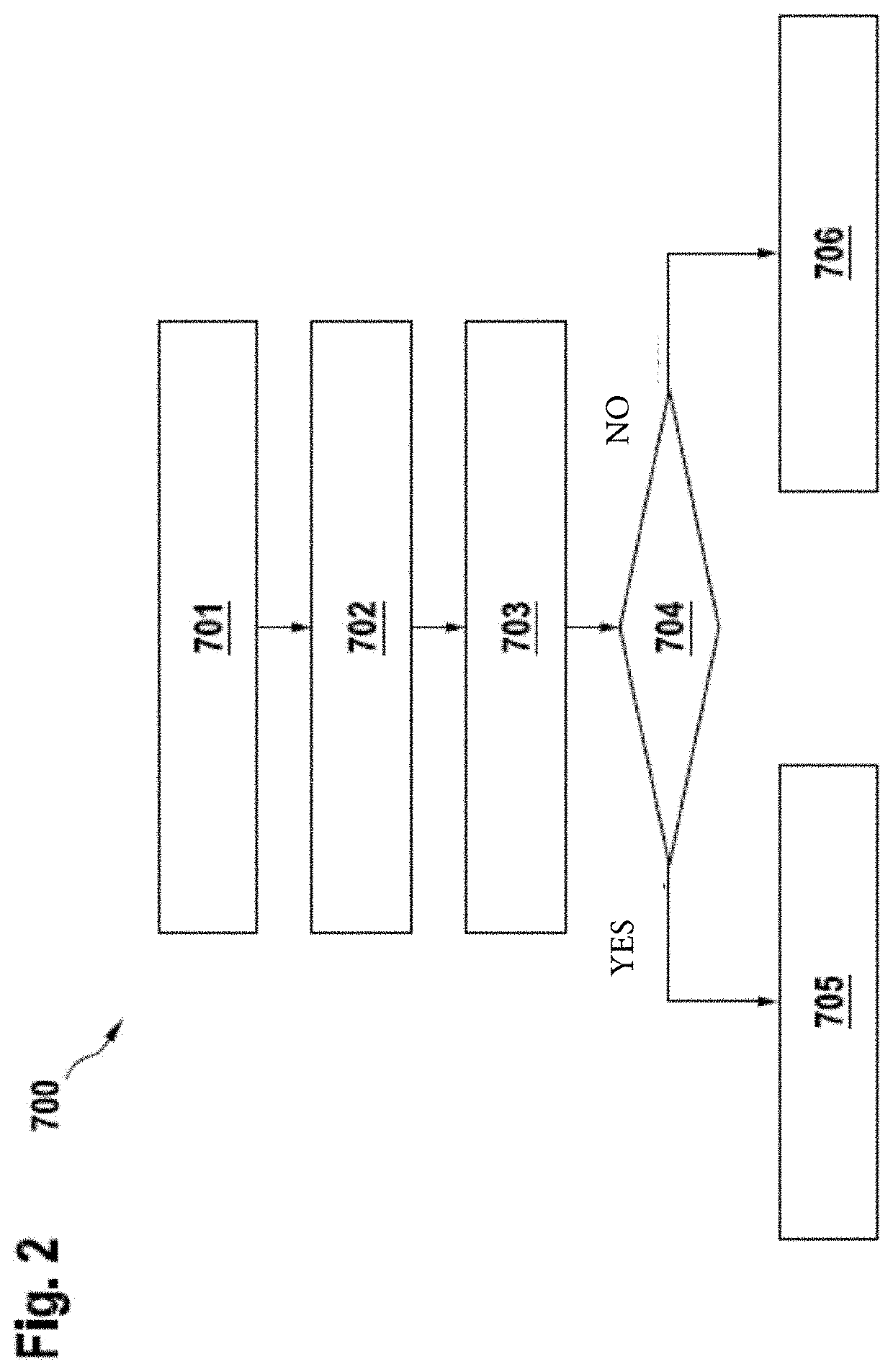

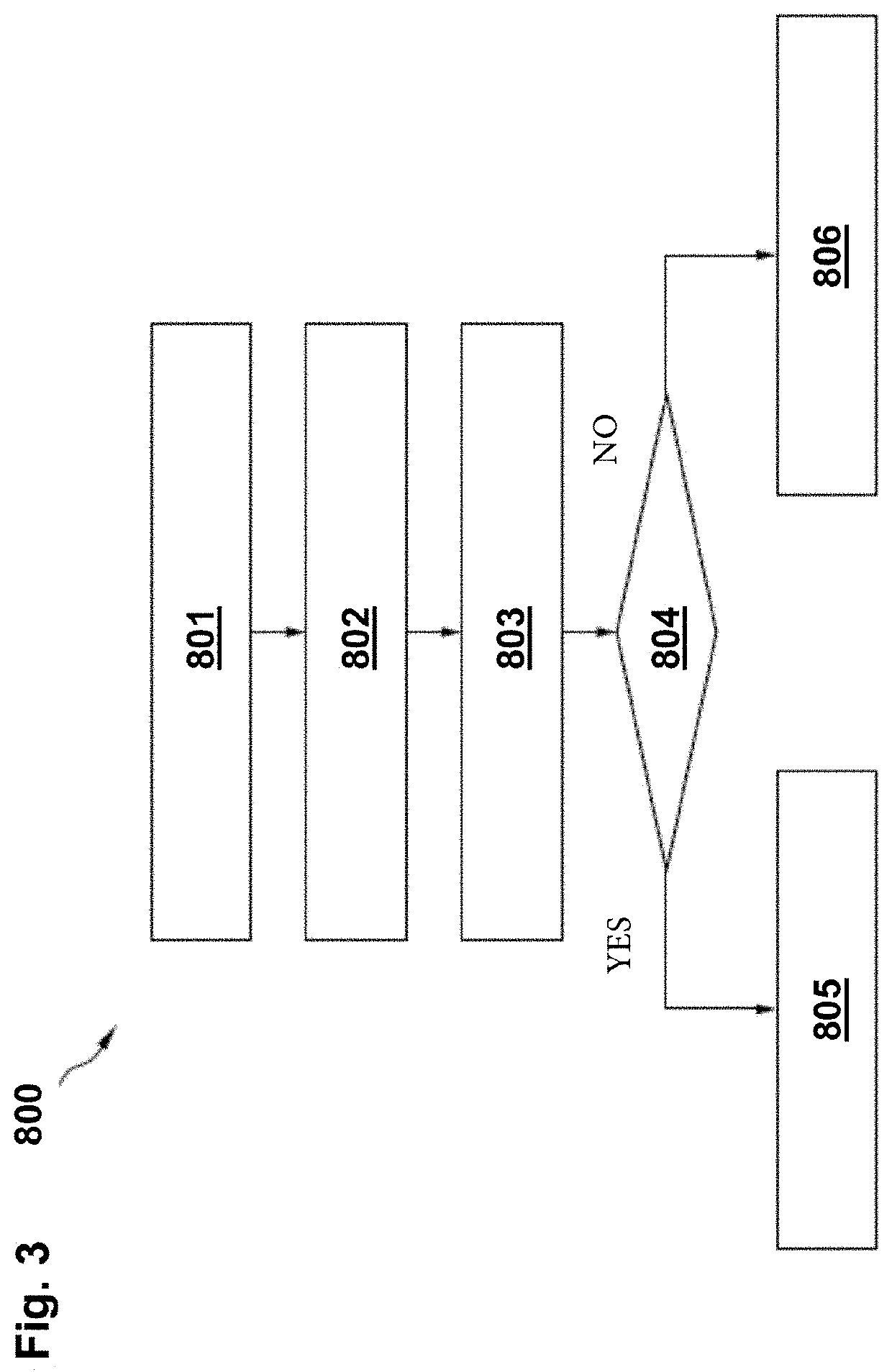

Device and method for measuring, simulating, labeling and evaluating components and systems of vehicles

ActiveUS20200174461A1Add depthHigh complexitySimulator controlElectric testing/monitoringFunctional testingControl system

A method and a device for the functional testing and evaluation of a control system. The method for functional testing of sensors, actuators, and / or a control logic system of a control system controlled in at least a partly automated manner has the following: sending at least one stimulus to a sensor, an actuator, and / or to the control logic system of the control system; reading out at least one reaction of the control system from the sensor, from the actuator, from the control logic system, and / or from a connection between these components; and using a metric module to compare the reaction with a stored expected reaction, the metric module determining a metric according to which deviations of the read-out reaction from the expected reaction are to be evaluated with respect to the intended function of the control system.

Owner:ROBERT BOSCH GMBH

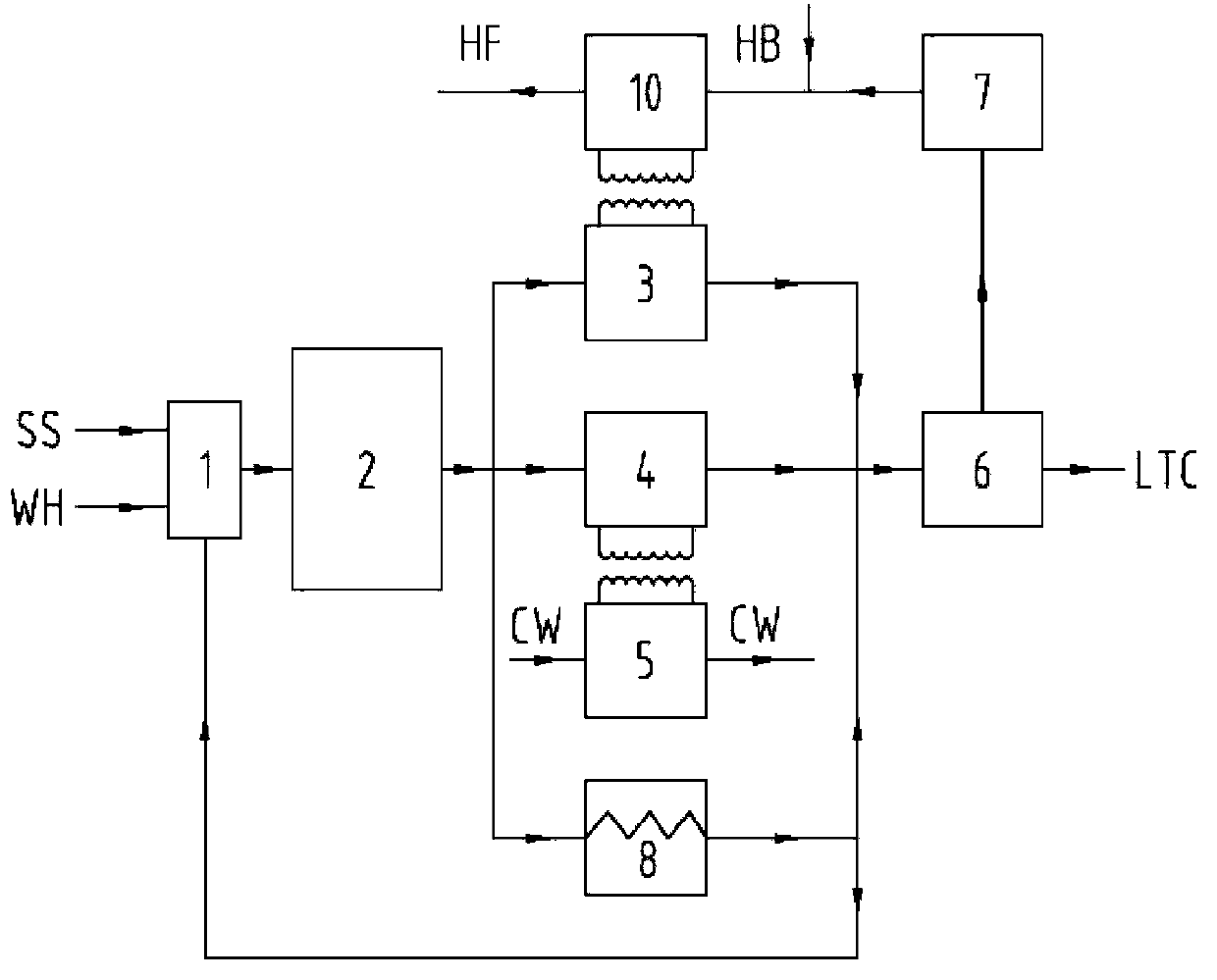

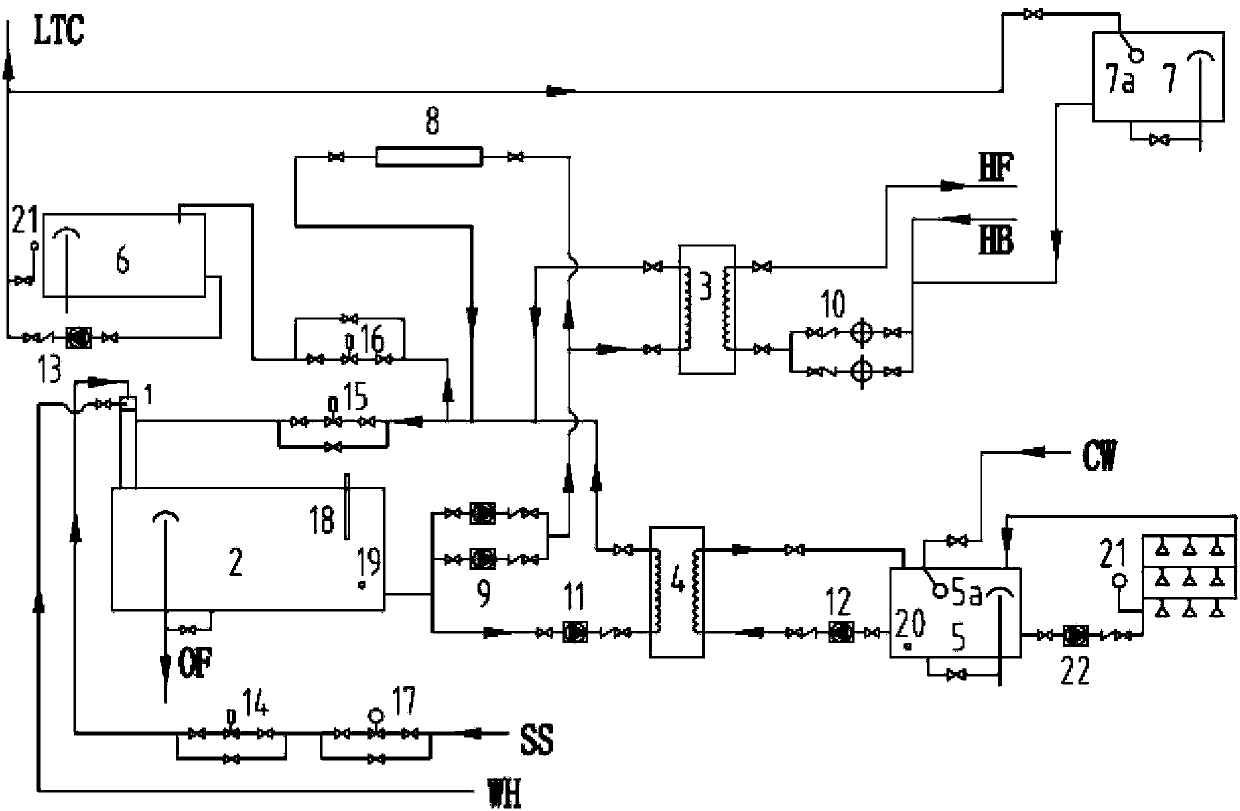

Steam waste heat recycling device and control method thereof

InactiveCN102967074BLow running costGuaranteed production demandOther heat production devicesEnergy industryWater bathsSolenoid valve

The invention discloses a steam waste heat recycling device and a control method thereof. The steam waste heat recycling device is characterized by comprising a steam-water converting system, a heating system, a bathing system, a water bath drying system and a low-temperature condensed water recycling system. According to the steam waste heat recycling device, waste heat of steam for production is fully utilized and the low-temperature condensed water is used for production, i.e., the steam supplied to an outside network for production is completely and fully utilized, and thus the production demand is ensured and the waste heat resources of the steam for the production are recycled and are used for heating, bathing and drying the water bath; the condensed water is recycled; and heat resource and water resource are basically and completely utilized without being wasted, so that the operation cost of production and manufacture enterprises is greatly reduced. Various waste heat recycling modes are integrated in one system; and any mode can be switched by opening or closing a pipeline valve or a solenoid valve, so that the selection for use by the production and manufacture enterprises is facilitated.

Owner:信天寰宇微电子(大连)有限公司

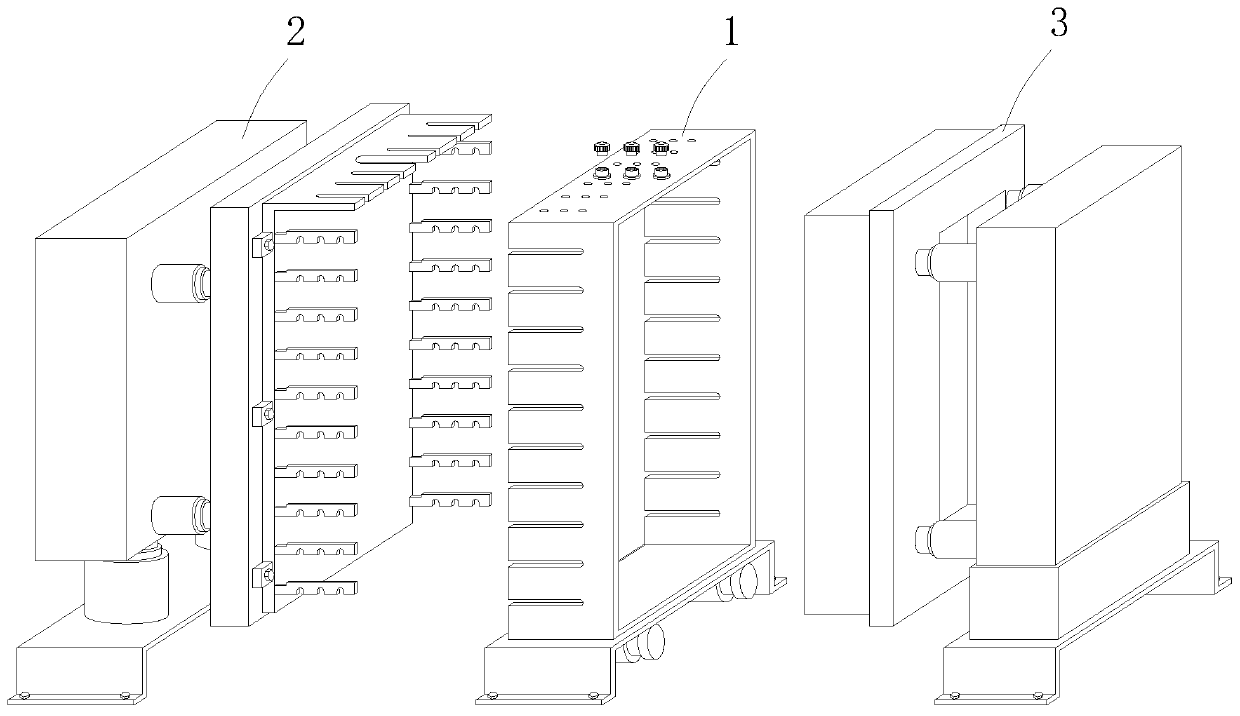

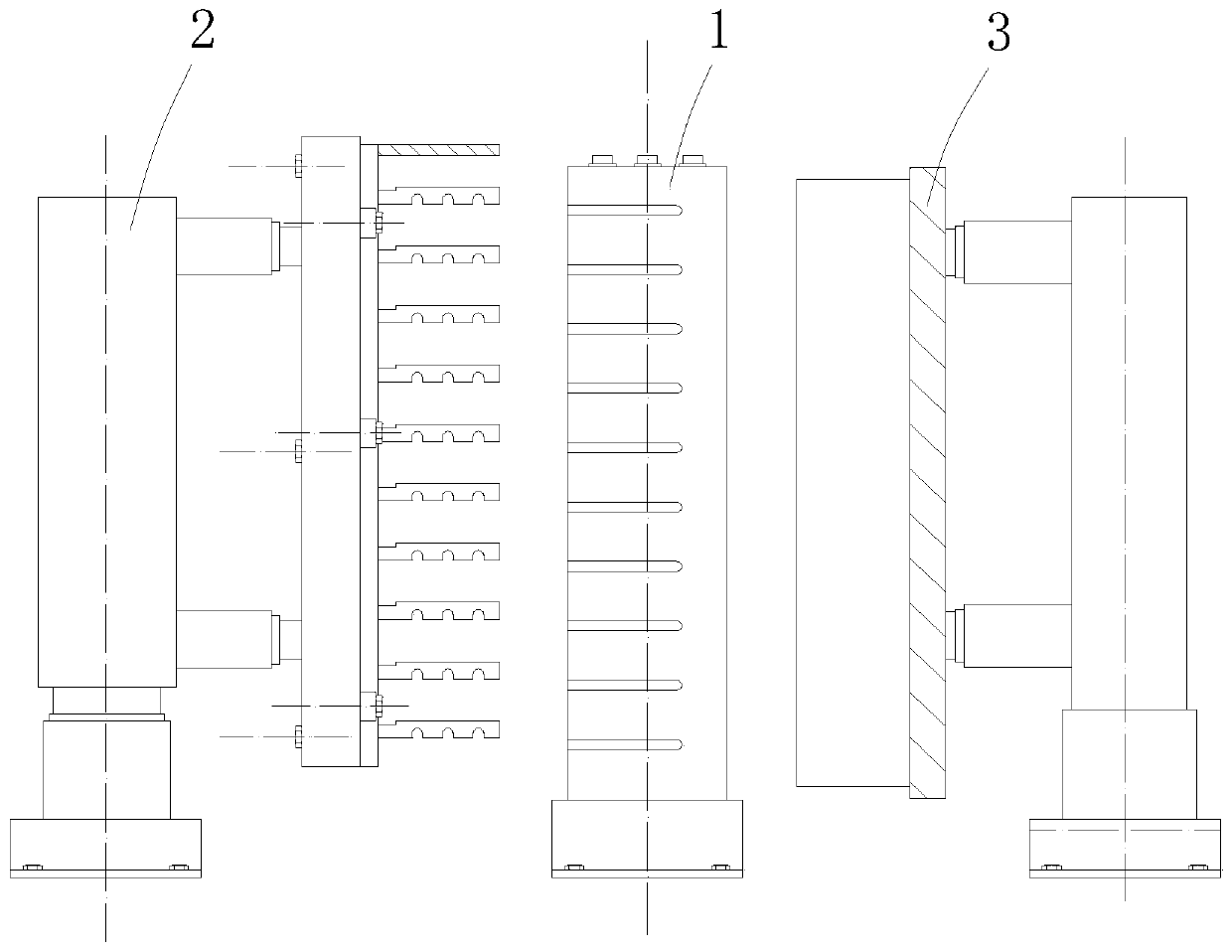

Molding equipment for high-rise building prefabricated wallboard part and machining method of molding equipment

ActiveCN111391073AImprove casting qualityGuaranteed mold closing and pouringDischarging arrangementFeeding arrangmentsConstruction engineeringWall plate

The invention relates to the technical field of building prefabricated parts, and provides molding equipment for a high-rise building prefabricated wallboard part and a machining method of the parts equipment. The molding equipment for the high-rise building prefabricated wallboard part and the machining method of the parts equipment aim to solve the problems that a large amount of time is consumed and the production efficiency is low due to the fact that disassembly is tedious after the wallboard part is formed due to the fact that an existing prefabricated wallboard part is usually molded inan open groove type mold. The molding equipment for the high-rise building prefabricated wallboard part comprises a structural mold, a cavity mold and a bottom mold which are vertically arranged in parallel in sequence; the structural mold comprises a base II fixed to the ground through bolts, a lifting air cylinder is arranged at the upper end of the base II, and an air cylinder base I which isvertically arranged is arranged at the telescopic end of the lifting air cylinder; and a structural mold base is arranged on the side, close to the cavity mold, of the air cylinder base I through a plurality of pushing air cylinders I, and a structural mold body is detachably arranged on the other side of the structural mold base through screws. The molding equipment for the high-rise building prefabricated wallboard part and the machining method of the parts equipment are particularly suitable for rapid high-quality molding of the high-rise building prefabricated wallboard part, and have highsocial use value and application prospect.

Owner:HEFEI NORMAL UNIV

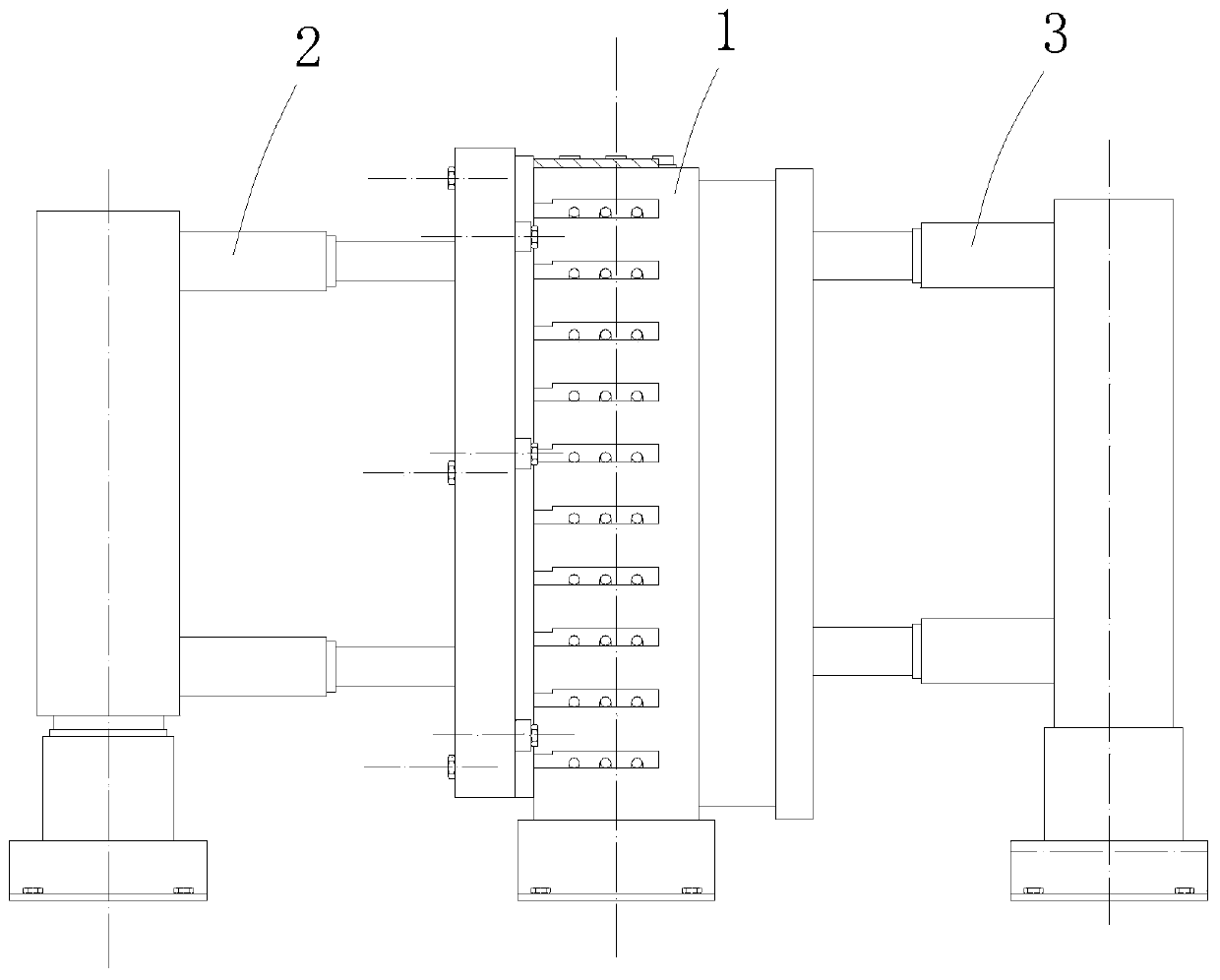

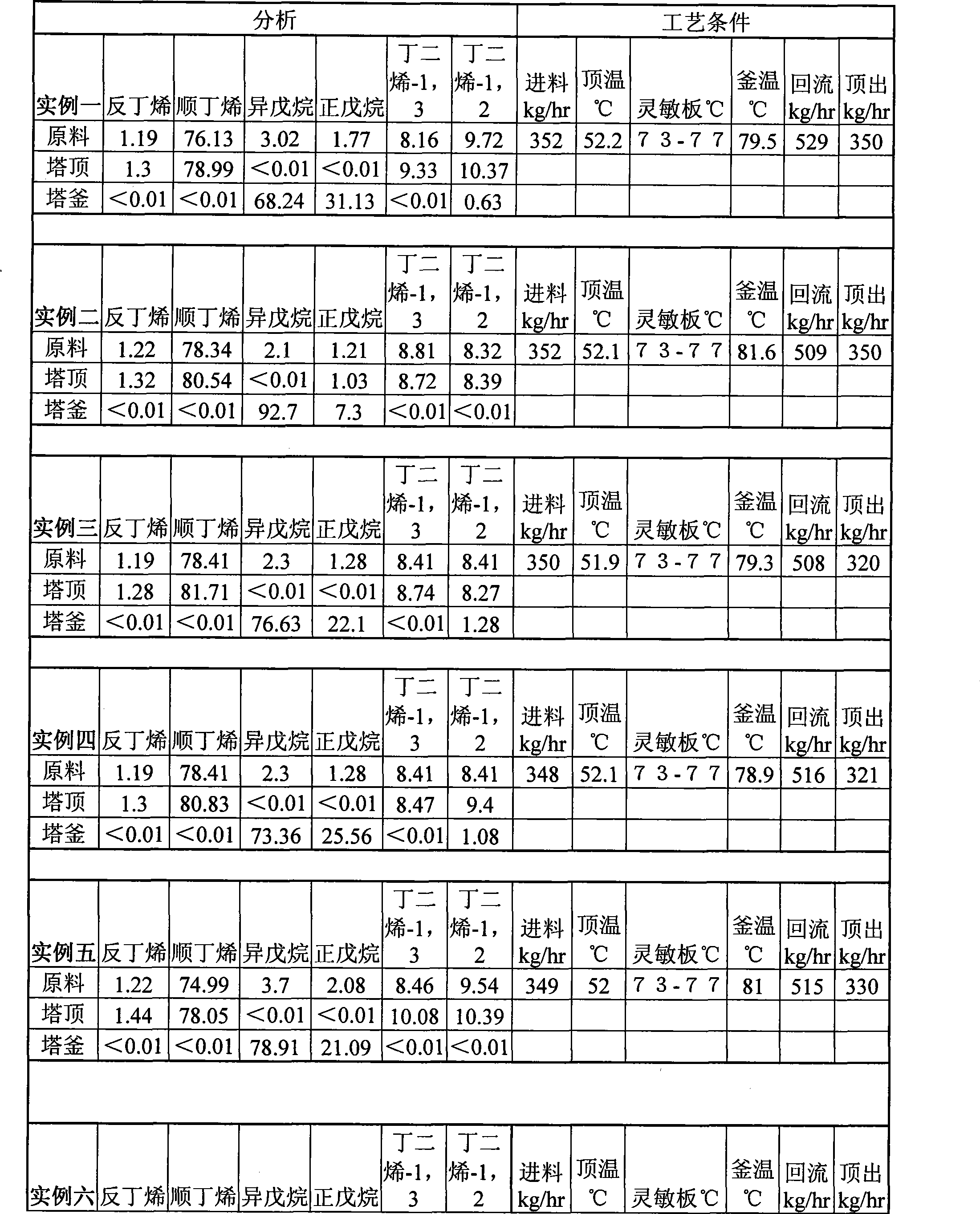

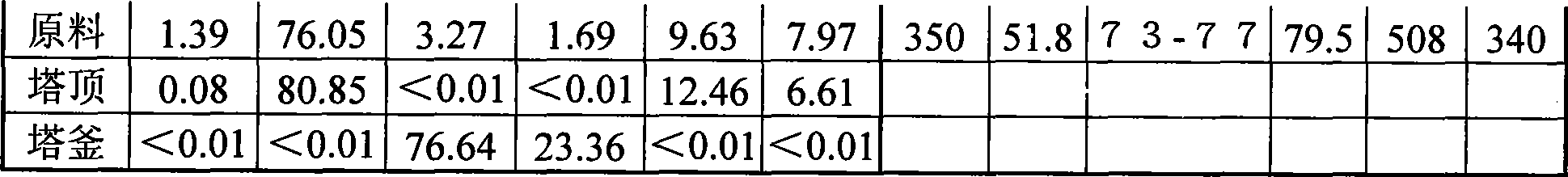

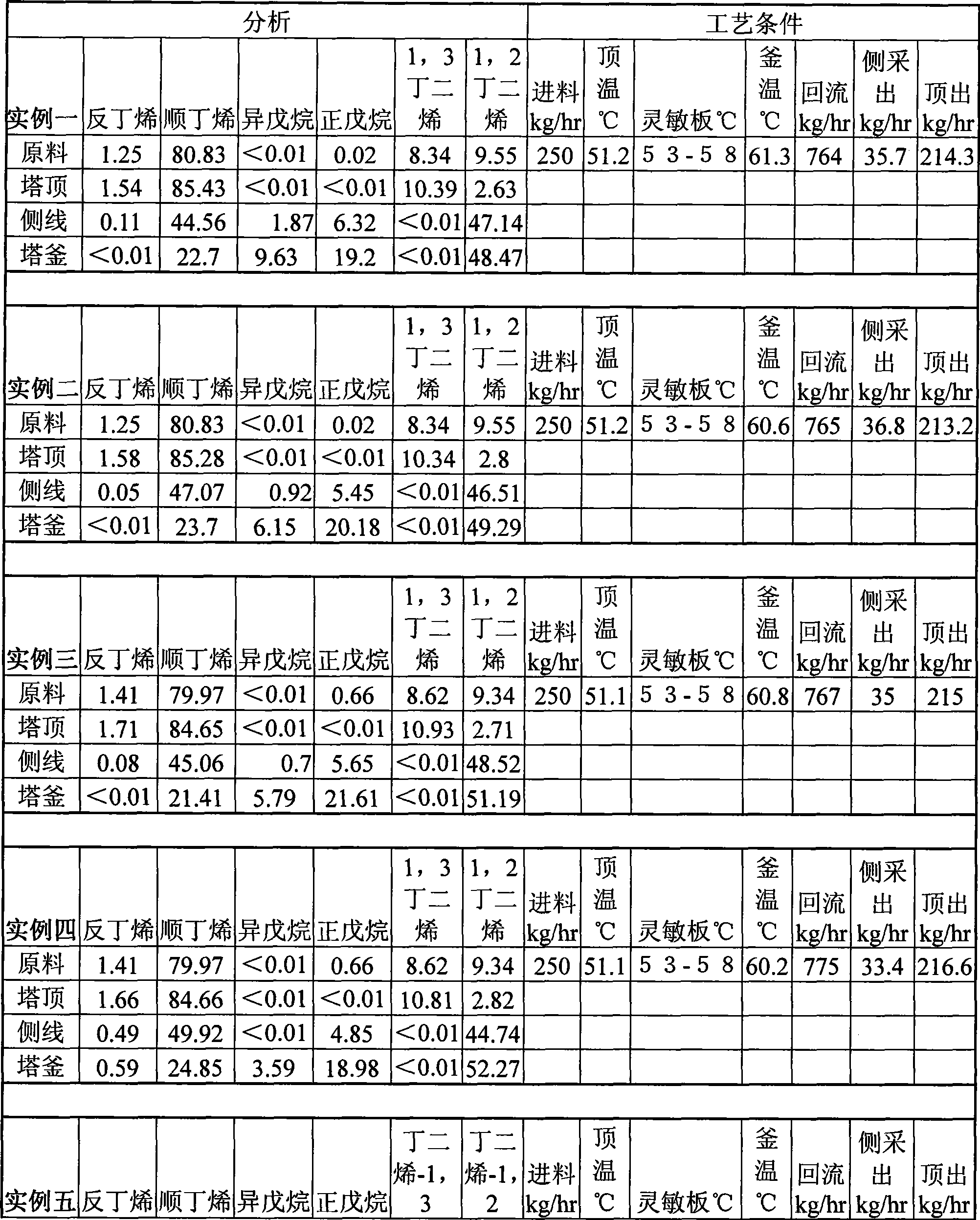

Process and equipment for preparing 1,2-butadiene by continuous method

ActiveCN101337858BGuaranteed production demandIncrease added valueDistillation purification/separationPtru catalystButadiene Dioxide

The invention discloses a process technique and a separation plant for continuously preparing styrene-butadiene rubber inhibitor by a separation method. The process comprises the following steps: selecting heavy components of the byproduct of 1,3-butadiene produced by the extraction method as the raw material containing 1,2-butadiene 5 to 12% (wt), washing with water to remove the trace amount ofa residual solvent, removing the heavy component and the light component on the same rectification tower by a common rectification method with side withdrawing, rectifying at a kettle temperature of 55 to 65 DEG C and a sensitive plate temperature of 52 to 62 DEG C, under 0.35 to 0.39 MPa and in an oxygen-free condition; adding a proper amount of polymerization inhibitor, and continuously withdrawing the product containing 1,2-butadiene with an amount equal to or larger than 40%. The method can obviate the problems in the production technology, the safety, the environment protection, etc. resulting from the factors such as the raw material, the catalyst and the byproducts, and also increase the additional value of the 1,3-butadiene byproducts, thereby achieving remarkable economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

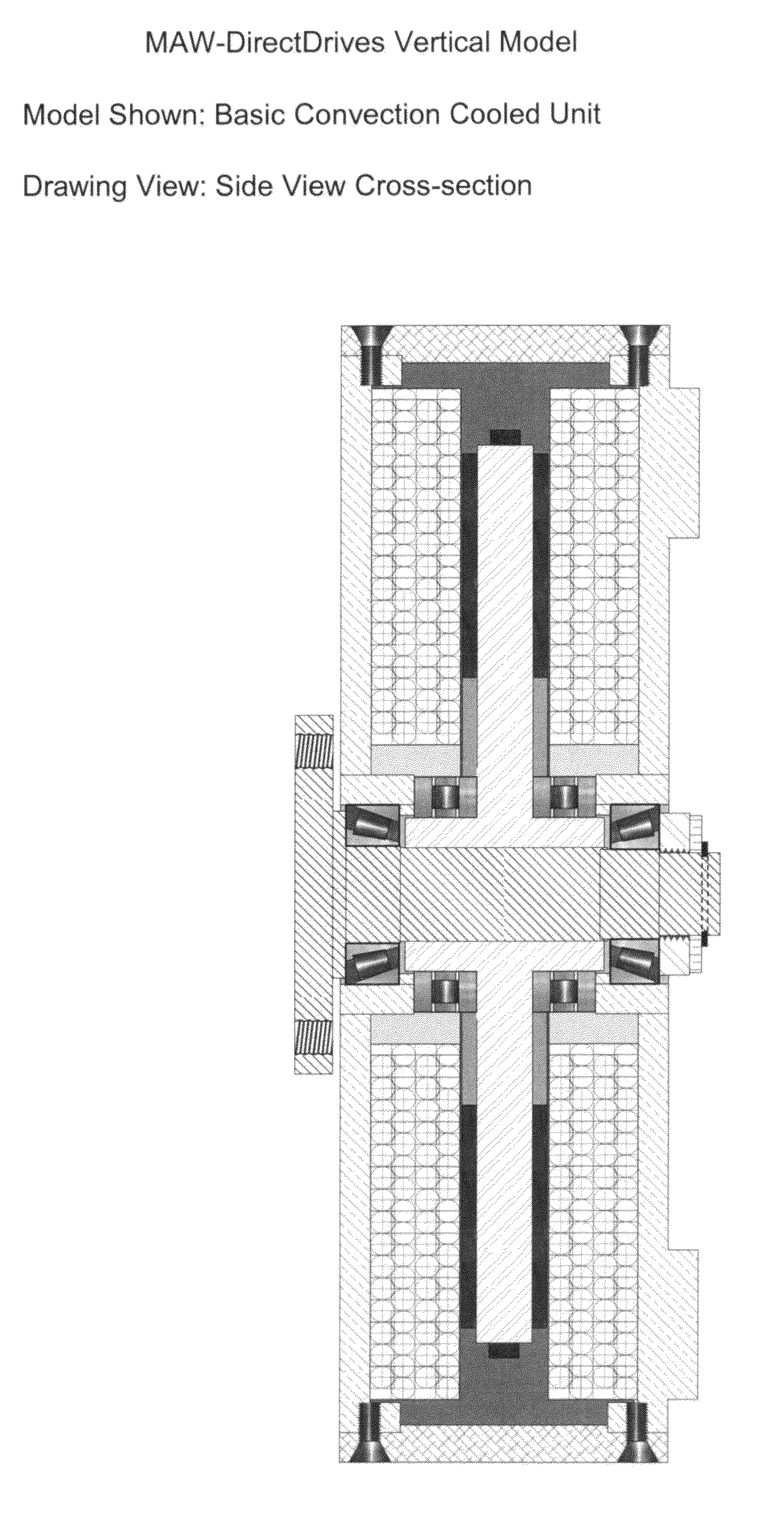

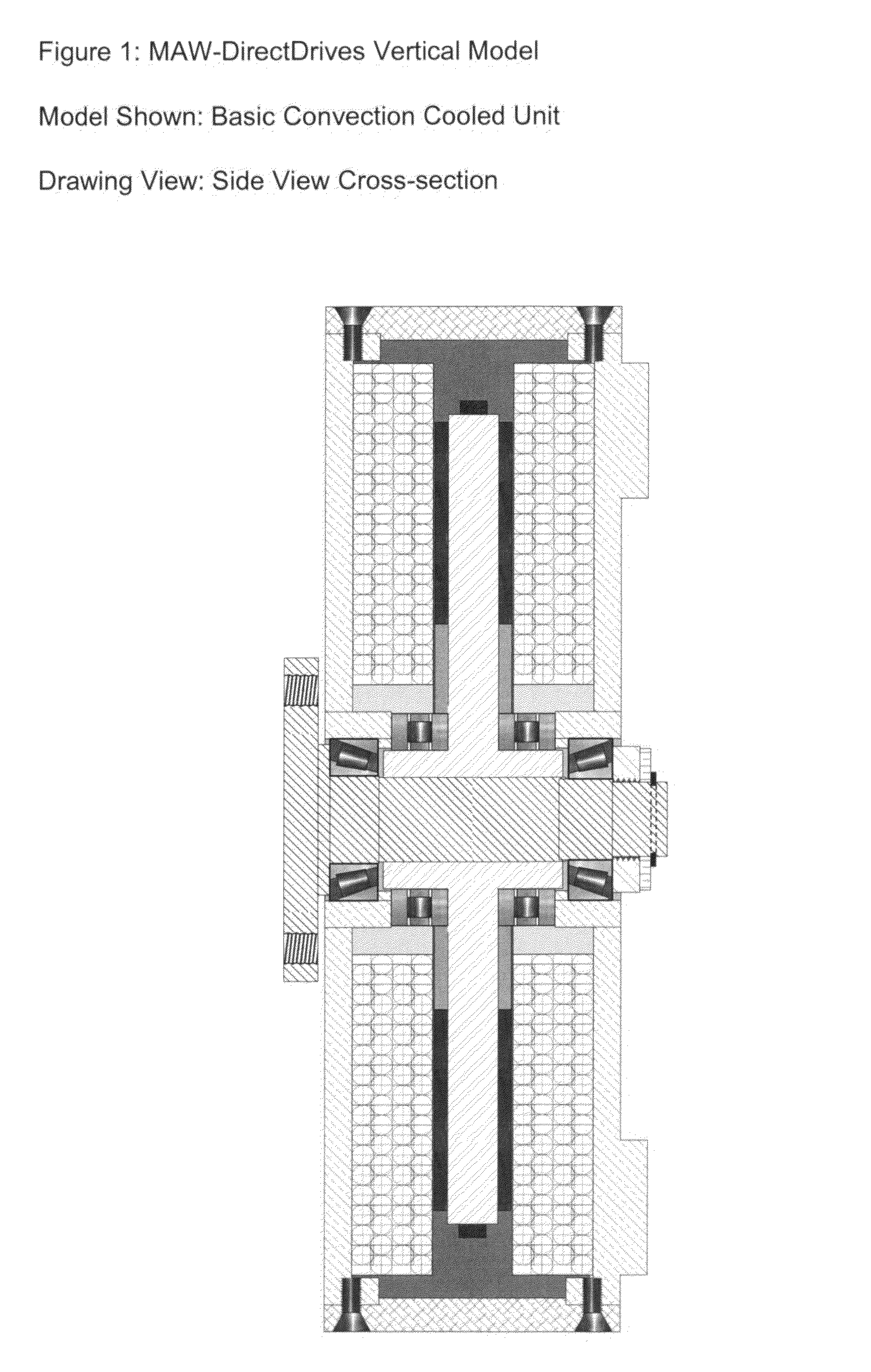

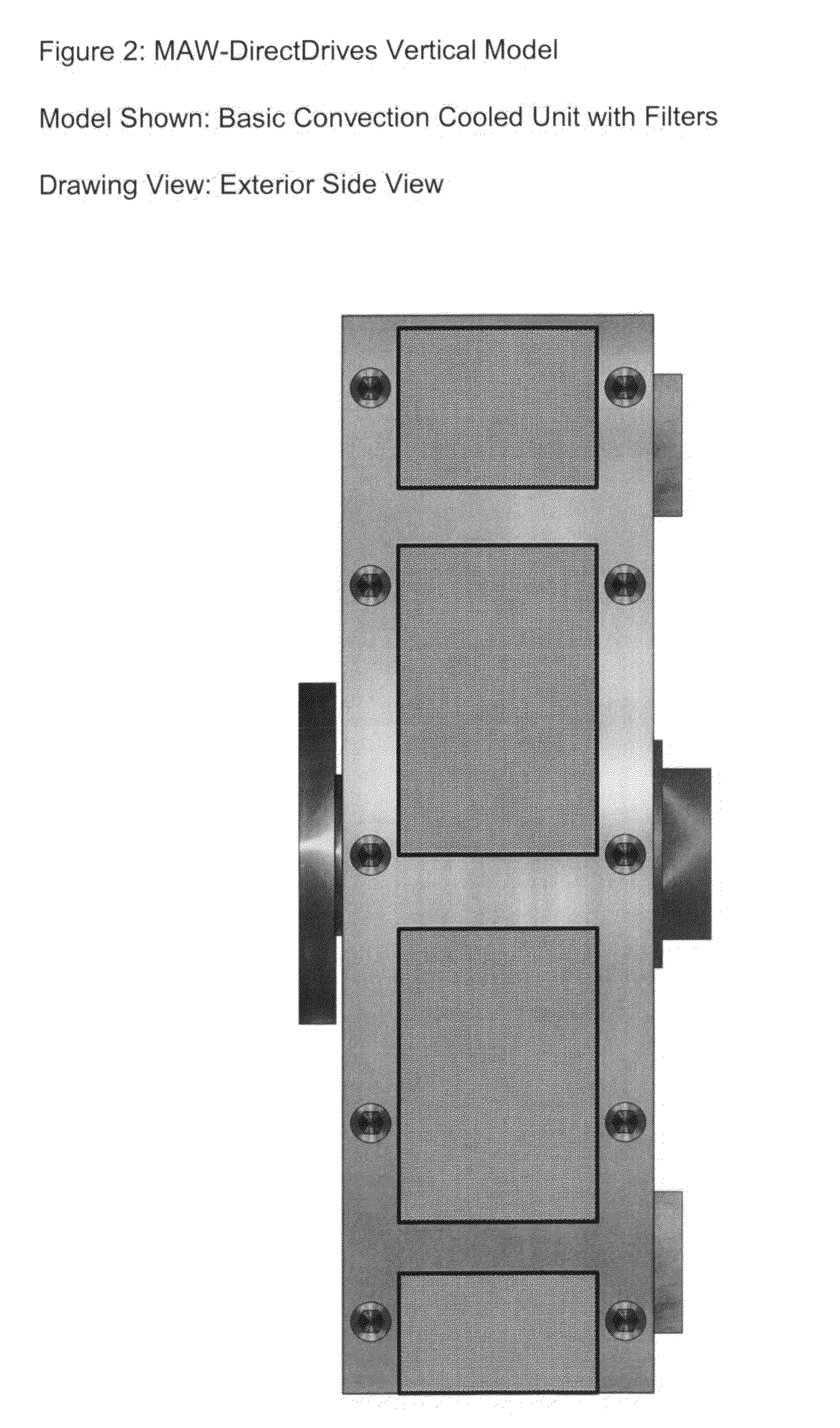

Self-contained & propelled magnetic alternator & wheel DirectDrive vertical units. aka:MAW-DirectDrives vertical model

InactiveUS20120205997A1Benefit efficiencyGuaranteed production demandMagnetic circuit rotating partsCooling/ventillation arrangementElectricityAlternator

MAW-DirectDrives Vertical Models are direct drive propulsion and electrical generating units for transportation vehicles utilizing wheels for motion, which connect onto the inside of wheels actuating rotation and braking electromagnetically while simultaneously utilizing the rotation to generate electricity to feed back into the supply for reducing the vehicle's requirement for operation. Two pancake style direct drive permanent magnets stators are mounted on sturdy metal mounting backs functioning as the unit's stationary outside faces and outer portion of the unit's wheel hub. The vehicle is supported from their rear face. The stators face one another with a two-sided permanent magnets drive-rotor disc between them accomplishing two functions simultaneously. The drive-rotor is connected to the Integrated Drive-plate Assembly's spindle perpendicular. The spindle with its threaded end traverses through each wheel hubs' bearings and unites the unit together with a lock nut. An attached exterior cylindrical housing keeps the unit rigid and parallel.

Owner:HANSEN MR DANA ALLEN

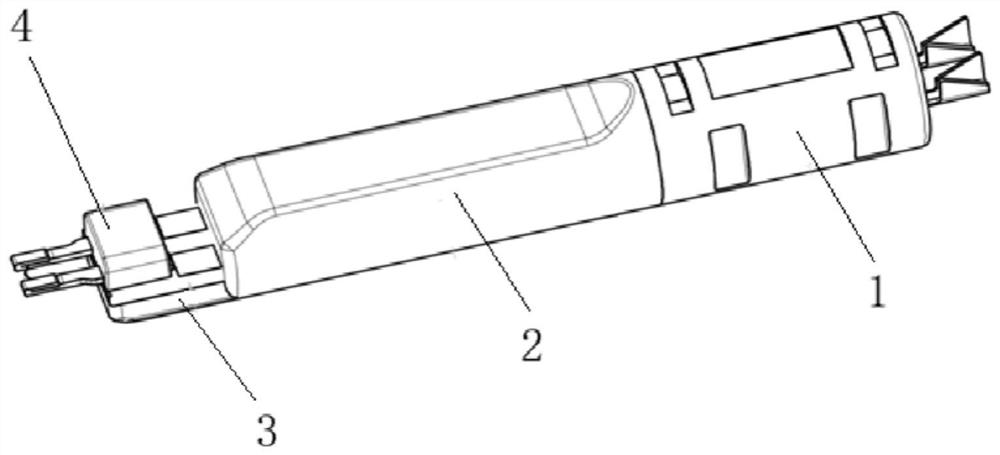

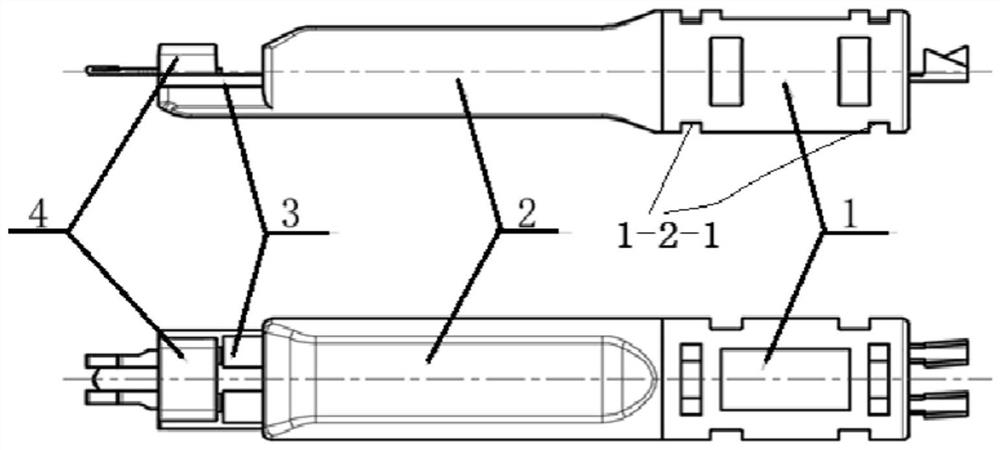

Internal spraying robot auxiliary tool and using method thereof

InactiveCN110732428ASimple designEasy to operateSpraying apparatusManipulatorCar doorManufacturing engineering

The invention discloses an internal spraying robot auxiliary tool and a using method thereof. The tool comprises a main body, and further comprises a clamping fastening mechanism and an adsorbing mechanism, wherein the clamping fastening mechanism is arranged on the main body and used for being in tightness clamping fixing with the vehicle body side, and the adsorbing mechanism is used for adsorbing and limiting vehicle doors. The vehicle doors are limited by the tool and prevented from releasing, thus the four doors of a whole vehicle are not released in the operation process in a line body,the tool does not damage an exposed finish paint film, the tool is simple in design, mounting and operation are easy, the tool or the tool structure is high in universality, and the manufacturing costof the tool is minimized.

Owner:CHERY COMML VEHICLE ANHUI

Asphalt preheating storage device

InactiveCN103693293APrecise temperature controlEasy to detectDomestic cooling apparatusLighting and heating apparatusInsulation layerHeat conducting

The invention provides an asphalt preheating storage device, which comprises an inner liner, an asphalt input pipe and an asphalt output pipe, wherein the asphalt input pipe is inserted from the upper part of the inner liner, the asphalt output pipe is arranged at the bottom of the inner liner, the asphalt preheating storage device also comprises a heating liner and a heat insulation layer, the heating liner is wrapped at the outer side of the inner liner, the heating liner comprises a heating liner body, an oil inlet pipe and heating bars, heat conducting oil is filled in the heating liner body, the oil inlet pipe is arranged at the top of the heating liner body, the heating bars are arranged at the bottom and the side part of the heating liner body, and the heat insulation layer is wrapped at the outer sides of the heating liner and the inner liner. The asphalt preheating storage device has the beneficial effects that a large number of asphalt raw materials can be stored, the asphalt raw materials are subjected to preheating treatment, the asphalt temperature can be accurately controlled, the production requirement is ensured, energy sources are also saved, meanwhile, the quality of the heat conducting oil can also be conveniently detected, and the safety of the production and the convenience and high speed of the maintenance are ensured.

Owner:TIANJIN SENTERUI ANTICORROSION MATERIAL

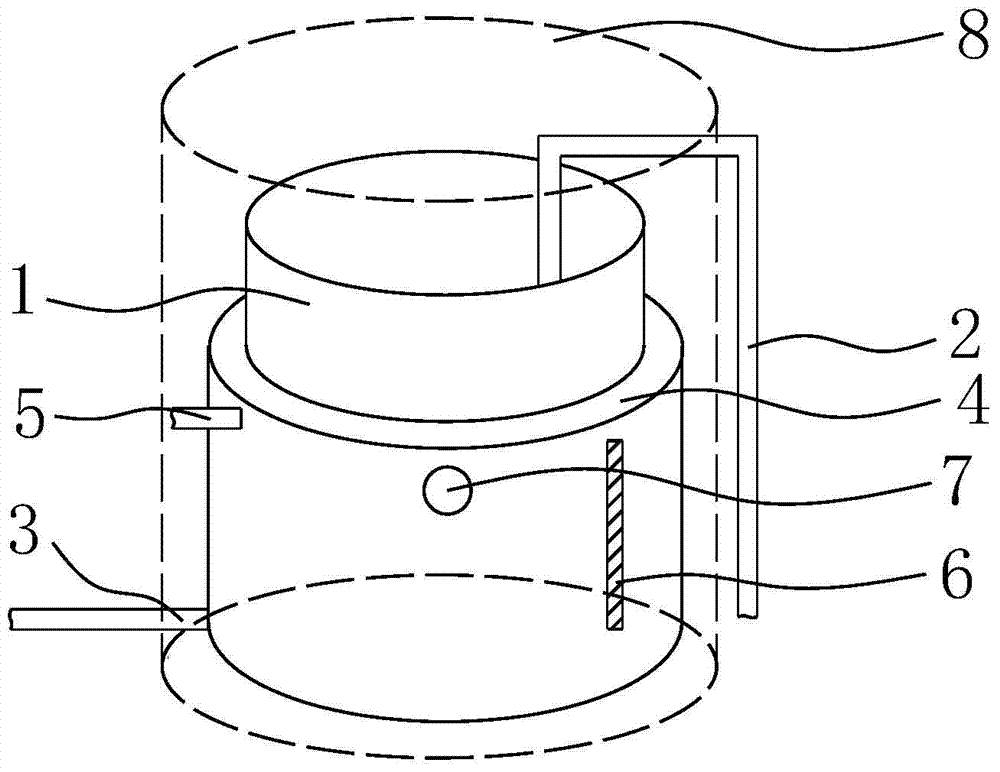

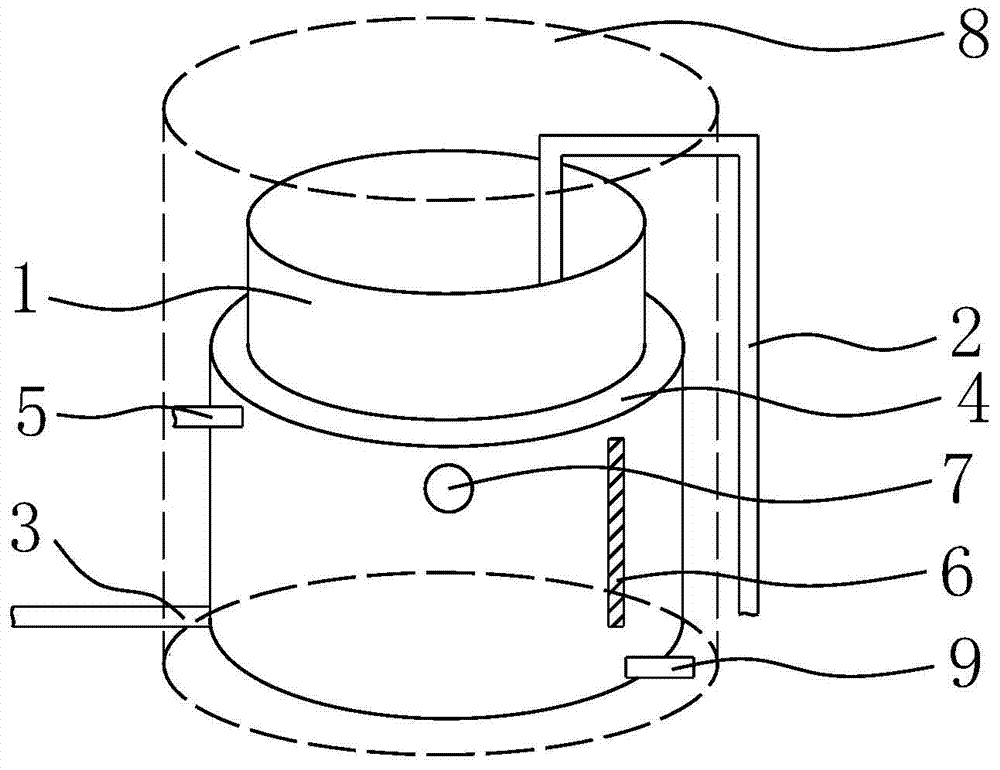

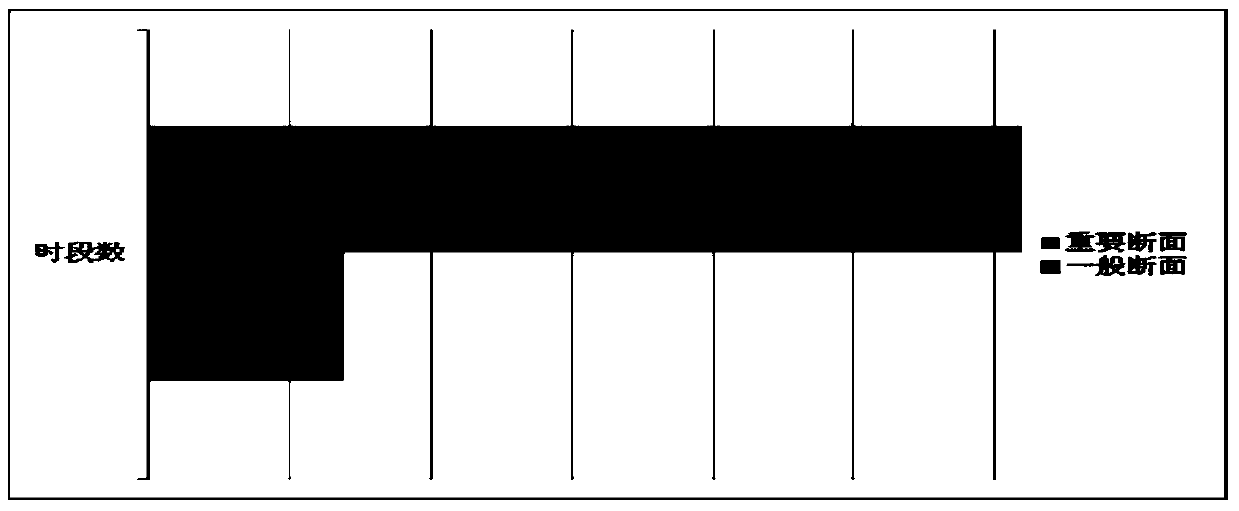

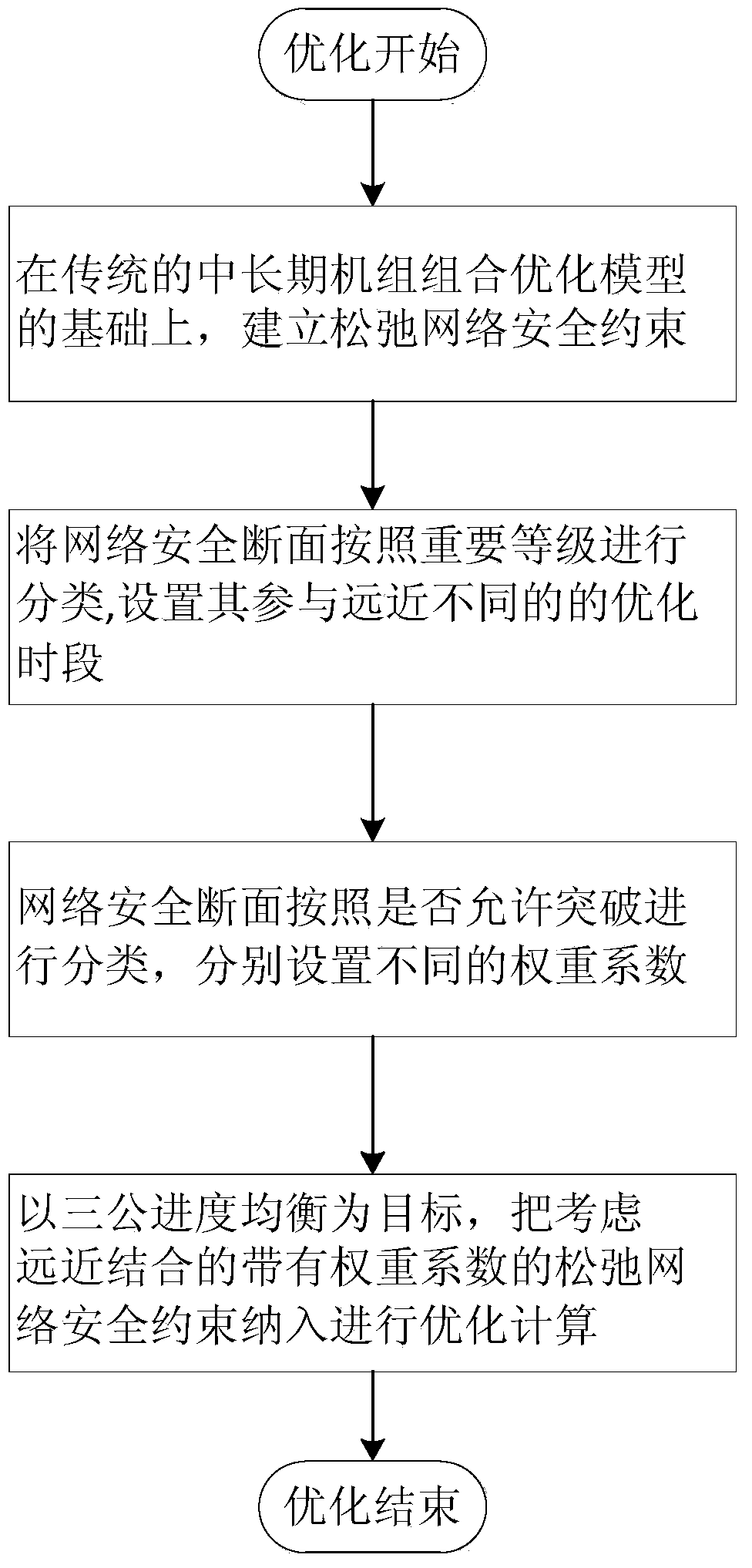

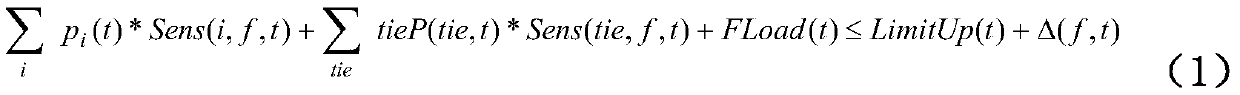

A mid-to-long-term relaxed network security constraint modeling method based on the combination of near and far

ActiveCN105787807BAvoid confusionEasy to solveData processing applicationsAlgorithmIndustrial engineering

The invention relates to a far-near combination type mid-and-long-term relaxation network security constraint modeling method. According to the method, firstly, the network security constraint is relaxed, so that the problem of no optimum solution is avoided. Meanwhile, according to practical production requirements, network security profiles are classified according to the importance level, and a security profile of a higher importance level is optimized during the entire optimization period. At the same time, general security profiles are optimized only during the recent optimization process. In this way, the dimensionality of the optimization calculation is greatly reduced, and the optimization time is shortened. At the same time, in combination with the actual production requirements, network security profiles are classified according to the judgment on whether or not to allow the breakthrough. That means, the network security profiles are classified into two types, wherein the breakthrough is allowed for one type of network security profiles and is not allowed for the other type of network security profiles. Different weight coefficients are arranged for the two types of network security profiles respectively. Therefore, the far-near combination type relaxation network security constraint containing weight coefficients is adopted for optimization calculation. As a result, a unit combination optimization scheme that meets the actual production requirements can be quickly obtained. The conditions of long optimization time and no optimum solution can be avoided.

Owner:STATE GRID CORP OF CHINA +2

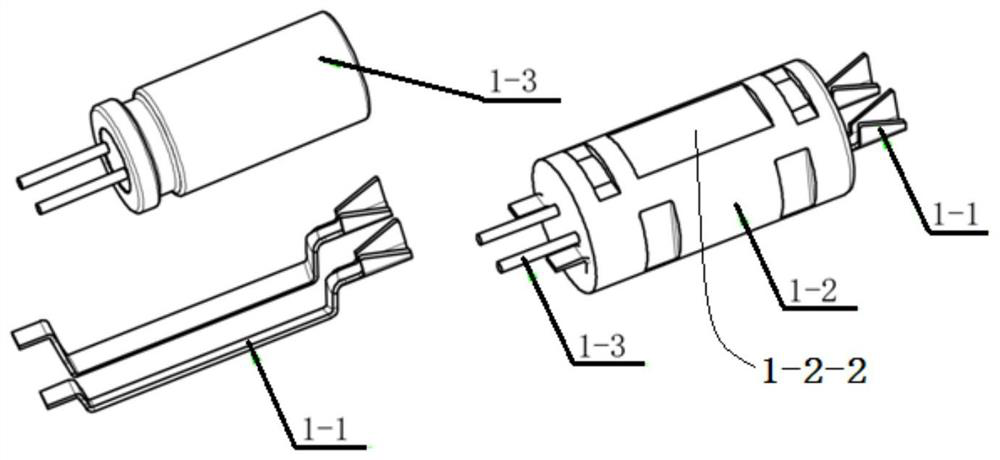

Electronic control module of electronic detonator and production process method of electronic control module

InactiveCN112129181ASimple processReliable and complex processAmmunition fuzesCapacitanceElectrolytic capacitor

The invention discloses an electronic control module of an electronic detonator. The electronic control module comprises a module encapsulation and injection molding block, a control circuit mainboard, a chip bridge wire terminal and a chip electrolytic capacitor with a connector, wherein the chip electrolytic capacitor with the connector, the module encapsulation and injection molding block, thecontrol circuit mainboard and the chip bridge wire terminal are integrally connected. The invention further discloses a production process method for producing the electronic control module. The manufacturing process is completed through encapsulation, injection molding and makeup. According to the production process method, a backhand-welding capacitor and a backhand-welding leg wire connector are integrally designed into an integrated chip piece, so that a backhand-welding process is avoided, and the whole process is fundamentally optimized; and a specially-designed makeup mode is adopted ineach procedure, the lifting stress effect of a simple support beam can be achieved in the whole process of chip mounting and backhand-welding of the chip electrolytic capacitor with the connector byadopting the makeup mode, therefore, automatic chip mounting is completely realized through a chip mounter, and production efficiency is greatly improved.

Owner:重庆云铭科技股份有限公司

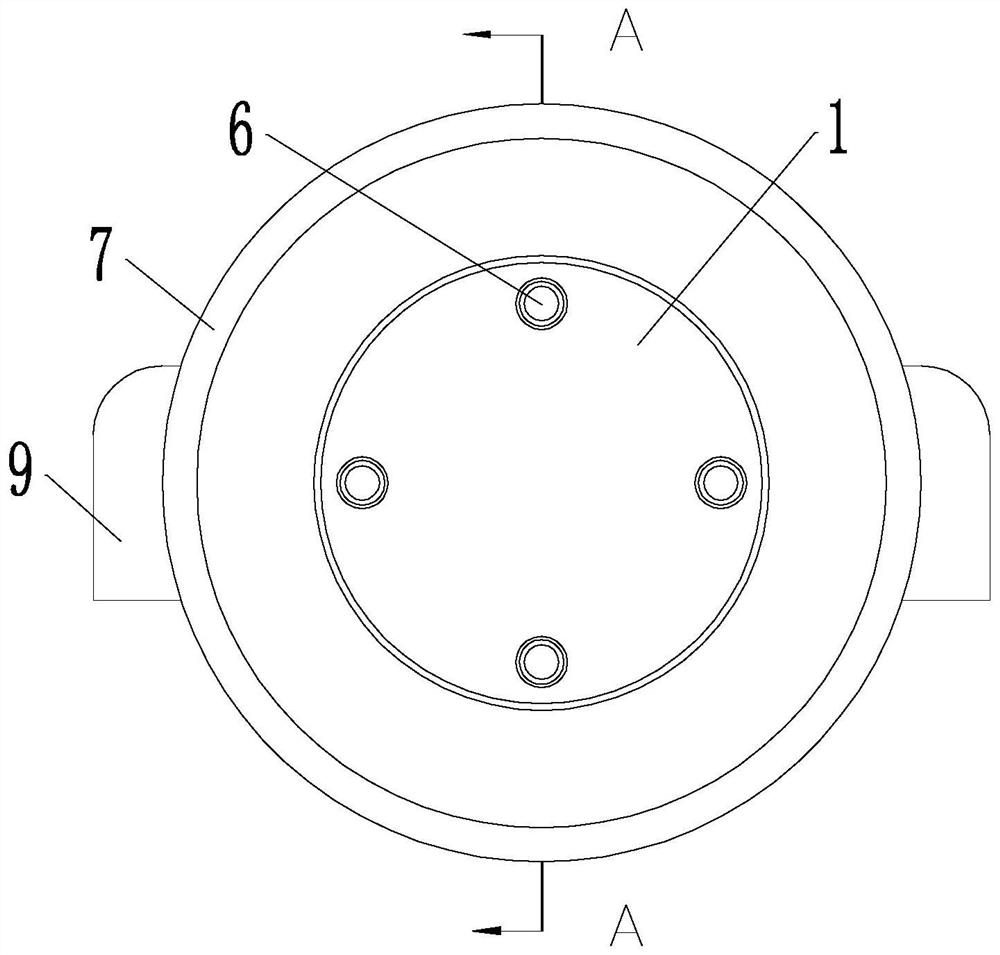

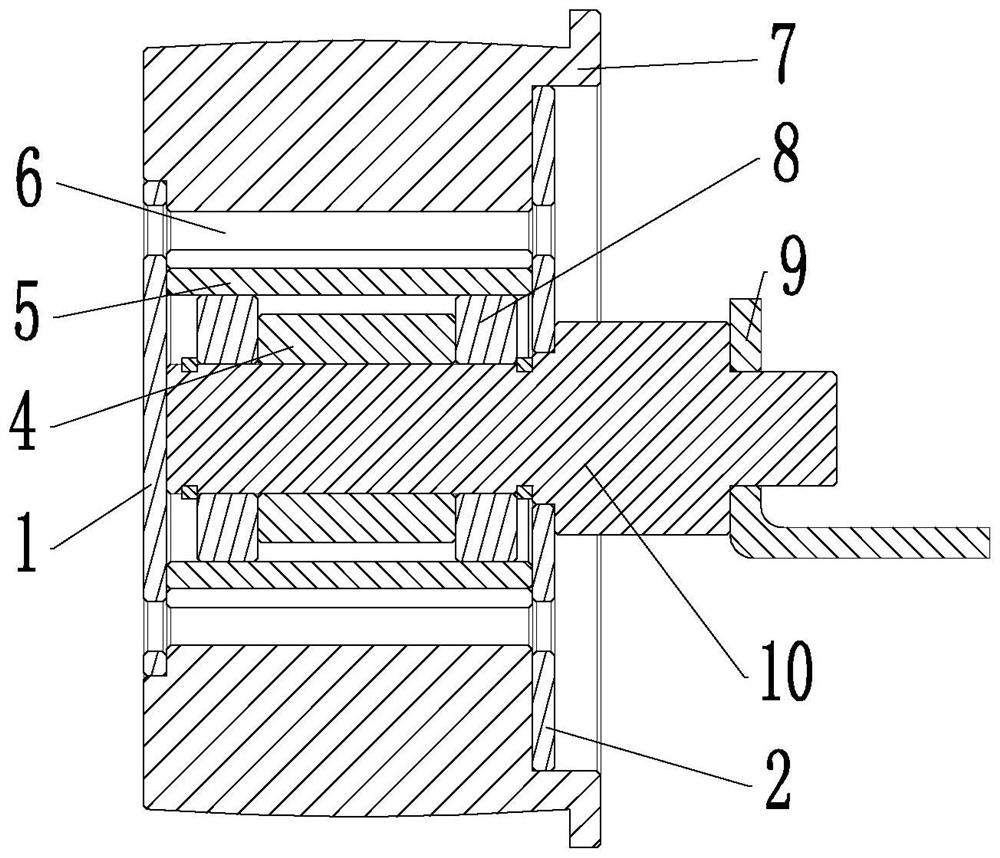

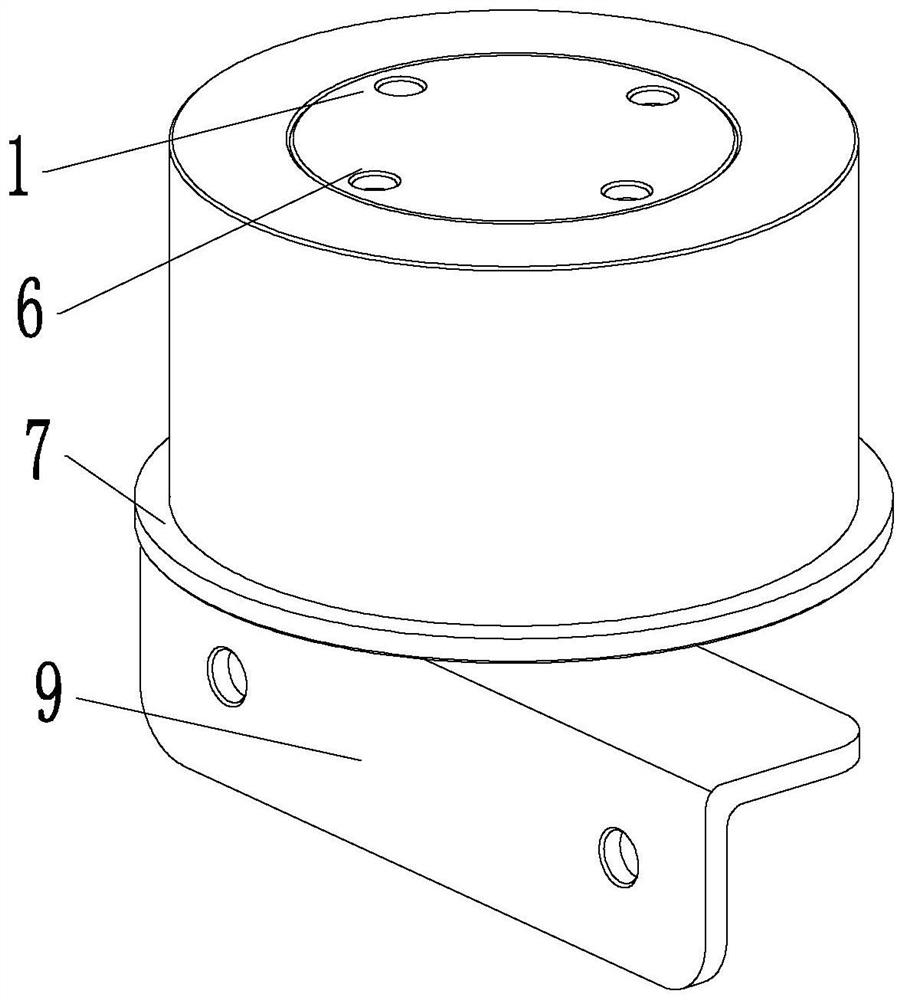

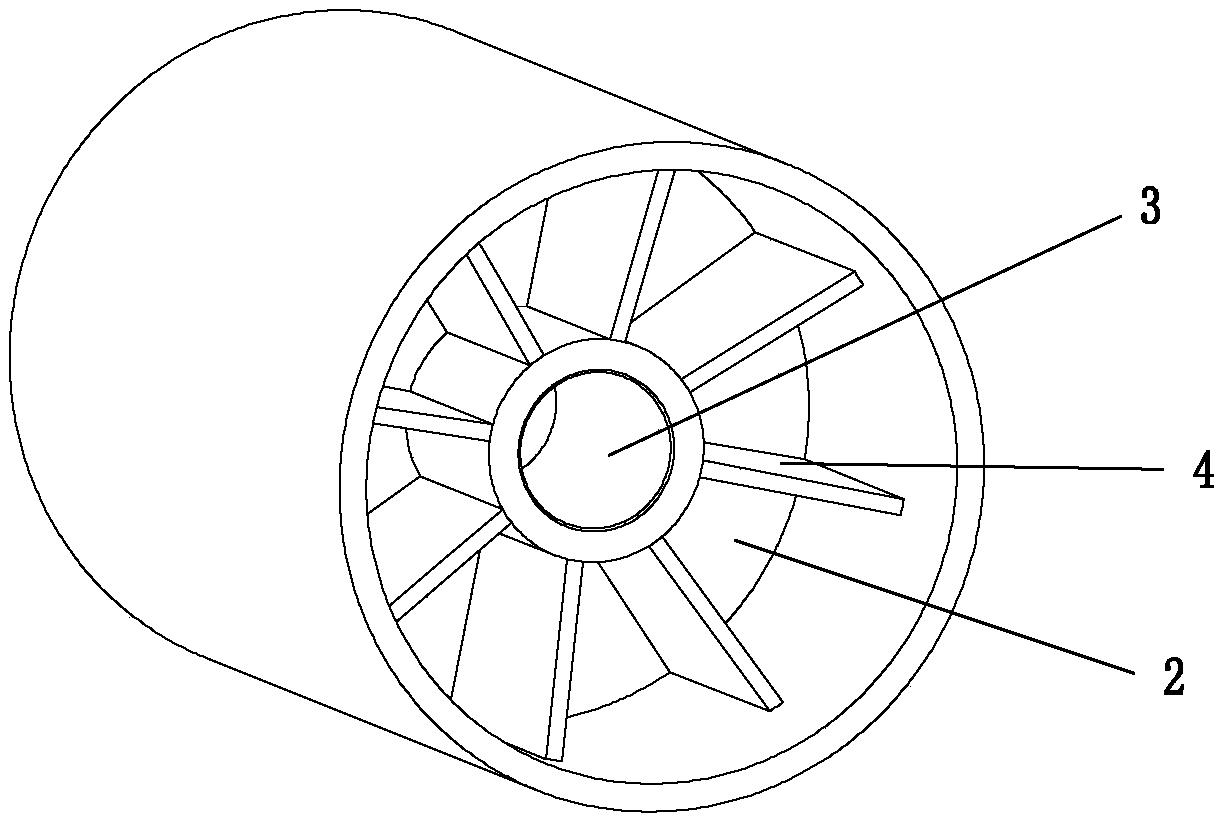

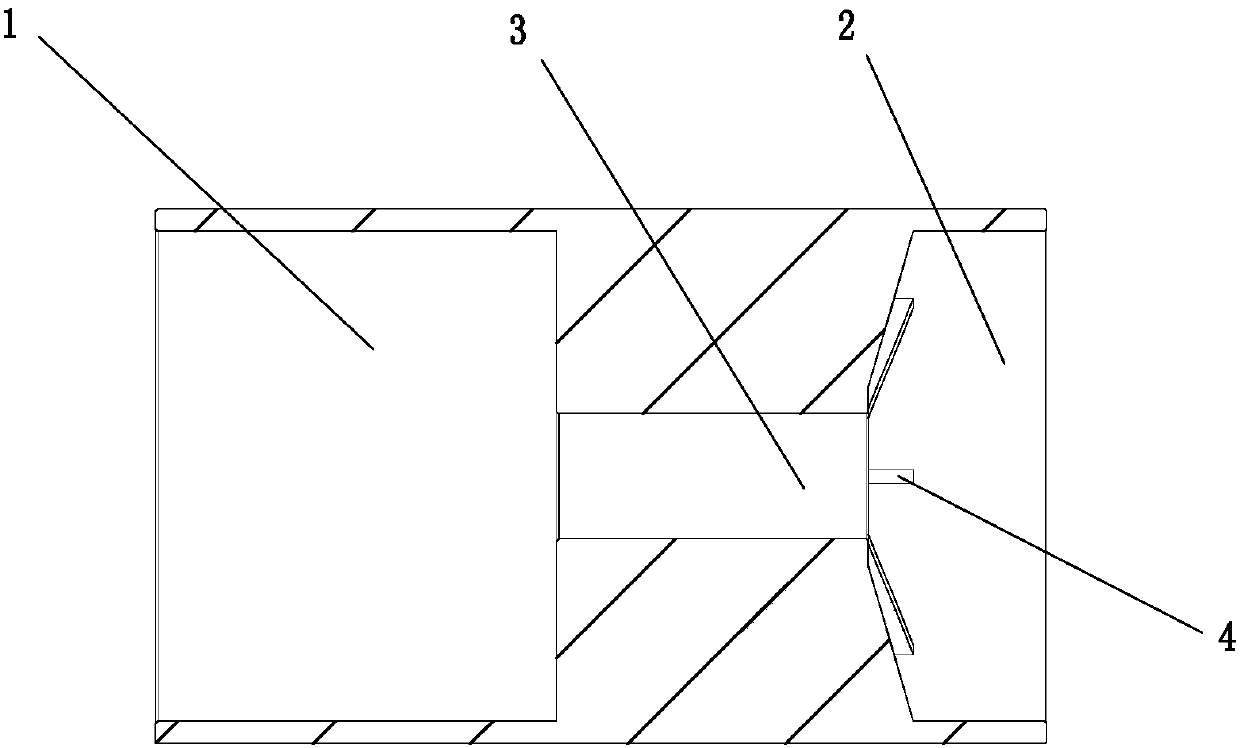

Spinning machine tangential belt tensioning guide wheel and guide wheel machining method thereof

PendingCN114393861AImprove toughnessReduce jumpingContinuous wound-up machinesDomestic articlesYarnStructural engineering

The invention discloses a spinning machine tangential belt tensioning guide wheel and a guide wheel machining method thereof, and belongs to the technical field of spinning equipment parts. According to the machining method of the tensioning guide wheel, multiple times of aging treatment is conducted on the spinning tangential belt tensioning guide wheel, and the machining method of tool and tool parameter design is adopted, so that the toughness of the tensioning guide wheel can be improved in the failure treatment process, and the problems that the spinning tangential belt tensioning guide wheel is large in jumping, poor in coaxiality, prone to deformation and the like in the production process are solved; the product quality of the spinning tangential belt tensioning guide wheel is improved, and the production requirement of high-quality yarn is met. According to the tensioning guide wheel, the inner ring sleeve is arranged on the base body of the tensioning guide wheel, and the whole frame body of the tensioning guide wheel is formed between the inner ring sleeve and the base body of the tensioning guide wheel through integral injection molding of the reinforcing ribs, so that the strength and toughness of the tensioning guide wheel are greatly improved, jumping of the tensioning guide wheel can be reduced during conveying of a tangential belt, and the service life of the tensioning guide wheel is prolonged. And the transmission stability of the tensioning belt wheel is improved.

Owner:浙江机电职业技术学院

Method for preparing P-xylene and propylene from methanol and/or dimethyl ether

ActiveUS9994496B2Guaranteed production demandImprove economyGroup 4/14 element organic compoundsMolecular sieve catalystAromatizationReaction system

This invention relates to a method for preparing p-xylene and propylene from methanol and / or dimethyl ether. This method comprises coupling two reaction processes, an aromatization reaction of methanol and / or dimethyl ether and an alkylation reaction of ethylene with methanol and / or dimethyl ether. The method of this invention produces p-xylene and propylene with a high selectivity by returning an ethylene-enriched component in reaction byproducts from preparation of p-xylene from methanol and / or dimethyl ether to the reaction system for performing alkylation reaction with methanol and / or dimethyl ether in the presence of catalysts.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Spinning winding roller machining technology

The invention provides a spinning winding roller machining technology and belongs to the technical field of spinning equipment parts. The technology comprises the following machining steps that nylonand glass fiber are adopted as raw materials, and are molded in an injection manner through an injection molding machine at the temperature of 245-255 DEG C; a spinning winding roller blank molded inan injection manner is placed for one to two months at the normal temperature; the blank obtained after normal temperature aging treatment is placed into clear water with the temperature between 15 DEG C and 25 DEG C to be subjected to aging treatment in water again, placing time is between 4.5 hours and 5 hours, and elastic deformation of the blank is further reduced; inner hole turning is carried out on the blank obtained after aging treatment in the water, and in the turning process, a first cylinder hole and a through hole are turned and formed at the same time; a tungsten steel reamer isadopted for grinding and penetrating the through hole; the bank formed through primary turning is placed into the water to be treated at the constant temperature; the blank which is placed in the water and machined primarily is taken out, the grinded inner hole serves as a locating basis, double-tip clamping and locating are adopted, and turning of the outer circle periphery face is carried out; and a circumferential rolling depression wheel is adopted for carrying out surface finishing process to form the product.

Owner:杭州量创科技咨询有限公司

A positioning mechanism for cutting and processing aluminum profiles

ActiveCN111872486BAchieving horizontal positioning requirementsHigh positioning accuracyPositioning apparatusMetal-working holdersEconomic benefitsEngineering

The invention discloses a positioning mechanism for cutting and processing aluminum profiles. For the cutting and processing of aluminum profiles in the present invention, firstly, a positioning bracket is used to perform initial positioning on the aluminum profiles to determine the equal-section cutting positions of the aluminum profiles. Then, press the upper side of the aluminum profile through the set first positioning platen, and then realize the positioning of the vertical position, and then press the side of the aluminum profile through the second positioning platen set in the auxiliary positioning mechanism. Tight positioning, realize the horizontal positioning requirements of aluminum profiles, and then increase the positioning accuracy, firmness and stability of aluminum profiles during cutting work, make the cutting work of aluminum profiles more smoothly, ensure the cutting quality of aluminum profiles, and then Ensure the actual needs of production work, improve the quality of production work, and ensure the economic benefits of production work.

Owner:辽宁永壮铝业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com