Spinning winding roller machining technology

A processing technology and winding roller technology, which is applied in the field of spinning and winding roller processing technology, can solve the problems of poor coaxiality, easy deformation, and large jumping of the spinning and winding roller, so as to improve product quality and reduce the amount of deformation. , the effect of twisting quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

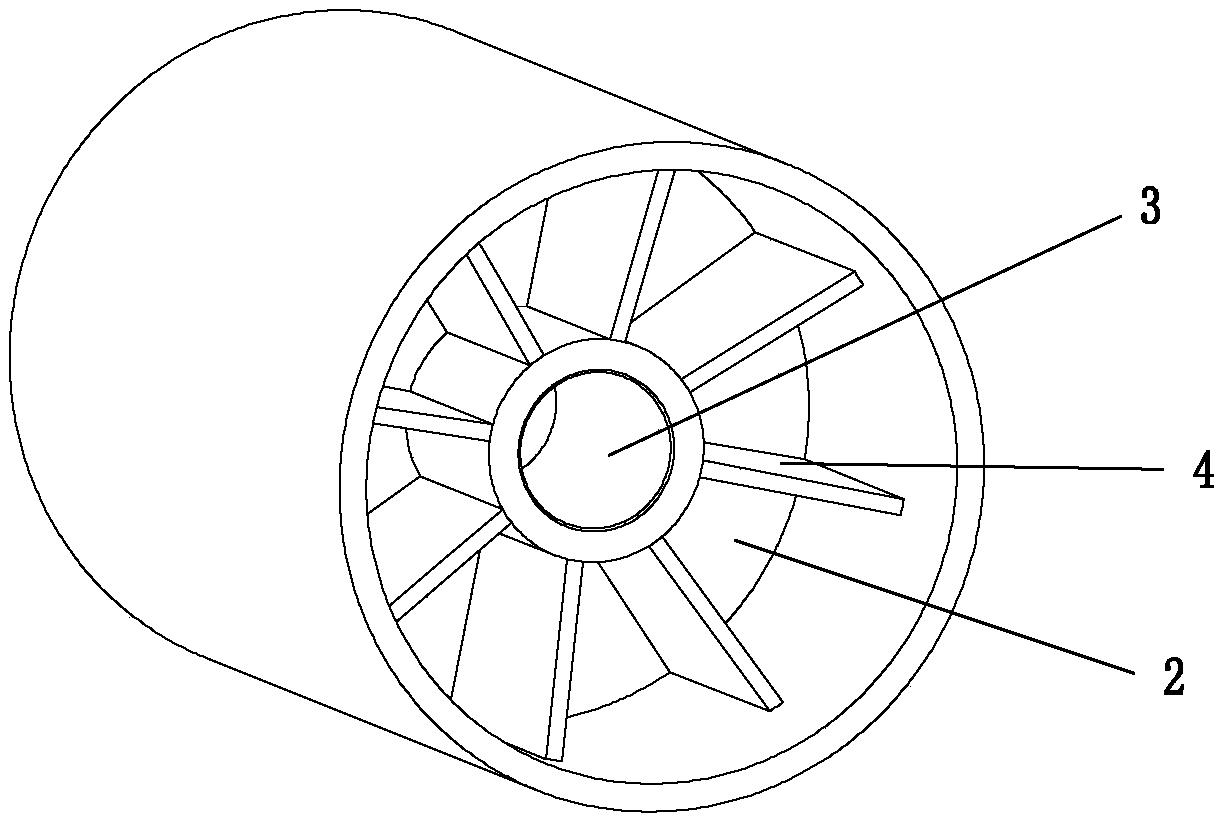

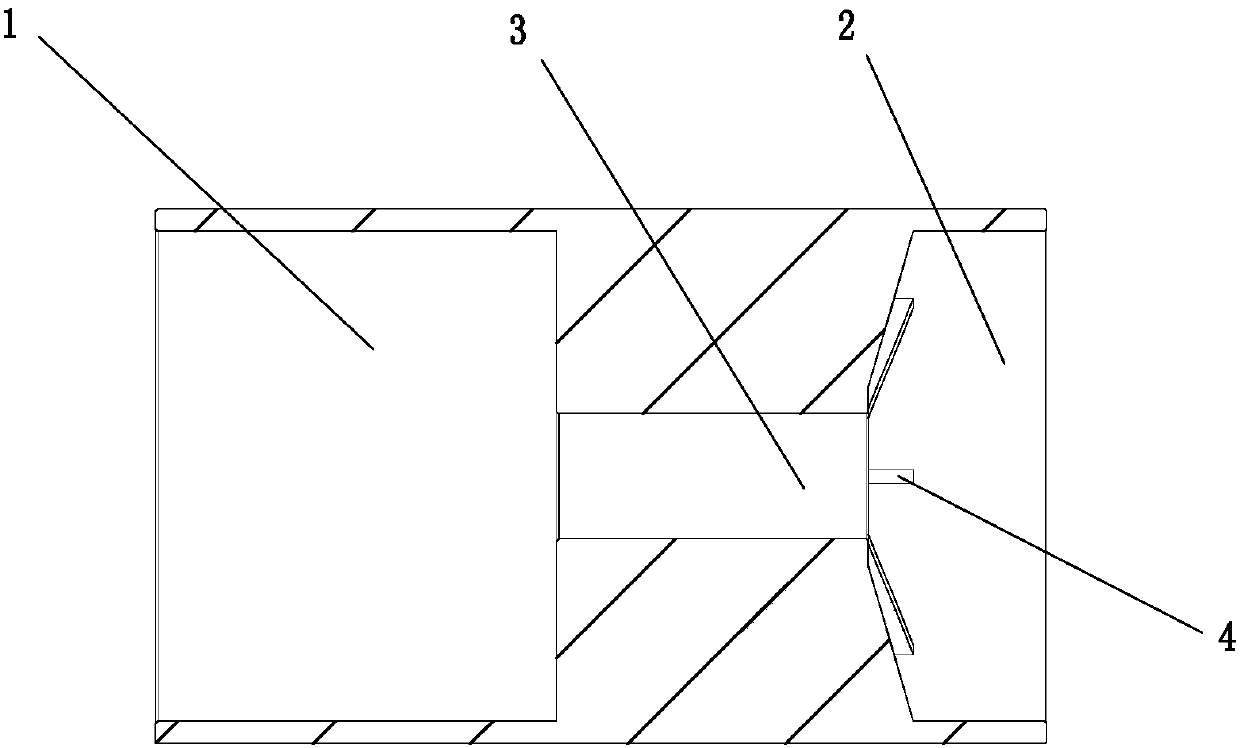

[0020] Such as Figure 1-Figure 2 As shown, one end of the spinning winding roller is provided with a concave first cylindrical hole 1, and the other end is provided with a concave second cylindrical hole 2, and there is a section between the first cylindrical hole 1 and the second cylindrical hole 2. The first cylindrical hole and the second cylindrical hole and its diameter is smaller than the through hole 3 of the diameter of the first cylindrical hole and the second cylindrical hole, and the inside of the second cylindrical hole is provided with supporting ribs distributed along the circumference of the second cylindrical hole wall 4. The through hole extends toward the second cylindrical hole to the middle of the second cylindrical hole, and the wall of the through hole formed in the second cylindrical hole is fixedly connected with the supporting rib 4 .

[0021] The spinning winding roll includes the following processing steps: the first step is to use nylon and glass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com