Process and equipment for preparing 1,2-butadiene by continuous method

A process technology, a butadiene technology, is applied in the field of continuous preparation of styrene-butadiene rubber inhibitor 1 by separation method, which can solve the problems of high technical cost, uneconomical, affecting the smooth production of styrene-butadiene equipment, etc., and achieve economic benefits and social benefits. Considerable benefits and the effect of increasing added value

Active Publication Date: 2011-09-07

CHINA PETROLEUM & CHEM CORP

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of the current 1,2-butadiene production technology status at home and abroad, if imported 1,2-butadiene from abroad will have supply problems, it needs to be further implemented; if the technology is imported, high technical fees will be paid, and there will be no Economical, but there is no source of 1,2-butadiene, which directly affects whether the 100,000 tons / year solution styrene-butadiene rubber plant can be put into production smoothly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The present invention will be further described below with specific embodiment.

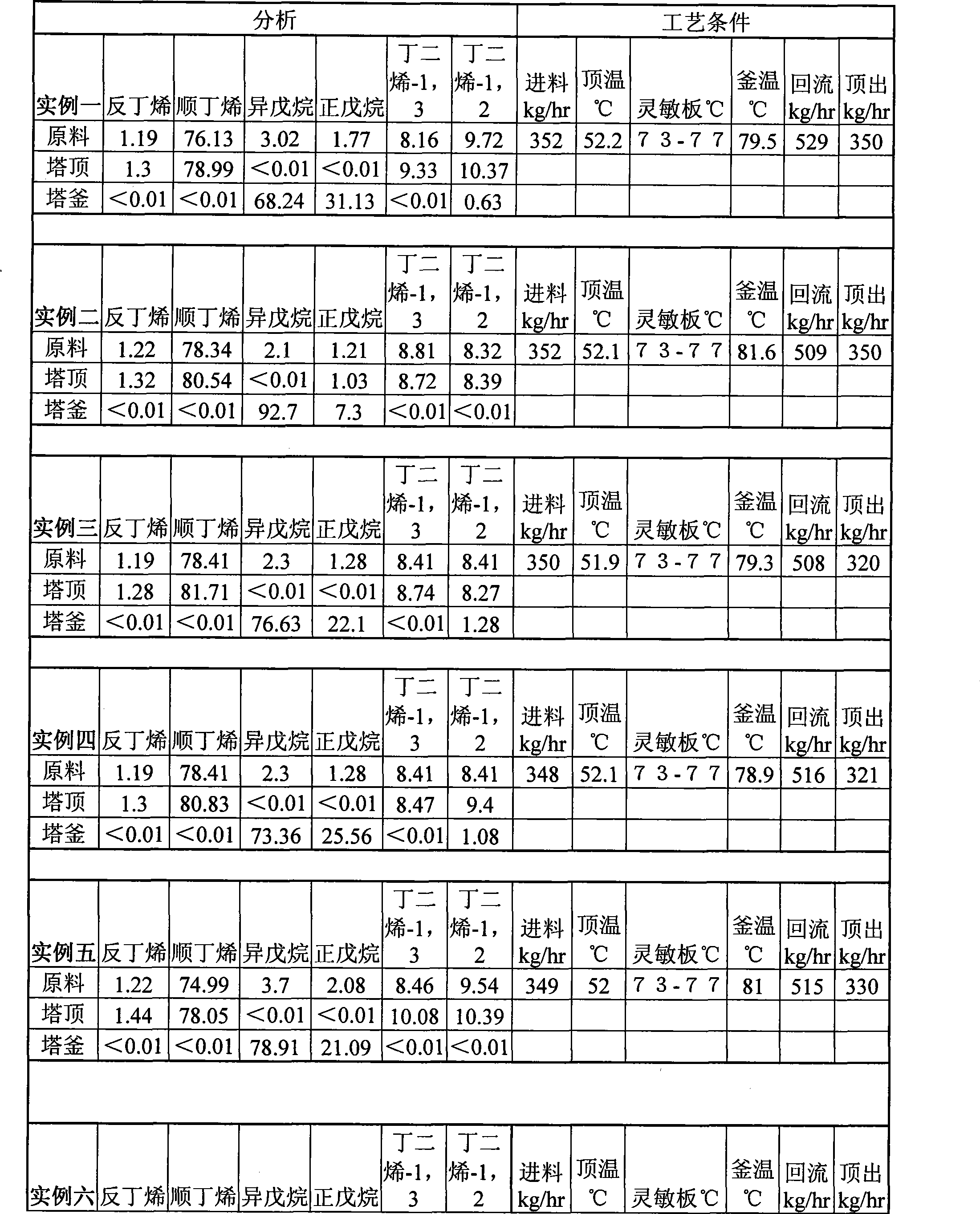

[0027] The raw material used in the present invention is the heavy fraction discharged from the tower kettle after extracting and producing butadiene by the acetonitrile method. It contains about 5% pentane, 10-20% 1,3-butadiene, 5-12% 1,2-butadiene, about 1% trans-butene, and the rest is butene.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

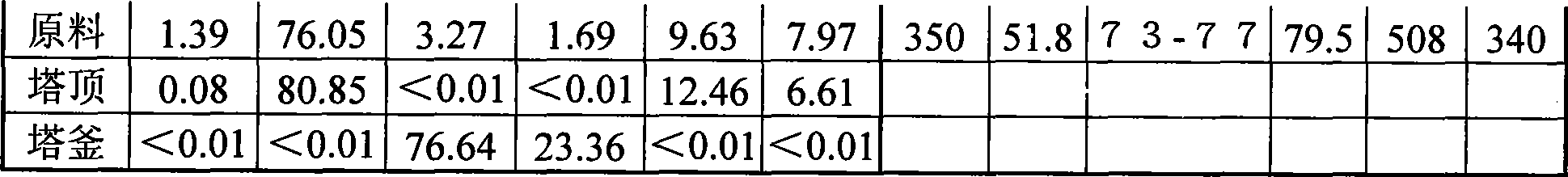

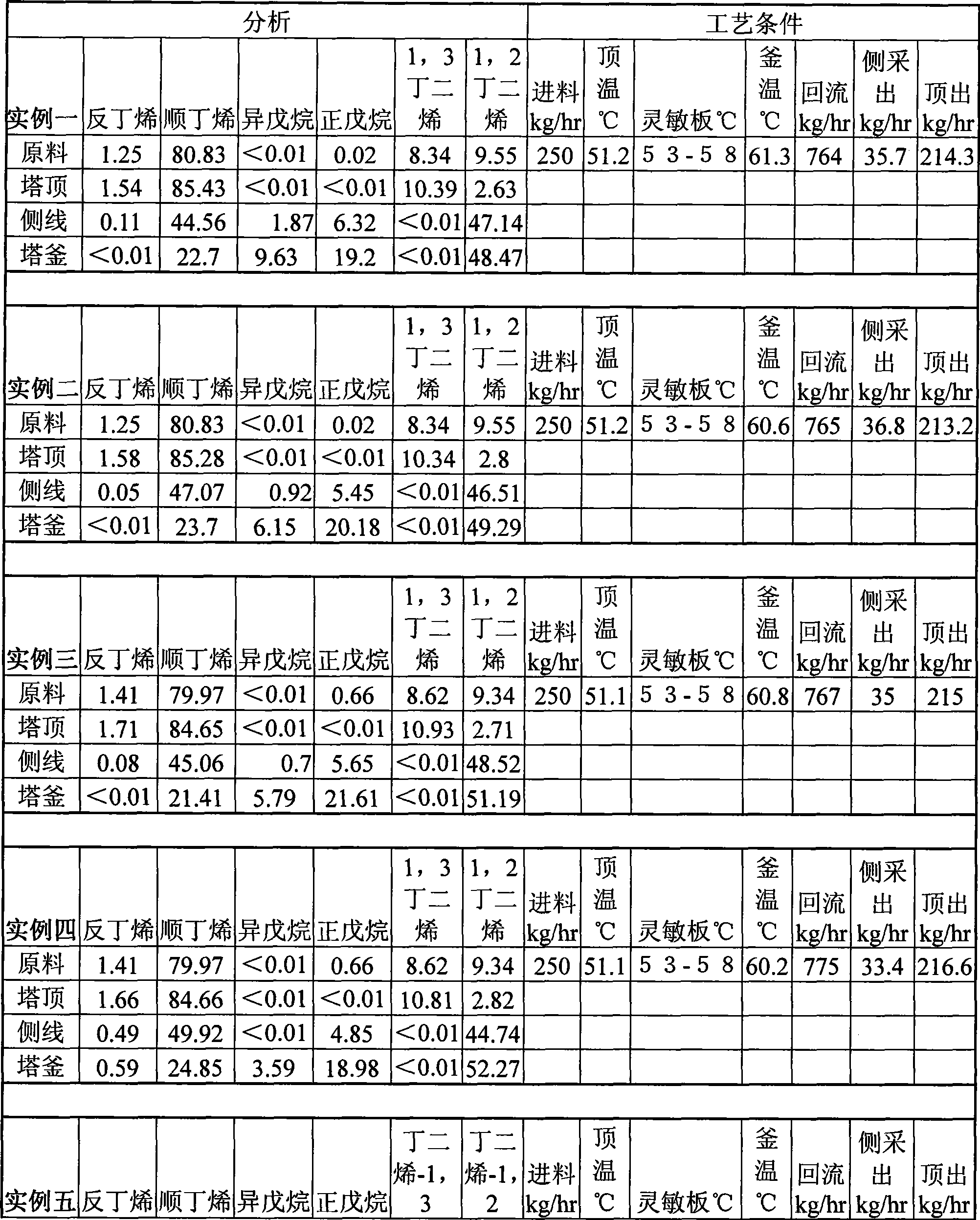

The invention discloses a process technique and a separation plant for continuously preparing styrene-butadiene rubber inhibitor by a separation method. The process comprises the following steps: selecting heavy components of the byproduct of 1,3-butadiene produced by the extraction method as the raw material containing 1,2-butadiene 5 to 12% (wt), washing with water to remove the trace amount ofa residual solvent, removing the heavy component and the light component on the same rectification tower by a common rectification method with side withdrawing, rectifying at a kettle temperature of 55 to 65 DEG C and a sensitive plate temperature of 52 to 62 DEG C, under 0.35 to 0.39 MPa and in an oxygen-free condition; adding a proper amount of polymerization inhibitor, and continuously withdrawing the product containing 1,2-butadiene with an amount equal to or larger than 40%. The method can obviate the problems in the production technology, the safety, the environment protection, etc. resulting from the factors such as the raw material, the catalyst and the byproducts, and also increase the additional value of the 1,3-butadiene byproducts, thereby achieving remarkable economic and social benefits.

Description

technical field [0001] The invention relates to a process technology and separation equipment for continuously preparing styrene-butadiene rubber inhibitor 1,2-butadiene by a separation method. Background technique [0002] In the continuous polymerization production of solution styrene-butadiene rubber, some of the active chains initiated by organolithium will form gels during the continuous polymerization process, so that the gel content in the rubber will increase significantly, and the product quality will decline, and these gels will also It will deposit in some parts of the reactor and continue to react with the monomer to form large gel micelles, which will cause blockage of the reactor and seriously affect production. Therefore, in the continuous polymerization of solution styrene-butadiene rubber, gel inhibitors capable of chain transfer must be added to inhibit gel formation by adjusting the reaction kinetics without reducing monomer conversion or affecting rubber ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C11/16C07C7/04

Inventor 韩方煜吴国旭侯亮袁征胡衮朱雪娣周华君

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com