Electronic control module of electronic detonator and production process method of electronic control module

A technology of electronic control module and electronic detonator, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of short process chain, complex manufacturing process, large size of post-welding electrolytic capacitors, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

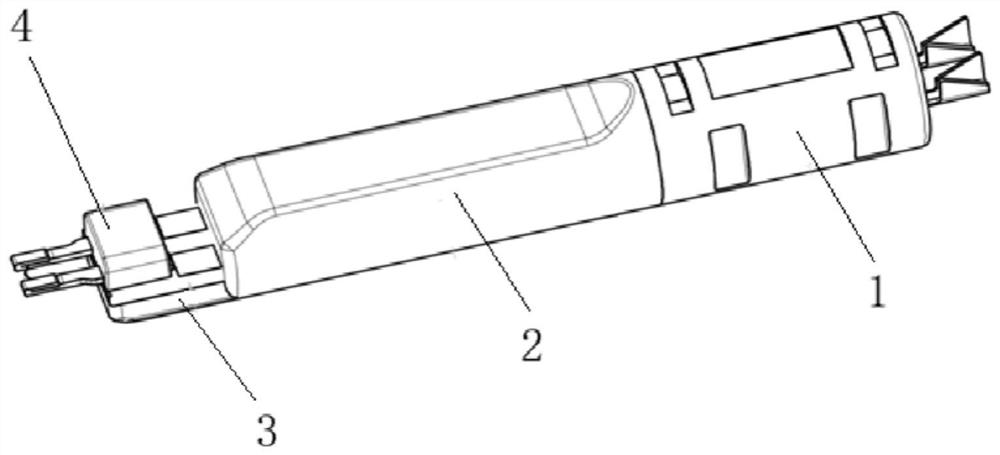

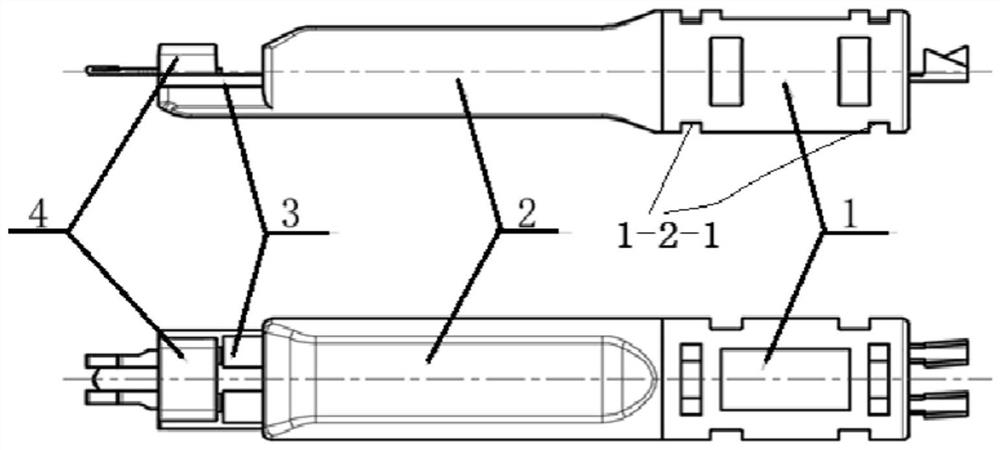

[0046] like Figure 1-4 As shown, this embodiment first provides an electronic detonator electronic control module, including module encapsulation injection molding blocks 1-22, a control circuit main board 3 and a patch bridge wire terminal 4, which is characterized in that: it also includes a sticker with a connector. The chip electrolytic capacitor 1, the chip electrolytic capacitor 1 with a connector, the module encapsulation injection molding block 1-22, the control circuit main board 3 and the patch bridge wire terminal 4 are integrally connected.

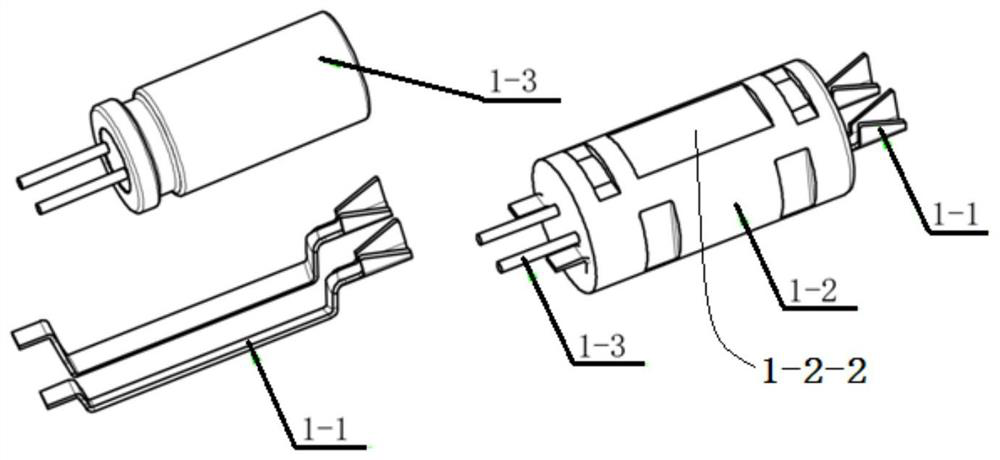

[0047] The patch type electrolytic capacitor 1 with a connector includes a pin connector 1-1, an encapsulation injection molding block 1-2 and an electrolytic capacitor 1-3 which are connected in sequence.

[0048] The length of the patch end of the pin connector 1-1 in the axial direction is smaller than the length of the pins of the electrolytic capacitor 1-3.

[0049] The upper surface of the patch end of the foot wire co...

Embodiment 2

[0066] like Figure 1-4 As shown, this embodiment firstly provides an electronic control module for an electronic detonator, including a module encapsulation injection molding block 1-22, a control circuit main board 3 and a chip bridge wire terminal 4, and is characterized in that: it also includes a chip with a connector The chip electrolytic capacitor 1, the chip electrolytic capacitor 1 with a connector, the module encapsulation injection molding block 1-22, the control circuit main board 3 and the chip bridge wire terminal 4 are integrally connected.

[0067] Further, the SMD electrolytic capacitor with connector 1 includes a leg connector 1-1, an encapsulating injection molding block 1-2 and an electrolytic capacitor 1-3 connected in sequence.

[0068] Further, the length of the patch end of the leg connector 1-1 in the axial direction is smaller than the length of the pins of the electrolytic capacitor 1-3.

[0069] Further, the upper surface of the patch end of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com