Spinning machine tangential belt tensioning guide wheel and guide wheel machining method thereof

A processing method and spinning machine technology, which can be applied in spinning machines, continuous winding spinning machines, metal processing, etc., can solve the problems of large jump, unstable rotation, poor coaxiality, etc., and achieve improved strength and The effect of resilience, ensuring production demand, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

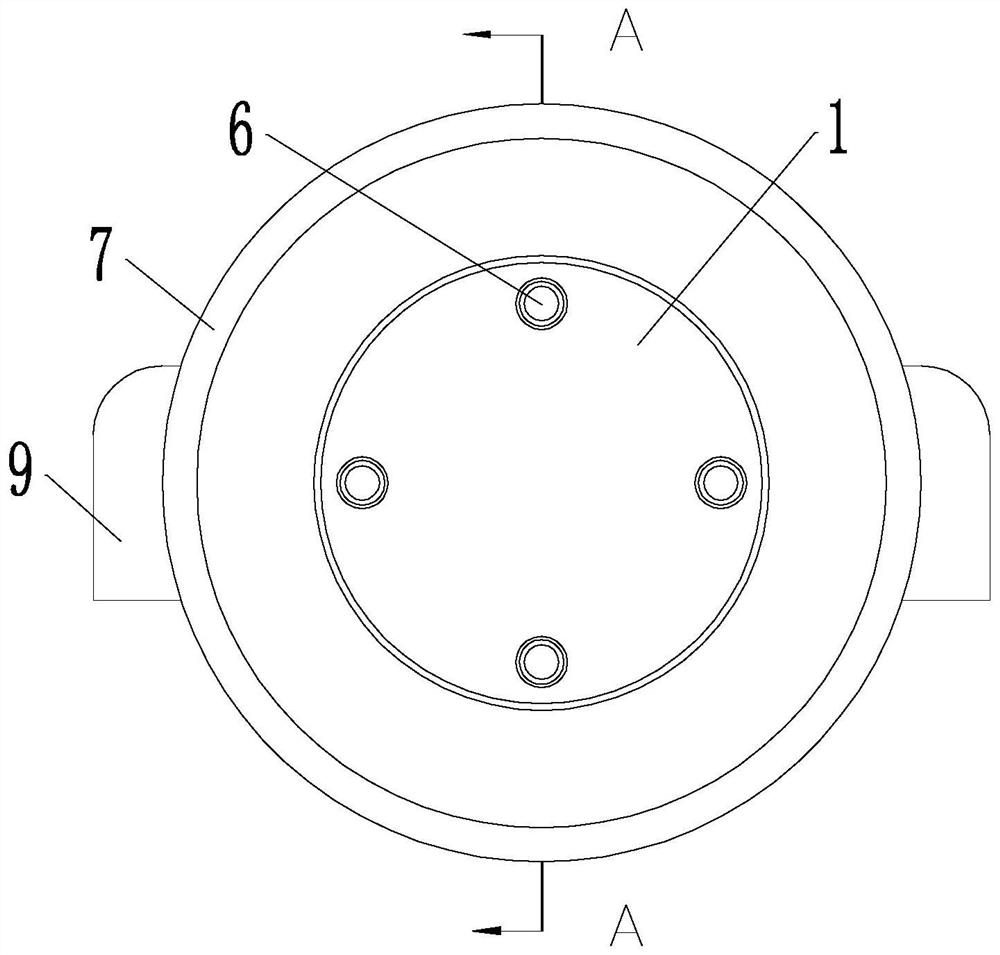

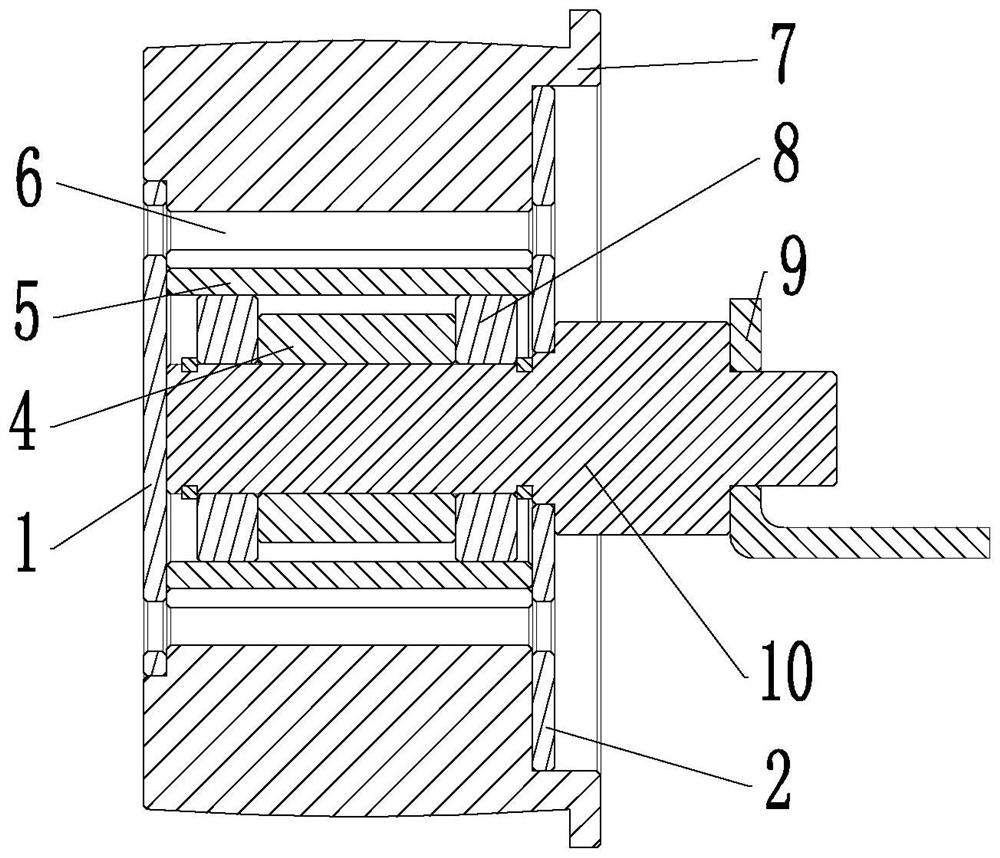

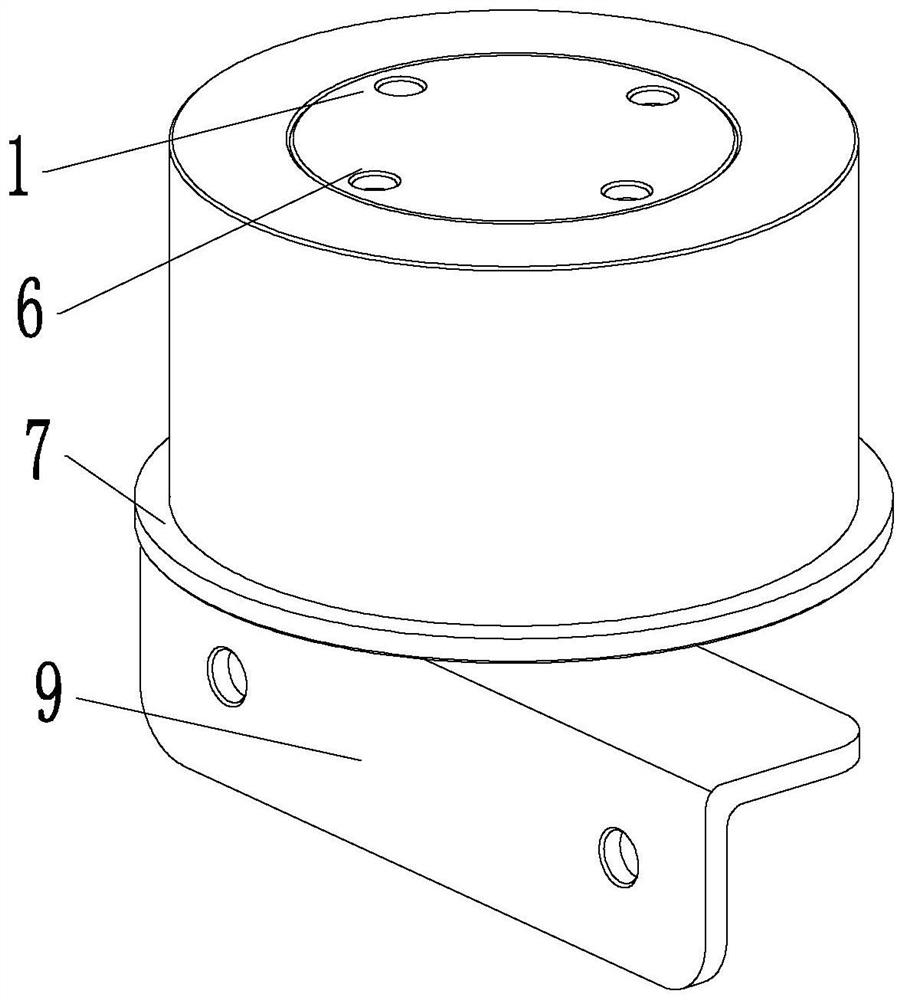

[0026] The specific embodiments of the present invention are described in detail below in conjunction with the accompanying drawings.

[0027] as Figures 1 to 4 As shown, the tension guide wheel of the present invention comprises a guide wheel matrix, the guide wheel base is provided in the axial direction of the transmission shaft piercing hole, the two ends of the transmission shaft piercing hole are formed separately to form the left end cover mounting counterhole and the right end cover plate mounting counterhole, the diameter of the left end cover plate mounting counterhole is less than the diameter of the right end cover plate mounting counterhole, the left end cover plate 1 and the right end cover plate 2 are fixed and installed in the left end cover mounting counterhole and the right end cover plate mounting counterhole, the transmission shaft mounting hole is set in the inner ring support sleeve 3, the inner ring support sleeve 3 is located between the left cover plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com