High-viscosity composite modified pitch and storing and heating device thereof

A composite modified asphalt and heating device technology, which is applied in the field of asphalt improvement, can solve problems such as waste, the production rate of anti-corrosion tape cannot be kept constant, and the mixing temperature limit, so as to avoid human burns or scalds, and solve drive and transmission delays. Time, high and low temperature performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, the high-viscosity composite modified asphalt of the present invention is realized in this way, a kind of high-viscosity composite modified asphalt, it is characterized in that, described composite high-viscosity modified asphalt raw material adopts the following components and weight percentage content : asphalt 85; modified compound 15;

[0055] Further, the asphalt includes the following components and their mass percentages are: 21.15%-23.43% of saturated components, 32.26%-46.00% of aromatic components, 21.64%-33.73% of colloids, and 7.96%-10.83% of asphaltenes.

[0056] Furthermore, the softening point of the pitch is 99.5°C-101.4°C.

[0057] Further, the modified compound is styrene-butadiene-styrene copolymer, desulfurized rubber particles and compatibilizer, or is styrene-isoprene-styrene copolymer, desulfurized rubber particles and phase Toner.

[0058] Further, the weight ratio of the styrene-butadiene-styrene copolymer to the desulfurized rub...

Embodiment 2

[0062] Embodiment 2, the preparation method of the high-viscosity composite modified asphalt of the present invention is:

[0063] (1) Styrene-butadiene-styrene copolymer / desulfurized rubber particles with a weight ratio of 1:1, or styrene-isoprene-styrene copolymer / desulfurized rubber with a weight ratio of 1:1 Mix the granules and compatibilizer evenly, react and mix in an internal mixer for 30 minutes at 160-170°C to obtain a modified compound, and obtain modified compound particles after mechanical granulation;

[0064] (2) Heat the base asphalt to 170°C-180°C, slowly add the modified composite particles, at a constant temperature, use a high-speed shear emulsifier to cut for 45 minutes, control the speed of the shearer to 3500-4500r / min, and then place Stir for 2 hours at a low speed under the agitator, and the composite high-viscosity modified asphalt is prepared.

Embodiment 3

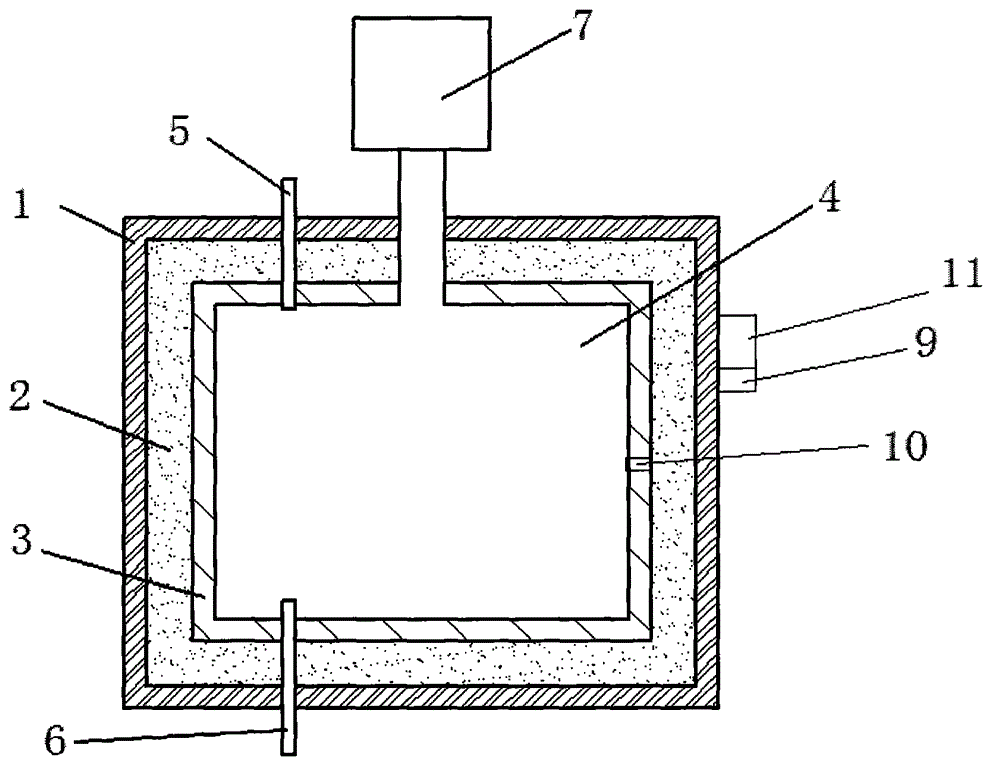

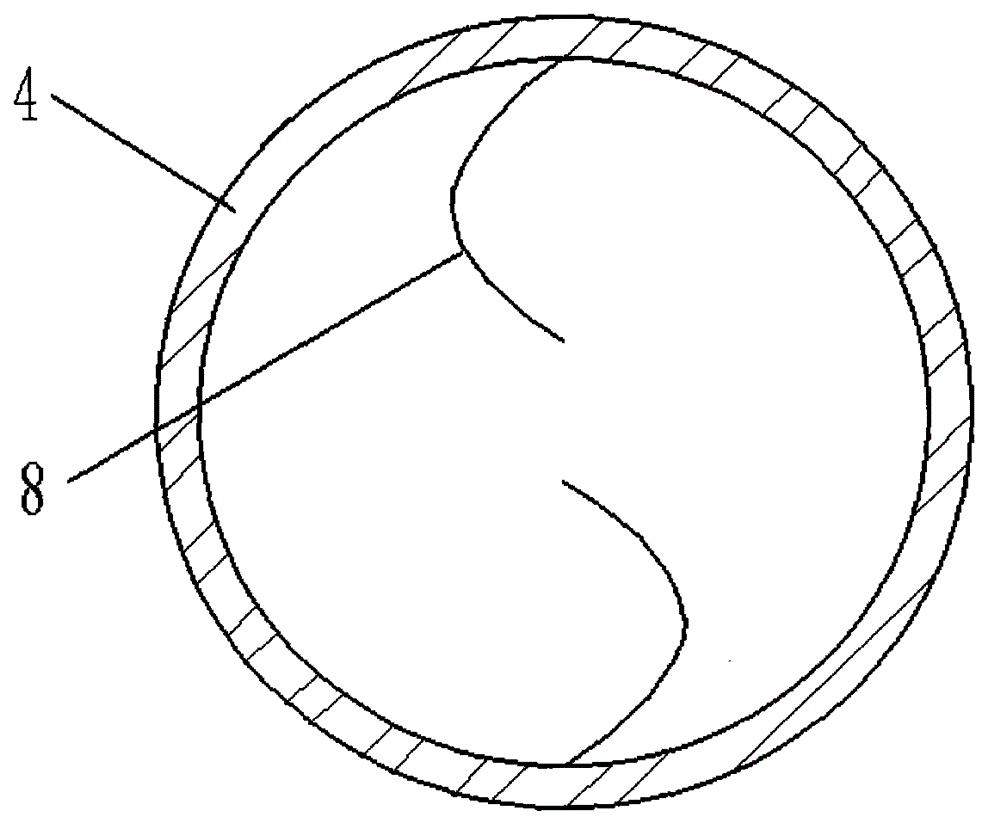

[0065] Example 3, figure 1 and figure 2 Shows the structure of the storage and heating device for high-viscosity composite modified asphalt provided by the present invention, mainly including: shell 1, insulation layer 2, heating tank 3, inner tank 4, asphalt injection pipe 5, asphalt outlet pipe 6, and rotation system 7 , spoiler 8, control switch 9, temperature sensor 10, temperature indicator 11;

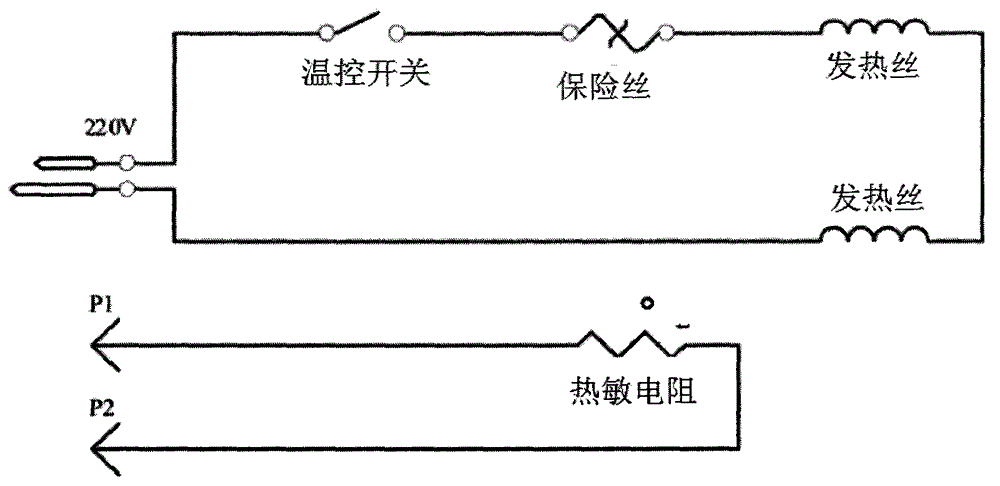

[0066] The storage heating device of the high-viscosity composite modified asphalt is provided with an outer shell 1, a heating liner 3 and an inner liner 4, the outer shell 1 is equipped with a temperature indicator 11 and a control switch 9 for the heating liner, and the inner liner 4 is equipped with A temperature monitoring device is installed, and the temperature monitoring device is connected to a temperature display instrument 11 through a wire; the temperature display instrument 11 is connected to the control switch 9, and the temperature monitoring device is a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com