Water-based zinc ion battery colloidal electrolyte, and preparation method and application thereof

A colloidal electrolyte and zinc-ion battery technology, which is applied in the direction of electrolyte immobilization/gelation, secondary batteries, circuits, etc., to achieve weak corrosion, reduce hydrogen evolution at the negative electrode, and reduce water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

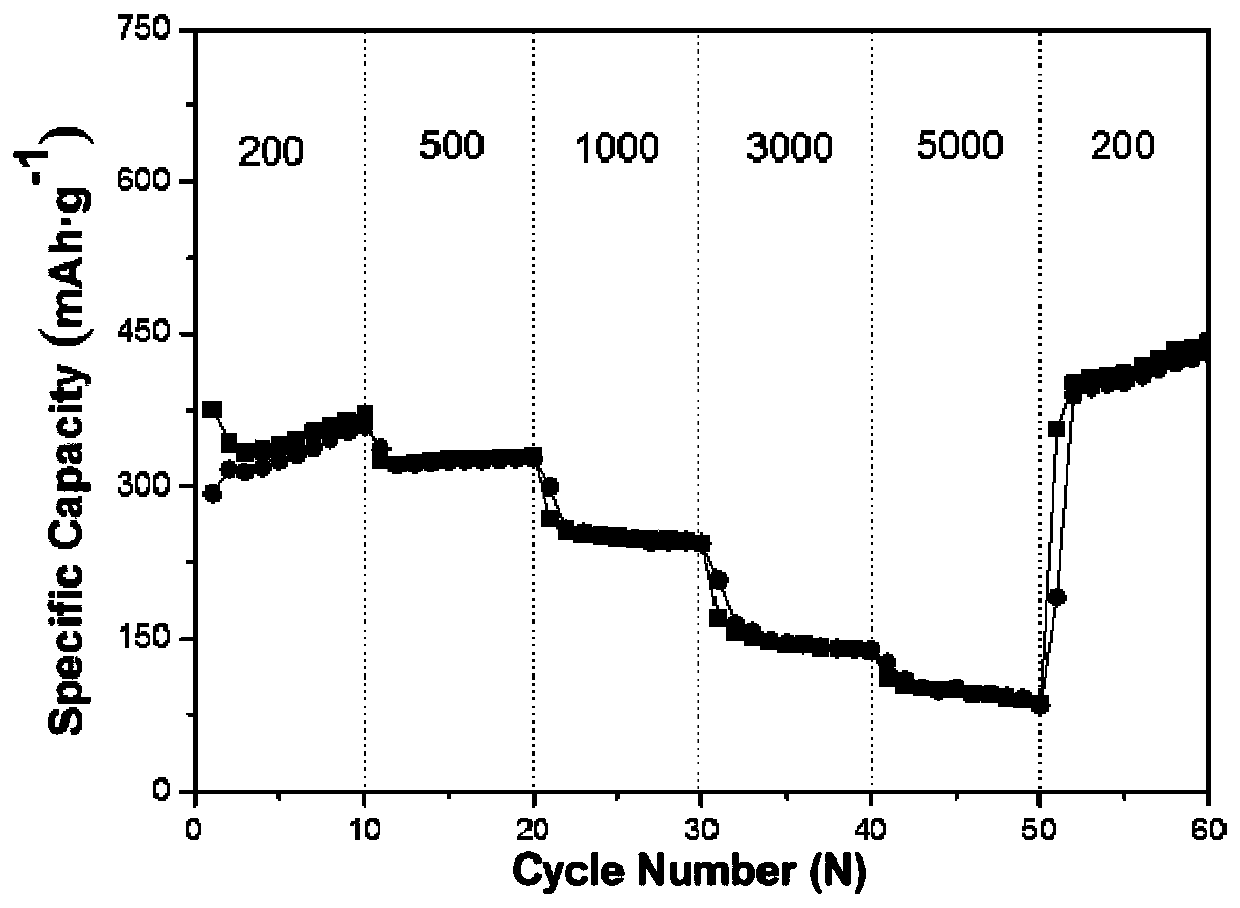

Embodiment 1

[0048] Firstly, a part of untreated kaolin was dissolved in deionized water, and the mixed solution was transferred to a centrifuge tube after continuous stirring for 3 hours under the condition of magnetic stirring. After washing with water, the kaolin was vacuum-dried at 80° C. for 12 hours.

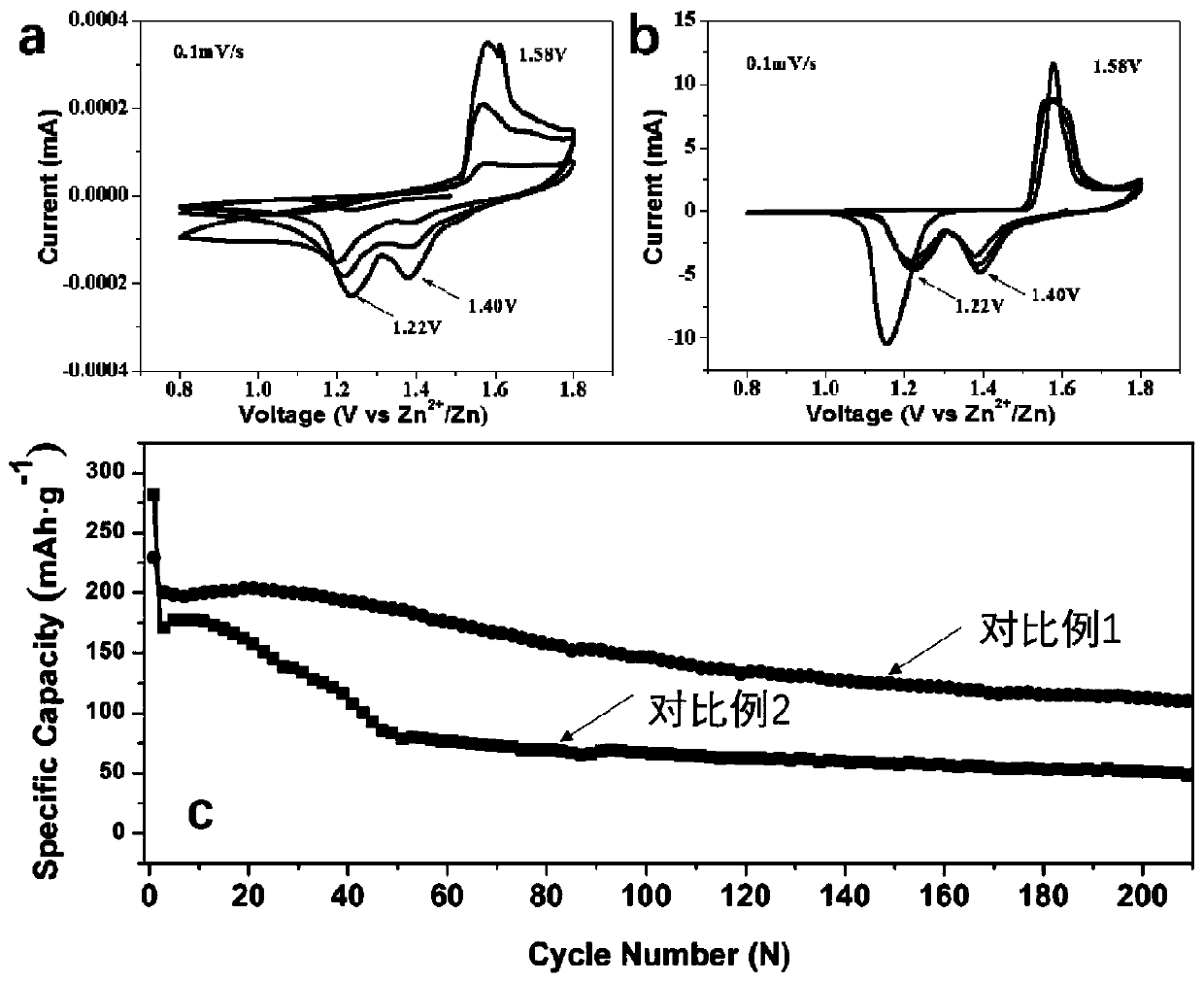

[0049] Weigh zinc sulfate and manganese sulfate of suitable quality and dissolve them in deionized water to prepare a mixed solution of zinc sulfate concentration of 2mol / L and manganese sulfate concentration of 0.1mol / L, then weigh 3g of dry-processed kaolin and add it to 10g of In the liquid electrolyte of zinc sulfate and manganese sulfate, that is, the clay material accounts for 23.07% of the mass concentration of the colloidal electrolyte. After continuous stirring for 1 hour under magnetic stirring conditions, the solution is ultrasonically treated for 10 minutes, and then continuously stirred for 5 hours under magnetic stirring conditions. A colloidal electrolyte with a certain v...

Embodiment 2

[0054] First, take a part of untreated kaolin and attapulgite (mass ratio 1:1) and dissolve it in deionized water. After stirring continuously for 3 hours under magnetic stirring conditions, transfer the mixed solution to a centrifuge tube. After washing with water, mix kaolin and attapulgite The sticks were vacuum-dried at 80°C for 12 hours.

[0055] Take zinc sulfate and manganese sulfate of appropriate quality and dissolve them in deionized water to prepare a mixed solution with a concentration of zinc sulfate of 2 mol / L and a concentration of manganese sulfate of 0.1 mol / L. The clay material accounts for 45% of the mass concentration of the colloidal electrolyte. After stirring continuously for 1 h under the condition, the solution was ultrasonically treated for 10 min, then stirred continuously for 1 h under the condition of magnetic stirring, and aged for 1 h to obtain a colloidal electrolyte with certain viscosity and plasticity.

[0056] The colloidal electrolyte of th...

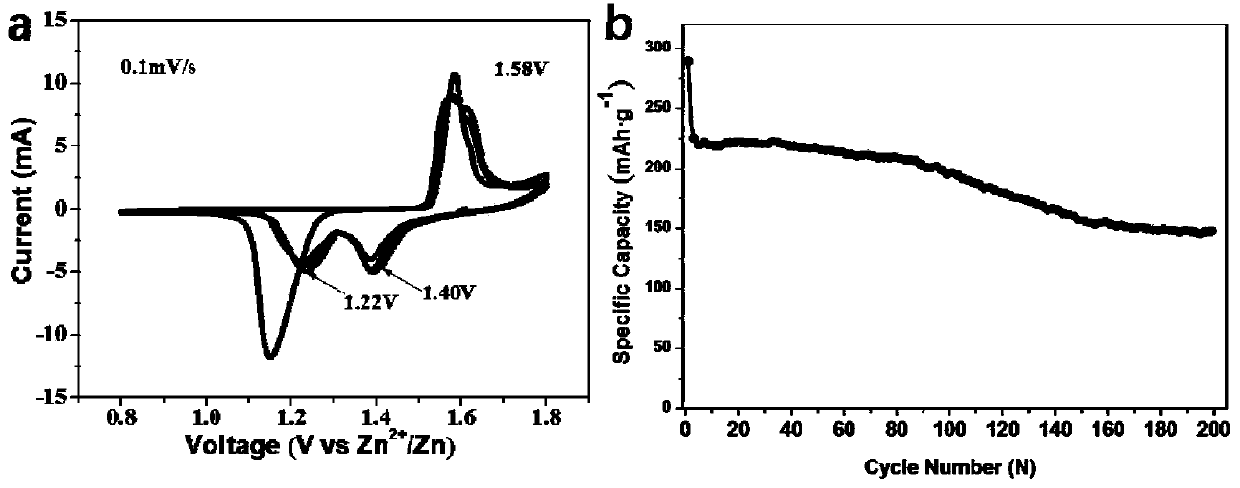

Embodiment 3

[0058] Firstly, a part of untreated kaolin was dissolved in deionized water, and the mixed solution was transferred to a centrifuge tube after continuous stirring for 3 hours under the condition of magnetic stirring. After washing with water, the kaolin was vacuum-dried at 80° C. for 12 hours.

[0059] Take zinc sulfate and manganese sulfate of suitable quality and dissolve them in deionized water to prepare a mixed solution with a concentration of zinc sulfate of 3mol / L and a concentration of manganese sulfate of 0.3mol / L, then weigh 5g of dry-processed kaolin and add it to 10g of In the mixed solution of zinc sulfate and manganese sulfate, that is, the clay material accounts for 33.33% of the mass concentration of the colloidal electrolyte. After continuous stirring for 1 hour under magnetic stirring conditions, the solution is ultrasonically treated for 10 minutes, then continuously stirred for 1 hour under magnetic stirring conditions, and aged for 10 hours. That is, a coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com