Normal temperature and normal pressure regeneration method for activated carbon for gold extraction

A technology of activated carbon and normal pressure, which is applied in the field of normal temperature and normal pressure regeneration of activated carbon for gold extraction, which can solve the problems of difficulty in forming the connection of the production process, secondary pollution, high energy consumption, etc., so as to improve the production efficiency of gold absorption, save energy and invest The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

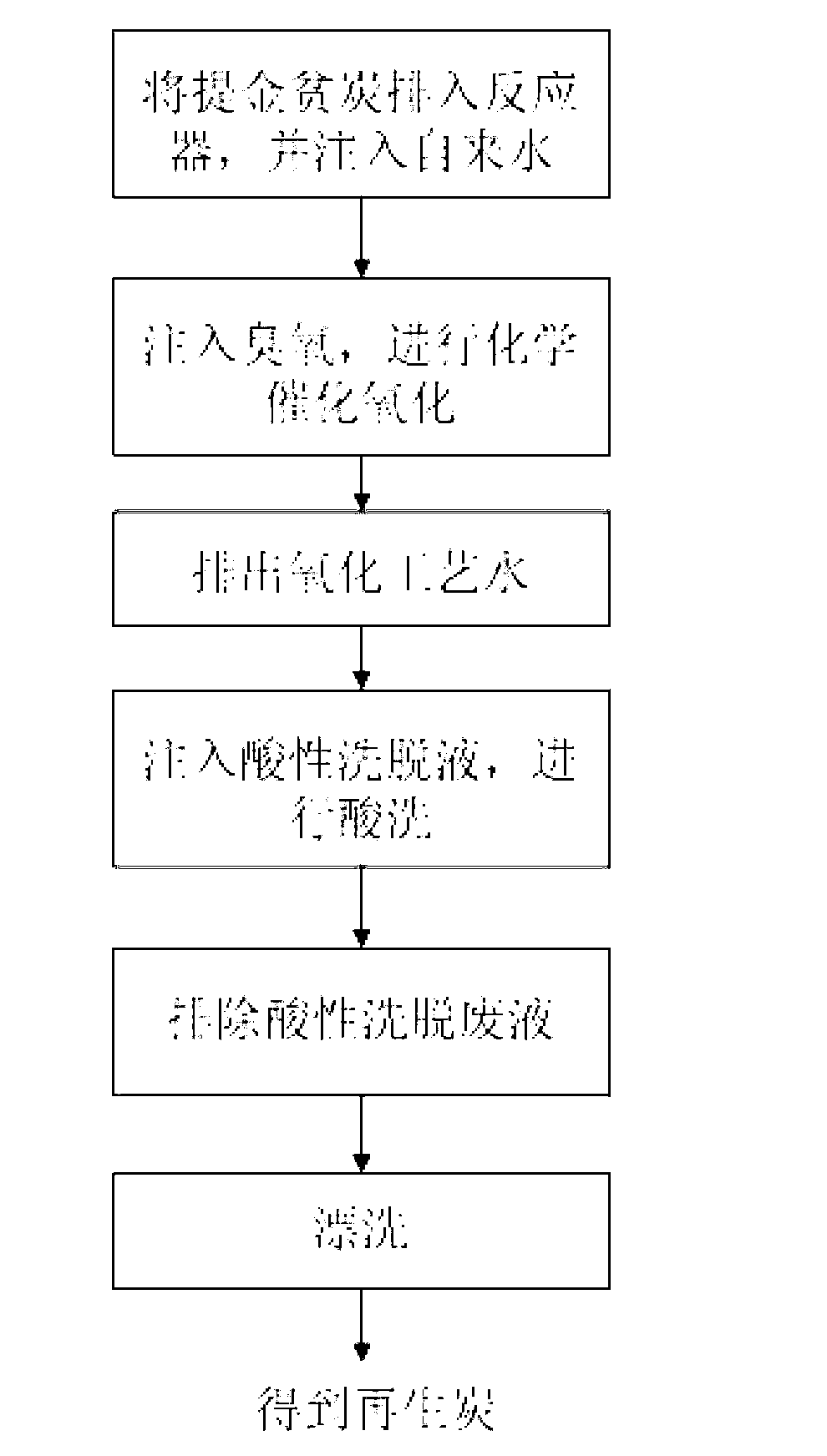

[0028] Embodiment 1: Carry out two-step regeneration of "oxidation-pickling" to gold-extracting poor carbon with an iodine value of 67%:

[0029] In this embodiment, both the oxidation process water and the rinsing water are tap water, and the activated carbon for gold extraction to be regenerated is a gold-extracting depleted carbon with an iodine value of 67% after repeated gold extraction. Its specific process is as figure 1 As shown, at first the gold-extracting poor carbon with an iodine value of 67% is discharged into the main reaction tank, the control module opens the check valve on the connecting pipeline between the auxiliary water tank and the main reaction tank, and injects tap water into the main reaction tank through the auxiliary water tank. The gold-extracting charcoal is submerged, and the one-way valve is closed after ensuring that the mass ratio of the gold-extracting charcoal to the tap water in the main reaction tank is 1:2. Start the ozone generator to c...

Embodiment 2

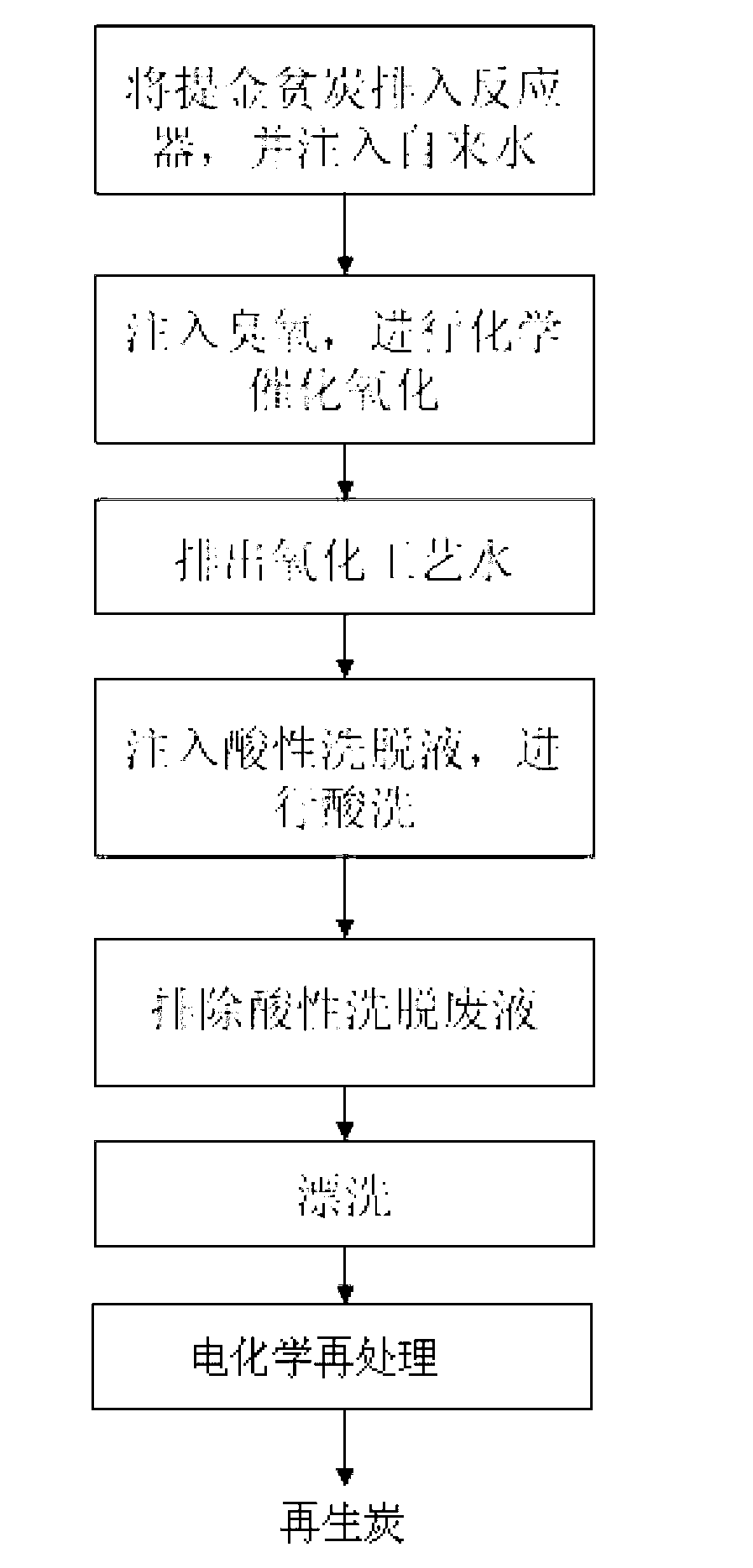

[0032] Example 2: Carry out three-step regeneration of "oxidation-pickling-electrochemical" on the gold-extracting depleted carbon with an iodine value of 72%

[0033] In this embodiment, tap water at normal temperature is used as the oxidation process water, and warm water at 60°C is used as the rinsing water; the activated carbon for gold extraction to be regenerated is gold-extracting depleted carbon with an iodine value of 72% after repeated gold extraction. At the same time, the "electrochemical treatment" step is added in this embodiment, thus, an electrochemical treatment tank is added to the system, and the electrochemical treatment tank is connected to the main reaction tank.

[0034] Its specific process is as figure 2As shown, at first the gold-extracting poor carbon with an iodine value of 72% is discharged into the main reaction tank, and tap water is injected into the main reaction tank through the auxiliary water tank to submerge the gold-extracting poor carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com