Rack of multi-cylinder long mesh paper machine for producing high filler paper

A technology of paper machine and high filler, applied in paper machine, paper making, textile and paper making, etc., can solve the problem that it cannot be used as the frame of fourdrinier multi-cylinder paper machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

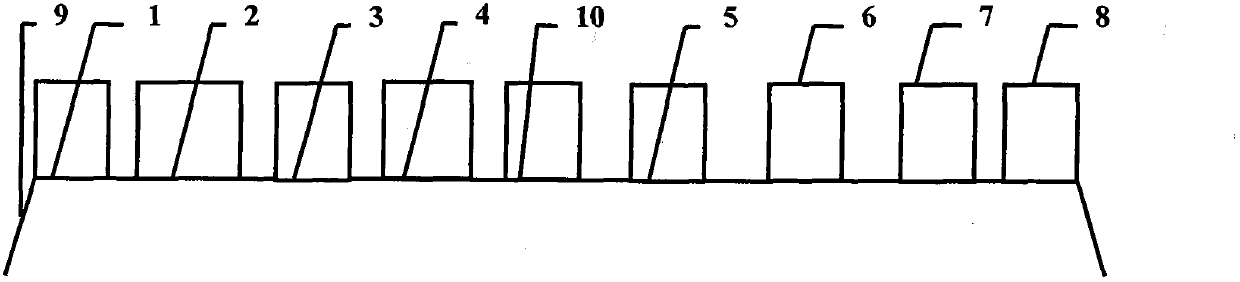

[0030] A frame of a fourdrinier multi-cylinder paper machine for the production of high-fill paper, such as figure 2 As shown, on the frame 9 there are headbox installation position 1, wire section installation position 2, press section installation position 3, front drying part installation position 4, enhanced drying device installation position 10, and sizing machine installation position 5 , The installation position of the enhanced drying device is 10, the installation position of the rear drying part is 6, the installation position of the calender is 7, and the installation position of the roll paper part is 8, and there is an appropriate distance between the positions;

[0031] The overall length of the frame 9 is increased by 10-25m relative to the overall length of the frame 9 of the traditional fourdrinier multi-cylinder paper machine with the same width and speed; the better increased length is 15-17m; the best increased length is 16.2m;

[0032] The overall length...

Embodiment 2

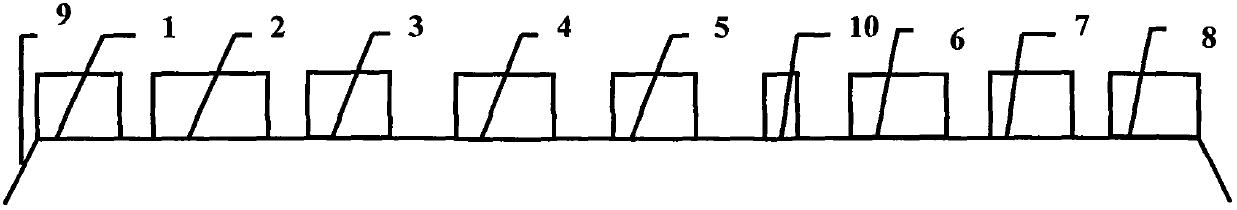

[0038] A frame of a fourdrinier multi-cylinder paper machine for the production of high-fill paper, such as image 3 As shown, on the frame 9 there are headbox installation position 1, wire section installation position 2, press section installation position 3, front drying part installation position 4, enhanced drying device installation position 10, and sizing machine installation position 5 , Installation position 6 of the post drying part, installation position 7 of the calender, installation position 8 of the roll paper part, and there is an appropriate interval between the positions;

[0039] The overall length of the frame 9 is increased by 9-23.5m relative to the overall length of the frame 9 of the traditional fourdrinier multi-cylinder paper machine with the same width and speed; the better increased length is 14-15.5m; the best increased length is 15m ;

[0040] The overall length of the frame 9 can be 9m, 10m, 11m, 12m, 13m, 14m, 15m, 16m, 17m, 18m with respect to...

Embodiment 3

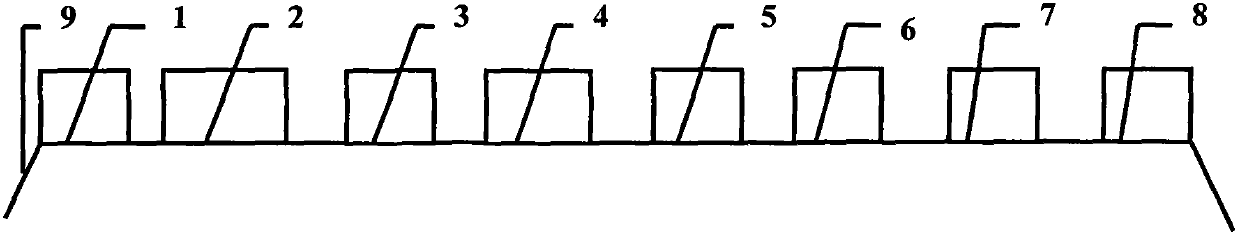

[0044] A frame of a fourdrinier multi-cylinder paper machine for the production of high-fill paper, such as Figure 4 As shown, on the rack 9 there are headbox installation position 1, wire section installation position 2, press section installation position 3, front drying part installation position 4, sizing machine installation position 5, and enhanced drying device installation position 10 , Installation position 6 of the post drying part, installation position 7 of the calender, installation position 8 of the roll paper part, and there is an appropriate interval between the positions;

[0045] The overall length of the frame 9 is increased by 9-23.5m relative to the overall length of the frame 9 of the traditional fourdrinier multi-cylinder paper machine with the same width and speed; the better increased length is 14-15.5m; the best increased length is 15m ;

[0046] The overall length of the frame 9 can be 9m, 10m, 11m, 12m, 13m, 14m, 15m, 16m, 17m, 18m with respect to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com