Molding equipment for high-rise building prefabricated wallboard part and machining method of molding equipment

A technology for high-rise buildings and molding equipment, which is applied to manufacturing tools, ceramic molding machines, mold auxiliary parts, etc. Pockmarked surface, better sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

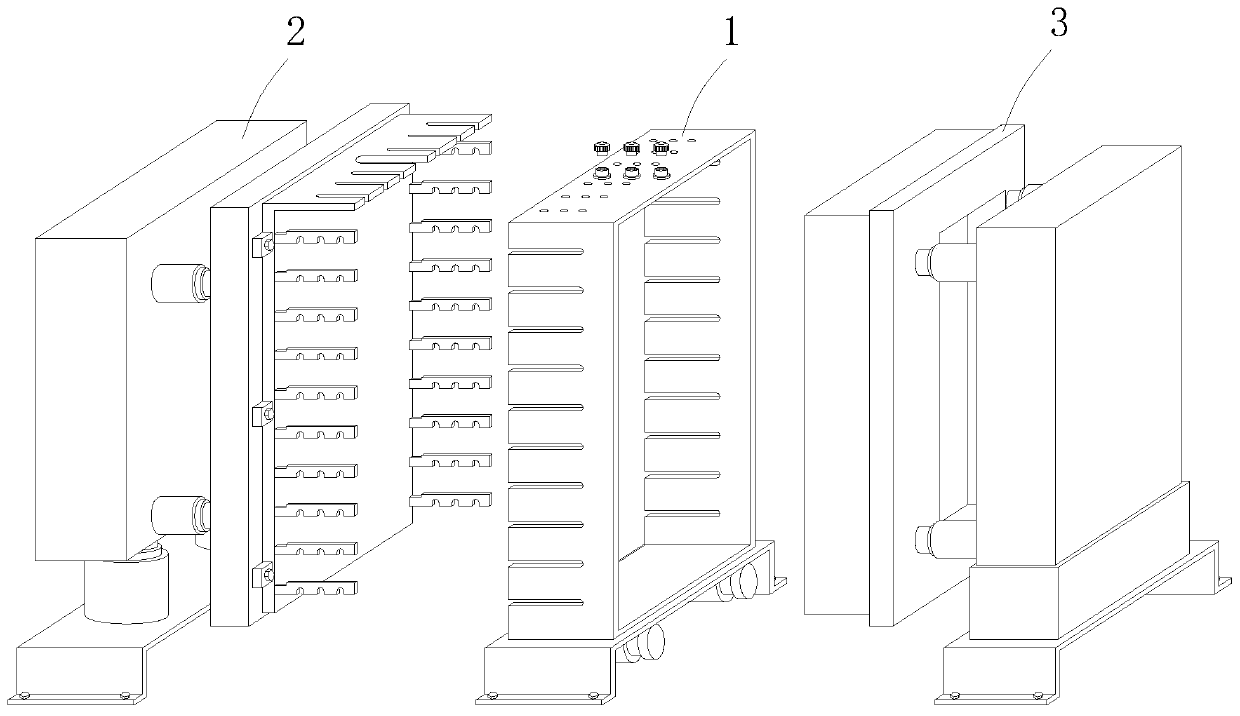

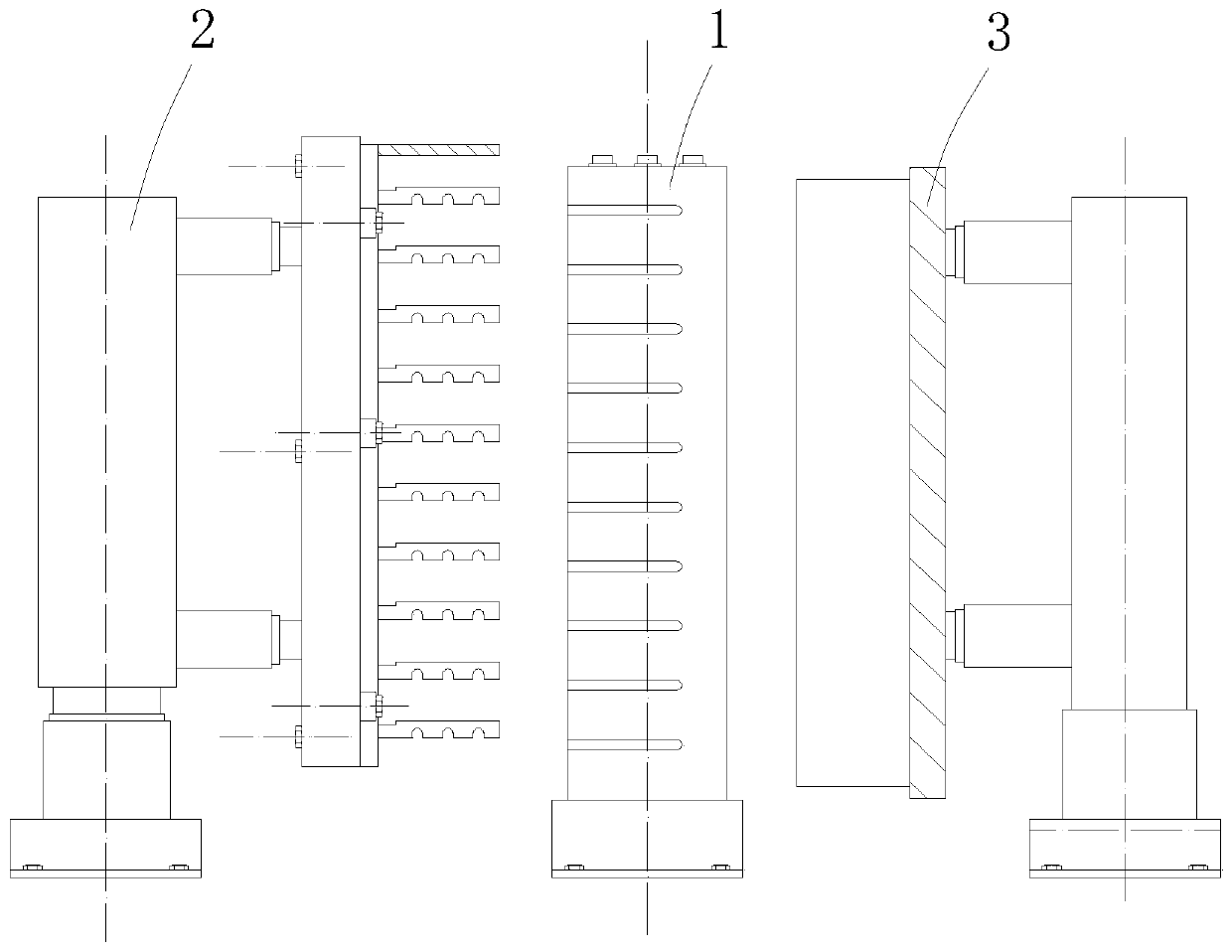

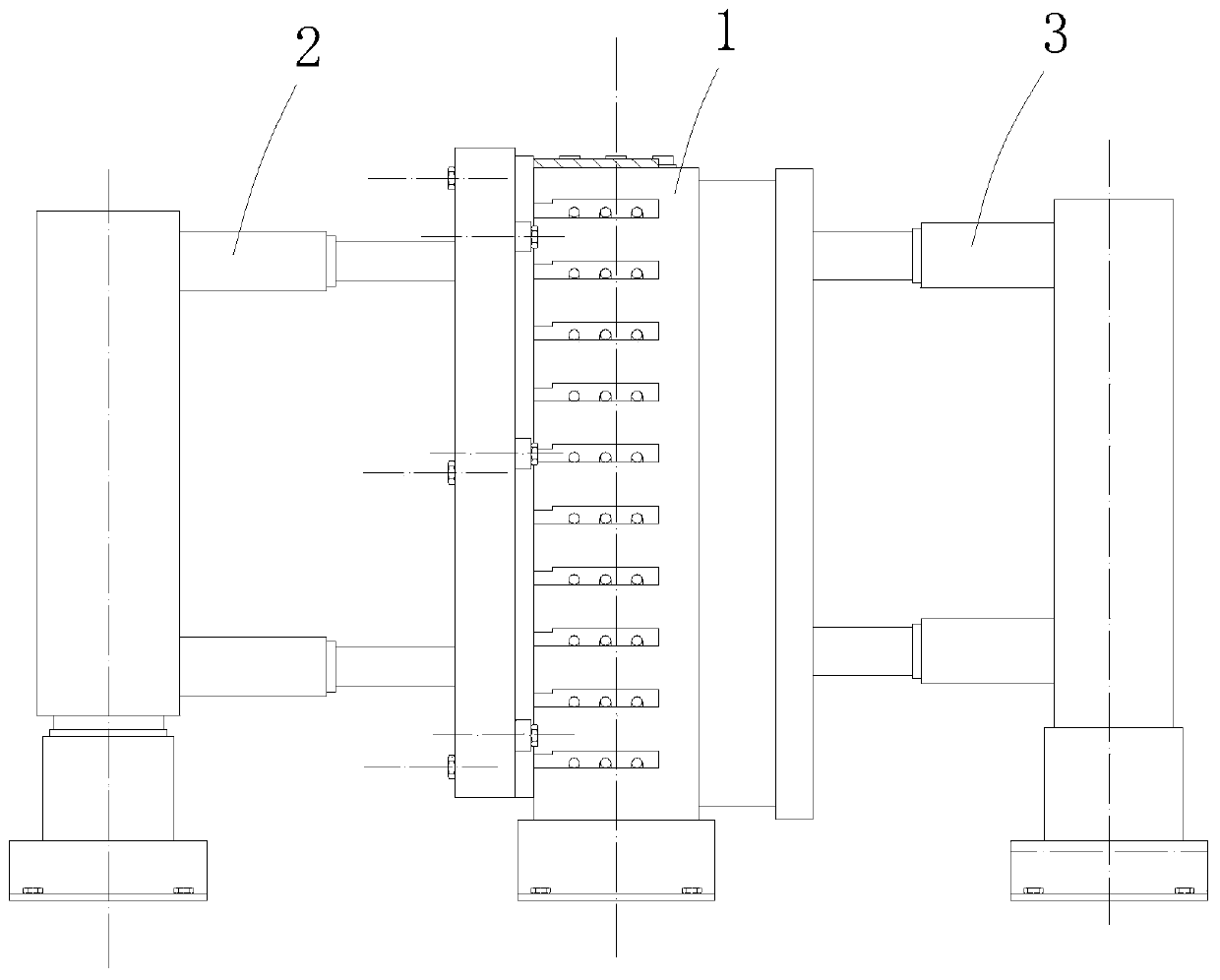

[0058] A forming equipment for prefabricated wall panels of high-rise buildings, such as Figure 1-3 As shown, it includes a structure mold 2, a cavity mold 1 and a bottom mold 3 arranged in parallel in a vertical direction;

[0059] In this embodiment, such as Figure 4 with 5 As shown, the structural mold 2 includes a base II 203 fixed on the ground by bolts, a lifting cylinder 202 is installed on the upper end of the base II 203, and a vertical cylinder seat I 201 is installed on the telescopic end of the lifting cylinder 202. The cylinder seat I 201 A structural mold base 205 is installed on the side close to the cavity mold 1 through multiple propelling cylinders I204, and a structural mold body 206 is detachably mounted on the other side of the structural mold base 205 by screws, and the structural mold body 206 is close to the cavity Two sets of side steel bar blocking plates 208 are installed symmetrically on the vertical edge of one side of the mold 1, and the bottom end ...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 lies in Picture 11 with 12 As shown, a cavity sealing module 4 for sealing a part of the casting cavity is detachably installed on the side of the structural mold base 205 close to the cavity mold body 101.

[0071] Such as Picture 11 As shown, a plurality of casting and bonding grooves 401 are provided on the side wall of the cavity-sealing module 4 close to the cavity mold body 101.

[0072] The cavity-sealing module 4 is set up to cooperate with the prefabricated wall panel a made of composite materials. Firstly, part of the panel is formed, and then the pouring slurry is replaced for adhesive pouring to ensure the production requirements of the prefabricated wall panel a. The setting of the pouring bonding groove 401 can make the first pouring part be formed with raised bonding columns, ensuring the close combination of the subsequent part of the slurry and the first forming part, and improving the molding quality ...

Embodiment 3

[0075] The present invention is based on the processing method of the high-rise building prefabricated wall panel forming equipment of the above-mentioned embodiment 1. The processing method includes the following steps:

[0076] Step 1. Clean the structure mold 2, the cavity mold 1 and the bottom mold 3, and coat the cavity surfaces of the structure mold 2, the cavity mold 1 and the bottom mold 3 with a release agent;

[0077] Step 2: Lay steel mesh a3 in the above-mentioned cavity mold 1;

[0078] Step 3: Push the structure mold 2 and the bottom mold 3 toward the cavity mold 1 to jointly construct a casting cavity;

[0079] Step 4. Quantitatively inject concrete slurry into the pouring cavity from the grouting port I 106, the grouting port II 107 and the grouting port III 108 above the cavity mold 1;

[0080] Step 5: The vibrating motor 105 at the lower part of the cavity mold 1 vibrates the concrete slurry in the pouring cavity, and the structural mold 2 and the bottom mold 3 continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com