Centrifugal casting machine set

A centrifugal casting machine and centrifugal casting technology, used in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of locking force distribution, affecting casting quality, affecting locking effect, etc., to avoid slippage , The production process is firm and reliable, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

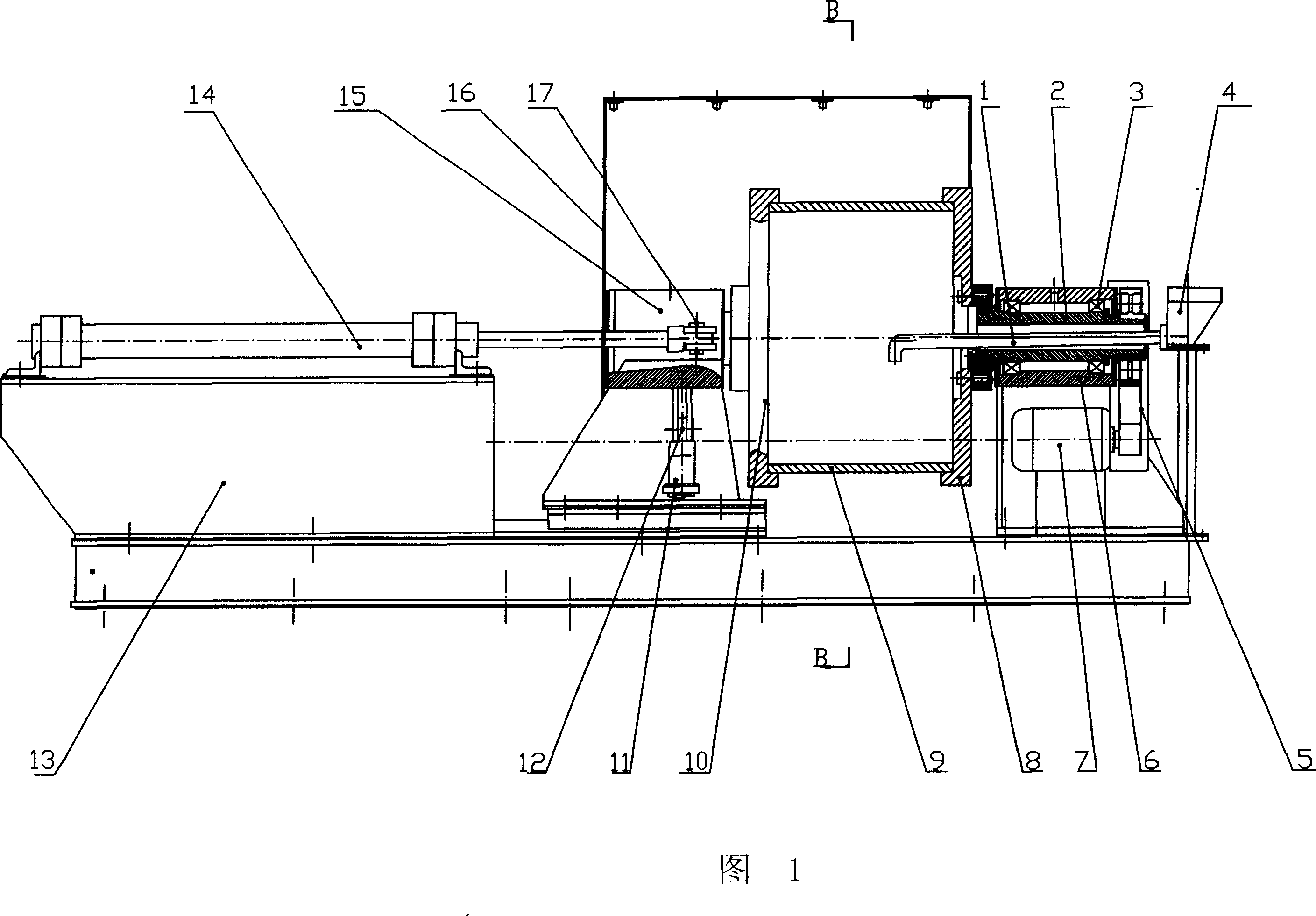

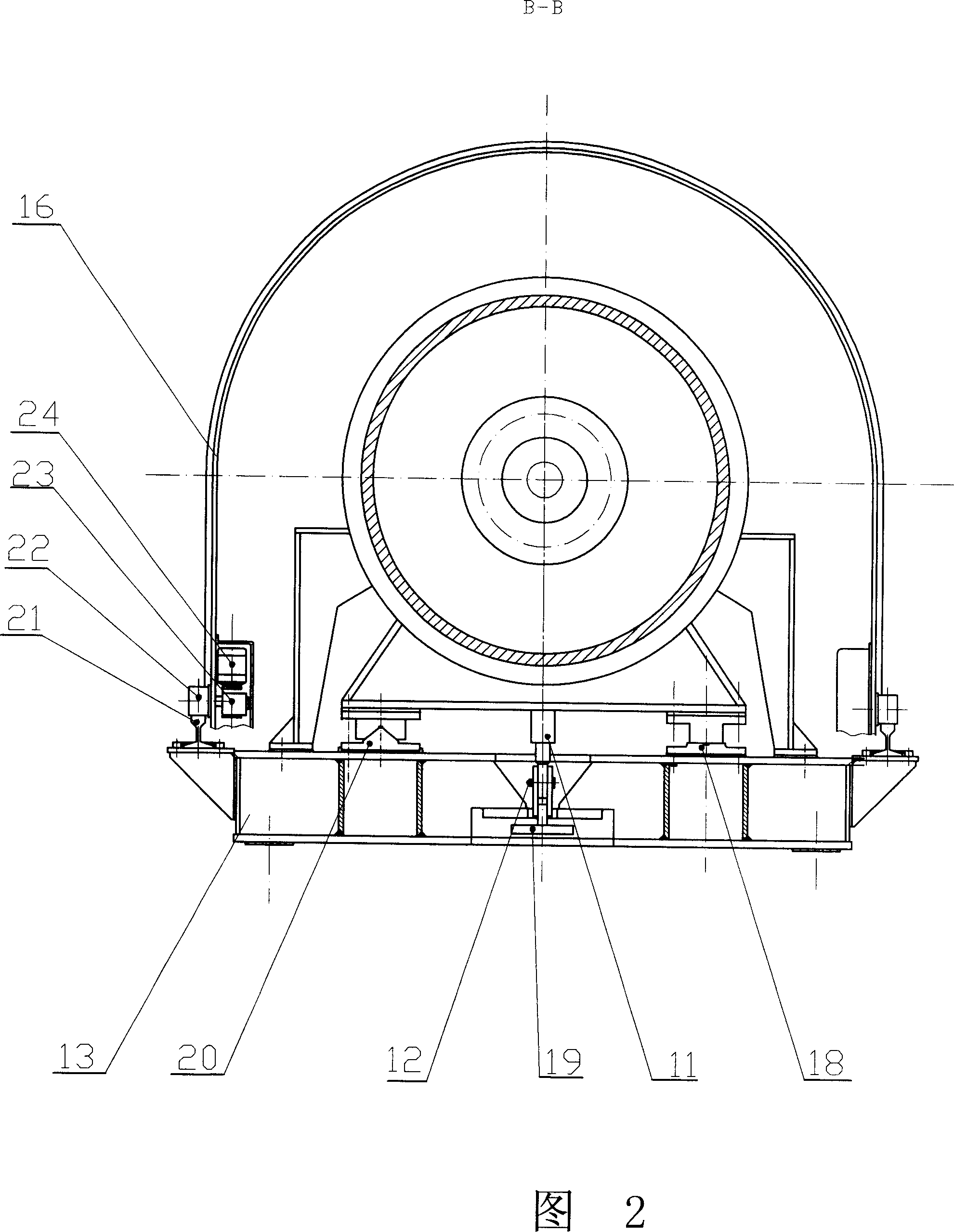

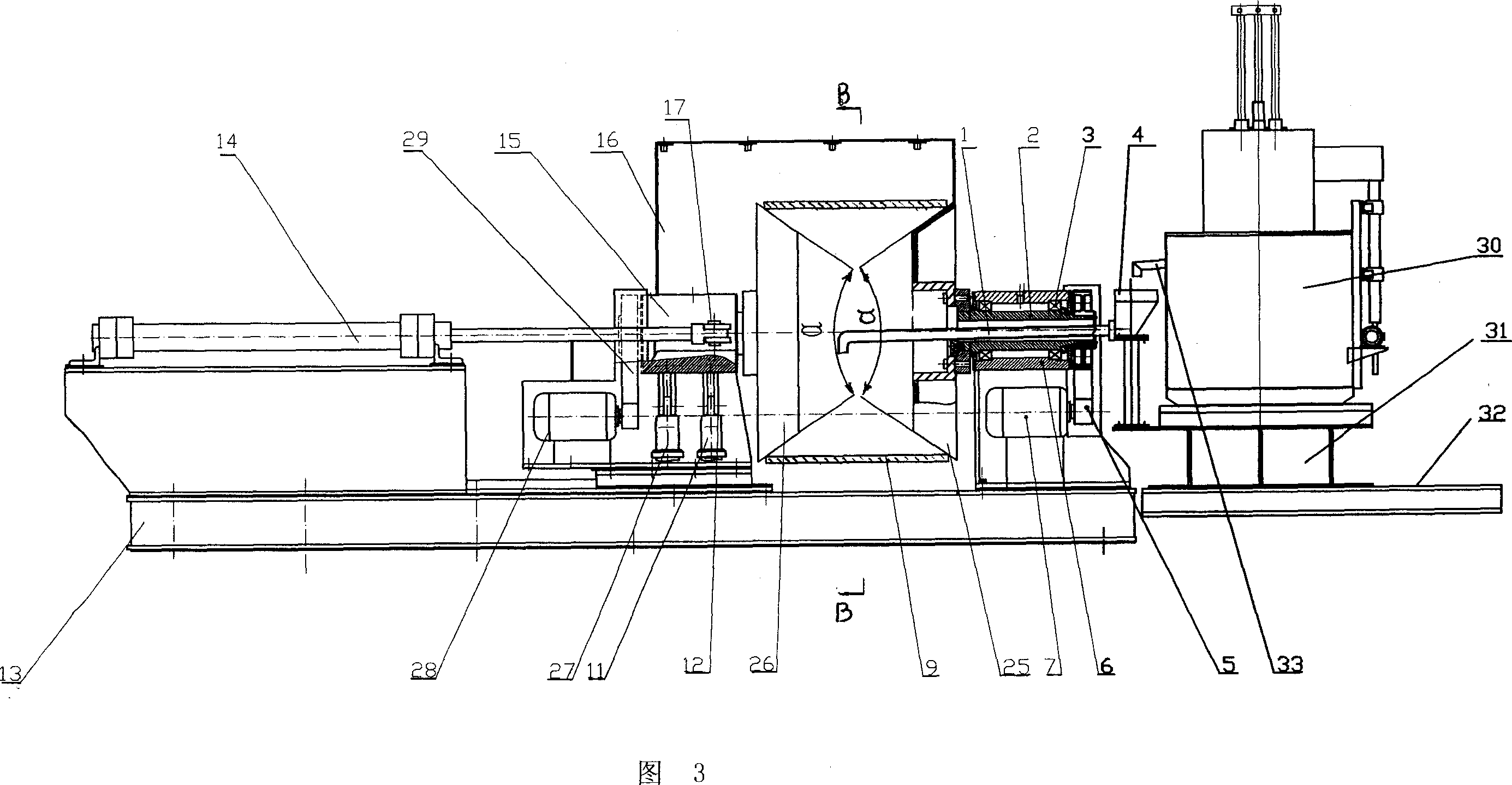

[0021] As shown in Figure 3, the metal melting furnace 30 is installed on the base 31 which is equipped with traveling wheels at the bottom and can move on the guide rail 32. The base 31 is equipped with a receiving hopper 4 and a pouring conduit 1. The garden cone shape top 25 and 26, the garden cone angle is α=65 °, drive the garden cone shape top 25 and 26 by belt transmission 5 and 29 respectively and do synchronously, motor 7 and 28 that rotate in the same direction are installed on frame 1 Above, the locking hydraulic cylinder 27 is installed side by side with the locking hydraulic cylinder 11 below the movable seat 15 . During production, workpiece 9 is packed between two garden cone-shaped tops 25 and 26, and then the top 26 is moved by advancing hydraulic cylinder 14, and workpiece 9 is clamped. The movable seat 15 is fixed by the locking hydraulic cylinders 11 and 27, and then the motors 7 and 28 are driven to rotate at a high speed through the belt drives 5 and 29 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com