Warm-mix asphalt and production device thereof

A technology for warm-mix asphalt and production equipment, which is applied in the field of asphalt modification, and can solve problems such as environmental pollution, inconvenient construction, and waste of heat energy, and achieve the effects of energy saving, simple structure, and simple and convenient construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the present invention is achieved in this way, a kind of warm mix asphalt, characterized in that the raw material components of the warm mix asphalt are 70# base asphalt or SBS asphalt, warm mix modifier and other additives.

[0047] Further, the asphalt includes the following components and their mass percentages are: 21.15%-23.43% of saturated components, 32.26%-46.00% of aromatic components, 21.64%-33.73% of colloids, and 7.96%-10.83% of asphaltenes.

[0048] Further, the softening point of the pitch is 99.5°C to 101.4°C.

[0049] Further, the warm mixing modifier is a synthetic linear aliphatic hydrocarbon or polyolefin asphalt modifier.

[0050] Further, the other additives are deodorants, flavor enhancers, compatibilizers, and oxidized pigments.

[0051] Further, the optimal asphalt ratio of the 70# base asphalt mixture is 4.6%-4.7%.

[0052] Further, the optimal asphalt ratio of the SBS asphalt mixture is 6.1%-6.2%.

[0053] Further, the compatibil...

Embodiment 2

[0079] Embodiment 2, the preparation method of warm mix asphalt of the present invention is:

[0080] (1) Mix the modifier and the additive evenly, and react and mix in an internal mixer for 30 minutes at 120° C. to obtain a modified compound, and obtain modified compound particles after mechanical granulation;

[0081] (2) Heat the base asphalt to 140°C, slowly add the modified composite particles, at a constant temperature, use a high-speed shear emulsifier to cut for 45 minutes, control the speed of the shear to 3500-4500r / min, and then place it in the mixer Stir at low speed for 30 minutes to prepare warm mix asphalt.

Embodiment 3

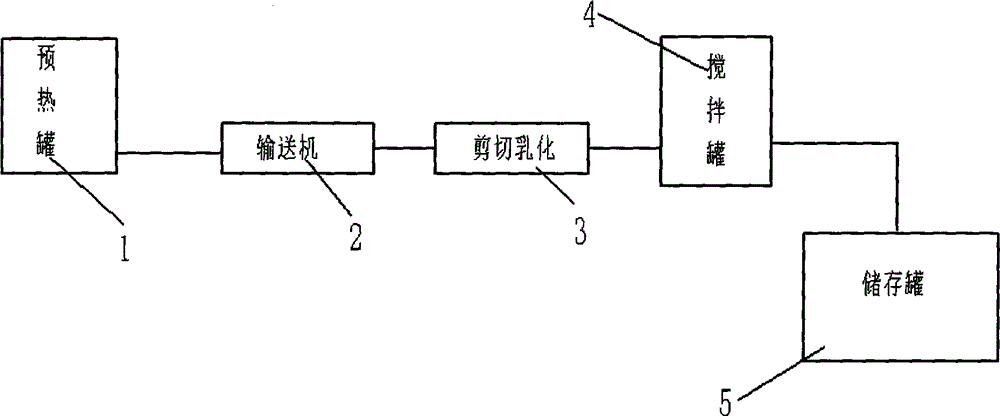

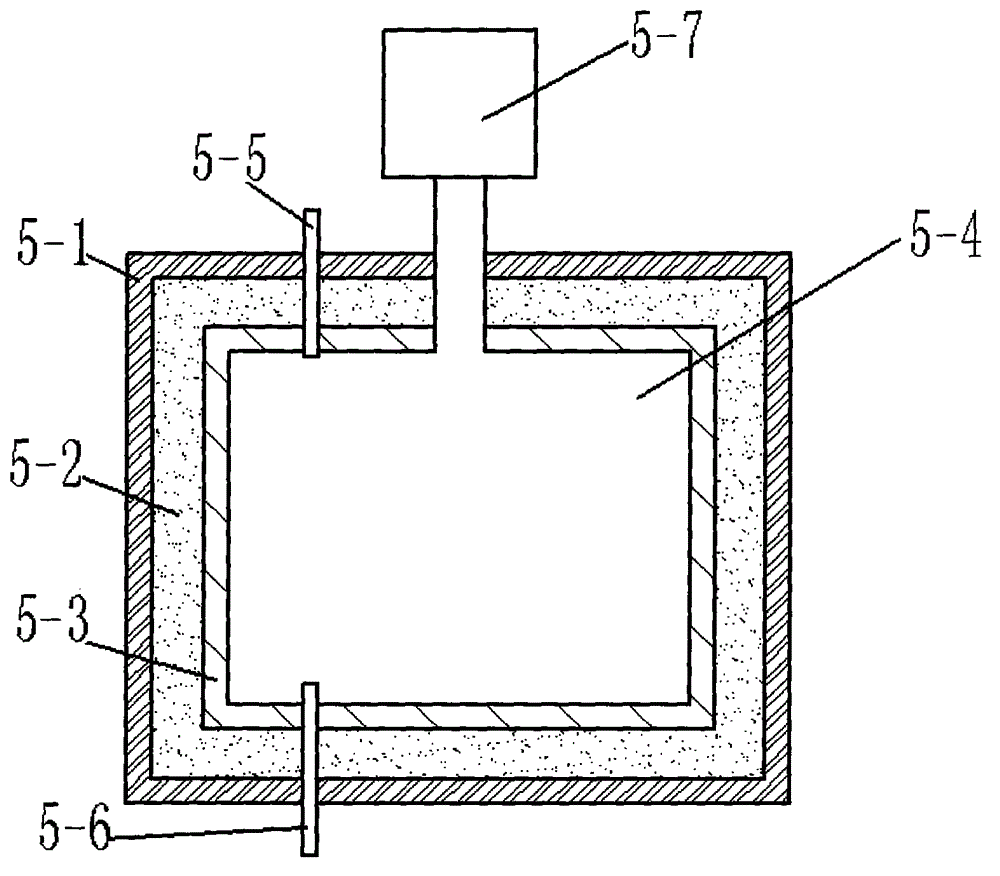

[0082] Example 3, figure 1 The structure of the production device provided by the invention is shown, figure 2 The structure of the liner in the production device is shown, as shown in the figure, it is used to prepare the production device for warm-mix asphalt according to claim 1, wherein the production device includes an asphalt preheating tank 1, batching System, screw conveyor 2, high-shear emulsifier 3, constant temperature mixing tank 4, asphalt storage tank 5 and motor control system, wherein, asphalt preheating tank 1 is connected with screw conveyor 2 and high-shear emulsifier 3 through the batching system connection, the high-shear emulsifier 3 is connected with the constant temperature mixing tank 4, and the asphalt stirred by the constant temperature mixing tank 4 is transported to the asphalt storage tank 5.

[0083] Further, the asphalt preheating tank 1 also includes a weighing device and a stirring system.

[0084] Further, the middle part of the tank body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com