High-efficiency turpentine distillation device

A distillation device and high-efficiency technology, applied in molecular distillation, distillation regulation/control, turpentine, etc., can solve problems such as environmental impact and high energy consumption, and achieve the effect of reducing distillation temperature and eliminating direct steam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

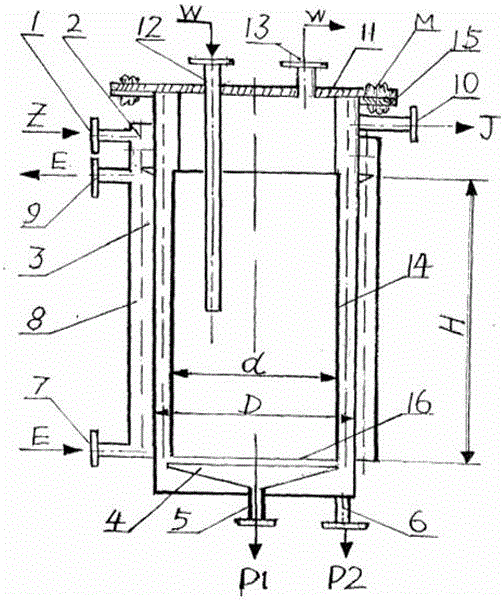

[0014] see Figure 1~2 , in the embodiment of the present invention, a kind of high-efficiency rosin distillation device comprises molecular evaporation cylinder and molecular cooler, and described molecular evaporation cylinder is straight cylindrical shape, and the tube outer wall of molecular evaporation cylinder has heating jacket 8, and in heating jacket 8. The lower part is provided with a heating source inlet 7, and the upper part is provided with a heat source outlet 9. There is a connecting flange 15 on the top of the molecular evaporation cylinder, and a vacuum pump interface 10, a turpentine resin liquid inlet 1 and a turpentine resin liquid separation ring are arranged below the connecting flange 15. 2. At the bottom of the molecular evaporation cylinder, there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com