Method for producing rosin

A technology of rosin and turpentine, which is applied in the fields of turpentine, natural resin refining, chemical instruments and methods, etc., and can solve the problems of low quality of rosin and turpentine products and the inability to meet the requirements of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

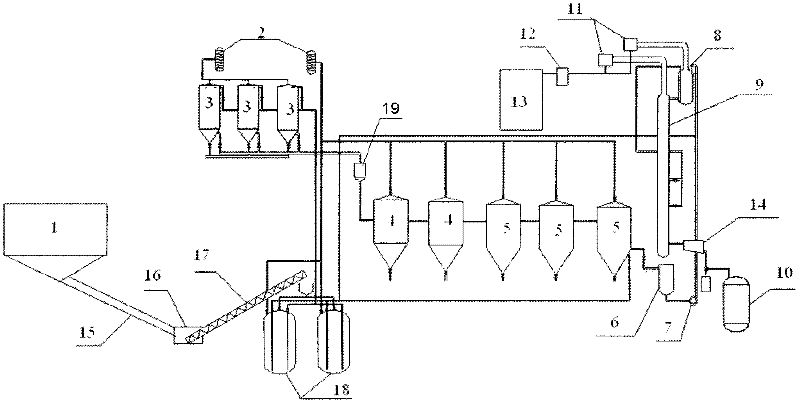

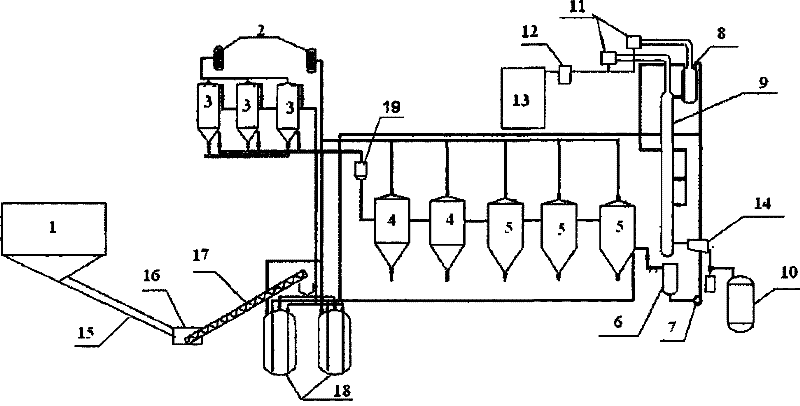

Embodiment 1: pic 1 preparation no. 1 Embodiment approach

[0077] 1. Melting process

[0078] The turpentine stored in the resin storage tank is sent to the resin outlet tank through the resin outlet pipe, and then sent to the feeding hopper by the screw conveyor, and then intermittently flows into the melting tank through the closed feeding valve. Add 600kg of turpentine and 600kg of water for every 2 tons of rosin in the melting kettle, and add 1.5kg of oxalic acid for decolorization. Direct steam is passed under the melting kettle, that is, open steam heating, and the temperature is kept at about 95°C to melt the rosin. The mixed steam of turpentine oil and water released during melting is recovered through a vapor-liquid separator and a condenser. The melted fat liquid is pressed into two high-position pots connected in series with steam, and the relatively coarse impurities are left on the filter plate at the lower part of the melting pot and cleaned regularly.

[0079] 2. Clarification process

[0080] After staying in the hig...

Embodiment 2

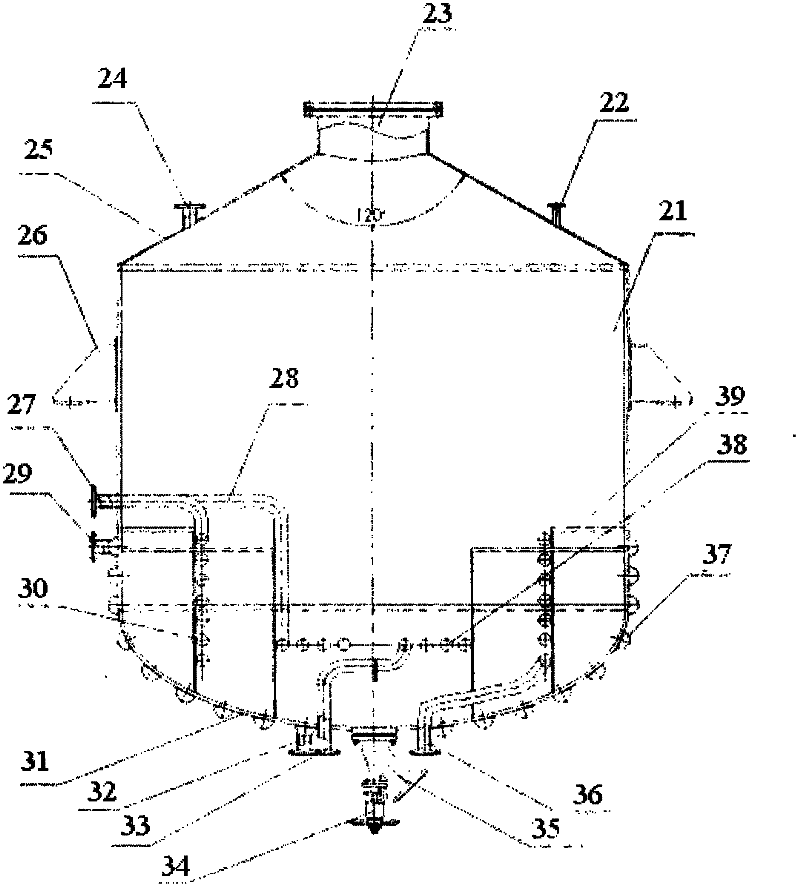

[0087] Embodiment 2: combine below figure 2 A second embodiment of producing rosin from rosin will be described.

[0088] Prepare unrefined rosin according to the method of Example 1. Put the metered liquid rosin into the refining kettle body 1 and the oval lower head 11 from the feed port 4, respectively open the oil inlet and outlet valves of the serpentine coil, the oil inlet and outlet valves of the mosquito coil coil, and the outer The oil inlet and outlet valves of the semi-circular coil allow the high-temperature heat transfer oil to enter the serpentine coil 10 and the mosquito coil respectively from the oil inlet 16 of the serpentine coil, the oil inlet 13 of the mosquito coil, and the oil inlet 12 of the outer semicircular coil. Pipe 18, outer semicircle coil pipe 17, and flow out from serpentine coil pipe oil outlet 7, mosquito coil oil outlet 8, outer semicircle pipe oil outlet 9 respectively. The rosin in the refining kettle is heated by the circulation of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com