One-step depicterizing and acid-reducing method of fruit juice with high pulp content

A high pulp and fruit juice technology, applied in food adsorption, food science, etc., can solve the problems of unsatisfactory flavor of fruit juice, restrictions on comprehensive utilization, and high fruit acid content, so as to improve the safety of fruit juice, improve production efficiency, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Juicing: After the fresh fruit is measured, graded and post-ripened, it is brushed to remove the dirt on the fruit surface, and the rotten fruit, broken fruit and impurities are removed by manual selection, and then sent to the classifier for classification, and then the juice is extracted to obtain the original juice and the pomace. Discard it as animal feed, etc.

[0029] (2) Juice coarse separation: the original juice is centrifuged at 2000 rpm in a horizontal screw centrifuge to obtain the crudely separated low pulp content (pulp content less than 3%) juice and pulp, and the pulp is pumped into the recovery tank for subsequent backfilling. into the buffer tank.

[0030] (3) Juice essence separation and enzyme inactivation: The crudely separated juice is then refined, and centrifuged at 6000rpm / min with a high-speed centrifuge to separate the juice and pulp. The juice with low pulp content (the pulp content is less than 1%) is sterilized and deactivated at 85°C f...

Embodiment 2

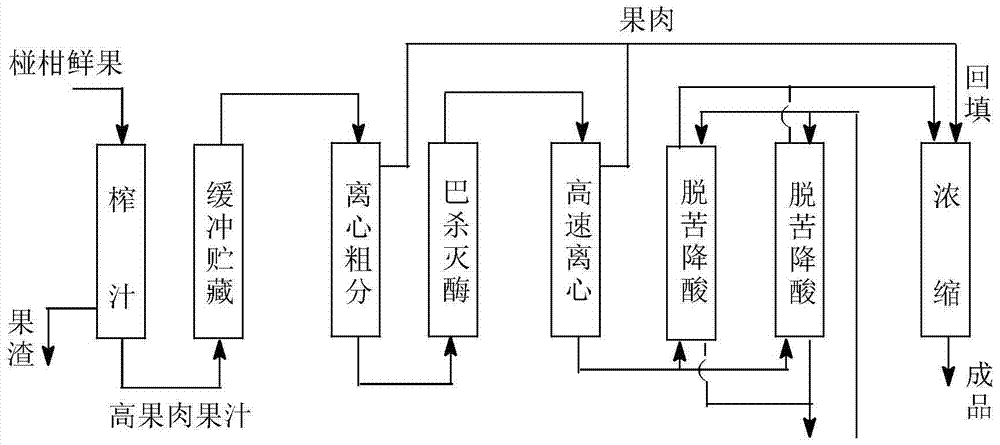

[0034] According to as figure 1 The flow chart shown is carried out,

[0035] (1) Juicing: After the fresh fruit is measured, graded and post-ripened, it is brushed to remove the dirt on the fruit surface, and the rotten fruit, broken fruit and impurities are removed by manual selection, and then sent to the classifier for classification, and then the juice is extracted to obtain the original juice and the pomace. Discard it as animal feed, etc.

[0036] (2) Juice coarse separation: the original juice is centrifuged at 2000 rpm in a horizontal screw centrifuge to obtain the crudely separated low pulp content (pulp content less than 3%) juice and pulp, and the pulp is pumped into the recovery tank for subsequent backfilling. into the buffer tank.

[0037] (3) Juice essence separation and enzyme inactivation: The crudely separated juice is then refined, and centrifuged at 6000rpm / min with a high-speed centrifuge to separate the juice and pulp. The juice with low pulp content (...

Embodiment 3

[0044] (1) Juicing: After the fresh fruit is measured, graded and post-ripened, it is brushed to remove the dirt on the fruit surface, and the rotten fruit, broken fruit and impurities are removed by manual selection, and then sent to the classifier for classification, and then the juice is extracted to obtain the original juice and the pomace. Discard it as animal feed, etc.

[0045] (2) Juice coarse separation: the original juice is centrifuged at 4200 rpm in a horizontal screw centrifuge to obtain the coarsely separated low pulp content (pulp content less than 3%) juice and pulp, and the pulp is pumped into the recovery tank for subsequent backfilling. into the buffer tank.

[0046] (3) Separation of fruit juice essence: the crudely separated fruit juice is then refined, and centrifuged at 7500 rpm with a high-speed centrifuge to separate the fruit juice and pulp. The juice with low pulp content (the pulp content is less than 1%) is sterilized and inactivated at 90°C for 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com