Forming wrapping apparatus of decorative board production equipment

A hemming device and a technology for decorative panels, which are applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as unfulfilled and insufficient hemming, and affect product quality, so as to ensure flatness, fullness, and width Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

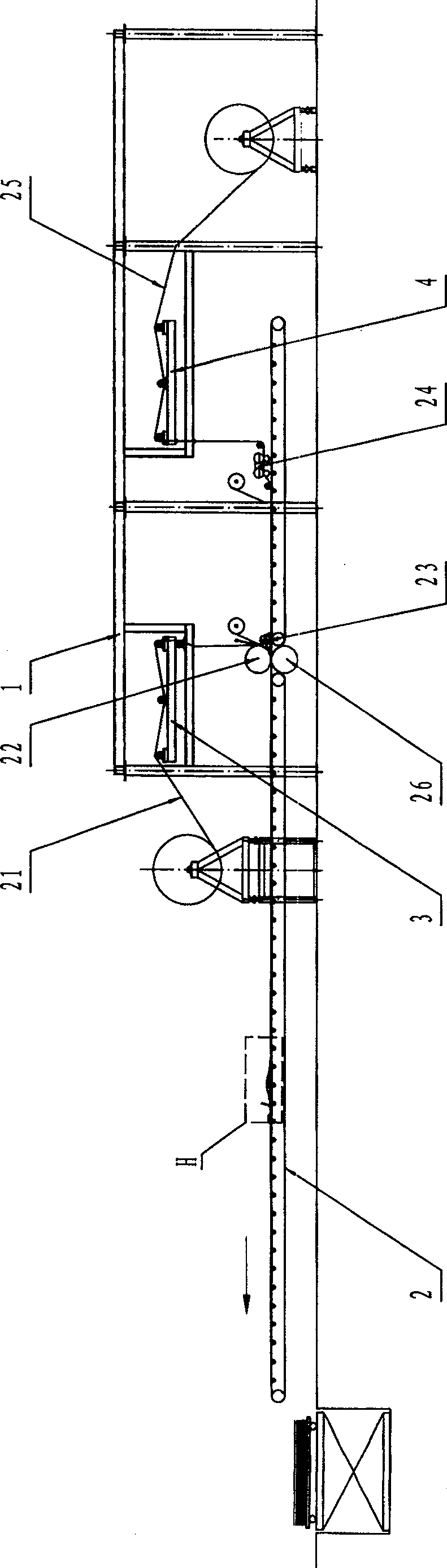

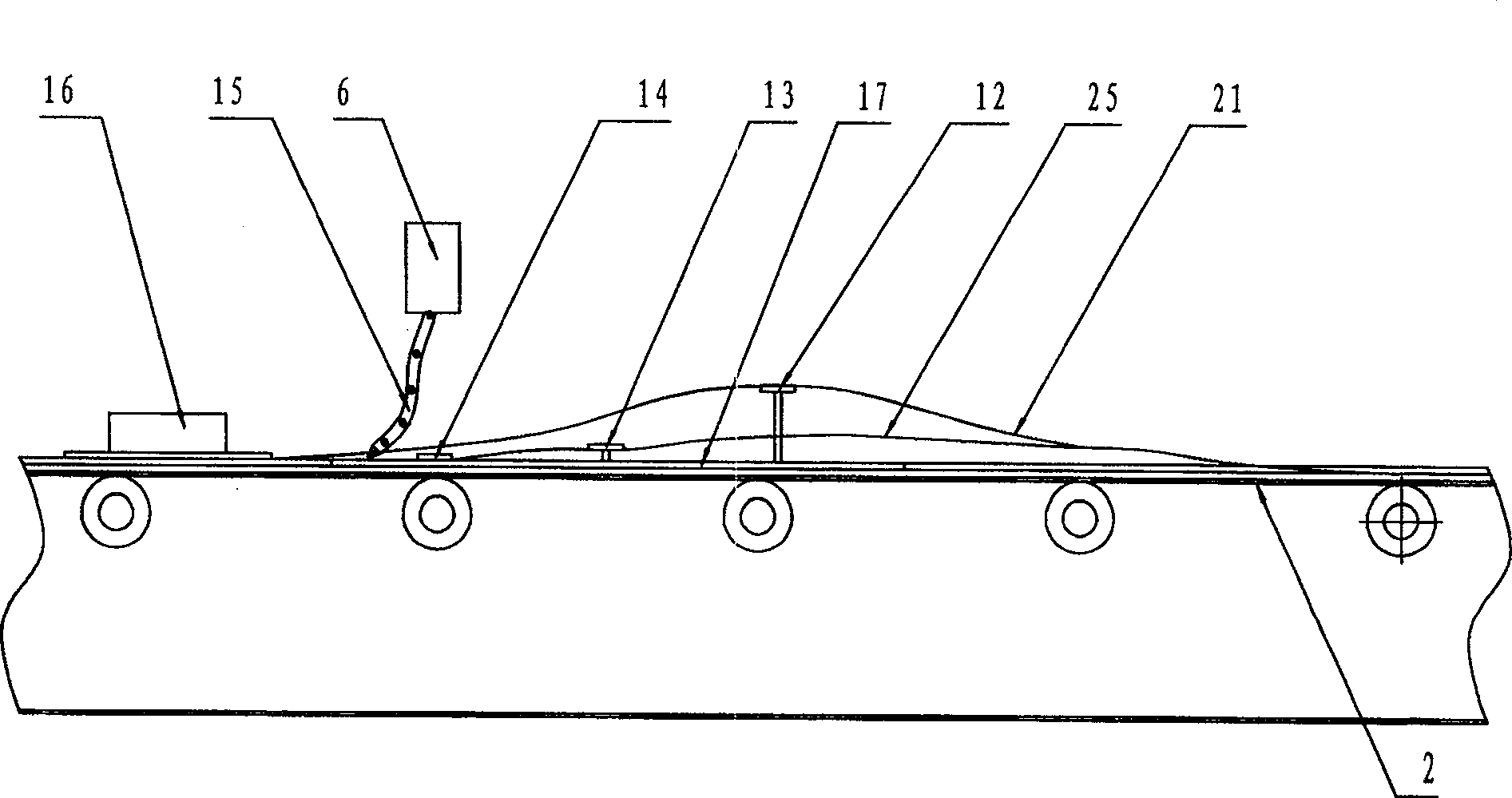

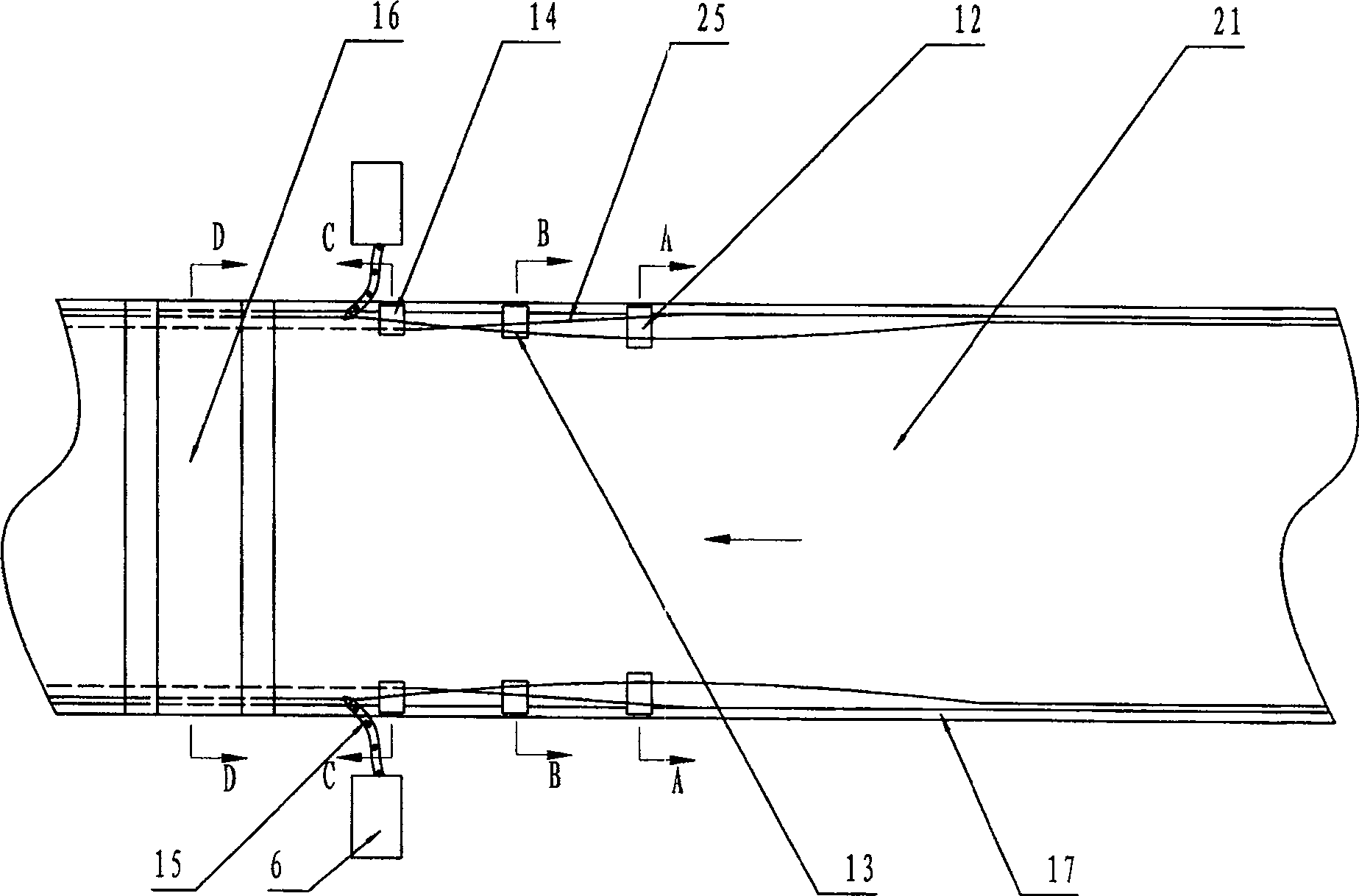

[0016] Such as figure 1 As shown, the decorative board production equipment of the present invention is mainly composed of a frame 1 and a conveyor belt 2, upper and lower forming press rollers 22 and 26, an upper protective surface layer 21 and its conveying mechanism 3, arranged in the frame 1, The lower protective surface layer 25 and its conveying mechanism 4, the scoring device 24, the hemming device H, etc., are characterized in that the hemming device H is set on the upper and lower forming press rolls in the decorative board production equipment The rear side of 22 and 26 is in the frame 1 on the side of the discharge direction. In this embodiment, such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the specific structure of the hemming device is: a pair of positioning baffles 17 are provided in the frame 1, the positioning baffles 17 are located on both sides of the conveyor belt 2, and the distance between the two positioning baffles 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com