Manufacturing process of motor train unit air conditioner flat top composition

A manufacturing process and EMU technology, applied in the manufacturing field, can solve the problems of high overall profile and dimensional tolerance requirements, difficult adjustment, large deformation, etc., to ensure overall profile, strong process cohesion, and production cycle. changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

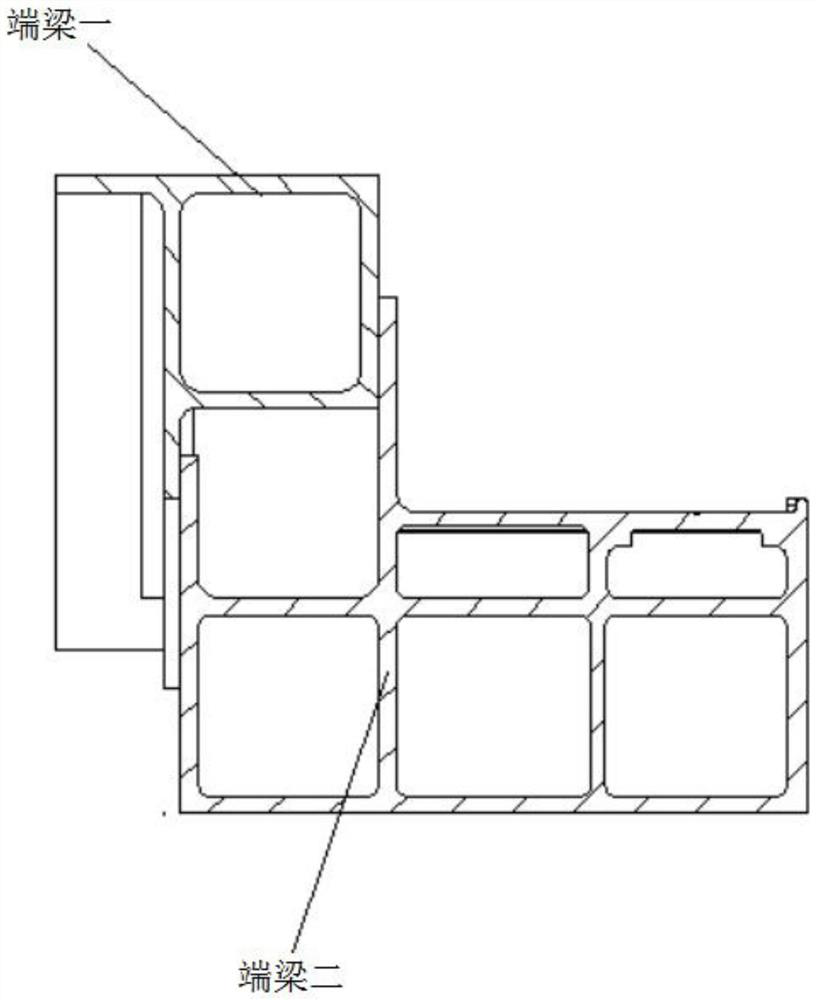

[0044] Step 1: Assemble and weld end beam 1 and end beam 2 separately, with a height dimension of 2mm, and use adjustment equipment to adjust after welding; such as Figure 1-2 shown;

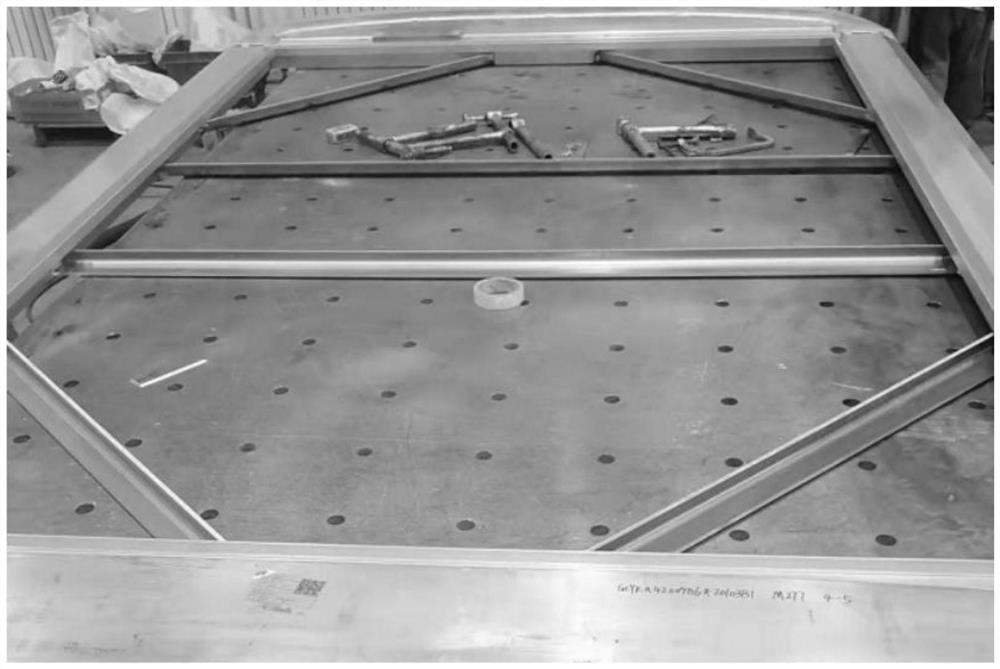

[0045] Step 2: Assemble the end beam 1 and end beam 2 with the side beam after welding, and assemble the angle aluminum reinforcement after ensuring the length and width of 2mm. image 3 shown;

[0046] Step 3: Measure the diagonal, and determine the welding sequence and direction of the weld between the end beam and the side beam according to the size of the diagonal. , and then weld the two smaller diagonals, welding in opposite directions, use a marker to mark the welding sequence and welding direction on the air conditioner flat top, weld according to the marking sequence and direction, and adjust the air conditioner flat top by welding. Form a diagonal line to ensure that the air-conditioning flat top is assembled to form a diagonal size of ±3mm after welding, such as Figure 4 shown; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com