A manufacturing process of the side beam assembly at the end of the head car of a standardized EMU

A manufacturing process and technology of EMUs, applied in the direction of manufacturing tools, vehicle parts, railway car body parts, etc., can solve the problem that the welding quality cannot be well guaranteed, the market demand cannot be well met, and the flatness and straightness requirements are high. problems, to achieve the effect of reducing deformation, changing production cycle and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

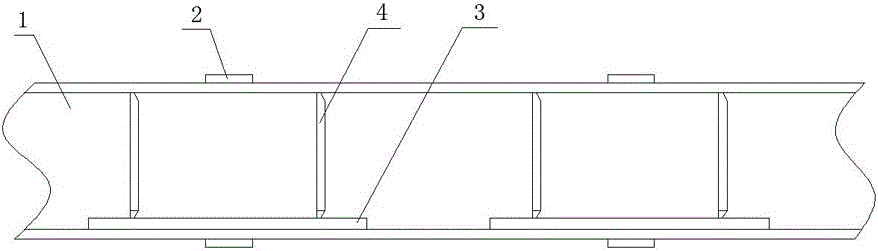

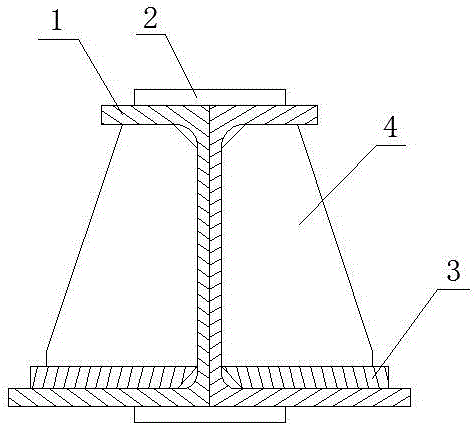

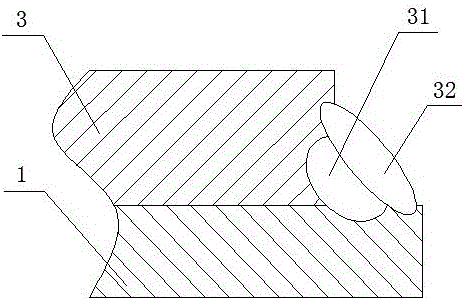

[0029] The structure of the side beam assembly at the end of the EMU head car of the present invention is as attached Figure 1-4 As shown, it includes a side beam 1 and a tie plate 2; there are two side beams 1 in total, and they are arranged back to back. It consists of a beam section with a base width of 270mm and a beam section with a base width of 400mm, with a total length of 3596.2mm. The beam section with a base width of 400mm has a length of 620mm. The seat plate 3 and the seat plate 3 are welded and fixed in the side beam 1, the seat plate first weld layer 31 and the seat plate second weld layer 32 are sequentially welded between the seat plate 3 and the side beam 1, the seat plate 3 and the side beam 1 are provided with a plurality of ribs 4, preferably, two ribs 4 are provided between each seat plate 3 and the side beam 1, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com