Manufacturing process for three girders of subway

A manufacturing process and subway technology, which is applied in the field of manufacturing the three major beams of the subway. It can solve the problems of difficulty in straightness adjustment, large penetration depth of corbel welds, and high flatness requirements, so as to achieve the change of process cohesion and production cycle. Short, effective work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

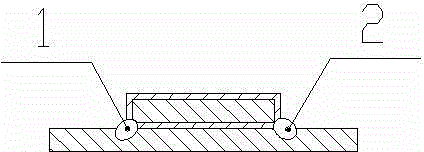

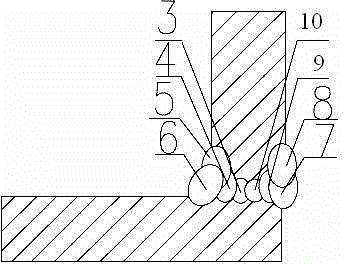

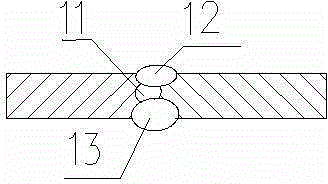

[0017] See attached Figures 1 to 3 As shown, the present invention prepares the three major beams of the subway. The three major beams of the subway include buffer beams, traction beams and corbel beams. The steps for preparing the buffer beams are two steps. The first step adopts non-melting electrode gas shielded welding method to utilize The digital welding machine WAVE3000 welding equipment welds the welding material with a diameter of 3.2 at a speed of 20-30 cm / min to buffer the left node 1, where the current intensity of the welding equipment is between 210-230A, and the arc voltage is between 11-13V. The heat input is 3.7~7.2 kJ / cm; the second step is to use the non-melting electrode gas shielded welding method to use the welding equipment to weld the welding material with a diameter of 3.2 at a speed of 20-30 cm / min to weld the right node 2 of the buffer, where the welding equipment The current intensity is between 210-230A, the arc voltage is between 11-13V, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com