Edge cutting system for home textile fabric

A technology of textile and edge trimming, which is applied in the cutting of textile materials, textile and paper making, spreading thin soft materials, etc., can solve the problems of width and size deviation of home textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

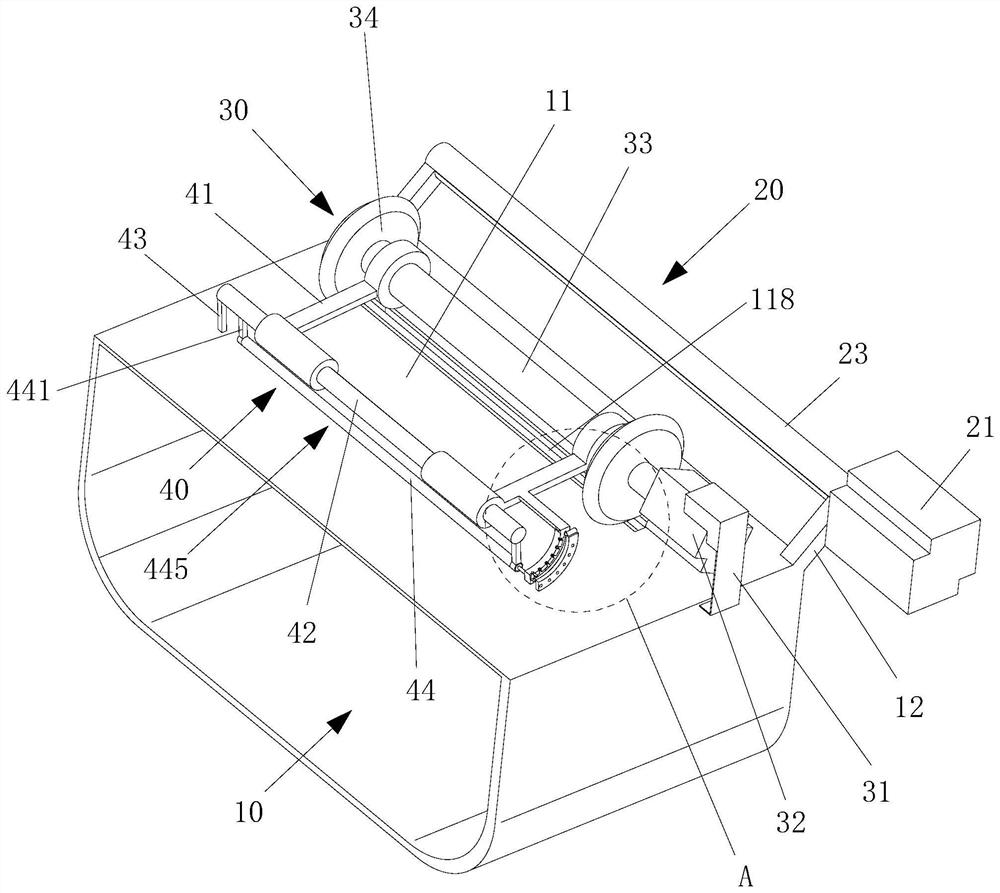

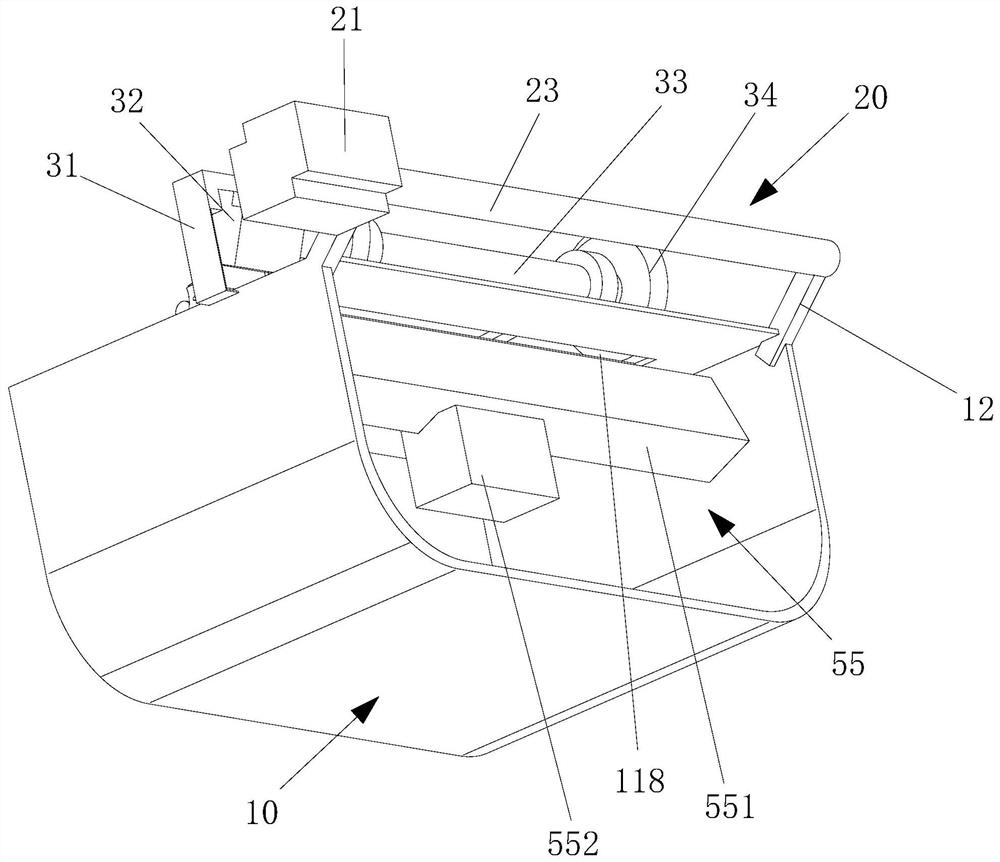

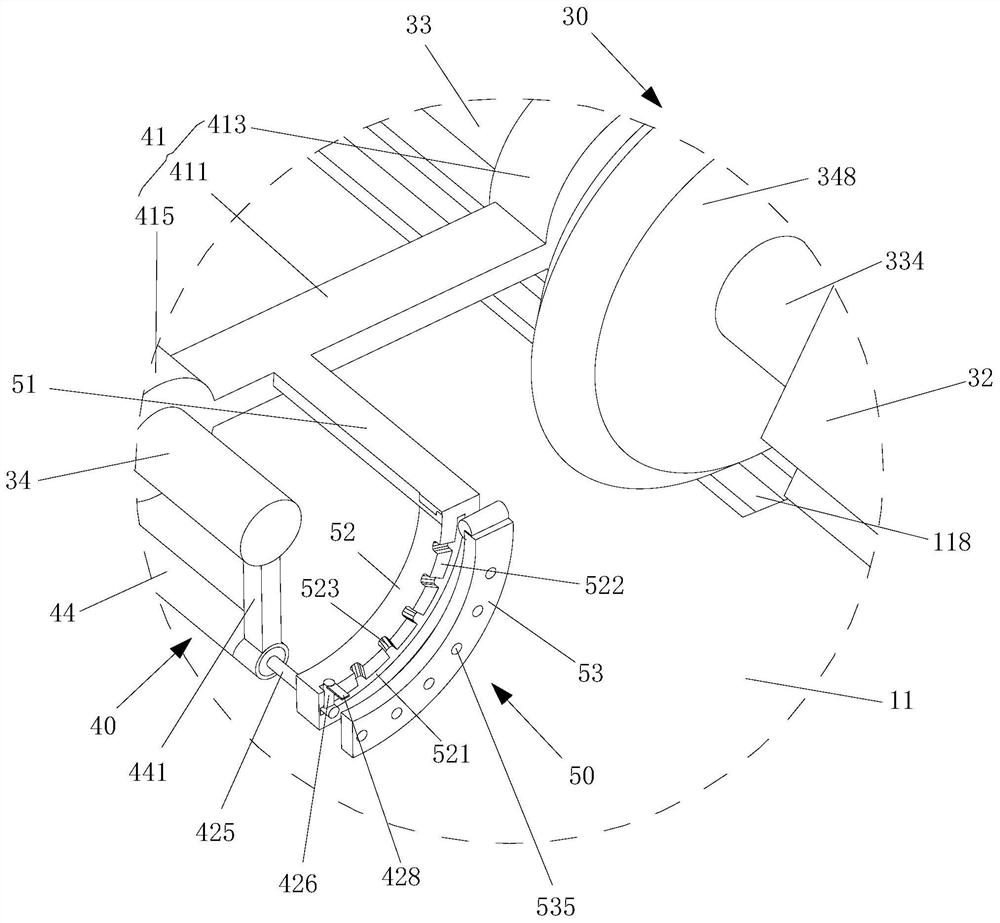

[0019] see Figure 1 to Figure 3 , an edge trimming system for home textile fabrics, including a support frame 10, a transmission assembly 20, an edge trimming assembly 30 and a paving assembly 40, the upper part of the support frame 10 is provided with a transmission plate 11, and the opposite sides of the support frame 10 respectively protrude There is a support rod 12, and the transmission assembly 20 includes a transmission cylinder 21 and a transmission roller 23. The transmission cylinder 21 is installed on one of the support rods 12, and one end of the transmission roller 23 is fixed on the output shaft of the transmission cylinder 21, and the other end is rotatably installed. On the other support rod 12, the trimming assembly 30 includes a mounting frame 31, a driving cylinder 32, a driving roller 33 and two trimming wheels 34. The mounting frame 31 is protruded on the top side of the supporting frame 10, and the driving cylinder 32 On the mounting frame 31, the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com